Understanding the Components of a Washer Diagram

The intricate workings of a laundry appliance are a marvel of engineering, comprising various elements that work in harmony to deliver cleanliness and efficiency. Each section plays a crucial role in ensuring that garments emerge fresh and spotless after every cycle. By delving into the specific functions and interrelations of these components, one can appreciate the sophistication behind this everyday tool.

To fully grasp the operational mechanism, it is essential to explore the various segments involved. From the systems responsible for water management to those facilitating agitation and drying, every feature is designed with a particular purpose. Understanding these functions not only enhances the user experience but also aids in troubleshooting common issues that may arise over time.

Moreover, gaining insight into the arrangement and design of these essential components empowers users to maintain their appliances effectively. Regular upkeep ensures longevity and optimal performance, transforming laundry tasks into a seamless experience. Embracing this knowledge opens the door to a deeper appreciation of modern conveniences in our daily lives.

Understanding Washer Components

In the realm of laundry appliances, a variety of elements work in harmony to ensure efficient operation and optimal performance. Each component plays a crucial role, contributing to the overall functionality and user experience. By familiarizing oneself with these key features, one can gain deeper insights into the mechanics behind the device and enhance maintenance and troubleshooting practices.

Key Elements of the System

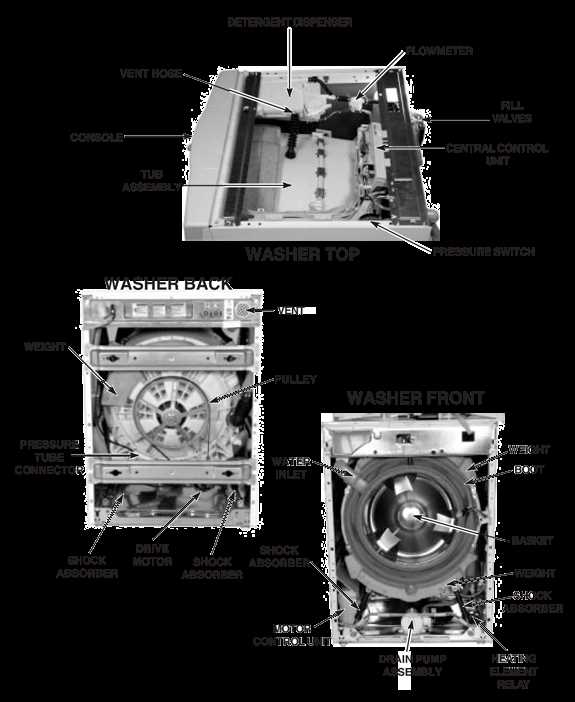

The core structure consists of a housing that protects internal mechanisms, while the drum serves as the primary chamber for clothing. The motor is essential for initiating movement, driving both the rotation and the various cycles. Additionally, the control panel offers user interface capabilities, allowing for selection of specific settings tailored to different fabrics and load sizes.

Supporting Features

Complementing these main components are various accessories designed to optimize performance. Hoses facilitate water intake and drainage, while filters help maintain cleanliness by trapping debris. Furthermore, sensors monitor conditions such as load balance and water levels, ensuring the operation runs smoothly and efficiently.

Key Functions of Washer Parts

Understanding the critical components of laundry appliances is essential for efficient operation. Each element plays a specific role, ensuring the overall functionality and effectiveness of the machine. From initiating cycles to controlling water flow, every section contributes to a seamless experience.

| Component | Function |

|---|---|

| Drum | Holds the items and facilitates movement during cleaning. |

| Agitator | Creates motion to enhance the cleaning process. |

| Motor | Powers the drum and agitator, driving their movement. |

| Control Panel | Allows users to select cycles and adjust settings. |

| Water Inlet Valve | Regulates the flow of water into the appliance. |

| Drain Pump | Removes excess water after each cycle. |

| Suspension System | Absorbs vibrations and stabilizes the unit during operation. |

Common Types of Washers Explained

Understanding the various types of fastening elements is crucial for ensuring optimal performance in mechanical applications. These essential components serve distinct purposes, each tailored to meet specific needs in assembly and maintenance. From providing support and distributing loads to preventing loosening and offering protection, the right selection can significantly enhance the reliability and longevity of connections.

One of the most frequently encountered variations is the flat variety, known for its simple design and effectiveness in load distribution. These elements help spread the force of a fastener, reducing the risk of damage to the materials being joined. Another notable type is the lock variant, which features unique shapes or materials that resist rotation and maintain tightness under vibration. This makes them ideal for applications where movement is common.

Specialized designs also exist, such as the fender type, which offers a larger surface area and is often used in automotive applications. Similarly, the rubberized option provides additional cushioning and helps prevent wear between surfaces. Understanding these differences allows for better decision-making when selecting components for various projects, ultimately leading to improved performance and durability.

How a Washer Operates Internally

This section explores the intricate mechanisms that enable the functioning of a typical cleaning appliance. Understanding these internal processes reveals how items are efficiently cleaned, ensuring optimal performance and longevity.

The operation of this appliance involves several coordinated actions:

- Water Intake: Fresh water is drawn into the unit, regulated by valves that ensure the correct amount is used based on the selected cycle.

- Mixing: Detergent is introduced and mixed with the water, creating a solution that effectively removes dirt and stains.

- Agitation: A central component moves back and forth or in a circular motion, allowing the items to be thoroughly immersed in the cleaning solution.

- Rinsing: After the cleaning cycle, the soiled water is drained away, and fresh water is added for rinsing, ensuring no residue remains.

- Spin Cycle: The final phase involves rapid spinning to extract excess moisture, preparing the items for drying.

Each of these processes is controlled by a sophisticated system that manages timing, temperature, and duration, leading to an effective cleaning experience.

Essential Parts for Efficient Washing

To achieve optimal cleanliness and care for garments, understanding the fundamental components of a laundry system is crucial. Each element plays a significant role in the overall performance, ensuring that fabrics are treated effectively while minimizing wear and tear. Recognizing how these integral sections function together can greatly enhance the laundry experience.

Core Elements of a Laundry System

Among the key features is the mechanism responsible for water circulation, which allows for thorough soaking and rinsing. Additionally, a robust filtration system is essential for trapping dirt and debris, ensuring that garments emerge fresh and unblemished. Furthermore, the heating element is vital for adjusting water temperature, catering to various fabric types and their specific cleaning requirements.

Efficient Operation and Maintenance

Regular upkeep of these components is imperative for sustained efficiency. Ensuring that the circulation system is free of blockages and that the filtration unit is routinely cleaned can prevent malfunctions and improve performance. By paying attention to these essential elements, users can maximize the effectiveness of their cleaning processes and extend the lifespan of their equipment.

Identifying Washer Diagram Symbols

Understanding the various symbols used in technical illustrations is crucial for effective interpretation and application. Each representation carries specific meanings that guide users in comprehending the components and their functionalities. By familiarizing oneself with these symbols, one can enhance their ability to troubleshoot, maintain, and assemble mechanical systems accurately.

Common Symbol Categories

- Shapes: Circles, squares, and triangles often denote different elements, such as fasteners or fittings.

- Lines: Solid lines typically represent connections, while dashed lines might indicate optional or hidden components.

- Text Annotations: Labels often accompany symbols, providing additional information about size, material, or function.

Interpreting Specific Icons

- Circle: Represents a fastening element, often indicating size and threading.

- Square: Typically signifies a mounting point or base support.

- Arrow: Shows direction of motion or flow, essential for understanding operational sequences.

Grasping these symbols enables users to navigate technical documents with confidence, ensuring efficient assembly and maintenance of various mechanisms.

Maintenance Tips for Washer Parts

Regular upkeep is essential for ensuring the longevity and efficiency of your laundry appliance. By focusing on key components and following a few simple guidelines, you can enhance performance and reduce the likelihood of malfunctions.

Routine Inspections

- Check for wear and tear on hoses and seals. Look for cracks or leaks that may lead to water damage.

- Examine the drum for foreign objects. Small items can cause noise and potential damage during cycles.

- Inspect filters regularly. Clogged filters can hinder operation and lead to inefficiency.

Cleaning Procedures

- Wipe down the exterior to prevent dust buildup and maintain a clean appearance.

- Run a cleaning cycle with vinegar or a specialized cleaner to eliminate residue inside.

- Keep the door seal clean and free from debris to avoid mold and unpleasant odors.

By adhering to these maintenance strategies, you can ensure optimal functionality and extend the lifespan of your laundry equipment.

Replacing Worn-Out Washer Components

Over time, various elements of your appliance can wear down, leading to inefficiencies or malfunctions. Addressing these issues promptly can ensure optimal performance and extend the lifespan of your unit. Understanding the signs of deterioration and knowing how to replace these elements is crucial for maintaining functionality.

Identifying Signs of Wear

Common indicators of deterioration include unusual noises, leaks, or decreased performance. If you notice any of these symptoms, it’s important to investigate further. Regular maintenance can help spot issues before they escalate, saving you time and money in the long run.

Steps for Replacement

To begin the replacement process, ensure the unit is unplugged for safety. Gather the necessary tools and new components that match your specific model. Follow a step-by-step guide tailored to your appliance type, ensuring each element is securely installed. After replacement, test the appliance to confirm proper functionality. Regularly checking and replacing worn components can prevent future problems and maintain efficiency.

Safety Features in Washer Design

In modern household appliances, various mechanisms are integrated to ensure user protection and operational reliability. These innovations aim to minimize risks associated with usage while enhancing the overall experience.

Key safety attributes include:

- Overload Protection: Mechanisms that prevent the device from functioning beyond its capacity, safeguarding internal components.

- Leak Detection: Systems designed to identify water leaks early, preventing damage and reducing hazards.

- Child Lock: Features that secure controls to prevent unintended operation by children.

- Automatic Shut-off: Timers that deactivate the machine after a predetermined period, reducing energy consumption and potential overheating.

- Vibration Control: Technology that minimizes excessive movement during operation, enhancing stability and reducing noise.

Implementing these features not only improves safety but also builds consumer trust, ensuring that appliances are both efficient and secure in everyday use.

Energy Efficiency in Washer Parts

Maximizing energy efficiency is crucial for reducing environmental impact and lowering utility costs. Various components contribute to the overall effectiveness of these appliances, ensuring they operate optimally while consuming minimal resources.

Several factors influence energy efficiency:

- Motor Technology: Advanced motors use less power while maintaining performance.

- Insulation: High-quality insulation helps retain heat, minimizing energy loss.

- Water Usage: Efficient designs require less water, reducing heating energy needs.

Understanding how these elements work together can lead to smarter choices and better sustainability practices.

- Choose energy-efficient models with high ratings.

- Maintain appliances regularly to ensure they function efficiently.

- Utilize eco-friendly settings when available.

Implementing these strategies not only benefits the environment but also enhances the longevity and performance of your equipment.

Innovations in Washer Technology

The realm of domestic cleaning appliances has undergone significant transformation, driven by advancements that enhance efficiency, sustainability, and user experience. These innovations reflect a shift toward smarter, more intuitive solutions that meet the demands of modern lifestyles while prioritizing environmental consciousness.

Smart Features and Connectivity

Modern cleaning devices now integrate smart technology, enabling users to control and monitor their appliances remotely. Features such as mobile app connectivity allow for personalized settings, cycle scheduling, and maintenance alerts, ensuring optimal performance and convenience.

Energy Efficiency and Sustainability

Recent developments emphasize energy conservation and reduced water consumption. New models are designed to minimize resource usage while maximizing cleaning effectiveness. This commitment to sustainability is further supported by the incorporation of eco-friendly materials and practices in manufacturing processes.

| Innovation | Description |

|---|---|

| Smart Controls | Allows remote access and programming through mobile applications. |

| Eco-Cycles | Optimized settings for reduced water and energy consumption. |

| Noise Reduction | Advanced engineering to minimize operational sound levels. |

| Self-Cleaning | Automated cleaning cycles that maintain internal hygiene. |

Diagnosing Issues with Washer Parts

Understanding the common challenges that arise within a cleaning appliance is crucial for effective maintenance and repair. When a unit fails to function as expected, identifying the underlying issues can significantly simplify the troubleshooting process. Recognizing the signs of malfunction and knowing where to look can save time and resources.

Common Symptoms and Their Causes

Several indicators can signal that something is amiss. For instance, if the appliance fails to start, it might point to electrical problems or a faulty switch. Unusual noises during operation may indicate worn components or misalignments. Additionally, leaks could stem from worn seals or damaged hoses, each requiring specific attention.

Steps for Troubleshooting

Begin by observing the behavior of the unit closely. Make a note of any irregular sounds, smells, or performance issues. Consulting the manual can provide insights into normal operation and highlight potential trouble spots. After gathering this information, perform a systematic check of the crucial systems involved. This methodical approach will help pinpoint the source of the problem and facilitate effective repairs.