Understanding the Yamaha 8hp Outboard Parts Diagram

Understanding the intricate details of a small marine propulsion unit can significantly enhance your maintenance and repair efforts. Whether you are an avid fisherman or a recreational boater, having a clear grasp of the essential elements involved in the functionality of your engine is vital. This section provides valuable insights into the various components that contribute to the overall performance of your vessel.

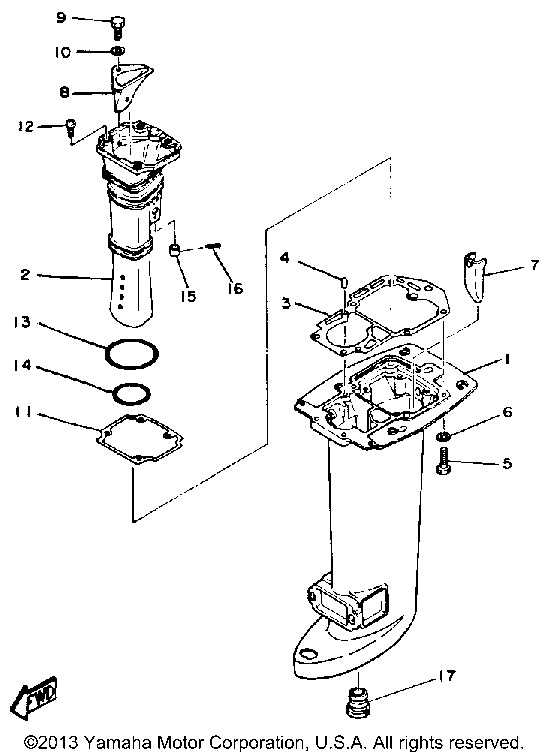

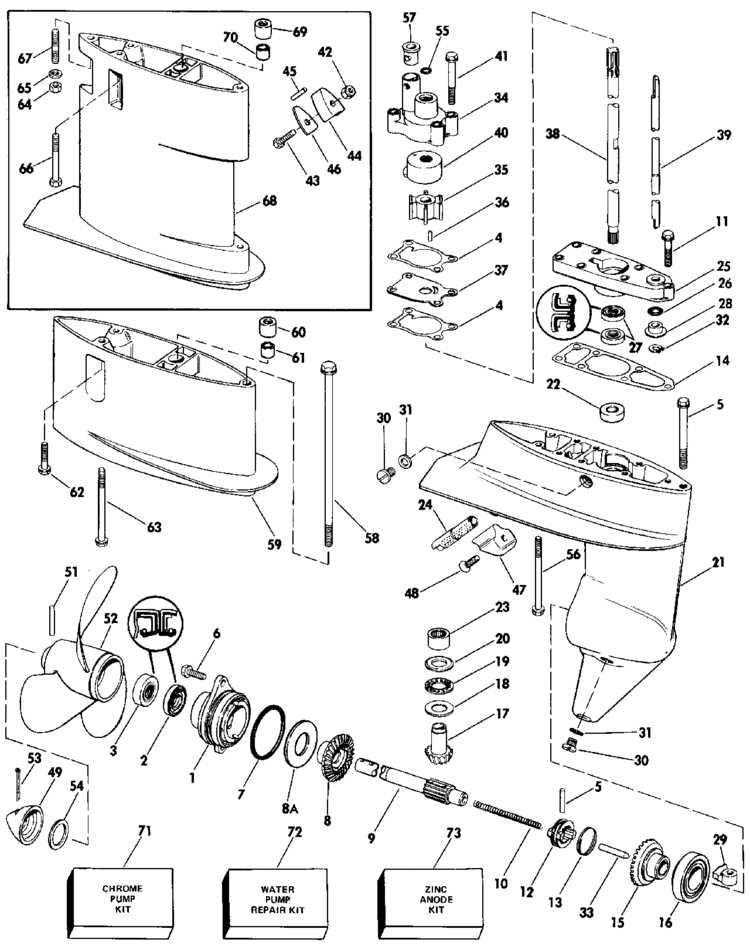

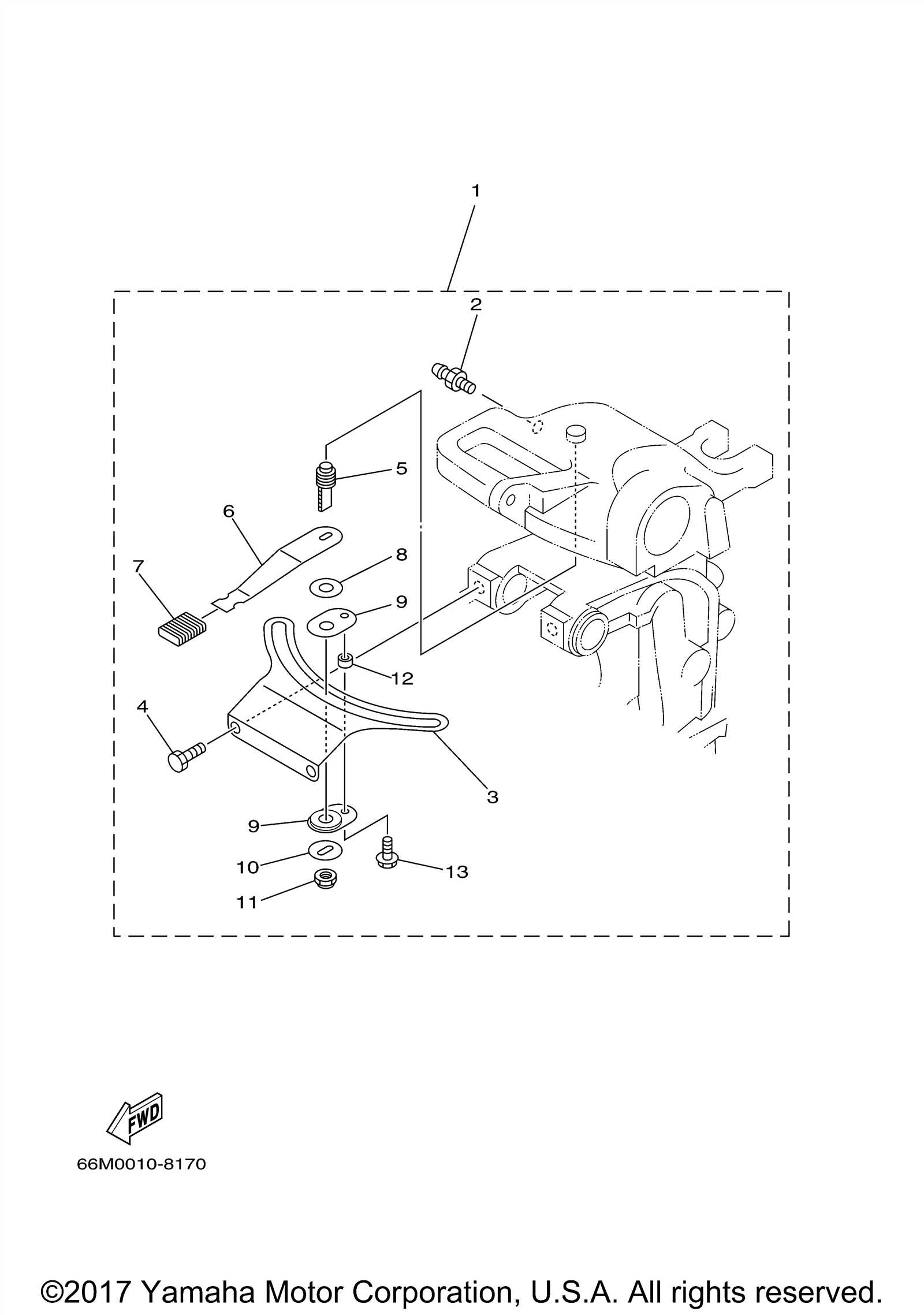

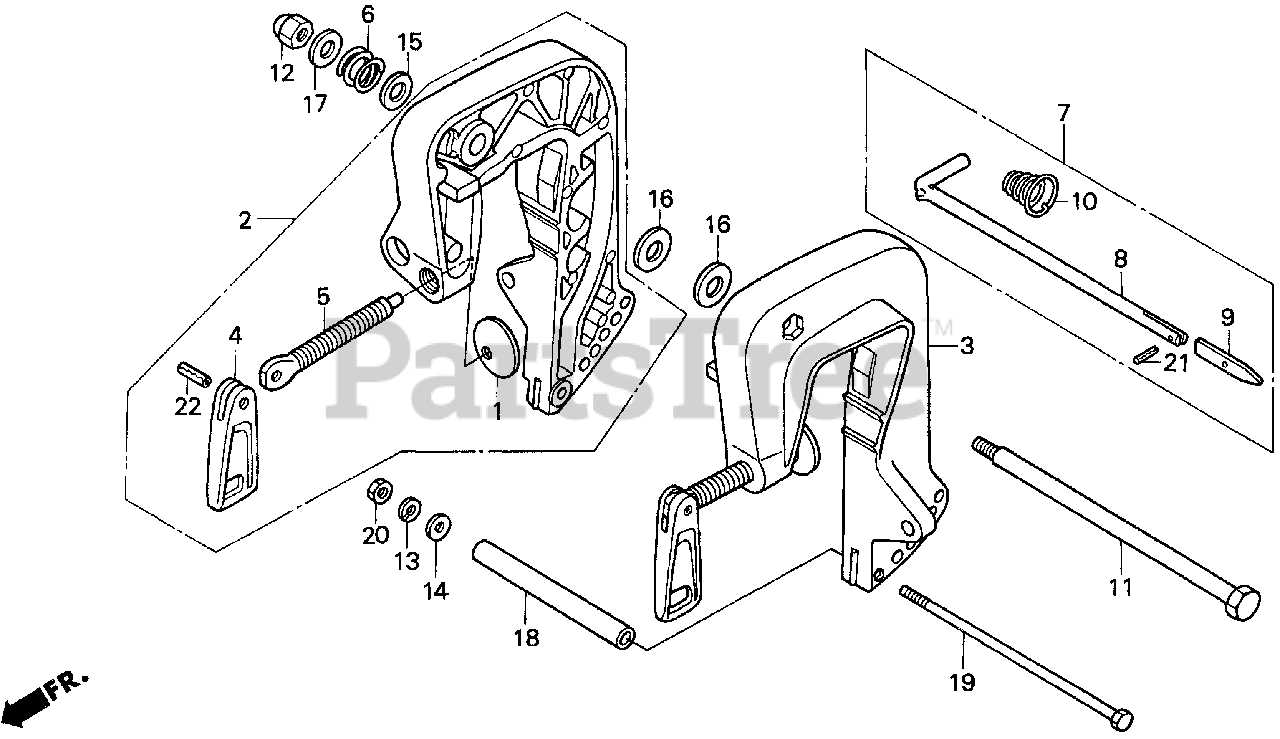

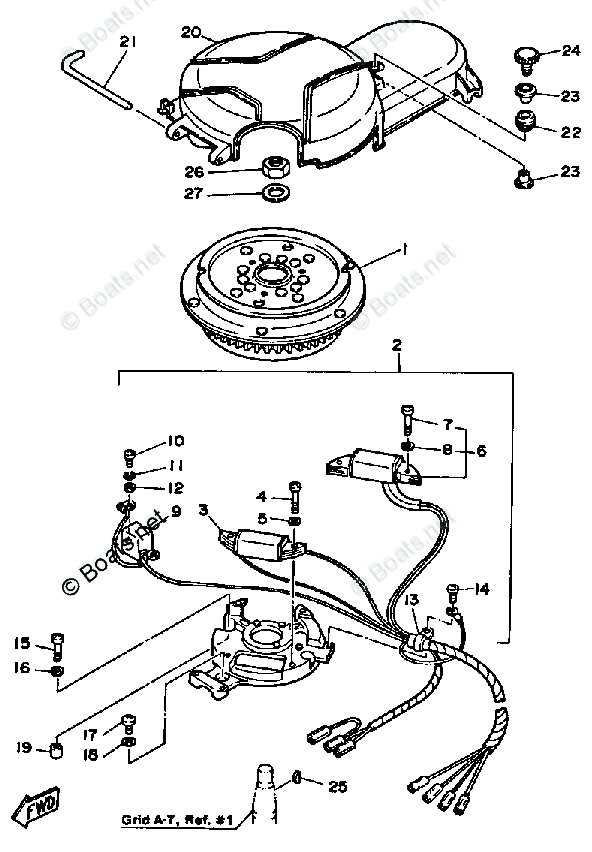

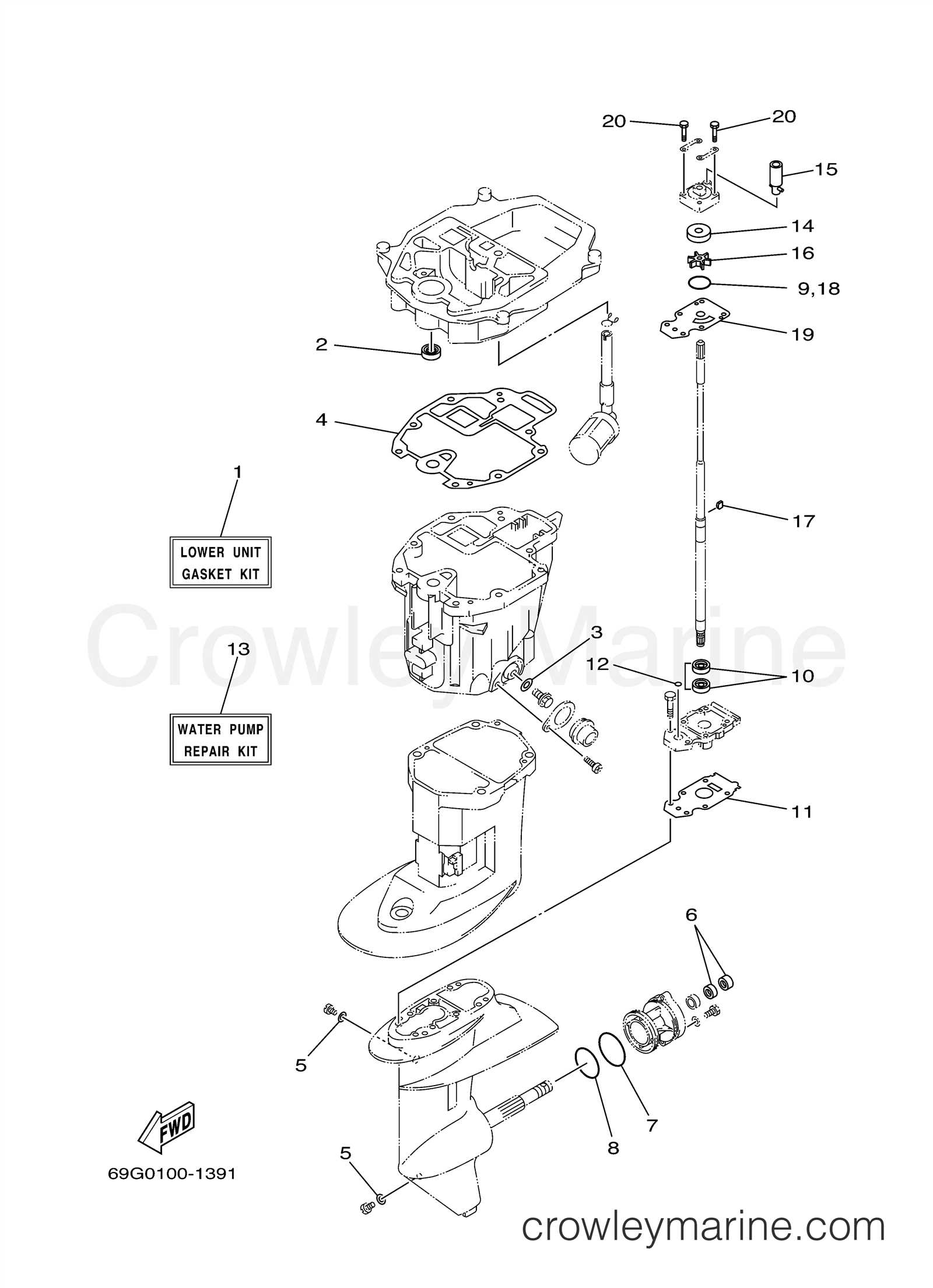

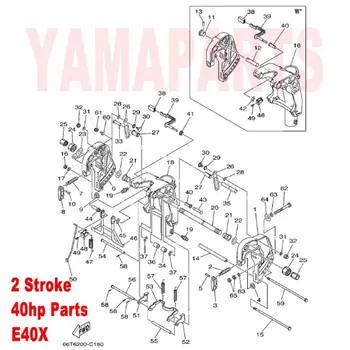

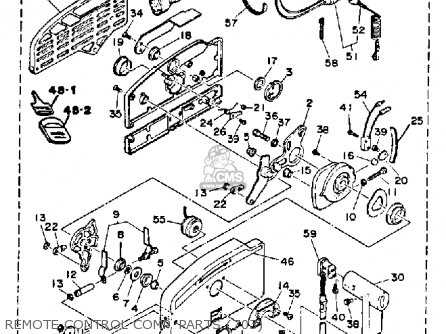

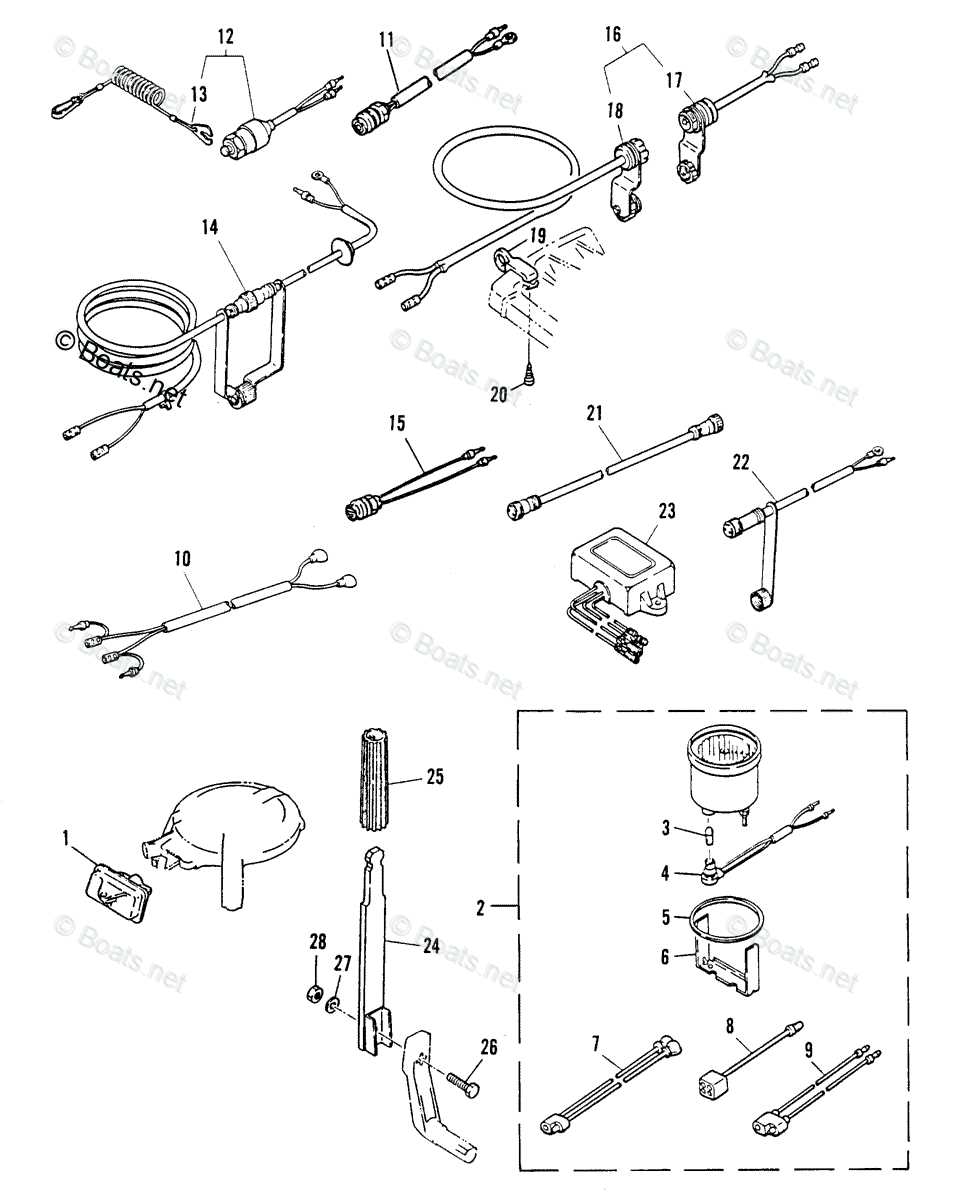

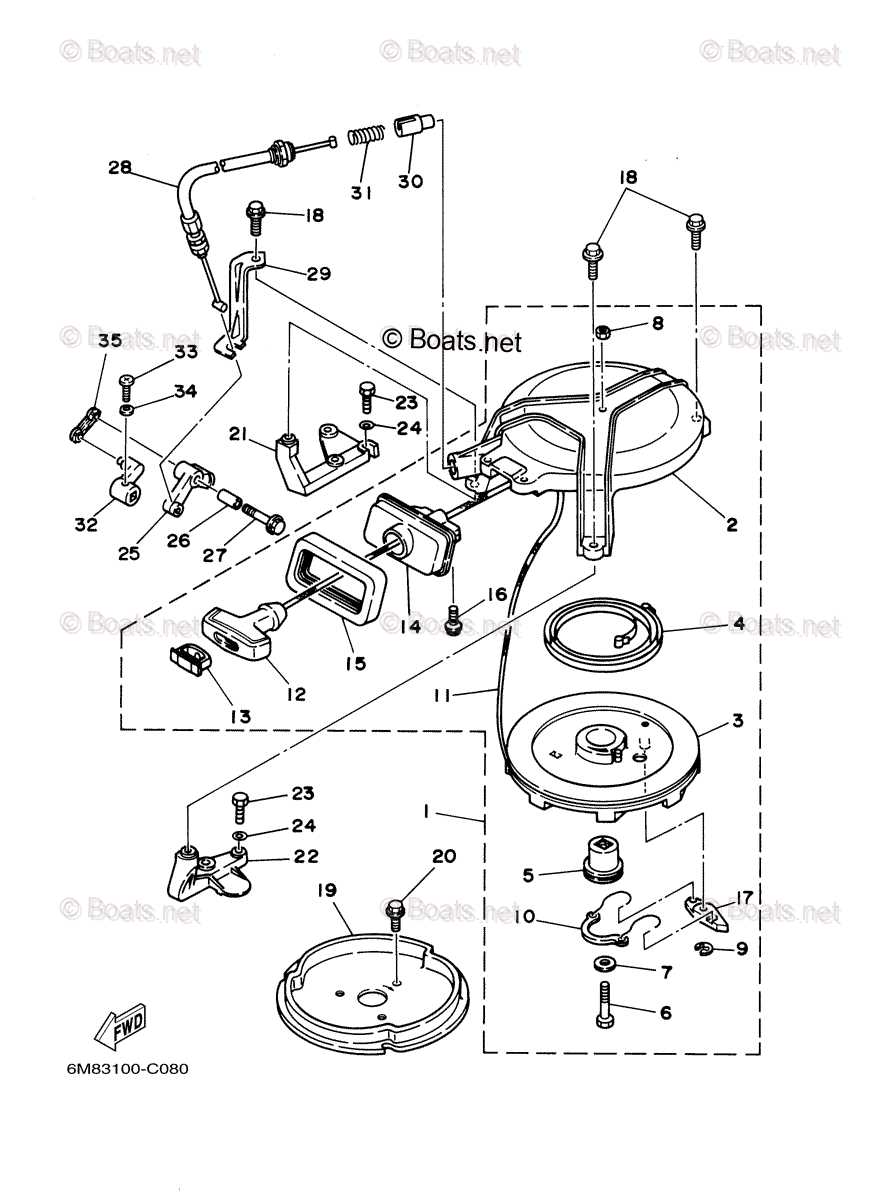

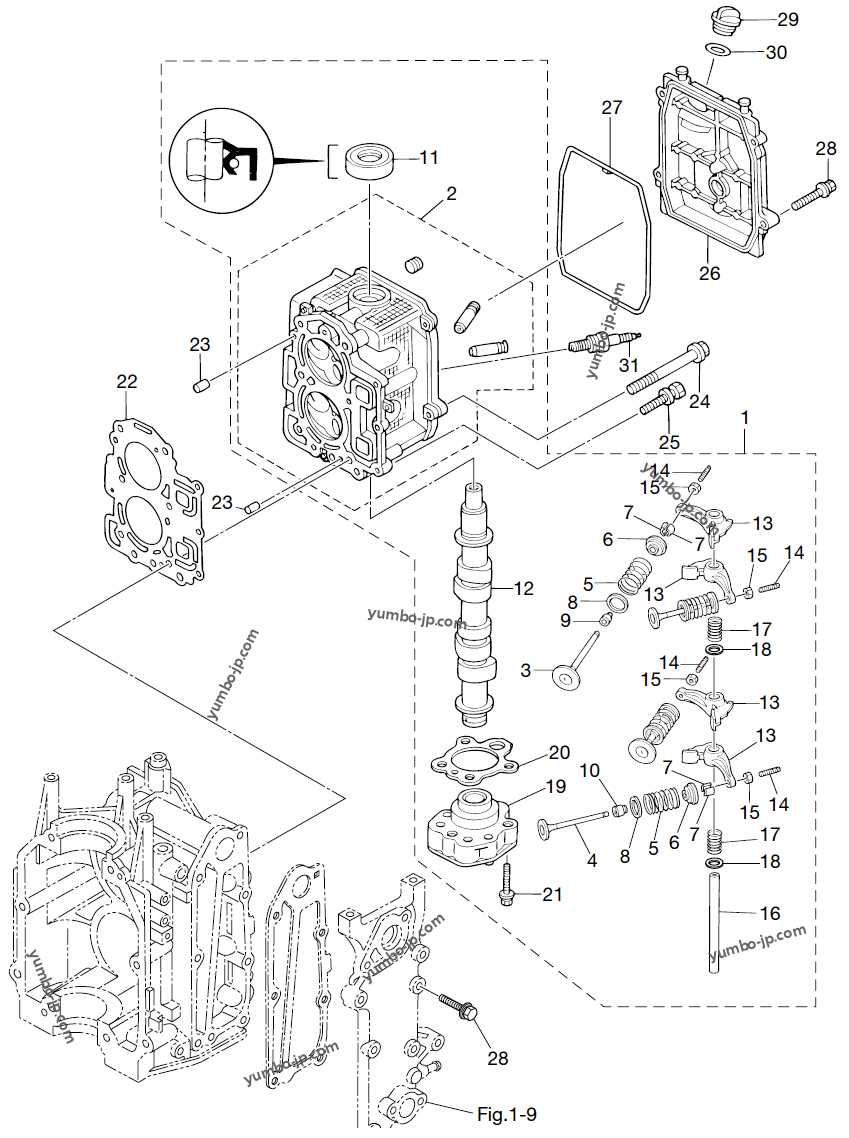

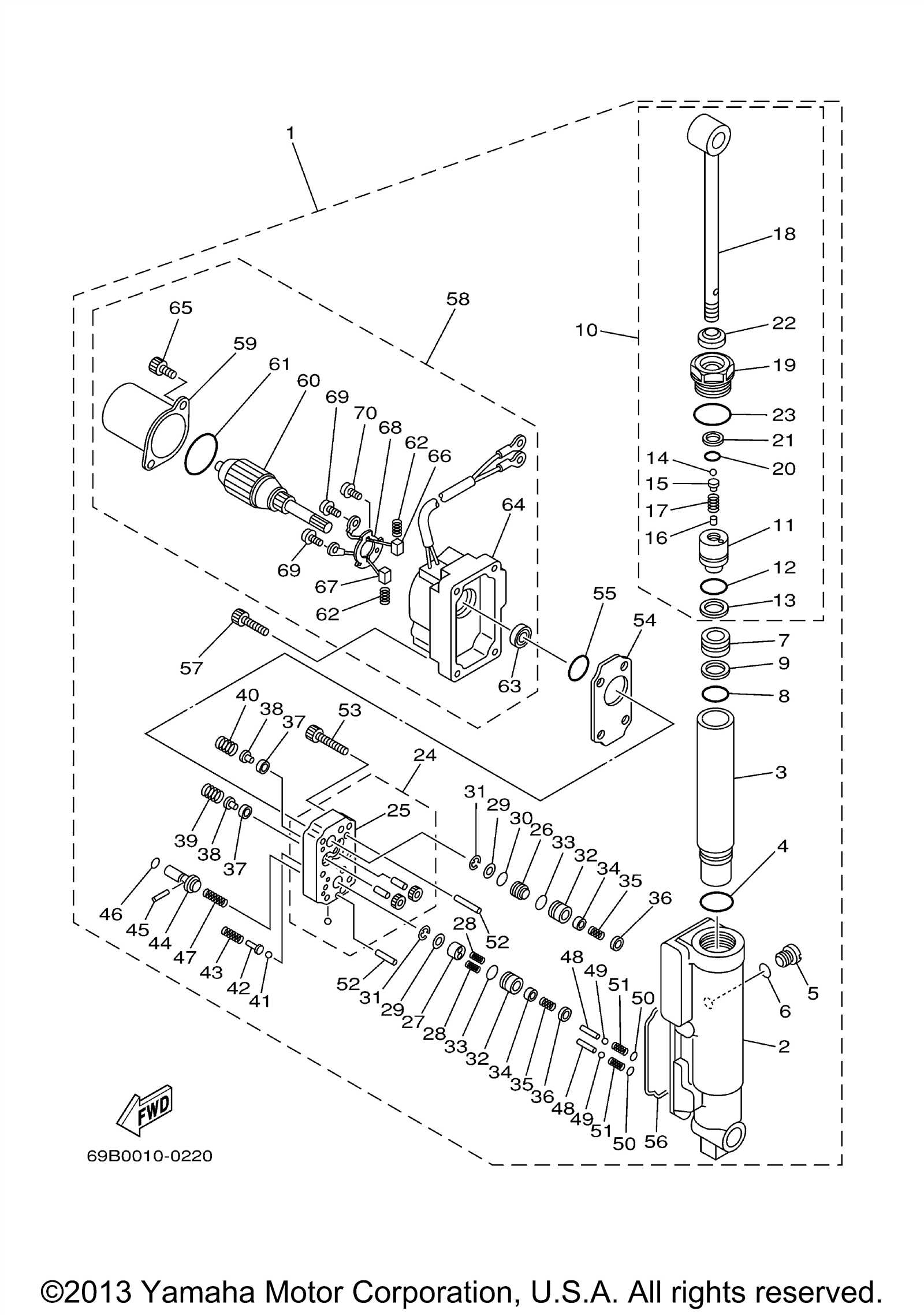

Familiarity with the assembly and layout of these mechanisms not only facilitates troubleshooting but also aids in identifying specific areas that may require attention or replacement. Visual aids can be particularly helpful in this regard, offering a structured perspective on how each element interacts within the system.

By delving into the anatomy of your propulsion system, you equip yourself with the knowledge needed to ensure optimal operation and longevity. This exploration serves as a practical guide, enabling you to maintain and enhance your marine experience effectively.

Understanding Yamaha 8hp Outboard Parts

Familiarizing oneself with the components of a small marine engine is essential for maintenance and optimal performance. Each element plays a critical role in ensuring that the vessel operates smoothly and efficiently. Knowledge of these individual parts not only aids in troubleshooting but also enhances the overall boating experience.

These engines consist of various key sections, including the power unit, fuel system, cooling apparatus, and control mechanisms. Understanding how these components interact helps in diagnosing issues and performing repairs. Whether it’s the ignition system or the propelling mechanism, each part contributes to the functionality of the craft.

Regular inspection and replacement of worn-out components can prevent larger problems and extend the life of the engine. This proactive approach allows boaters to enjoy their time on the water without the anxiety of unexpected breakdowns. A comprehensive understanding of the machinery leads to more informed decisions regarding upkeep and enhancements.

Importance of Parts Diagrams

Understanding the structure and components of any mechanical device is essential for effective maintenance and repair. Visual representations of individual elements play a crucial role in simplifying complex systems, ensuring that users can identify and address specific issues with ease.

- Clarity: Visual guides provide clear depictions of various components, making it easier to comprehend their arrangement and function.

- Efficiency: Quick reference materials save time during repairs, allowing technicians to locate parts swiftly and accurately.

- Prevention of Errors: Detailed illustrations help reduce mistakes by providing precise information about assembly and disassembly procedures.

Moreover, such resources enhance communication among professionals, enabling collaborative efforts in troubleshooting and repairs. They serve as valuable educational tools, helping novice users familiarize themselves with the inner workings of the machinery.

- Access to accurate information fosters confidence in users.

- Clear visuals aid in the proper reassembly of components.

- Well-organized resources can significantly improve overall operational efficiency.

In summary, visual representations are indispensable for anyone involved in the upkeep of mechanical equipment, ensuring both longevity and reliability in performance.

Key Components of the Outboard

Understanding the essential elements of a marine propulsion unit is crucial for maintaining optimal performance. Each component plays a specific role, contributing to the efficiency and reliability of the system. Familiarity with these parts can aid in troubleshooting and enhance the overall boating experience.

Main Elements

- Engine: The heart of the system, responsible for converting fuel into mechanical energy.

- Gearcase: Houses the transmission components, facilitating the transfer of power to the propeller.

- Propeller: A crucial element that propels the vessel through the water by converting rotational energy into thrust.

- Fuel System: Includes the tank, lines, and carburetor, ensuring a steady flow of fuel to the engine.

- Cooling System: Prevents overheating by circulating water through the engine to dissipate heat.

Additional Components

- Ignition System: Initiates the combustion process, essential for engine operation.

- Control Mechanism: Allows the operator to manage speed and direction, ensuring safe navigation.

- Electrical System: Powers the ignition and other electronic components, crucial for reliable functionality.

- Mounting Bracket: Secures the unit to the transom of the boat, providing stability and support.

Each of these components works in harmony, underscoring the importance of regular maintenance and timely repairs to ensure long-lasting performance on the water.

Common Issues and Replacement Parts

When operating a small marine engine, users may encounter several typical challenges that can affect performance and reliability. Understanding these issues and knowing how to address them through appropriate replacements is crucial for maintaining optimal functionality.

Common complications often stem from wear and tear, inadequate maintenance, or environmental factors. Identifying these problems early can help in prolonging the lifespan of the engine and ensuring smoother operation. Below is a table outlining frequent issues along with their corresponding replacement components.

| Issue | Replacement Component |

|---|---|

| Overheating | Cooling water pump |

| Fuel leakage | Fuel line or gaskets |

| Difficulty starting | Starter motor or spark plugs |

| Rough idling | Carburetor cleaning kit |

| Excessive vibration | Mounting rubber or propeller |

Addressing these issues promptly with the correct replacements can significantly enhance the engine’s performance and reliability. Regular maintenance checks are advisable to prevent minor problems from escalating into major repairs.

How to Read a Parts Diagram

Understanding an assembly illustration can greatly enhance your ability to identify components and their relationships within a mechanical system. This visual guide provides a clear representation of each element, allowing users to locate specific items quickly and understand their functions. By familiarizing yourself with these illustrations, you can streamline repairs and maintenance.

Start by examining the legend or key, which usually provides explanations of symbols and codes used in the illustration. This section is crucial for interpreting what each label or number represents. Pay attention to the scale as well; it indicates the size of each item in relation to others, helping you grasp the overall layout.

Next, follow the numbering system typically used in these visuals. Each component is usually assigned a unique identifier, making it easier to reference in parts lists or manuals. Take note of how components are grouped; often, related items are clustered together, showing their connection and interaction within the system.

Lastly, practice identifying common features such as mounting points, fastening types, and connection methods. Recognizing these aspects will enable you to visualize how components fit together and function as a cohesive unit, facilitating a more effective approach to assembly or disassembly tasks.

Where to Find Quality Parts

Finding reliable components for marine engines is essential for maintaining performance and longevity. Various sources offer a wide range of options, ensuring you can access the necessary elements for effective repairs and upgrades. This guide explores the best places to source high-quality materials that meet your needs.

Authorized Dealers

One of the most trustworthy options is to visit authorized dealerships. These establishments provide genuine components that guarantee compatibility and durability. Engaging with knowledgeable staff can also help you identify the right items for your specific requirements.

Online Marketplaces

Another convenient avenue is online platforms. Reputable websites often feature extensive catalogs, complete with customer reviews and ratings. Look for sellers who offer return policies and customer support to ensure you receive satisfactory products. Additionally, consider exploring specialized forums and communities where enthusiasts share recommendations and experiences regarding various suppliers.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your marine engine requires regular upkeep and attention. By following a series of essential maintenance practices, you can significantly extend the life of your motor and enhance its efficiency. This section outlines key strategies that every owner should adopt for the best results.

First, it is vital to conduct routine inspections. Regularly check for any signs of wear or damage, focusing on critical components such as the fuel system, cooling system, and electrical connections. Addressing minor issues early can prevent major problems down the line.

Additionally, clean and replace filters as needed. Maintaining clean fuel and air filters ensures that your engine runs smoothly and efficiently, reducing the risk of performance issues caused by contaminants.

Another important aspect is proper lubrication. Use the recommended oils and lubricants to minimize friction and wear on moving parts. Regularly checking and topping off oil levels will help maintain optimal function.

Finally, winterizing your engine before long periods of inactivity is crucial. Properly preparing your motor for storage can prevent damage from environmental factors and ensure it starts easily when the time comes to use it again. By implementing these maintenance tips, you can enjoy a more reliable and long-lasting engine.

Installation Instructions for Key Parts

This section provides essential guidance for the proper installation of vital components in your marine engine. Following these instructions will ensure optimal performance and longevity of your equipment. Each step is designed to simplify the process, making it accessible for both beginners and experienced users.

| Component | Installation Steps | Tips |

|---|---|---|

| Propeller |

1. Align the propeller with the drive shaft. 2. Slide it onto the shaft until it fits snugly. 3. Secure with the retaining nut, tightening it appropriately. |

Ensure the propeller is compatible with your engine specifications. |

| Fuel Filter |

1. Locate the filter housing. 2. Unscrew the old filter and remove it. 3. Install the new filter in the same orientation and tighten it securely. |

Check for any leaks after installation. |

| Starter Motor |

1. Disconnect the battery before starting. 2. Remove the old motor by unscrewing the mounting bolts. 3. Position the new starter and secure it with the bolts. |

Always reconnect the battery last to avoid short circuits. |

| Water Pump |

1. Drain the cooling system if necessary. 2. Remove the cover and take out the old impeller. 3. Place the new impeller in the correct position and reassemble. |

Regular maintenance can extend the life of your water pump. |

Safety Considerations When Repairing

When undertaking maintenance or repairs on marine engines, ensuring safety should be a top priority. Proper precautions help prevent accidents and injuries, safeguarding both the individual and the equipment. By adhering to established safety protocols, you can create a secure environment for repair work.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial during any repair task. This includes gloves to protect your hands from sharp edges and chemicals, safety goggles to shield your eyes from debris, and non-slip footwear to prevent falls. Ensuring that your PPE is in good condition and fits properly can significantly reduce the risk of injury.

Work Environment Safety

Creating a safe workspace is essential. Ensure the area is well-ventilated, especially when working with fuel or chemicals. Keep tools organized and remove any unnecessary items to prevent tripping hazards. Additionally, be aware of your surroundings and ensure that there are no distractions that could lead to accidents while working on the machinery.

Comparing OEM and Aftermarket Options

When it comes to selecting components for marine engines, enthusiasts often face a crucial decision between original equipment manufacturer (OEM) products and aftermarket alternatives. Each category presents its own set of benefits and drawbacks that can influence performance, cost, and longevity.

Advantages of OEM Products

- Quality Assurance: OEM items are manufactured to meet specific standards, ensuring compatibility and reliability.

- Warranty Support: Purchasing original components often comes with a manufacturer’s warranty, providing peace of mind.

- Consistent Performance: OEM options are designed to work seamlessly with the engine, resulting in optimal performance.

Benefits of Aftermarket Alternatives

- Cost-Effectiveness: Aftermarket products are typically more affordable, offering a budget-friendly solution for repairs.

- Variety: A broader range of options can be found, allowing for customization and specialized features.

- Accessibility: Aftermarket components are often more readily available through various retailers and online platforms.

Ultimately, the choice between OEM and aftermarket options depends on individual preferences, budget constraints, and the specific requirements of the engine in question.

Cost Factors for Replacement Parts

Understanding the expenses associated with acquiring new components for marine engines is crucial for maintaining optimal performance and reliability. Several variables influence these costs, which can vary significantly based on a range of factors.

- Brand Reputation: Well-known manufacturers often charge a premium due to their established quality and reliability.

- Material Quality: Components made from durable materials tend to cost more but offer better longevity and performance.

- Availability: Rare or hard-to-find items may be more expensive due to limited supply, increasing shipping costs and seller markups.

- Technological Features: Advanced components with innovative technologies may command higher prices compared to basic versions.

- Market Demand: Fluctuations in demand can lead to price increases, especially during peak boating seasons.

When planning for replacements, it is essential to consider these factors to make informed decisions that balance quality and cost-effectiveness.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components for small marine engines. Understanding the various elements and their functions can help users maintain and troubleshoot their equipment more effectively.

What should I consider when selecting components?

When choosing components, it’s crucial to ensure compatibility with your engine model. Additionally, consider the quality of the materials and the manufacturer’s reputation to avoid premature wear or failure.

How can I identify the right component for my engine?

To accurately identify the correct component, refer to the user manual that comes with your engine. It often contains specific details regarding the required specifications. Alternatively, consulting with a professional or utilizing online resources can provide valuable assistance.