Understanding the Briggs Stratton 16 HP Vanguard Parts Diagram

Exploring the intricate world of small engines reveals a complex interplay of parts that contribute to their efficiency and functionality. This examination provides insights into the various elements that make up a 16 horsepower model, emphasizing the importance of each component in ensuring optimal performance. By gaining familiarity with these elements, users can enhance their maintenance skills and troubleshoot issues more effectively.

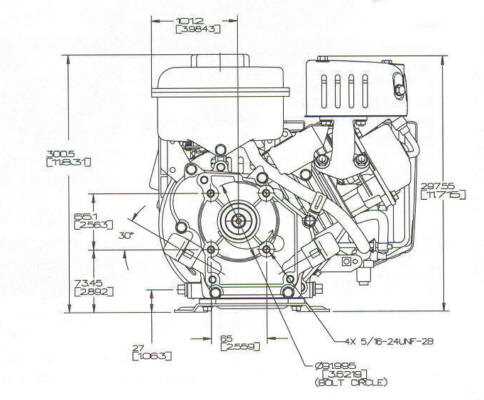

Identifying individual components is crucial for anyone looking to service or upgrade their machinery. A well-organized visual representation aids in comprehending how each piece interacts within the larger system. This understanding not only simplifies repairs but also empowers users to make informed decisions regarding replacements or enhancements.

In this discussion, we will delve into the specific elements that comprise this powerful engine, offering a clear outline of their arrangement and function. Whether you are a seasoned technician or a novice enthusiast, recognizing the layout of these vital components can significantly improve your engagement with the engine and its performance capabilities.

Understanding Briggs & Stratton Engines

Engines from this well-known manufacturer are renowned for their reliability and performance across various applications. These power units have become a staple in outdoor equipment, providing the necessary strength to tackle diverse tasks. A closer look at their design reveals the intricacies that contribute to their effectiveness and longevity.

At the core of these machines lies a robust construction that balances power and efficiency. Each component plays a vital role, from the combustion chamber to the ignition system, ensuring smooth operation. The engineering behind these models often emphasizes ease of maintenance, allowing users to keep their equipment in optimal condition with minimal effort.

Furthermore, understanding the specific features of these engines can enhance user experience. Knowledge of the various systems involved, such as fuel delivery and cooling, enables operators to troubleshoot issues more effectively. Additionally, familiarity with maintenance practices can significantly extend the lifespan of these reliable power sources.

In summary, the study of these engines not only highlights their mechanical prowess but also empowers users to maximize their functionality. With the right insights, one can appreciate the engineering excellence that has made these power units indispensable in countless applications.

Overview of Vanguard 16 HP Features

The 16 HP engine is designed for durability and efficiency, making it a popular choice for various applications. This powerhouse is built to handle demanding tasks while providing reliable performance over time.

Power and Performance: With a robust horsepower rating, this engine delivers ample torque, ensuring it can manage heavy loads with ease. Its design focuses on maximizing output while minimizing fuel consumption.

Durability: Constructed with high-quality materials, the engine is engineered to withstand challenging conditions. Features such as a heavy-duty air filtration system help to protect internal components from debris and contaminants.

Ease of Maintenance: Accessibility to critical components allows for straightforward maintenance, ensuring the engine remains in top condition. Routine checks and servicing are simplified, which extends the life of the unit.

Vibration Reduction: Advanced engineering techniques have been implemented to minimize vibrations, enhancing operator comfort and reducing wear on the engine over time. This feature is especially beneficial during extended use.

Versatility: This engine is adaptable for a wide range of applications, from commercial equipment to residential tools, making it a versatile choice for various users.

In summary, the 16 HP unit combines power, reliability, and user-friendly features, making it an excellent option for those seeking a dependable engine for their needs.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians, enabling them to identify each element within a complex system. By providing clarity, these illustrations enhance the efficiency of both troubleshooting and assembly processes.

Clarity is one of the primary benefits of using visual guides. They simplify intricate arrangements, allowing users to quickly locate specific components. This efficiency can save valuable time during repairs, reducing the overall downtime of equipment.

Additionally, these illustrations foster comprehension. They provide a clear view of how parts interact, which is vital for diagnosing issues accurately. Understanding the relationships between different elements can prevent missteps and ensure that repairs are conducted correctly.

Moreover, having access to these resources promotes confidence in users. Whether a professional mechanic or a DIY enthusiast, being equipped with accurate visual references helps individuals feel more assured in their ability to manage repairs effectively. This confidence can lead to better maintenance practices and extended equipment lifespan.

Common Applications for Vanguard Engines

These robust power units are widely utilized across various industries due to their reliability and efficiency. Their versatile design makes them suitable for numerous applications, ranging from commercial equipment to specialized machinery.

- Landscaping Equipment:

- Commercial lawn mowers

- Leaf blowers

- Snow removal machines

- Construction Tools:

- Generators

- Concrete saws

- Earth augers

- Agricultural Machinery:

- Farm tractors

- Ride-on tillers

- Pumping systems

- Industrial Equipment:

- Pressure washers

- Industrial vacuums

- Power washers

The adaptability of these engines allows them to be integrated into a wide range of applications, ensuring optimal performance and durability in demanding environments.

Key Components of 16 HP Models

The 16 horsepower engines are engineered with several essential elements that contribute to their robust performance and efficiency. Understanding these key components allows for better maintenance and optimal operation of the machinery they power.

| Component | Description |

|---|---|

| Engine Block | The core structure that houses internal components and withstands high pressures. |

| Cylinder Head | Seals the combustion chamber, facilitating efficient air-fuel mixing and combustion. |

| Piston | Moves up and down within the cylinder, converting fuel energy into mechanical work. |

| Crankshaft | Transforms linear motion of the piston into rotational energy, driving the output shaft. |

| Carburetor | Mixes air and fuel in the correct ratio for optimal combustion performance. |

| Ignition System | Initiates combustion by producing a spark at the right moment in the engine cycle. |

| Cooling System | Prevents overheating by circulating coolant and facilitating air flow. |

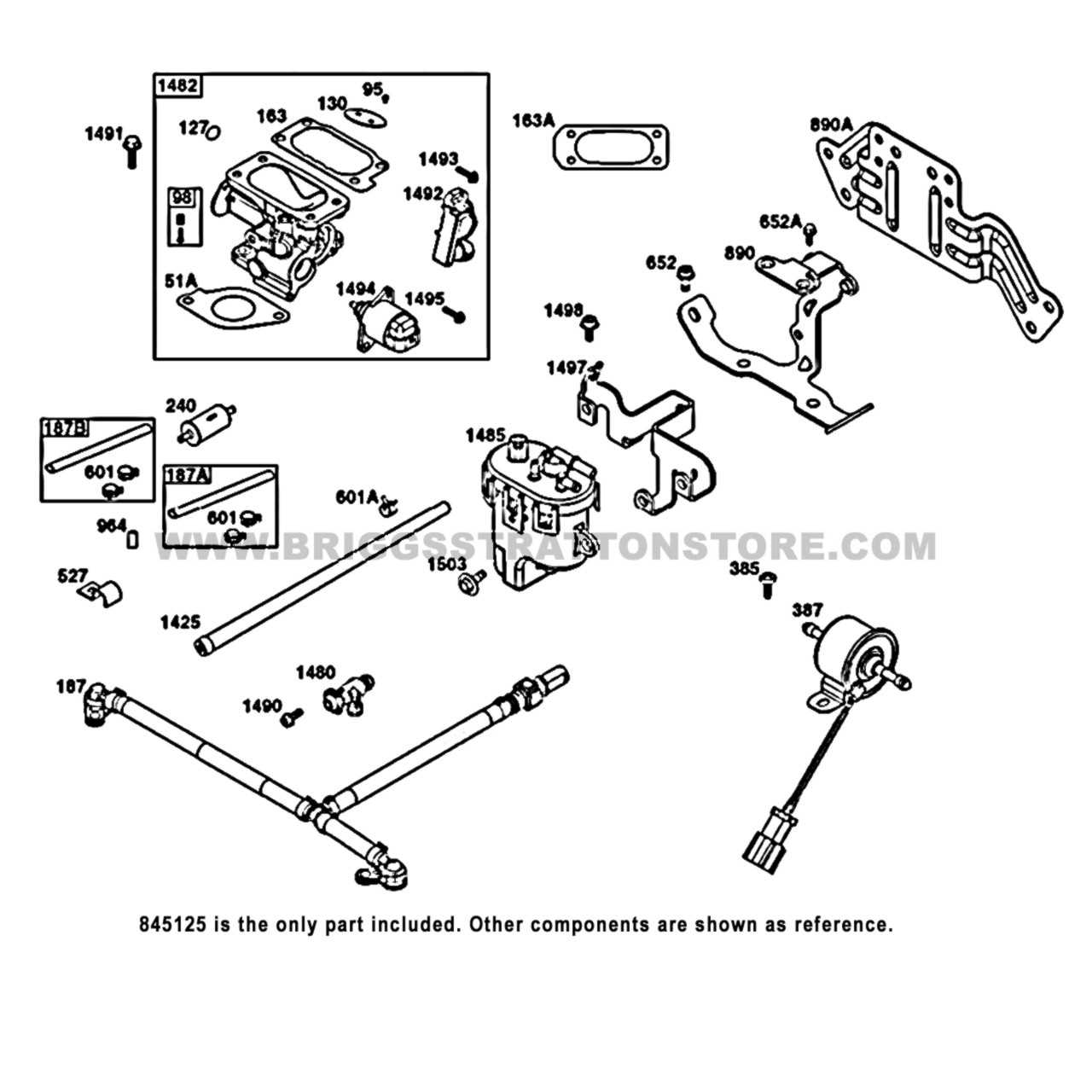

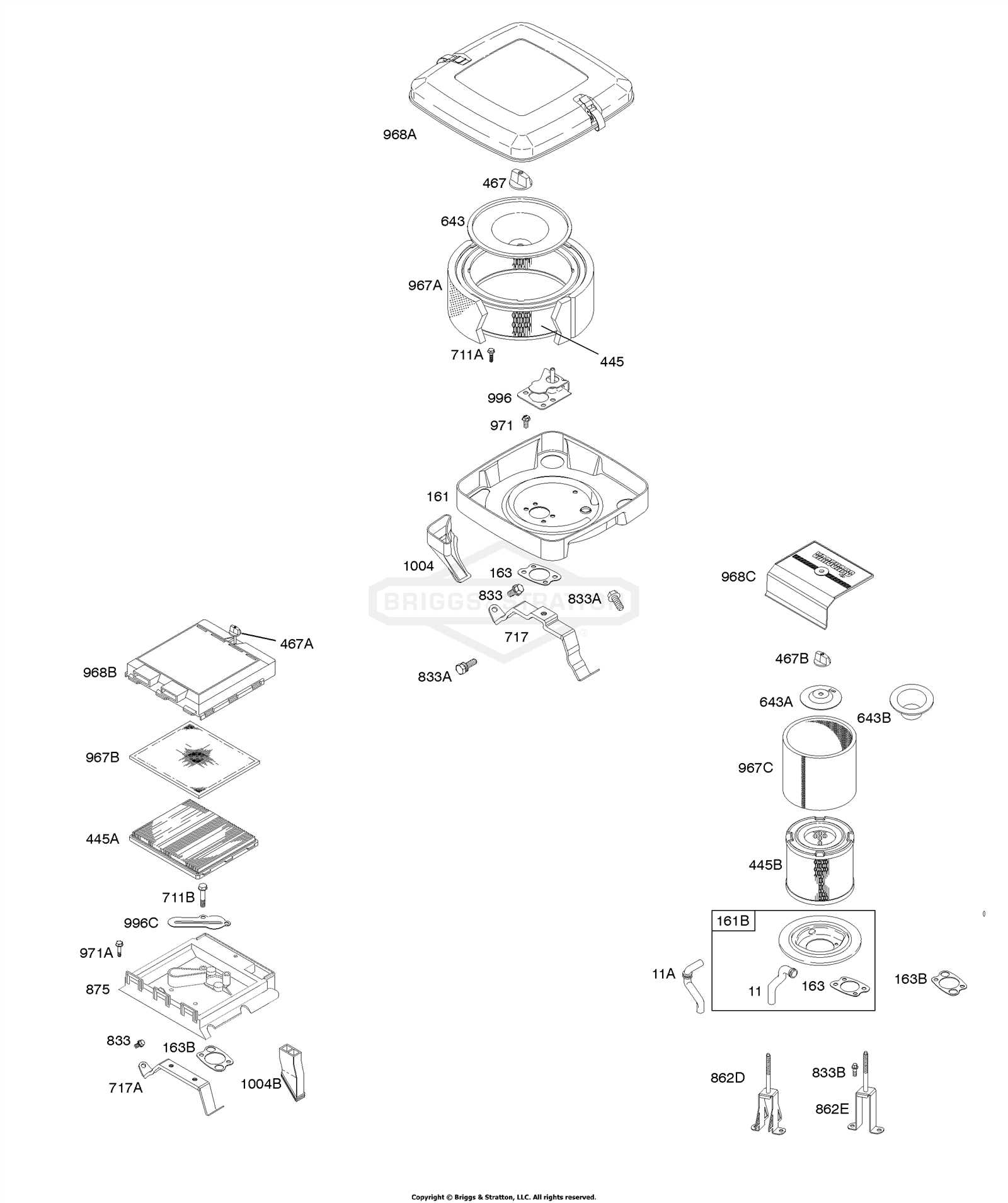

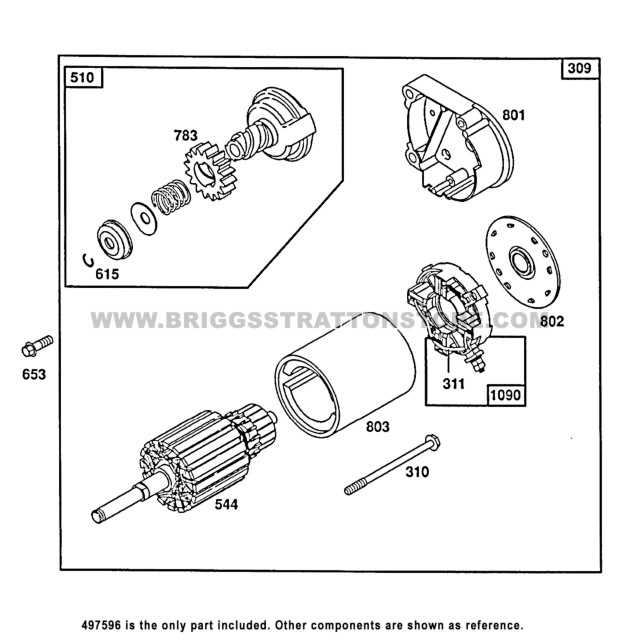

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs. These visuals provide a clear representation of components and their relationships within machinery. Familiarizing yourself with these illustrations can streamline the identification and sourcing of necessary elements, ultimately enhancing your repair efficiency.

Familiarize Yourself with Symbols

Every illustration includes specific symbols that represent various components. Learning these symbols is crucial, as they often vary between manufacturers. A legend or key may accompany the visual, providing insights into what each symbol signifies. Make sure to refer to this key frequently, especially when first encountering the illustration.

Follow the Numbering System

Many illustrations employ a numbering system to categorize elements. This system not only helps in identifying individual parts but also indicates how they fit together. Pay close attention to the sequence; it often reveals the assembly order or functional relationships between components. By understanding this flow, you can better grasp how to approach disassembly or repairs.

Maintenance Tips for Vanguard Engines

Regular upkeep is crucial for ensuring optimal performance and longevity of your engine. By adhering to a systematic maintenance routine, you can prevent common issues and enhance efficiency. This section offers essential guidelines to keep your machinery running smoothly.

Routine Checks

Start with regular inspections of critical components. Check the oil level frequently and replace it according to the manufacturer’s recommendations. Clean or replace the air filter to ensure proper airflow and engine breathing. Additionally, inspect the spark plugs for wear and replace them as needed to maintain a strong ignition system.

Seasonal Maintenance

As seasons change, so should your maintenance practices. Before winter, ensure that all fluids are topped off and the fuel system is stabilized. During warmer months, focus on cleaning the cooling fins and ensuring that the cooling system is free of debris. Storing your equipment properly during off-seasons can also prevent rust and damage.

Remember to document all maintenance activities for future reference and to track any recurring issues. By prioritizing these practices, you’ll not only enhance performance but also extend the life of your engine.

Replacing Worn Parts Effectively

Maintaining optimal performance in any machinery requires timely intervention when components show signs of wear. Identifying and replacing degraded elements not only enhances functionality but also extends the lifespan of the equipment. Understanding the critical role of each component is essential for effective maintenance and ensures smooth operation.

1. Assessing Wear

Regular inspections are vital for spotting deterioration. Look for signs such as unusual noises, vibrations, or decreased efficiency. A systematic approach to evaluation helps in pinpointing which items require replacement.

2. Selecting Quality Replacements

When choosing new components, prioritize high-quality options that match the original specifications. Investing in durable materials ensures longevity and reliability, reducing the frequency of future replacements.

3. Proper Installation

Follow manufacturer guidelines during installation to guarantee correct fitting. Inaccurate placement can lead to further issues, negating the benefits of the new component. Utilize appropriate tools and techniques for a secure and efficient installation.

4. Regular Maintenance

After replacing worn elements, incorporate a routine maintenance schedule. Regular checks can help catch potential issues early, preventing extensive damage and costly repairs. Establishing a consistent upkeep routine is key to maximizing performance.

In conclusion, timely replacement of worn components, coupled with careful selection and proper installation, plays a crucial role in maintaining equipment efficiency. Adopting a proactive maintenance strategy will ultimately save time and resources, ensuring reliable operation over time.

Finding Genuine Replacement Parts

When it comes to maintaining machinery, sourcing authentic components is crucial for ensuring longevity and optimal performance. High-quality replacements not only enhance functionality but also provide peace of mind that your equipment will operate smoothly.

Why Choose Authentic Components?

- Durability: Genuine items are designed to withstand wear and tear, reducing the need for frequent replacements.

- Performance: Original components ensure that the machine operates as intended, maximizing efficiency.

- Compatibility: Authentic replacements are specifically engineered to fit seamlessly, preventing potential damage caused by ill-fitting alternatives.

How to Identify Reliable Suppliers

- Research: Look for authorized dealers and manufacturers with a solid reputation.

- Reviews: Check customer feedback to gauge the quality of service and product authenticity.

- Certifications: Ensure the supplier is recognized by industry standards for selling genuine items.

Common Issues with 16 HP Engines

Engines in the 16 horsepower range are widely used in various applications, from lawn care to industrial equipment. While reliable, these power units can experience several common problems that may affect performance and longevity.

- Starting Difficulties:

- Weak battery or faulty ignition system can prevent starting.

- Clogged fuel lines or filters may restrict fuel flow.

- Overheating:

- Low coolant levels can lead to overheating issues.

- Blocked air intakes or cooling fins impede proper airflow.

- Poor Performance:

- Worn spark plugs can cause misfires and reduced power.

- Dirty carburetors often lead to fuel delivery problems.

- Excessive Vibration:

- Unbalanced components or loose parts can create abnormal vibrations.

- Worn bearings may also contribute to increased shaking during operation.

- Oil Leaks:

- Worn gaskets and seals can lead to oil escaping from the engine.

- Improper maintenance can exacerbate leak issues over time.

Identifying and addressing these issues early can help ensure optimal performance and extend the lifespan of the engine.

Upgrades for Improved Performance

Enhancing engine efficiency can significantly boost the overall functionality of your equipment. By implementing specific modifications, users can achieve better power output, fuel efficiency, and longevity. This section explores various enhancements that can elevate performance levels, ensuring a more reliable and effective operation.

| Upgrade | Description | Benefits |

|---|---|---|

| High-Performance Air Filter | Replaces the standard filter with one that allows better airflow. | Improved combustion and increased power. |

| Aftermarket Carburetor | A carburetor designed for optimized fuel and air mixture. | Enhanced throttle response and overall performance. |

| Performance Exhaust System | An upgraded exhaust that reduces back pressure. | Increased horsepower and improved sound. |

| Upgraded Ignition Coil | A coil that delivers a stronger spark for better ignition. | More efficient fuel combustion and easier starts. |

| Engine Tune-Up Kits | Includes spark plugs, filters, and oil for maintenance. | Maintains optimal performance and reliability. |

By considering these upgrades, users can maximize their engine’s potential, leading to enhanced performance and satisfaction in their operational tasks.

Resources for Engine Repair Guides

Having access to reliable resources is crucial for anyone looking to repair or maintain their engine. Whether you’re a novice or an experienced technician, comprehensive guides can provide the necessary insights and instructions for successful troubleshooting and repairs. This section outlines valuable materials and references that can enhance your understanding and skills in engine maintenance.

Online Communities and Forums

Engaging with online communities can be an excellent way to gain knowledge and share experiences. Numerous forums are dedicated to engine enthusiasts, where members exchange tips, troubleshooting advice, and repair techniques. Participating in these platforms can lead to valuable connections and a wealth of information that is often not found in traditional manuals.

Instructional Videos and Tutorials

Visual learning can significantly improve your understanding of complex repairs. Numerous platforms offer instructional videos that cover a wide range of engine maintenance topics. These tutorials often provide step-by-step demonstrations, making it easier to follow along and apply what you learn. Consider subscribing to channels that specialize in engine repairs for regular updates and new content.

Frequently Asked Questions About Vanguard Engines

This section addresses common inquiries regarding high-performance power units, providing clarity on various aspects to help users maximize their experience. Understanding these engines can enhance maintenance, operation, and overall satisfaction.

Common Questions

- What are the primary applications for these engines?

- How can I improve the longevity of my engine?

- What type of fuel should I use for optimal performance?

- How often should I perform maintenance checks?

Maintenance and Troubleshooting

- Regularly check and change the oil to ensure smooth operation.

- Inspect air filters periodically and replace them when necessary.

- Pay attention to unusual noises, as they can indicate underlying issues.

- Consult the manual for specific troubleshooting steps related to your model.