Pallet Racking Parts Diagram Explained

In modern warehousing and logistics, efficient organization is paramount. A well-structured system allows for optimal space utilization, easy access to goods, and streamlined operations. By exploring the various elements that comprise these frameworks, one can gain insights into their functionality and advantages.

Each component plays a critical role in supporting the overall structure, contributing to stability and efficiency. Familiarity with these elements not only aids in selecting the right configuration but also enhances safety and productivity within the storage environment.

This article will delve into the intricacies of the various components involved in these systems, illustrating their interactions and significance in creating an effective storage solution. Understanding these relationships will empower managers and operators to make informed decisions tailored to their specific needs.

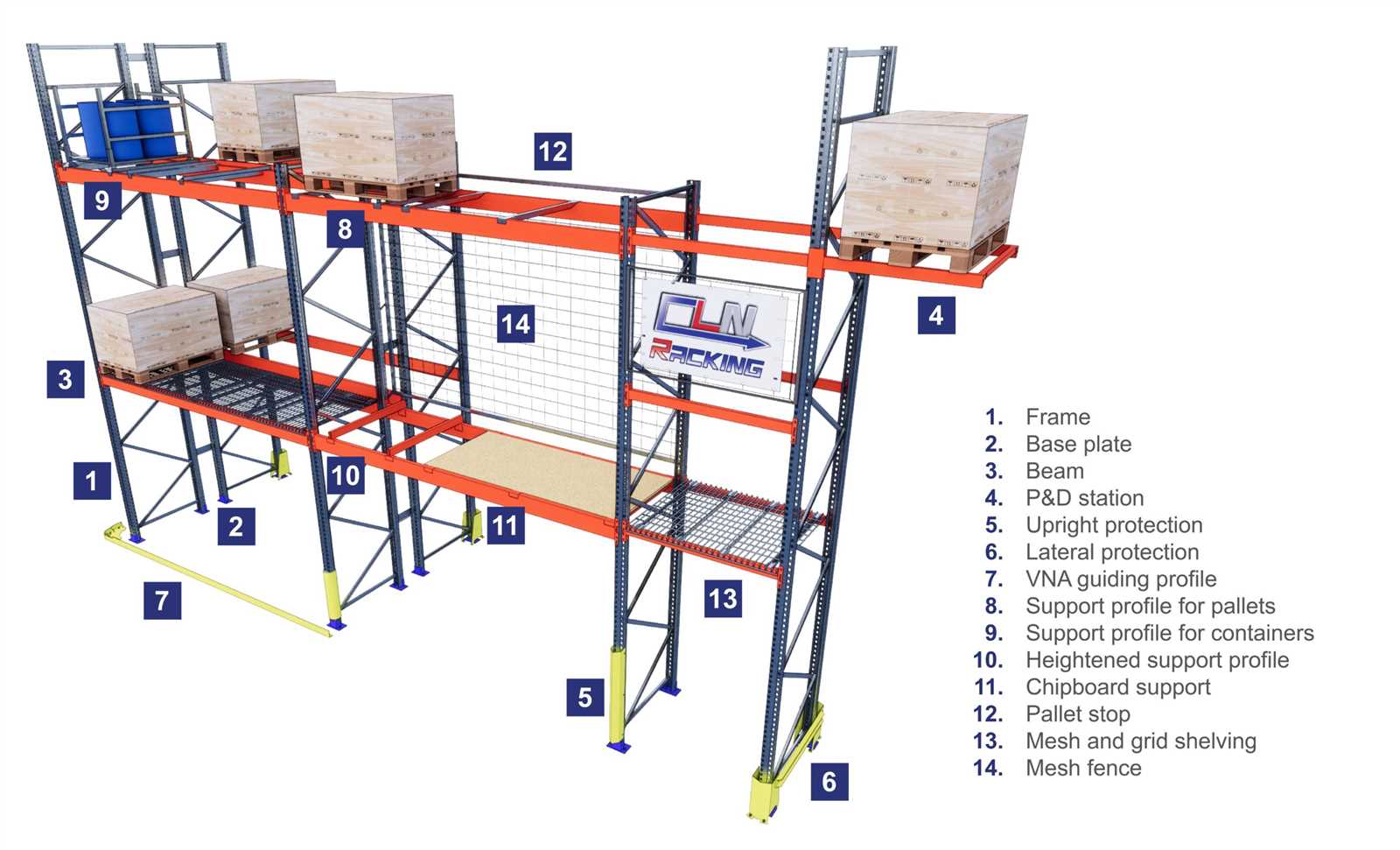

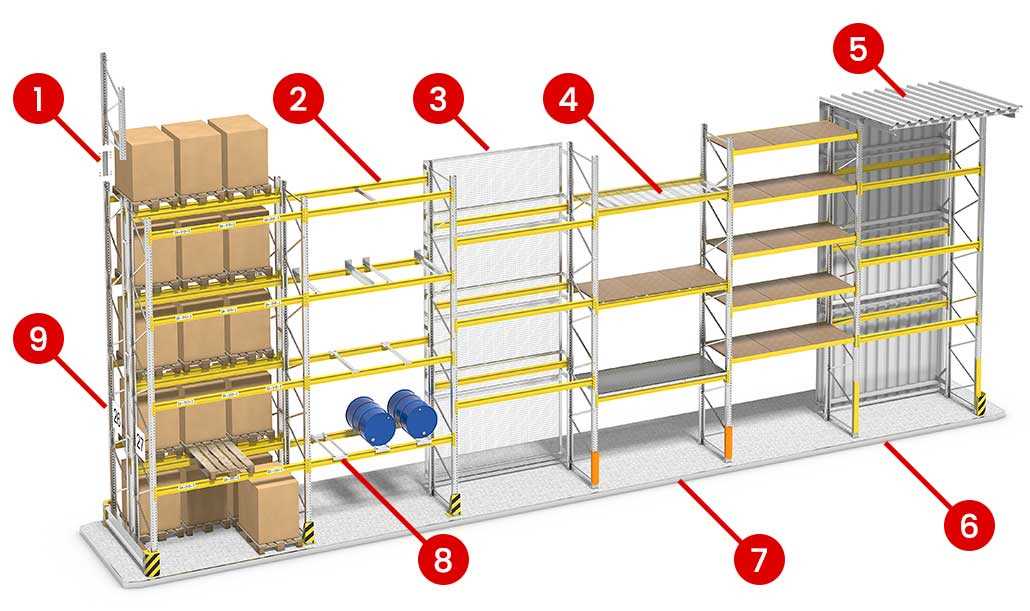

Pallet Racking Components Overview

This section provides a comprehensive look at the essential elements that form the backbone of an efficient storage system. Understanding these components is crucial for optimizing space and ensuring the safety and functionality of the setup.

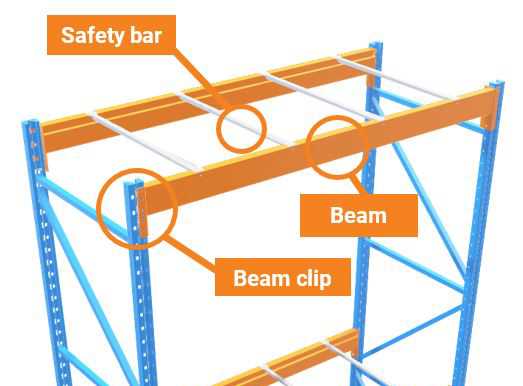

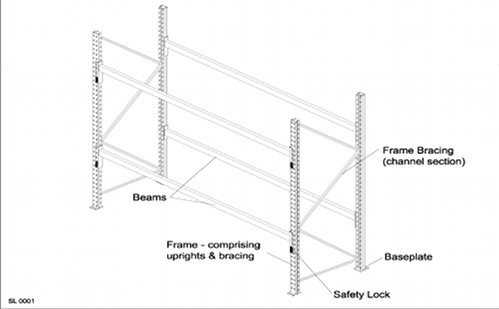

At the core of these structures are the vertical supports, which provide stability and strength. They are designed to bear the weight of stored items while allowing for easy access. Horizontal beams connect these supports, creating levels for placing goods. The combination of these components establishes a robust framework suitable for various storage needs.

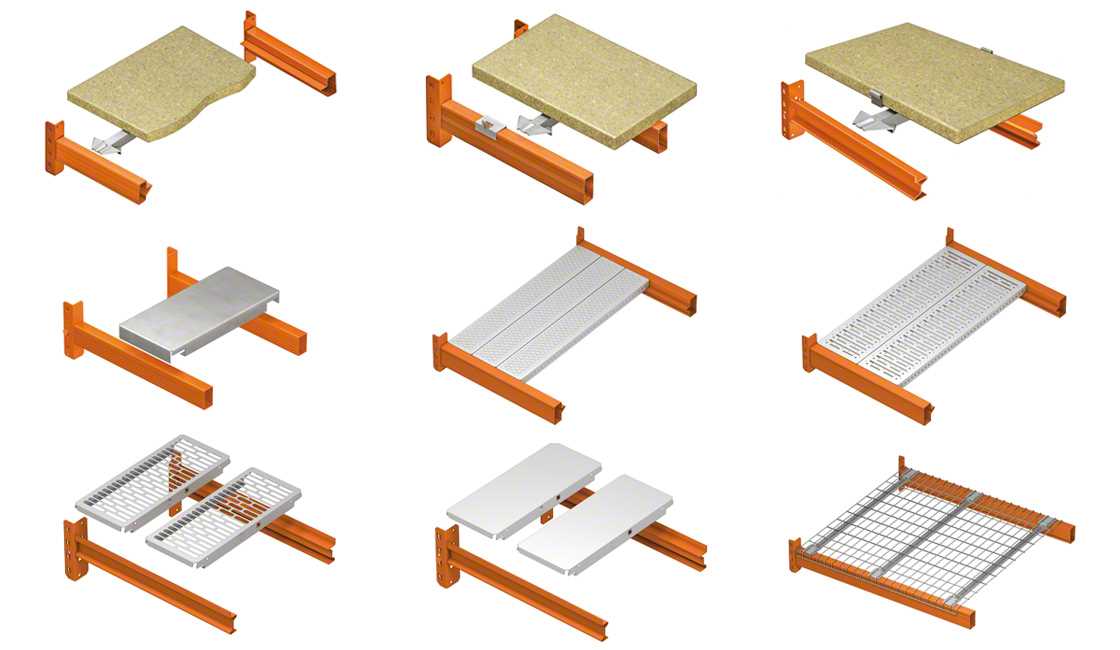

In addition to the main supports and beams, accessory items play a significant role in enhancing functionality. Bracing ensures that the assembly remains rigid and secure, while safety clips help to prevent accidental dislodgment of stored materials. Decking options further improve usability by providing flat surfaces for different types of products.

Finally, protective elements such as guards and post protectors are essential for safeguarding both the structure and personnel. By incorporating these various components, a storage system can achieve maximum efficiency, safety, and organization.

Types of Pallet Racking Systems

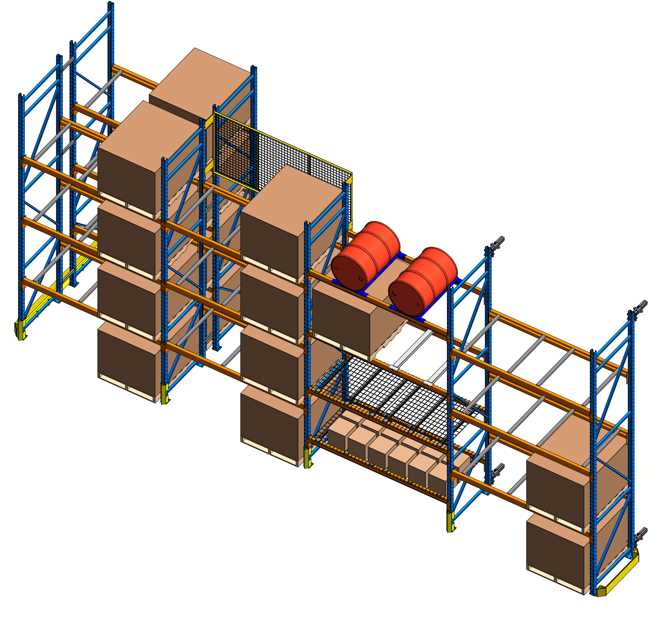

In modern warehousing, various systems are designed to optimize storage and accessibility. Each type serves specific needs, enhancing efficiency and organization in material handling.

| System Type | Description |

|---|---|

| Selective Storage | Offers easy access to all items, allowing for quick retrieval and high versatility. |

| Drive-In | Enables high-density storage by allowing forklifts to enter rows for loading and unloading. |

| Push Back | Utilizes a gravity-driven mechanism to store items in a last-in, first-out manner. |

| Flow Rack | Employs rollers to move items automatically toward the picking area, enhancing picking speed. |

| Mobile Shelving | Features movable units to create flexible aisles, maximizing space efficiency. |

Essential Parts of Racking Structures

Understanding the fundamental components of storage systems is crucial for optimizing space and ensuring efficiency in warehouses and industrial settings. Each element plays a significant role in maintaining structural integrity and functionality, allowing for effective organization and accessibility of goods.

Key Components

The primary elements include vertical supports, which provide stability and bear the load of stored items. Horizontal beams connect these supports, creating levels for placing products. Additionally, braces and connectors enhance the overall strength, ensuring that the framework can withstand various forces and weight distributions.

Supplementary Features

Accessories such as safety clips and row spacers contribute to a secure environment, preventing accidental dislodgement of items. Properly designed shelves and dividers further enhance the usability of the system, allowing for tailored storage solutions that meet specific operational needs.

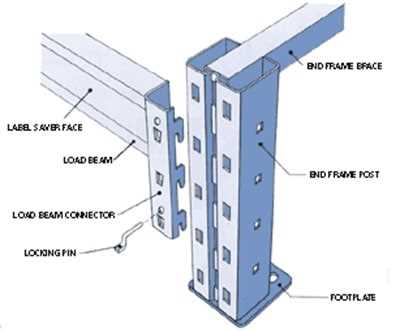

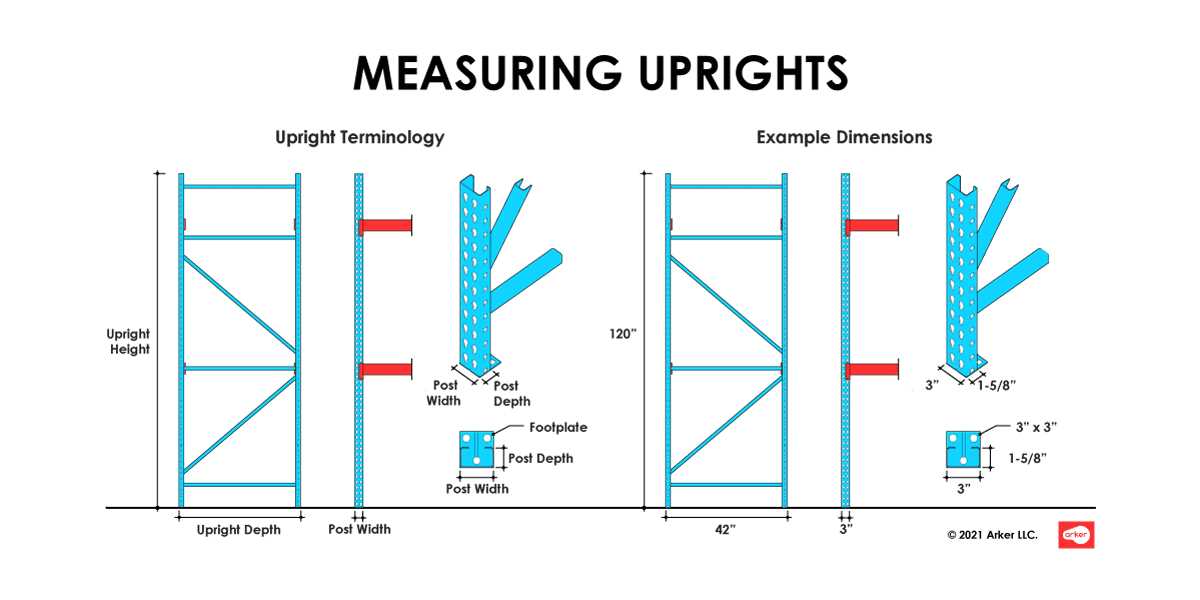

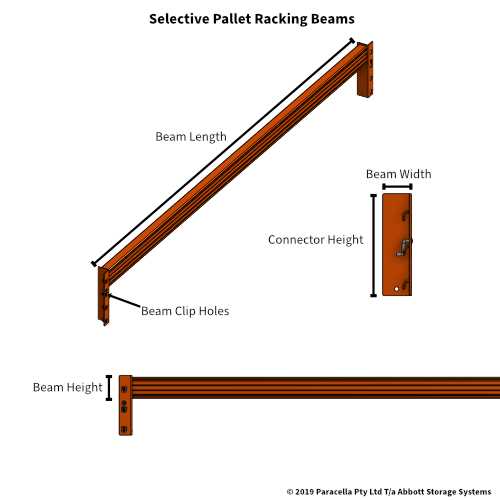

Understanding Beam and Upright Design

In the realm of storage solutions, the structural elements play a pivotal role in ensuring stability and efficiency. The interplay between horizontal supports and vertical columns defines the framework’s strength and capacity. By examining these components closely, one can grasp their significance in optimizing storage space and maintaining safety.

| Component | Description |

|---|---|

| Horizontal Support | These elements distribute weight evenly across the framework, providing the necessary support for various loads. |

| Vertical Column | These structures bear the load from above and anchor the system, ensuring stability and resilience. |

Understanding the design principles behind these crucial elements allows for better planning and utilization of storage systems, ultimately enhancing operational efficiency.

Safety Features in Racking Systems

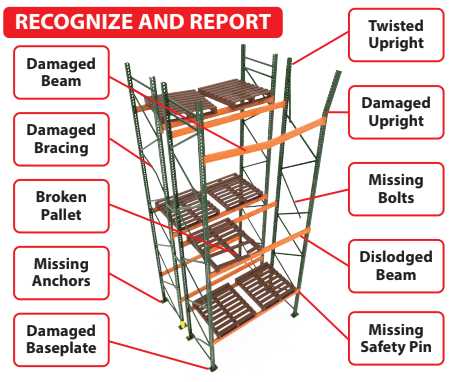

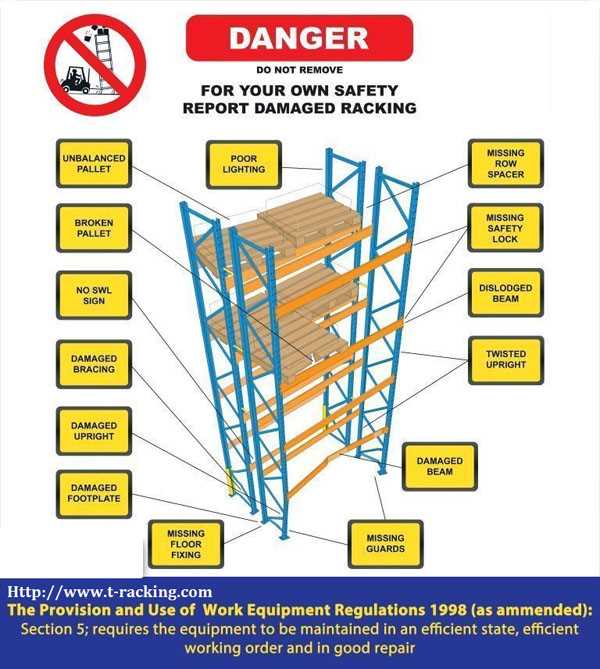

Ensuring the protection of personnel and inventory is paramount in storage solutions. Various mechanisms are implemented to enhance stability and prevent accidents, thereby fostering a secure working environment. These features are essential for safeguarding both assets and individuals, creating a robust framework for effective operations.

Load Capacity Management

One critical aspect involves the proper assessment of weight limits. Systems are designed to handle specified loads, with indicators and labels to guide users. Regular inspections ensure that these capacities are adhered to, minimizing the risk of overloading and potential collapse.

Structural Integrity Enhancements

Reinforcements and protective barriers play a vital role in maintaining stability. These enhancements are strategically placed to absorb impacts and prevent shifts that could lead to hazardous situations. Additionally, the use of high-quality materials ensures durability and reliability over time.

Importance of Load Distribution

Proper allocation of weight within storage systems is crucial for maintaining stability and safety. An even distribution ensures that structures remain secure, minimizing the risk of failure and accidents. This principle not only affects the integrity of the system but also influences operational efficiency and longevity.

Benefits of Even Weight Allocation

Balanced load placement enhances safety, reduces wear on components, and optimizes space utilization. Additionally, it facilitates easier access to materials and helps in maintaining organization within the storage environment.

Risks of Poor Load Distribution

Improperly distributed weight can lead to structural instability, increased maintenance costs, and potential hazards for personnel. It is essential to adhere to guidelines that prevent these issues, ensuring that the storage framework operates effectively.

| Risk | Consequence |

|---|---|

| Uneven Weight | Structural Failure |

| Overloading | Increased Wear |

| Improper Placement | Accidents |

Assembly Process for Pallet Racking

The construction of storage systems involves a series of methodical steps to ensure stability and safety. Each component plays a crucial role in creating a robust framework that supports various loads while maintaining ease of access and organization.

Preparation and Planning

Before commencing assembly, it is essential to evaluate the area where the system will be set up. Measuring the space accurately allows for effective planning, ensuring that the structure fits seamlessly. Gathering all necessary tools and components beforehand simplifies the process and minimizes interruptions.

Step-by-Step Assembly

Starting with the base, secure the vertical supports to the ground using appropriate anchors. This foundational step is vital for overall stability. Next, connect the horizontal beams, ensuring they are level and properly aligned. Utilizing a level tool during this stage can help achieve the necessary precision. Once the main frame is established, proceed to install additional cross-bracing for enhanced strength. Regularly check connections and joints to guarantee everything is tightly secured and aligned.

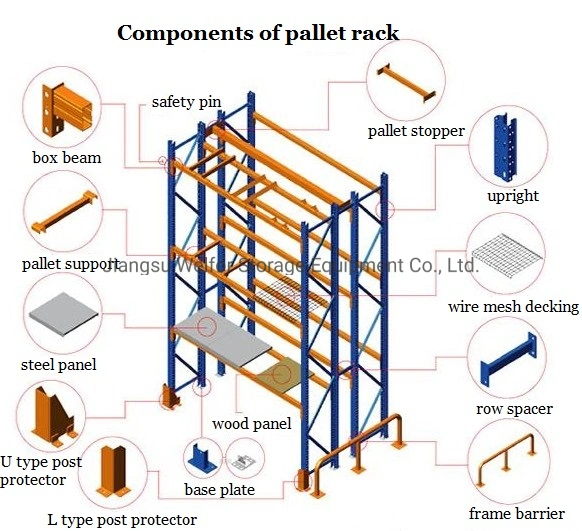

Common Accessories for Racking Systems

In any storage environment, the right accessories can enhance efficiency and safety, ensuring that the system operates at its best. These components play a crucial role in maximizing space utilization and providing stability for various stored items.

Here are some of the most frequently used accessories:

- Beam Supports: Essential for securing horizontal elements, providing additional load capacity.

- Upright Protectors: These shields help prevent damage from forklifts and other equipment, ensuring longevity.

- Wire Decking: A grid-like platform that offers support while allowing for visibility and ventilation.

- End Panels: These panels create a finished look and prevent items from falling off the sides.

- Label Holders: Useful for organization, these holders display important information about stored items.

Incorporating these components can lead to improved organization and increased safety in any storage setting.

Maintenance Tips for Racking Parts

Regular upkeep is essential to ensure the longevity and safety of storage systems. By following best practices, you can prevent wear and tear, thereby enhancing performance and reducing replacement costs.

1. Routine Inspections: Conduct frequent assessments to identify any signs of damage or deterioration. Look for cracks, rust, or misalignment.

2. Cleanliness Matters: Keep surfaces clean and free from debris. Dust and grime can lead to corrosion and affect stability.

3. Load Management: Ensure that loads are evenly distributed and do not exceed recommended weight limits. This helps maintain structural integrity.

4. Component Tightness: Regularly check and tighten bolts and connections. Loose fittings can lead to instability and increase the risk of failure.

5. Documentation: Maintain records of inspections and repairs. This can aid in tracking performance over time and identifying recurring issues.

6. Training: Educate personnel on proper handling and storage practices to minimize damage and maximize safety.

Regulations Governing Racking Installations

Ensuring the safety and efficiency of storage systems involves adherence to a range of regulations. These guidelines are designed to minimize risks associated with structural failures and to protect both personnel and inventory. Compliance with these standards is not merely a legal requirement but also a commitment to operational excellence.

National and Local Standards: Various organizations establish regulations that dictate how storage systems should be constructed and maintained. This includes specifications for materials, load capacities, and installation procedures. It’s essential for businesses to familiarize themselves with both national and local standards that apply to their operations.

Inspection and Maintenance: Regular inspections are crucial to ensure that systems remain compliant with safety regulations. Maintenance schedules should be implemented to address wear and tear, ensuring ongoing structural integrity. Failure to conduct these inspections can lead to serious safety hazards.

Training and Certification: Employees involved in the setup and management of storage solutions should receive appropriate training. Certification programs can equip staff with the necessary knowledge to recognize potential hazards and implement safe practices effectively.

Documentation: Keeping detailed records of compliance, inspections, and maintenance activities is vital. These documents serve as evidence of adherence to regulations and can be essential during audits or inspections by regulatory authorities.

Future Trends in Racking Technologies

The landscape of storage solutions is evolving rapidly, driven by advancements in technology and shifting industry demands. As businesses seek greater efficiency and adaptability in their operations, innovative systems are emerging to meet these needs, ensuring optimal use of space while enhancing accessibility.

One of the most significant trends is the integration of automation into storage systems. Automated solutions are increasingly replacing traditional manual processes, allowing for quicker retrieval and organization of goods. This shift not only reduces labor costs but also minimizes human error, leading to improved accuracy in inventory management.

Another key development is the rise of smart technology within storage environments. With the implementation of sensors and IoT devices, companies can monitor their inventory in real-time, gaining insights into stock levels and movement patterns. This data-driven approach facilitates better decision-making and enhances overall operational efficiency.

Additionally, the focus on sustainability is shaping future storage designs. Companies are exploring eco-friendly materials and energy-efficient systems to reduce their environmental impact. This trend not only appeals to environmentally conscious consumers but also aligns with regulatory requirements for reducing carbon footprints.

Lastly, modular systems are becoming increasingly popular, allowing for customizable configurations that can easily adapt to changing business needs. This flexibility enables companies to maximize their storage capacity without the need for significant overhauls or renovations.