Comprehensive Guide to Honda GX35 Parts Diagram

The design and structure of small, highly efficient engines play a pivotal role in various applications, from landscaping tools to industrial machines. With precision engineering, these devices achieve a balance of power and fuel efficiency, making them reliable for a wide range of tasks. However, understanding how each component fits together is key to maintaining and optimizing performance over time.

Whether you’re an experienced technician or a DIY enthusiast, knowing how different sections of the engine interact can help with troubleshooting and repairs. By examining the structure and arrangement of components, you can gain deeper insights into the operation of this compact powerhouse, ensuring longevity and optimal function in demanding conditions.

This section offers a clear exploration of the essential mechanisms involved, breaking down the key elements of this engine model. With a careful look at its core components, you’ll be better equipped to handle maintenance, replacements, and enhancements, keeping your machinery in top shape.

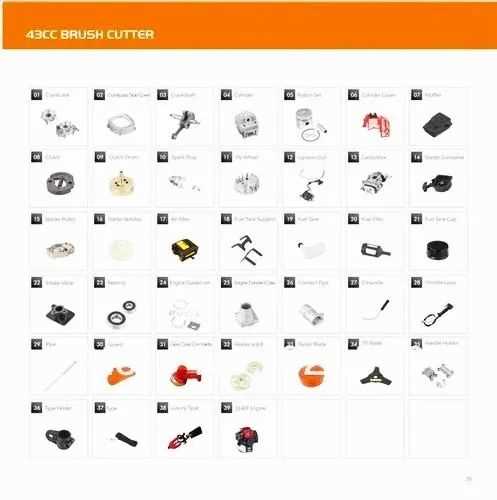

Overview of Honda GX35 Components

The internal structure of this small engine system is a complex arrangement of several key elements, all working in unison to ensure smooth performance. Each piece plays a crucial role in the operation, and together they provide the necessary efficiency and power output required for demanding tasks.

Key System Elements

- Combustion chamber: The core where the fuel ignition process occurs, driving the entire system.

- Crankshaft assembly: Converts the linear motion from combustion into rotational power for various applications.

- Cylinder: A vital part responsible for housing the piston and ensuring proper compression and combustion.

Supporting Components

- Fuel intake: Controls the flow of fuel into the combustion chamber for optimal efficiency.

- Air filter: Ensures that only clean air enters the system, protecting it from contaminants.

- Cooling mechanism: Maintains the engine’s temperature during operation, preventing overheating.

Key Features of the GX35 Engine

This compact power unit combines efficiency with durability, making it a reliable choice for various applications. Its design emphasizes low emissions, minimal noise, and a high level of performance, while maintaining a lightweight and fuel-efficient build. The engine is recognized for its robust construction and adaptability across different environments, providing smooth operation and long-lasting reliability.

| Feature | Description |

|---|---|

| Efficiency | Built for low fuel consumption without sacrificing output, making it economical for prolonged use. |

| Emissions Control | Designed to meet modern environmental standards, reducing harmful emissions significantly. |

| Low Noise | Equipped with noise reduction technology, ensuring quieter operation compared to similar models. |

| Lightweight | Compact and easy to handle, making it versatile for portable machine

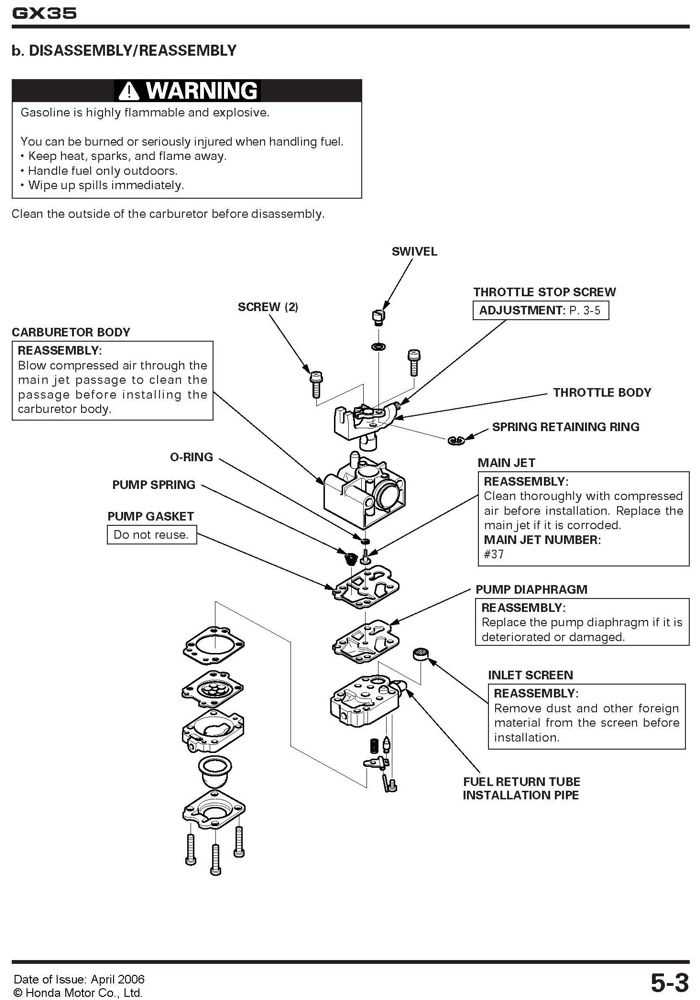

Common Issues and Fixes for GX35 PartsSmall machinery often encounters wear and tear due to prolonged use, and certain components can develop problems over time. Understanding how to identify and resolve common mechanical faults is crucial to maintaining efficiency and prolonging the lifespan of the equipment. Below are some typical issues you might face and effective solutions to get everything back in working order. Engine Starting Problems: A common issue users experience is difficulty in getting the motor running. This is often related to the fuel system or spark plug condition. Ensuring the fuel is fresh and the plug is clean can typically resolve this. Overheating: Another frequent concern is the device running hotter than normal. This may stem from blocked air filters or insufficient lubrication. Cleaning the filters and checking oil levels regularly can prevent such problems. Vibration and Noise: Excessive vibration or unusual noise might indicate loose or worn components in the system. Tightening screws and inspecting the internal parts for wear can usually fix this problem. Throttle Response Issues: If the power output seems inconsistent or sluggish, it could be due to a clogged carb Maintenance Tips for LongevityTo ensure reliable performance over time, proper upkeep is essential. Regular maintenance helps prevent wear and tear, keeping the equipment running smoothly for extended periods. Adopting a consistent care routine will not only boost durability but also optimize efficiency. Regular CleaningAccumulation of dirt and debris can hinder operation, so routine cleaning is crucial. Pay attention to air intake areas, as clogging here can reduce efficiency.

Scheduled LubricationLubricating moving parts minimizes friction and wear. Following a regular lubrication schedule will prevent overheating and extend the machine’s lifespan.

Identifying Critical Engine PartsUnderstanding the essential components of an internal combustion motor is vital for maintaining and troubleshooting it effectively. These key elements ensure that the entire system operates smoothly, and knowing their role can help in diagnosing potential issues early on. Core Structural ComponentsThe main framework of the engine consists of several primary sections that are responsible for housing and supporting various mechanisms. These include elements responsible for maintaining pressure, facilitating combustion, and ensuring stability throughout the operation. Without these fundamental parts, the motor’s performance would be compromised. Vital Moving Mechanisms

Moving elements play a crucial role in transforming energy and ensuring smooth operation. They interact with other essential pieces to provide the necessary motion and power output. Proper lubrication and maintenance of these mechanisms are crucial to avoid wear and ensure longevity. Replacement Guidelines for Worn-Out ComponentsEnsuring the optimal performance of any machinery often requires the timely replacement of worn or damaged elements. Identifying which components need attention is crucial for maintaining efficiency and extending the lifespan of the equipment. This section offers practical advice on how to effectively address the replacement of these critical parts. First and foremost, regular inspections should be conducted to identify signs of wear, such as cracks, corrosion, or unusual noises during operation. Keeping a maintenance log can help track the condition of individual components over time. Once a worn-out part is detected, it is essential to source a suitable replacement that meets or exceeds the original specifications. Utilizing high-quality materials can enhance durability and performance. When replacing components, follow the manufacturer’s guidelines for disassembly and reassembly to prevent damage to other parts. Proper tools and techniques are vital for ensuring a secure fit and reliable function. Additionally, after replacing any parts, a thorough test run should be performed to confirm that the machine operates smoothly and efficiently. In summary, timely detection and replacement of worn-out components are key to maintaining the functionality of your equipment. By adhering to systematic inspection routines and employing quality replacements, you can ensure your machinery continues to operate effectively for years to come. How to Source Genuine PartsObtaining authentic components for your machinery is crucial for maintaining optimal performance and longevity. Using high-quality replacements ensures reliability and safety, ultimately preserving the efficiency of your equipment. Here are some effective strategies to secure genuine items for your needs. Research Authorized DealersStart by identifying certified retailers or distributors specializing in the specific brand of your equipment. These authorized sources are likely to offer a wide selection of original components and can provide the necessary documentation to verify authenticity. Additionally, they often have trained staff who can assist with product inquiries and recommendations. Utilize Online Platforms

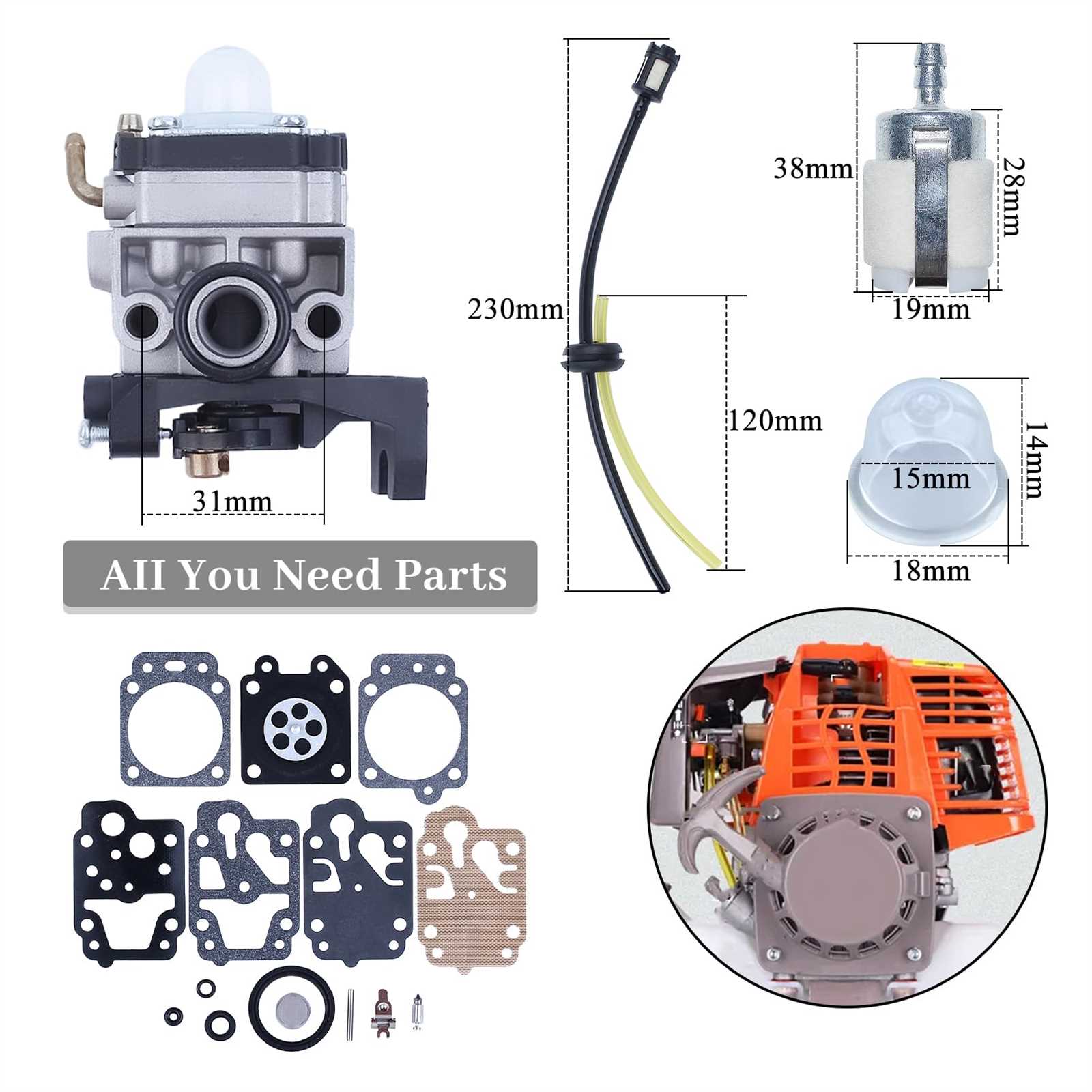

Many manufacturers maintain official websites featuring online shops where you can purchase verified components directly. Ensure that you are browsing the official site to avoid counterfeit items. Additionally, reputable e-commerce platforms may feature sections dedicated to genuine offerings, complete with customer reviews and ratings to guide your purchasing decision. Consider Local Repair Shops that specialize in your equipment’s brand. These establishments often have established relationships with suppliers and can assist you in sourcing authentic components tailored to your specific requirements. Remember to always verify the part numbers and specifications to ensure compatibility with your equipment. Investing time in sourcing genuine components will pay off in the long run, contributing to the efficiency and durability of your machinery. Understanding the Fuel System StructureThe fuel system is a critical component of small engines, designed to ensure that the combustion process runs smoothly and efficiently. This system consists of various elements that work together to deliver the right amount of fuel to the engine, facilitating optimal performance. A clear understanding of this structure is essential for effective maintenance and troubleshooting, as it directly influences the overall operation of the engine. Key ComponentsAt the heart of the fuel system lies the fuel tank, which stores the necessary liquid until it is required for combustion. Fuel lines transport the liquid from the tank to the carburetor, where it is mixed with air in precise proportions. A fuel filter is often included in this system to remove impurities, ensuring that only clean fuel reaches the engine. These components must function harmoniously to maintain efficiency and prevent potential issues. Operation MechanismOnce the fuel reaches the carburetor, it undergoes a critical transformation. The mixing of fuel and air is essential for creating a combustible mixture, which is then drawn into the combustion chamber. The delivery of fuel is regulated by the throttle, allowing the engine to respond dynamically to the user’s demands. Understanding this operation mechanism is vital for diagnosing performance problems and ensuring that the engine runs at its best. Troubleshooting the Ignition SystemDiagnosing issues within the ignition mechanism is essential for maintaining optimal performance. A malfunctioning ignition can lead to starting difficulties or erratic engine behavior. Identifying and resolving these problems will ensure that your equipment operates smoothly and efficiently. Common Symptoms of Ignition Problems

Steps for Troubleshooting

By systematically following these steps, you can effectively identify and resolve ignition-related issues, enhancing the overall performance and reliability of your equipment. Importance of Regular Air Filter ChecksEnsuring optimal performance in any small engine requires attention to various components, particularly the air filtration system. The air filter plays a crucial role in maintaining engine efficiency by preventing contaminants from entering the combustion chamber. Regular inspections and replacements of this vital part can significantly affect the longevity and functionality of the machinery. Enhanced Engine Efficiency

When the air filter is clean, it allows for a proper air-to-fuel ratio, leading to improved combustion. This enhances overall engine efficiency, resulting in better performance and reduced fuel consumption. Conversely, a clogged filter restricts airflow, causing the engine to work harder and ultimately leading to power loss and increased emissions. Prevention of DamageFailing to check the air filter regularly can lead to serious engine issues. Dust and debris that bypass a dirty filter can cause wear and tear on critical engine components, leading to costly repairs. By routinely inspecting and maintaining the air filtration system, you can avoid unnecessary damage and ensure the engine operates smoothly. Exploring the GX35 Exhaust SystemThe exhaust mechanism of small engines plays a crucial role in their overall performance and efficiency. Understanding its components and functionality can significantly enhance maintenance practices and ensure optimal operation. This section delves into the intricacies of the exhaust structure, emphasizing its significance in engine management and emissions control. Key Components of the Exhaust MechanismThe exhaust assembly typically includes several essential elements, such as the muffler, exhaust pipe, and manifold. Each part works synergistically to redirect harmful gases away from the engine and minimize noise output. The muffler serves to dampen sound while allowing for the smooth escape of exhaust gases. Meanwhile, the exhaust pipe channels these gases from the engine to the atmosphere, while the manifold connects the engine cylinders to the exhaust outlet, ensuring efficient gas flow. Importance of Regular Maintenance

Regular upkeep of the exhaust system is vital for maintaining engine performance and longevity. Over time, components may wear down or become clogged, leading to reduced efficiency and increased emissions. It is essential to periodically inspect and clean these parts, ensuring that the flow of exhaust is unobstructed. Proper maintenance not only enhances performance but also contributes to environmental sustainability by reducing harmful emissions. |