Understanding the Honda Lawn Mower Engine Parts Diagram

For anyone seeking to enhance their knowledge about their outdoor equipment, a thorough exploration of its individual elements can be incredibly beneficial. This segment aims to illuminate the intricate components that work harmoniously within your mechanical tools, ensuring they function at their peak performance.

By delving into the various segments of this machinery, you can uncover the ultimate secrets to maintaining and troubleshooting your devices. Understanding how each piece contributes to the overall operation not only enhances efficiency but also extends the lifespan of your equipment.

Whether you’re a novice or a seasoned user, grasping the layout and functionality of these critical components can empower you to tackle repairs and upgrades with confidence. Embrace the opportunity to familiarize yourself with the essential building blocks of your devices.

Understanding Honda Lawn Mower Engines

Exploring the inner workings of small motorized machines reveals the intricacies that power their performance. A comprehensive grasp of these mechanisms not only enhances maintenance but also fosters better decision-making for repairs and upgrades. By examining key components and their functions, users can ensure optimal operation and longevity.

Key Components Overview

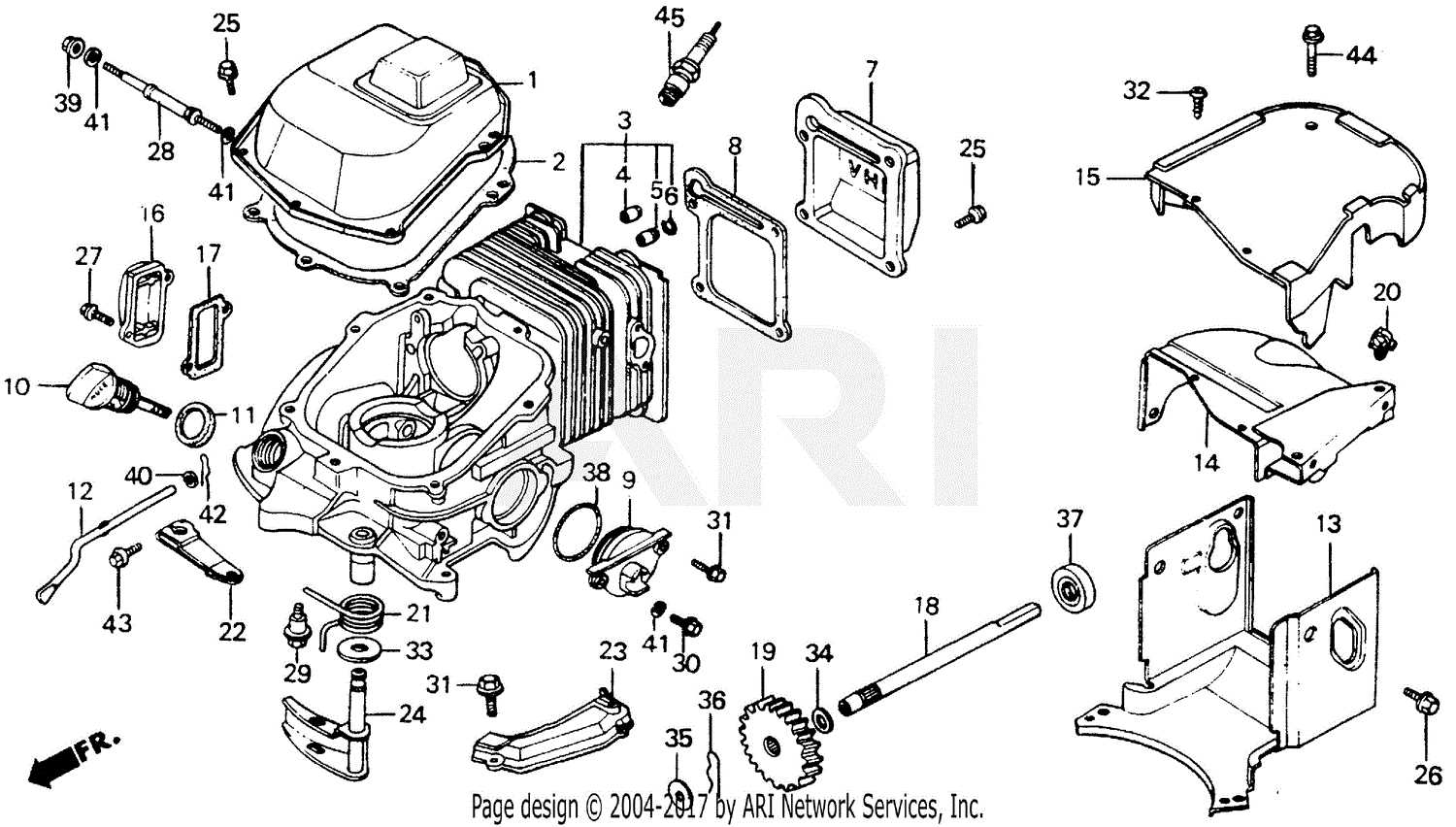

Every motor consists of several vital elements that work together seamlessly. Understanding these components is essential for troubleshooting and efficient use.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and is integral to the combustion process. |

| Piston | Moves within the cylinder, converting pressure into mechanical energy. |

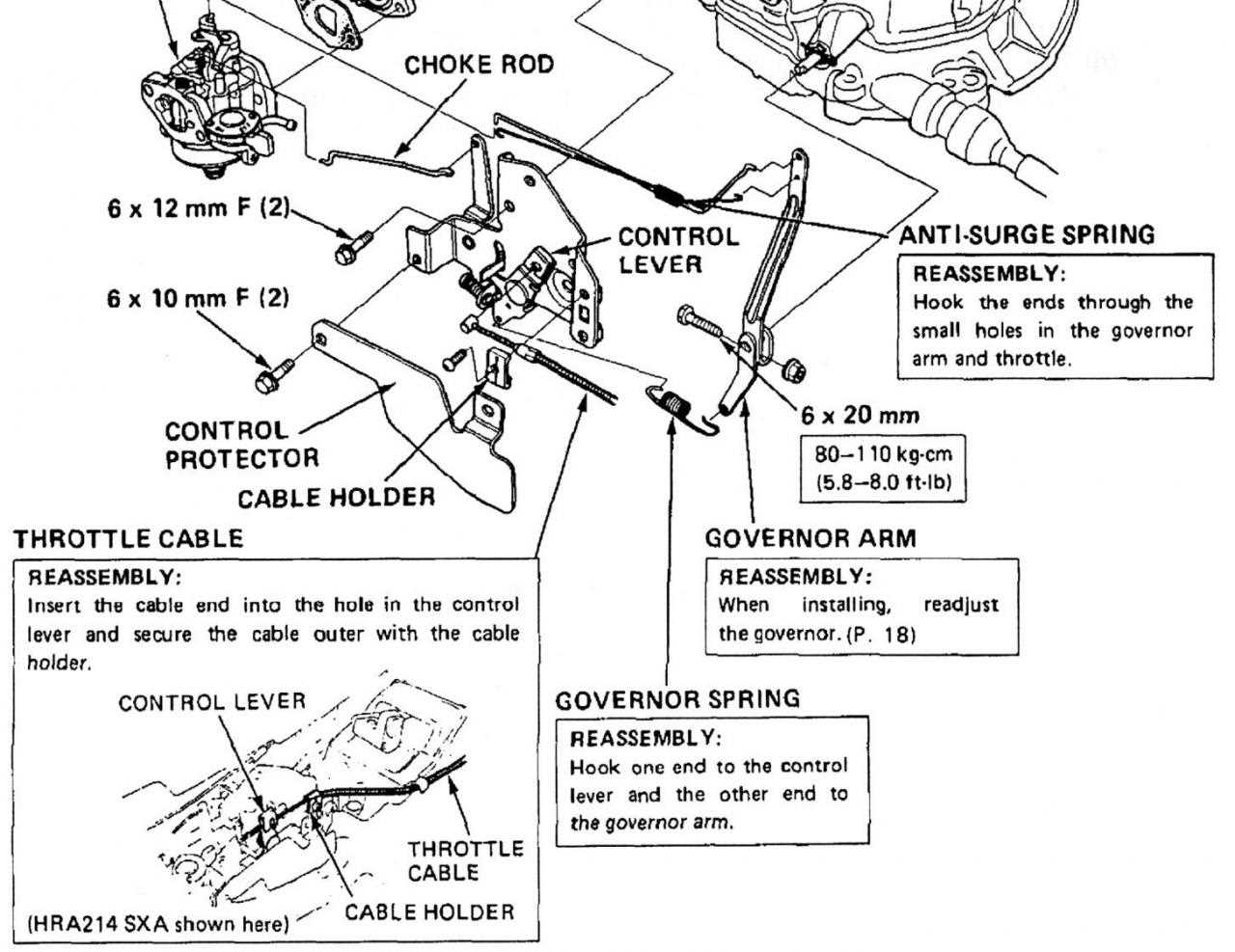

| Carburetor | Mixes air and fuel for optimal combustion. |

| Ignition System | Provides the spark necessary to ignite the air-fuel mixture. |

Maintenance Tips

Regular upkeep is crucial for ensuring the efficiency of small engines. Simple tasks, such as checking oil levels, cleaning filters, and inspecting spark plugs, can significantly extend the lifespan of the machinery. Understanding the role of each component allows for targeted maintenance, preventing larger issues from arising.

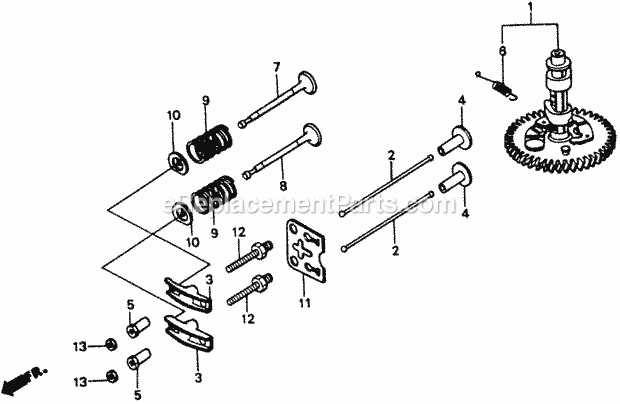

Key Components of the Engine

Understanding the essential elements that contribute to the functionality of a power unit is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance and longevity.

Major Elements

- Fuel System: Responsible for delivering the necessary fuel to the combustion chamber.

- Ignition System: Initiates the combustion process, ensuring the power unit starts efficiently.

- Cooling System: Maintains appropriate temperature levels to prevent overheating.

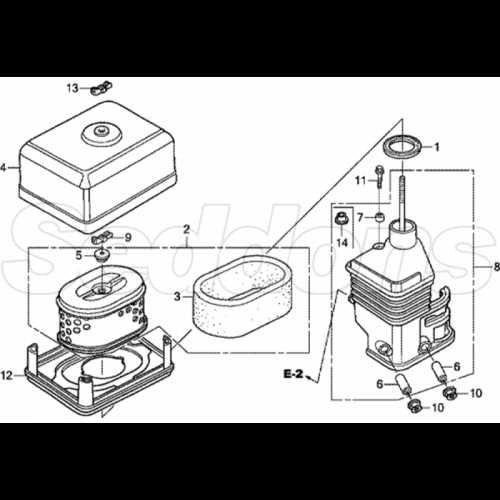

Supporting Components

- Air Filter: Cleans incoming air to enhance combustion quality.

- Exhaust System: Directs gases away from the unit, promoting safety and efficiency.

- Crankshaft: Converts linear motion into rotational energy, powering the mechanism.

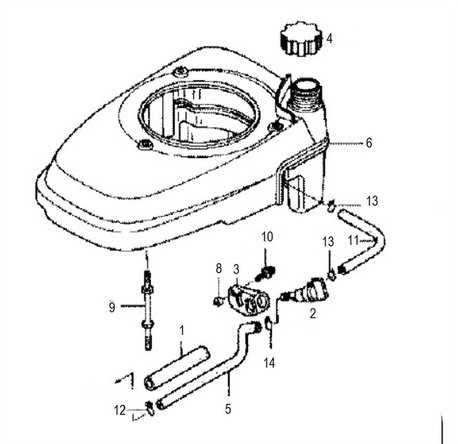

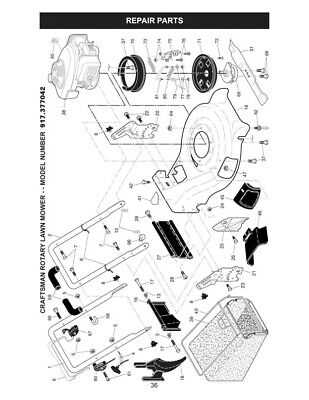

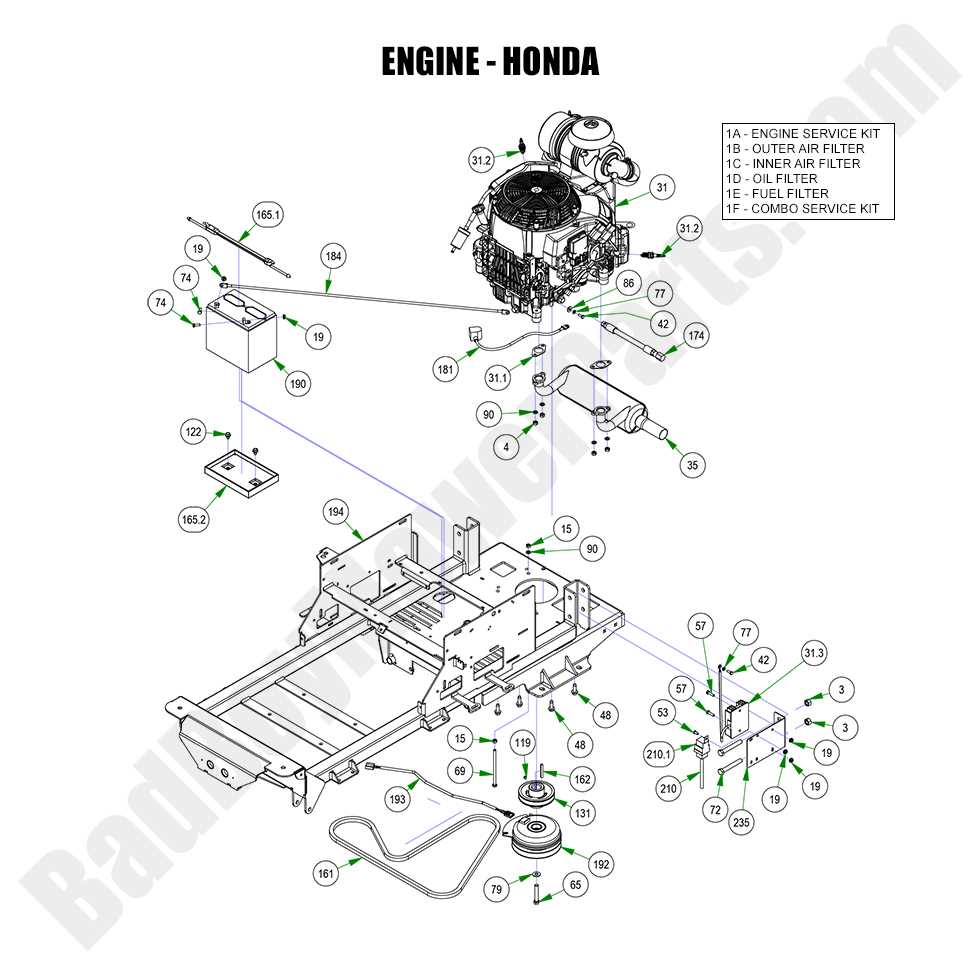

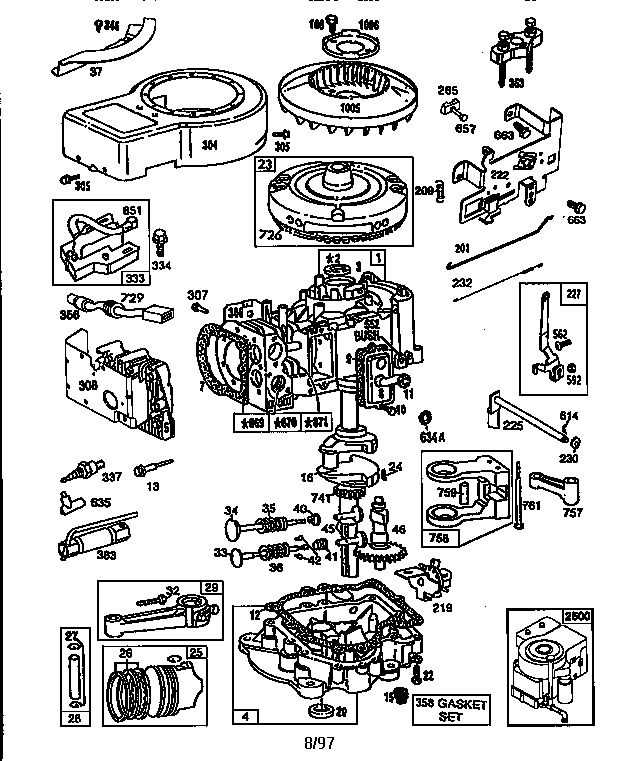

How to Read the Parts Diagram

Understanding a schematic can greatly enhance your ability to maintain and repair equipment. These visual representations provide a detailed overview of components and their relationships, making it easier to identify necessary replacements or adjustments. Here’s how to effectively interpret such a representation.

- Familiarize Yourself with Symbols: Each element in the illustration has a specific symbol. Knowing these can help you quickly identify components.

- Identify Component Labels: Most diagrams include labels or numbers next to each part. These correspond to a parts list, making it easier to find specific items.

- Understand the Layout: Components are typically organized in a logical manner. Grouping similar items can provide insights into their function and connection.

By grasping these fundamentals, you’ll be better equipped to navigate the intricacies of your equipment’s layout and efficiently locate what you need for repairs.

- Start with the Overview: Look for a general view of the assembly to understand how parts fit together.

- Trace Connections: Follow lines or arrows that indicate how parts are linked or interact with one another.

- Refer to the Parts List: Use the corresponding list to ensure you’re ordering the correct items for replacements.

With practice, reading these schematics will become second nature, streamlining your maintenance tasks significantly.

Common Engine Problems and Solutions

Understanding the frequent issues that can arise in power equipment is essential for effective maintenance and repair. Here are some typical problems and their corresponding solutions.

- Difficulty Starting:

- Check the fuel level and quality.

- Inspect the ignition system for faults.

- Examine the air filter for blockages.

- Overheating:

- Ensure the cooling fins are clean and unobstructed.

- Check the oil level and condition.

- Verify that the exhaust system is clear.

- Uneven Performance:

- Inspect the spark plug for wear.

- Examine the fuel filter for clogs.

- Ensure the carburetor is properly calibrated.

- Excessive Vibration:

- Check for loose components.

- Inspect the blades for damage.

- Ensure the crankshaft is aligned properly.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor machinery requires regular care and attention. Adopting proactive measures can significantly extend its operational life and enhance performance. Implementing simple practices can make a substantial difference in efficiency and reliability.

Regular Inspection

Routine checks are crucial. Look for signs of wear, leaks, or unusual noises. Early detection of issues can prevent more significant problems down the line.

Proper Cleaning

Keep components free from debris and dirt. Regular cleaning helps maintain optimal performance and prevents corrosion, which can shorten lifespan.

| Maintenance Task | Frequency |

|---|---|

| Check Oil Levels | Every Use |

| Replace Air Filter | Every 25 Hours |

| Sharpen Blades | Every Season |

| Inspect Belts and Cables | Every 50 Hours |

Identifying Worn Out Parts

Recognizing when components have degraded is crucial for maintaining optimal performance. Over time, certain elements may exhibit signs of wear that can affect overall functionality. Understanding these indicators can help in timely replacements and prevent further damage.

Visual Inspection: Regularly examine each item for cracks, fraying, or discoloration. Any visible deterioration often signals the need for replacement.

Performance Issues: If the machine struggles to operate smoothly, it may indicate underlying problems. Listen for unusual noises or notice decreased efficiency as signs of potential wear.

Physical Testing: Gently manipulate movable parts to assess their condition. Resistance or unusual stiffness can reveal significant wear.

Proactive monitoring of these factors ensures longevity and reliability, allowing for effective intervention when necessary.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues related to small engines. By following a structured process, you can identify problems and implement effective solutions, ensuring optimal performance and longevity of your equipment.

Tools and Materials Needed

Before starting the repair process, gather the necessary tools and materials. Having everything on hand will streamline your work and minimize disruptions.

| Tool/Material | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws |

| Wrench Set | For loosening and tightening bolts |

| Replacement Parts | To replace any faulty components |

| Oil | For lubrication |

| Cleaning Supplies | To keep surfaces clean and free of debris |

Repair Steps

Follow these steps to effectively address issues:

- Start by disconnecting the power source to ensure safety.

- Identify the symptoms and diagnose the problem.

- Refer to the assembly guide for the specific model to understand the layout and function of components.

- Carefully remove any necessary covers or housing to access the internal parts.

- Inspect all components for wear, damage, or blockages.

- Replace or repair any defective parts as identified in your diagnosis.

- Reassemble all components, ensuring everything is securely fastened.

- Reconnect the power source and perform a test run to verify repairs.

Essential Tools for Engine Work

When undertaking mechanical tasks, having the right instruments is crucial for efficiency and precision. Various tools can enhance the overall experience, making it smoother and more productive. From basic implements to specialized equipment, each plays a vital role in achieving optimal results.

Basic Hand Tools

Every technician should start with fundamental hand tools such as wrenches, screwdrivers, and pliers. These implements are essential for loosening or tightening components, allowing for seamless assembly and disassembly. Investing in quality versions ensures durability and reliability in the long run.

Specialized Equipment

In addition to standard tools, specialized equipment like torque wrenches and multimeters can significantly improve accuracy. A torque wrench ensures that fasteners are tightened to the correct specifications, while a multimeter helps diagnose electrical issues. These tools ultimately contribute to a well-functioning system.

Fuel and Oil Recommendations

Proper maintenance of your machine is crucial for optimal performance and longevity. Choosing the right fuel and lubricant can significantly enhance efficiency and reduce wear over time.

When selecting fuel, consider the following:

- Use fresh, unleaded gasoline with an octane rating of 87 or higher.

- Avoid using fuel that contains more than 10% ethanol.

- Store fuel in a clean, sealed container to prevent contamination.

For oil, adhere to these guidelines:

- Opt for a high-quality, detergent oil designed for four-stroke applications.

- Choose the appropriate viscosity based on temperature conditions; typically, 10W-30 is recommended.

- Change the oil regularly to ensure optimal performance.

Following these recommendations will help your equipment run smoothly and efficiently, ultimately prolonging its lifespan.

Upgrading Your Honda Engine Parts

Enhancing the performance of your machinery can lead to significant improvements in efficiency and longevity. By selecting superior components and utilizing advanced technology, you can transform your equipment into a more powerful and reliable tool for various tasks. This section will explore effective strategies for elevating the functionality of your machinery.

Choosing High-Quality Components

Opting for premium materials can greatly influence the overall performance of your system. Look for durable options that promise longevity and resilience under pressure. Investing in reputable brands often yields better results, ensuring your machinery operates at its best.

Maintenance and Upkeep

Regular maintenance is essential for achieving optimal performance. Schedule periodic check-ups and replace worn elements promptly. This proactive approach will not only enhance efficiency but also prolong the lifespan of your equipment, allowing you to maximize your investment.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. Adopting specific measures can significantly enhance your protection while working with mechanical devices.

- Always wear appropriate personal protective equipment (PPE), including gloves and safety goggles.

- Disconnect the power source before starting any repair to avoid accidental activation.

- Work in a well-ventilated area to minimize exposure to fumes and dust.

- Keep your workspace organized to prevent tripping hazards and misplacing tools.

By following these guidelines, you can create a safer environment that minimizes risks associated with repair tasks.

Finding Genuine Replacement Parts

Ensuring optimal performance and longevity of your equipment requires sourcing authentic components. Identifying reliable suppliers and understanding the significance of quality can enhance your maintenance efforts.

- Research authorized dealers to guarantee authenticity.

- Compare specifications to match your requirements.

- Check for warranties and return policies to safeguard your purchase.

When seeking authentic components, consider the following tips:

- Consult user manuals for accurate part numbers.

- Join online forums for recommendations from fellow users.

- Verify reviews of suppliers to assess reliability.

Ultimately, investing in genuine replacements not only improves functionality but also preserves the integrity of your equipment.