Ditch Witch 1010 Parts Diagram Explained

The intricacies of specialized machinery can often seem daunting, yet they play a pivotal role in various industries. Gaining insight into the elements that comprise these robust tools is essential for optimal performance and maintenance. This exploration aims to unravel the complexities involved, providing clarity on each significant aspect.

In this section, we will examine the critical elements that contribute to the functionality of a particular piece of equipment. Understanding how these components interact can lead to improved efficiency and longevity. With detailed illustrations and descriptions, you will be empowered to navigate through the essential features effectively.

By delving into the specifics, you will uncover the ultimate understanding needed for effective usage and troubleshooting. Whether you are a seasoned operator or a newcomer, this guide is designed to enhance your knowledge and operational skills.

Ditch Witch 1010 Overview

This section provides a comprehensive look at a specific piece of equipment designed for underground construction and utility installation. This machine is essential for efficient digging and trenching, making it a valuable asset in various projects.

Key Features

- Robust construction for durability in challenging environments

- Powerful engine for optimal performance

- Advanced hydraulic system for enhanced digging capabilities

- Ergonomic design for operator comfort and ease of use

Applications

- Installing utilities such as water, gas, and electricity

- Excavation for landscaping and construction

- Repair and maintenance of underground infrastructure

- Directional drilling for precise installation

Understanding the Equipment’s Purpose

This section explores the essential functions of the machinery designed for underground operations. By grasping its core objectives, users can appreciate how this equipment enhances efficiency in various tasks.

Key Functions

The primary roles of this tool revolve around excavation, installation, and maintenance. It is engineered to streamline processes, reduce manual labor, and improve safety on site.

Operational Benefits

Utilizing this machinery leads to quicker project completion and minimizes disruptions in surrounding areas. Its design allows for versatility, making it suitable for diverse applications.

| Function | Description |

|---|---|

| Excavation | Efficiently removes soil and other materials for trenching tasks. |

| Installation | Facilitates the placement of pipes and cables underground. |

| Maintenance | Assists in the upkeep of existing underground infrastructure. |

Key Features of Ditch Witch 1010

This compact yet powerful machine is designed for efficiency and versatility, making it a valuable asset for various construction and landscaping tasks. Its robust build and innovative technology contribute to superior performance in challenging environments.

Versatility and Maneuverability

The equipment is engineered for multiple applications, including trenching, digging, and landscaping. Its agile design allows for easy navigation in tight spaces, ensuring that operators can access hard-to-reach areas without hassle.

Durability and Reliability

Constructed with high-quality materials, this machine is built to withstand rigorous use. Its long-lasting components and reliable performance minimize downtime, providing users with confidence in their investment and productivity.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They serve as essential tools for understanding the assembly and interaction of various elements, allowing operators and technicians to identify specific pieces easily. Clear illustrations enhance communication, streamline troubleshooting, and ultimately contribute to more efficient operations.

Moreover, having access to these visuals fosters a deeper comprehension of the equipment, empowering users to undertake repairs with confidence. By reducing ambiguity, they minimize the risk of errors and ensure that replacements are accurate and timely. This efficiency can lead to significant cost savings and increased longevity of the machinery.

In addition, these resources can be invaluable during training sessions, helping new users quickly familiarize themselves with complex systems. As such, the value of these graphical representations extends beyond mere identification, underpinning a culture of safety and proficiency in handling machinery.

Main Components of the Machine

Understanding the essential elements of this equipment is crucial for effective operation and maintenance. Each component plays a significant role in the overall functionality, ensuring efficiency and durability during various tasks.

Power System

The power system serves as the heart of the machinery, providing the necessary energy to drive all operations. It typically includes a robust engine and related systems that optimize performance and reliability.

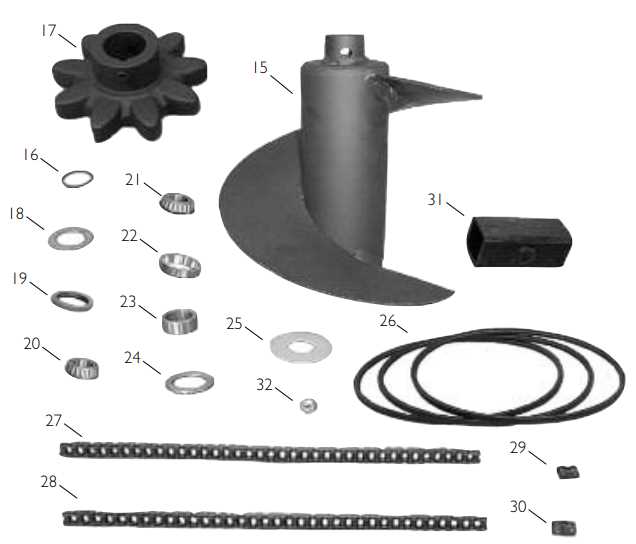

Excavation Tools

Excavation tools are vital for achieving precise digging and trenching. These tools come in various shapes and sizes, designed to adapt to different soil conditions and project requirements, allowing for ultimate versatility.

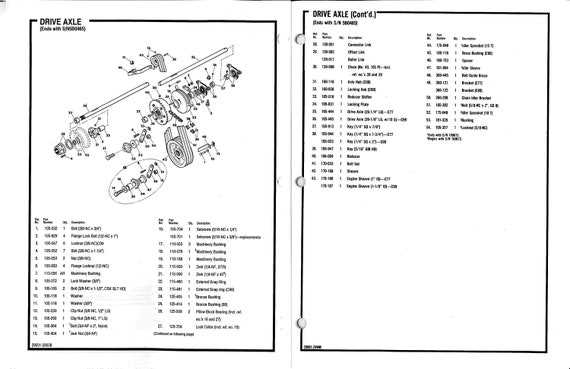

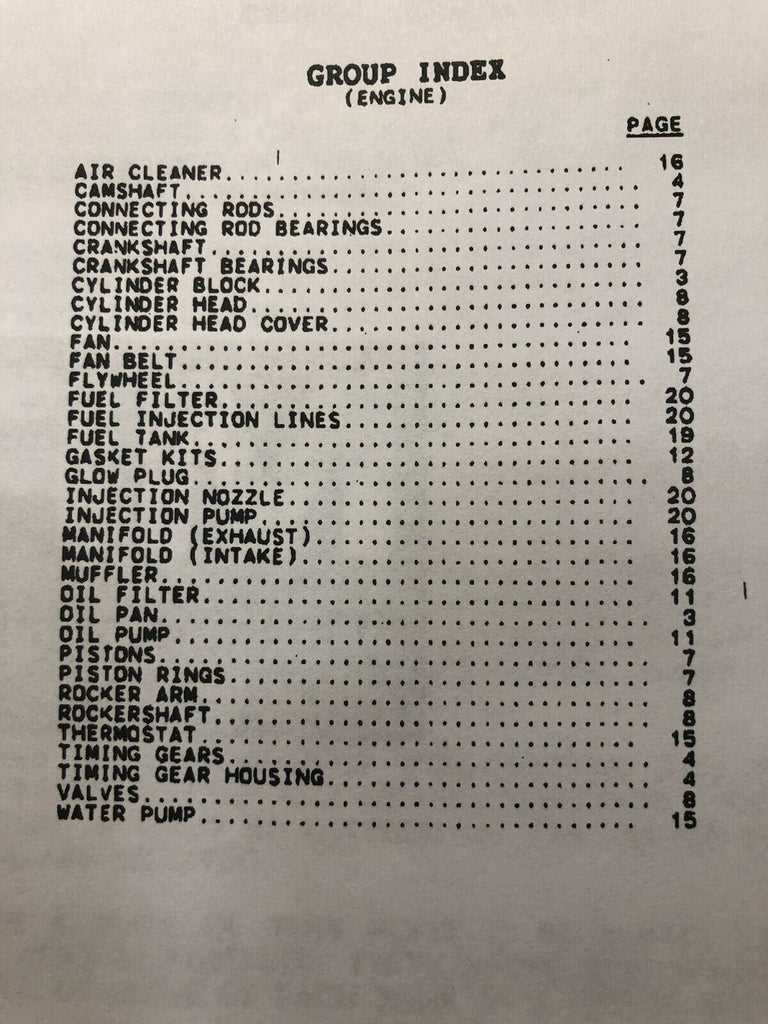

How to Read Parts Diagrams

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide a clear layout of various elements and their connections, making it easier to identify specific items and their functions.

Begin by familiarizing yourself with the overall layout. Each section typically groups related components, allowing you to quickly locate what you need. Look for labels and symbols that indicate the name and specifications of each element.

Next, pay attention to the numbering system used in the visual. This system often correlates with a list that details each part’s description and any applicable part numbers, which can be crucial when ordering replacements.

Finally, take note of any notes or warnings included in the illustration. These can provide vital information about assembly, disassembly, or compatibility, ensuring that you use the correct components for your task.

Common Issues and Troubleshooting

This section addresses frequent problems encountered with specific machinery and offers guidance on resolving them effectively. Understanding these challenges can enhance performance and prolong the lifespan of the equipment.

Performance Deterioration

One common issue is a noticeable decline in operational efficiency. This can stem from various factors, including inadequate maintenance, worn components, or incorrect settings. Regular inspections and timely replacements are essential to ensure optimal functionality.

Fluid Leaks

Fluid leaks can significantly impact performance and safety. Identifying the source of the leak, whether from seals, hoses, or connections, is crucial. Prompt repairs and using quality replacement parts can mitigate further complications.

Maintenance Tips for Longevity

Ensuring the durability of your machinery involves consistent care and attention. Regular maintenance not only enhances performance but also extends the operational life of the equipment. Implementing a few key practices can lead to significant improvements in reliability and efficiency.

Regular Inspections

Conducting frequent evaluations of all components helps identify wear and tear before they escalate into serious issues. Look for signs of damage or corrosion, and address them promptly to avoid costly repairs.

Proper Lubrication

Keeping moving parts well-lubricated reduces friction and prevents overheating. Use high-quality lubricants as recommended by the manufacturer, and ensure that all applicable areas are serviced regularly to maintain optimal functionality.

Ordering Replacement Parts Effectively

Efficient procurement of components is crucial for maintaining machinery performance and reducing downtime. Understanding the specifics of what you need, including compatibility and quality, can streamline the process. Clear communication with suppliers and utilizing reliable sources will enhance your ordering experience.

Start by accurately identifying the required components, including any serial numbers or specifications. This ensures you receive the correct items on the first attempt, minimizing delays. Additionally, keeping an organized inventory can help track which items need replenishment.

Engage with reputable vendors who offer comprehensive catalogs and support services. Comparing options not only helps in finding the best deals but also allows for informed decisions based on reviews and recommendations from other users.

Finally, maintain records of previous orders and transactions. This practice aids in quicker reordering and can also provide insights into which suppliers consistently deliver quality items on time.

Compatibility with Other Models

Understanding the interchangeability of components across various models can significantly enhance maintenance and repair processes. This knowledge allows operators and technicians to efficiently source replacements and make informed decisions about equipment upgrades or modifications.

Shared Components

Many machines in the same category often utilize similar or identical components, which can lead to cost savings and improved availability of parts. Identifying these shared elements not only simplifies repairs but also provides flexibility when considering enhancements or retrofitting.

Model Variations

While certain models may share common features, it’s crucial to recognize the specific variations that exist. Differences in size, power requirements, and mounting configurations can affect compatibility. Always refer to the manufacturer’s specifications to ensure that any modifications or replacements will function as intended.

Upgrading and Modifying Components

Enhancing and altering equipment elements can significantly boost performance and efficiency. This section explores various strategies to optimize functionality and ensure longevity of your machinery through thoughtful upgrades.

Identifying Key Areas for Improvement

To begin, assess the current capabilities of your machinery. Focus on components that may limit overall effectiveness, such as power systems or control mechanisms. Targeting these areas can lead to transformative results.

Choosing the Right Enhancements

When selecting modifications, consider both compatibility and performance. Investing in high-quality alternatives can yield long-term benefits. Additionally, consulting with experts or referring to detailed resources can aid in making informed decisions.

Resources for Further Learning

To deepen your understanding of machinery components and their functionalities, various resources are available that cater to different learning styles. Whether you prefer visual aids, hands-on manuals, or online courses, a wealth of information can enhance your expertise.

Recommended Books

| Title | Author | Year |

|---|---|---|

| Heavy Equipment Maintenance | John Smith | 2020 |

| Understanding Machinery | Jane Doe | 2019 |

Online Learning Platforms

Websites like Coursera and Udemy offer courses focused on equipment operations and maintenance, enabling learners to explore the subject in detail from the comfort of their homes.

Safety Precautions During Use

When operating heavy machinery, prioritizing safety is essential to prevent accidents and injuries. Ensuring that all operators and nearby personnel are aware of the risks involved can significantly enhance the overall safety of the work environment.

Before starting, always inspect the equipment thoroughly. Check for any signs of wear or damage that could compromise safety. Familiarize yourself with the operator’s manual and understand the machine’s controls and functions.

Proper attire is crucial; wear appropriate safety gear, including hard hats, gloves, and eye protection. Avoid loose clothing that could become entangled in moving parts. Ensure that footwear provides adequate support and traction.

Maintain a clear work area by keeping all non-essential personnel at a safe distance. Establish a designated zone for operation and communicate effectively with team members to avoid misunderstandings.

Lastly, never underestimate the importance of mental focus. Stay alert and avoid distractions while operating machinery to ensure safe and efficient work practices.