Understanding the Stihl BR 800C Parts Diagram

In the realm of outdoor power tools, comprehending the intricate details of various models is essential for optimal performance and maintenance. Each piece of machinery comprises numerous elements, each contributing to its overall functionality. By familiarizing yourself with these components, you can ensure your equipment operates smoothly and efficiently.

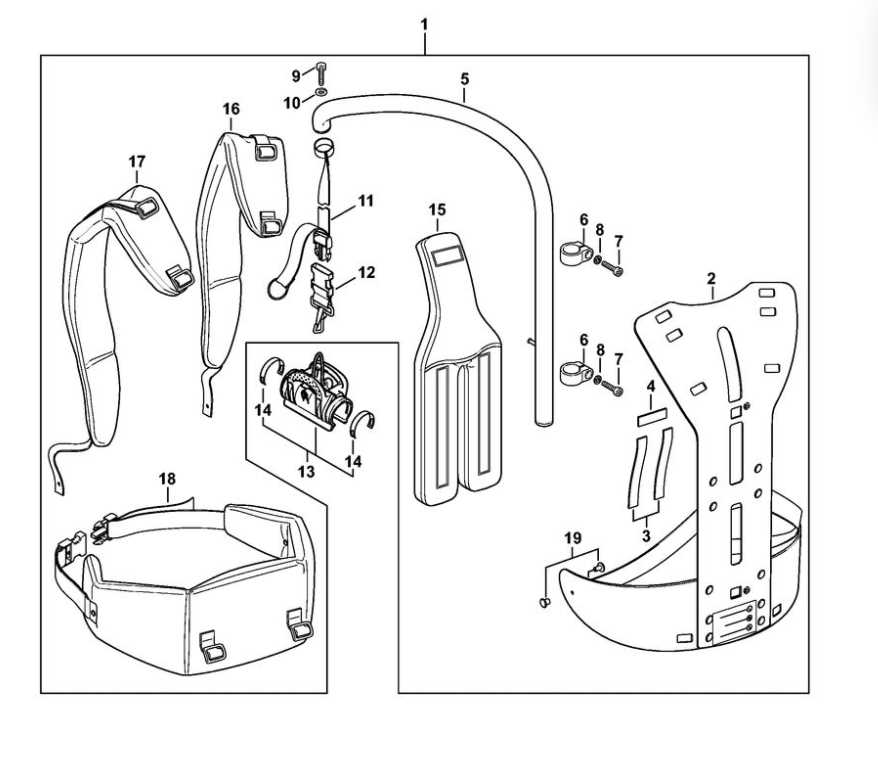

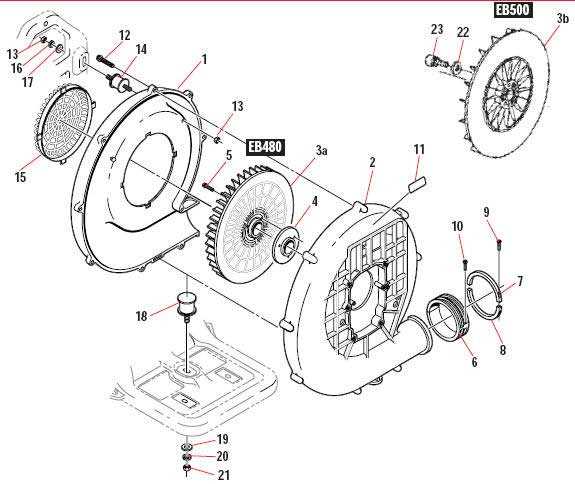

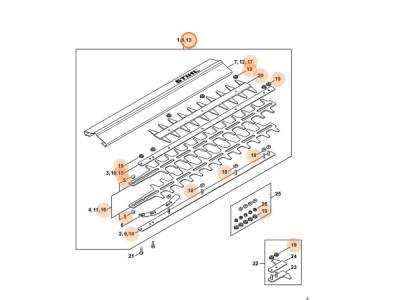

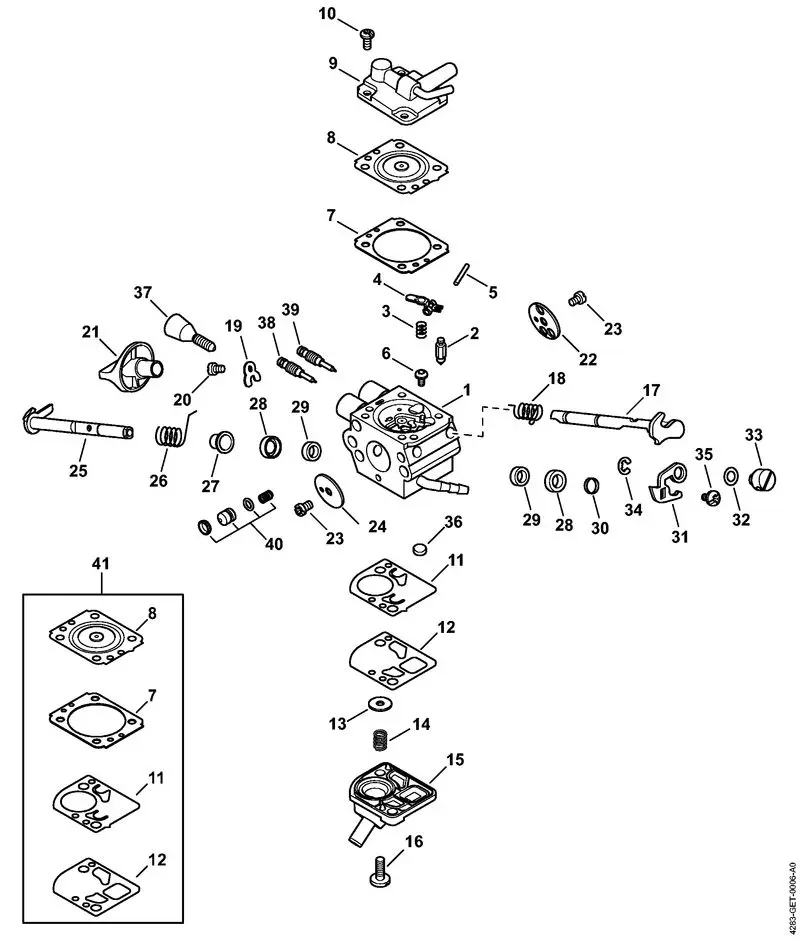

Visual representations of these assemblies offer a valuable resource for both new users and seasoned professionals. They allow for a clearer understanding of how each part interacts within the larger system. This knowledge not only aids in identifying specific issues but also enhances your ability to execute repairs and replacements when necessary.

In this article, we will explore the critical elements involved in the operation of a popular model, providing insights that can help you navigate maintenance and repairs with confidence. Whether you are looking to troubleshoot a problem or simply enhance your understanding, this overview will serve as a beneficial guide.

Understanding Stihl BR 800C Components

When exploring the inner workings of high-performance equipment designed for yard maintenance, it’s crucial to comprehend the various elements that contribute to its functionality. Each component plays a specific role, ensuring efficient operation and optimal performance in demanding tasks.

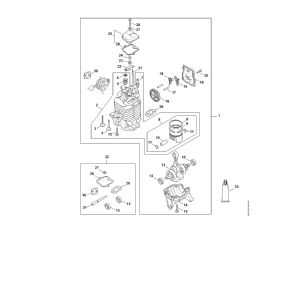

Engine: The heart of any machinery, the engine is responsible for powering the device. Its design affects not only the overall efficiency but also the weight and balance, which are vital for user comfort during prolonged use.

Fuel System: This system ensures that the engine receives the appropriate mixture of fuel and air. Proper calibration is essential for achieving maximum power output and minimizing emissions, thereby promoting environmentally friendly usage.

Air Filtration: An effective filtration mechanism protects the engine from dust and debris, which could lead to premature wear and decreased performance. Regular maintenance of this component is necessary to maintain optimal airflow and engine longevity.

Starter Mechanism: A reliable starting system is crucial for ease of use. Whether manual or automatic, the starter should facilitate quick ignition, allowing the user to get to work without unnecessary delays.

Handle and Controls: Ergonomically designed handles and intuitive controls enhance user experience. Comfort and accessibility in control placement allow for better handling and reduce fatigue during extended operation.

Understanding these key components not only aids in proper maintenance but also enhances the overall user experience, leading to greater efficiency and satisfaction in outdoor tasks.

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for effective maintenance and repair. Visual representations of components play a vital role in simplifying the complex structures of equipment. They serve as essential guides, allowing users to identify individual elements and comprehend their relationships within the system.

Facilitating Repairs

When a machine encounters issues, having a clear visual reference aids in pinpointing the source of the problem. Users can quickly locate specific elements, which streamlines the repair process and minimizes downtime. This efficiency not only saves time but also reduces the likelihood of mistakes during maintenance.

Enhancing Understanding

Visual aids provide an intuitive grasp of how various parts interact and function together. This understanding is essential for both novice users and seasoned technicians, as it fosters better troubleshooting skills. By visualizing the assembly and disassembly of components, users gain confidence in their ability to manage repairs independently.

Key Features of the BR 800C

This powerful outdoor tool is designed for efficiency and user comfort, making it ideal for both professional landscapers and dedicated homeowners. Its advanced engineering and innovative components set it apart in the market, ensuring optimal performance in a variety of conditions.

- High Airflow Capacity: This model boasts an impressive airflow, allowing users to clear large areas quickly and effectively.

- Ergonomic Design: The thoughtfully crafted handle and lightweight construction minimize fatigue, enabling longer working sessions.

- Variable Speed Control: Users can easily adjust the airflow to match different tasks, providing versatility and precision.

- Low Noise Operation: Designed to operate quietly, it’s suitable for use in noise-sensitive environments without sacrificing power.

- Efficient Fuel Consumption: Engine technology ensures reduced emissions and extended run times, promoting eco-friendliness.

- Durability: Built with high-quality materials, this tool can withstand tough conditions and prolonged use.

In summary, this device combines strength, comfort, and efficiency, making it an indispensable asset for tackling outdoor cleaning tasks with ease.

Common Replacement Parts Explained

Maintaining outdoor power equipment often requires understanding key components that may need regular attention or replacement. Familiarity with these elements can enhance performance and prolong the lifespan of your machinery. This section will highlight essential components typically subject to wear and provide insights into their functions.

Fuel Filter: The fuel filter plays a critical role in ensuring clean fuel reaches the engine. Over time, it can become clogged, leading to reduced performance and efficiency. Regular replacement helps maintain optimal flow and engine health.

Air Filter: An air filter safeguards the engine by trapping dirt and debris from the air intake. A dirty or damaged filter can restrict airflow, causing the engine to run poorly. Periodic checks and replacements are necessary to ensure proper air circulation.

Spark Plug: This component ignites the fuel-air mixture in the combustion chamber. Worn or fouled spark plugs can lead to hard starts, misfires, or decreased power. Routine replacement is crucial for consistent engine performance.

Cutting Head: The cutting head is vital for effective operation, whether for trimming or clearing. Regular wear can impact cutting efficiency, so timely replacements ensure precision and safety during use.

Throttle Cable: The throttle cable controls the engine’s power output. If it frays or breaks, it can lead to inconsistent performance or complete loss of throttle response. Monitoring its condition can prevent unexpected issues.

By understanding these key components, users can better manage maintenance tasks and ensure their equipment operates smoothly and efficiently. Regular inspections and timely replacements are essential for optimal functionality.

How to Read a Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations serve as a guide, helping users identify and locate various elements within a machine. By familiarizing yourself with these representations, you can streamline your repair process and enhance your overall efficiency.

Key Components of the Visual Representation

- Labels: Each part is often accompanied by a label, providing a name or code that corresponds to its function.

- Numbers: Reference numbers can be used to indicate the specific location of parts, making it easier to find replacements.

- Connections: Lines or arrows may illustrate how parts interact or connect with one another, showing the flow of operation.

- Groupings: Components may be organized into sections, allowing for a clearer understanding of related parts.

Steps to Interpret the Illustration

- Start with the Overview: Look at the entire image to get a sense of the layout and how the components fit together.

- Identify Key Areas: Focus on specific sections that are relevant to your repair or maintenance needs.

- Cross-reference with Documentation: Use accompanying manuals or lists to confirm the names and numbers of each component.

- Follow the Connections: Trace the lines or arrows to understand how different elements work together.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your outdoor equipment involves a combination of regular upkeep and attentive practices. By following a few essential guidelines, you can enhance performance, minimize wear, and ultimately save on future repairs.

Regular Cleaning

Keep your device free from debris and dirt. After each use, wipe down surfaces and remove any grass or leaves that may have accumulated. Frequent cleaning prevents buildup that can lead to corrosion or mechanical issues.

Routine Inspections

Conducting periodic checks on key components is vital. Examine filters, spark plugs, and fuel lines for any signs of wear or damage. Addressing minor issues before they escalate can significantly prolong the life of your machinery. Additionally, ensure proper lubrication of moving parts to maintain smooth operation.

Identifying Parts by Model Number

Understanding the components of your equipment is essential for maintenance and repairs. Each model is assigned a unique identifier, allowing users to accurately find and source the necessary elements for optimal functionality. Recognizing these numbers can significantly simplify the process of identifying replacements or upgrades.

Benefits of Using Model Numbers

Utilizing the designated model identifiers ensures precision when seeking out specific components. This practice minimizes confusion, especially when similar devices may have overlapping features. Furthermore, knowing the model number aids in accessing detailed information about compatibility and installation.

How to Locate Model Numbers

Typically, the model number can be found on a label or stamped directly onto the device. Checking the user manual or manufacturer’s website can also provide valuable insights. Once located, this number serves as a gateway to discovering a wealth of resources, from technical specifications to assembly instructions.

Where to Purchase Genuine Parts

When it comes to maintaining outdoor power equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Whether you’re a professional landscaper or a DIY enthusiast, having reliable suppliers for high-quality replacements can make all the difference in your equipment’s efficiency.

Authorized Dealers are often the best choice for finding genuine replacements. These retailers typically offer a wide range of items, backed by manufacturer warranties. You can also benefit from the expertise of knowledgeable staff who can assist you in identifying the correct components for your specific model.

Additionally, official websites of manufacturers provide convenient access to their catalogs. You can browse through available selections, compare options, and order directly from the source. This ensures that you receive original items that meet strict quality standards.

For those who prefer online shopping, reputable e-commerce platforms often carry a selection of authentic components. However, it’s essential to verify the seller’s credibility to avoid counterfeit products. Reading customer reviews and checking ratings can help ensure a satisfactory purchase.

Lastly, consider joining community forums or groups related to your equipment. Members often share recommendations for trusted suppliers and can provide insights based on their experiences. This can lead you to valuable resources for acquiring the genuine items you need.

Troubleshooting Common Issues

Maintaining equipment can often lead to unexpected challenges. Understanding how to identify and resolve these issues can save time and ensure optimal performance. This section outlines common problems encountered with outdoor power tools and provides practical solutions to get your device back in working order.

- Device Won’t Start

- Check the fuel level and quality; old or contaminated fuel can cause starting issues.

- Inspect the spark plug for wear or damage; replacing it may resolve the problem.

- Ensure the choke is in the correct position, as improper settings can hinder ignition.

- Reduced Power Output

- Examine the air filter for clogs; cleaning or replacing it can enhance airflow and efficiency.

- Look for blockages in the exhaust system that could restrict performance.

- Verify that the throttle is functioning properly and not sticking.

- Excessive Vibration

- Check for loose or damaged components; tightening or replacing them may resolve the issue.

- Inspect the cutting attachment for wear and ensure it is balanced correctly.

- Examine the handle and frame for any cracks or misalignments that could contribute to vibration.

- Overheating

- Monitor the operation duration; prolonged use can cause overheating.

- Ensure the cooling fins are clean and unobstructed to allow for proper airflow.

- Check the oil levels and quality, as inadequate lubrication can lead to overheating.

By systematically addressing these common issues, users can maintain the longevity and reliability of their outdoor equipment. Regular inspections and timely maintenance are key to preventing these problems from arising.

Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures required to assemble and disassemble your equipment safely and effectively. Understanding these processes is essential for maintenance and repairs, ensuring optimal performance and longevity of the machine.

Disassembly Steps

Follow these steps to carefully disassemble the unit for maintenance or inspection:

| Step | Description |

|---|---|

| 1 | Ensure the machine is turned off and disconnected from any power source. |

| 2 | Remove any attachments or accessories from the main body. |

| 3 | Use the appropriate tools to loosen and remove screws and bolts. |

| 4 | Carefully detach the components, noting their arrangement for reassembly. |

Assembly Steps

To reassemble the unit, adhere to the following instructions:

| Step | Description |

|---|---|

| 1 | Start by aligning the components as per the disassembly notes. |

| 2 | Secure each part using the screws and bolts, ensuring they are tightened properly. |

| 3 | Reattach any accessories or attachments that were removed. |

| 4 | Perform a final check to ensure everything is in place before powering on. |

Comparing BR 800C with Other Models

When evaluating powerful outdoor equipment, it’s essential to consider how various models stack up against one another. This comparison helps users understand the strengths and weaknesses of different machines, allowing for an informed decision based on their specific needs.

One of the standout features of this particular model is its impressive engine capacity, which offers enhanced performance and efficiency compared to its counterparts. In contrast, lighter models tend to prioritize portability and ease of use, making them suitable for less demanding tasks. Users seeking power may find that the robust option excels in large-scale operations, while those needing a more maneuverable alternative might prefer the smaller versions.

Moreover, fuel consumption is another critical factor. The high-capacity variant often provides longer run times, reducing the frequency of refueling during extended work sessions. However, some other options may offer better fuel efficiency, appealing to those who prioritize lower operational costs.

Noise levels also play a significant role in the comparison. The quieter machines tend to be favored for residential areas where noise restrictions are in place, whereas the more powerful models might generate a louder output, suited for larger, open spaces.

Ultimately, the choice between models hinges on individual requirements, including the type of tasks, the environment in which the equipment will be used, and personal preferences regarding weight and noise. Each model has unique characteristics that cater to specific user demands, making it vital to assess all options thoroughly.