Comprehensive Guide to John Deere Z465 Parts Diagram

In the world of landscaping machinery, comprehending the intricate assembly of components is essential for efficient maintenance and repair. This knowledge not only enhances performance but also prolongs the lifespan of the equipment.

Exploring the various elements involved can ultimately lead to a more streamlined approach in addressing any mechanical issues that may arise. By gaining insights into the structure and functionality of these vital pieces, users can ensure optimal operation.

Whether you are a seasoned professional or a novice, familiarizing yourself with these essential components will empower you to tackle repairs with confidence. Embracing this understanding will transform your experience and efficiency in lawn care.

Understanding John Deere Z465 Components

Familiarizing oneself with the various elements of a mowing machine can significantly enhance its performance and maintenance. Each component plays a crucial role in ensuring efficiency and longevity.

The main elements include:

- Engine: The powerhouse that drives the entire system.

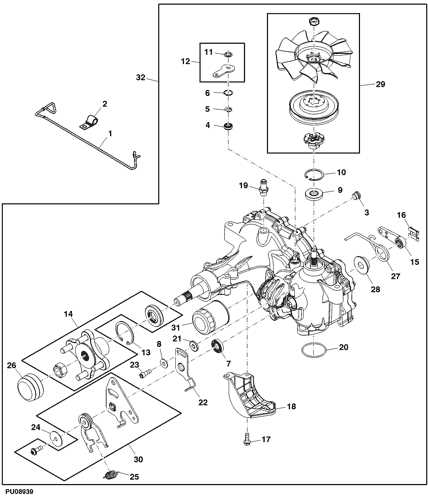

- Transmission: Facilitates speed adjustments and power delivery.

- Blades: Essential for achieving a clean and precise cut.

- Chassis: Provides structural integrity and support.

- Fuel system: Responsible for proper energy supply.

Understanding these components allows operators to maintain their equipment effectively and identify potential issues early on.

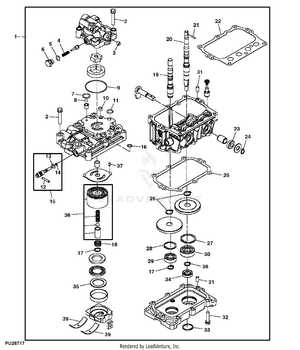

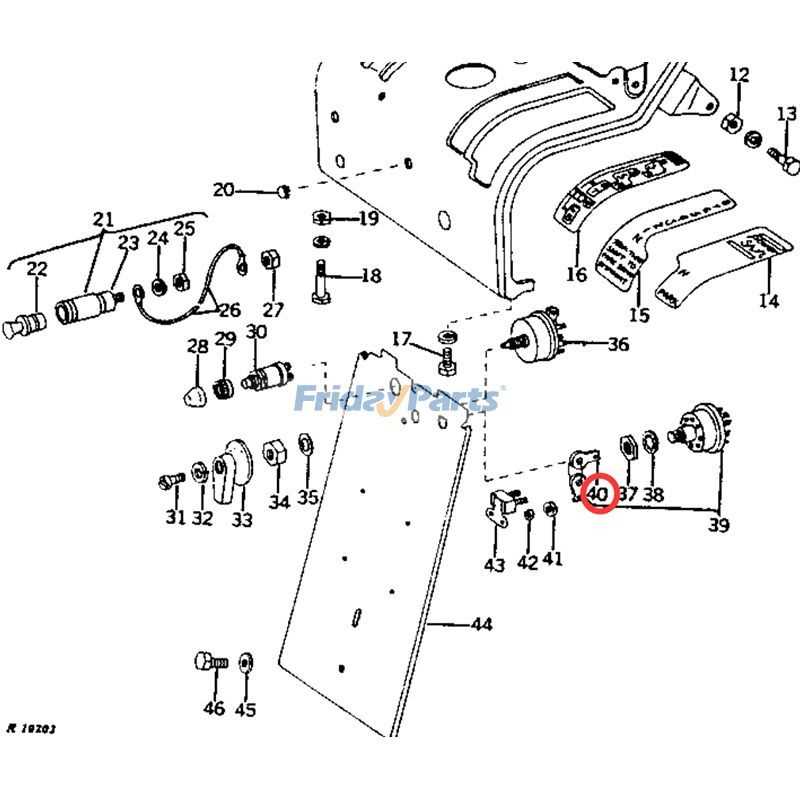

Importance of Parts Diagrams

Visual representations of component arrangements play a crucial role in the maintenance and repair of machinery. They facilitate a clearer understanding of how different elements interact, enabling technicians to diagnose issues efficiently and accurately. By illustrating the relationship between various parts, these illustrations serve as valuable references during servicing tasks.

Furthermore, these graphical aids enhance the overall efficiency of repairs by providing a roadmap for assembly and disassembly. They minimize the risk of misplacement or damage to components, ultimately saving time and resources. Technicians can quickly locate specific pieces, ensuring that maintenance procedures are executed with precision.

Moreover, such visual tools are essential for training purposes. They equip new personnel with the knowledge needed to navigate complex systems, thereby fostering a deeper comprehension of the machinery involved. This educational aspect promotes safety and proficiency, which are paramount in any operational setting.

Overview of Z465 Mower Features

This section provides an in-depth look at the innovative features of the specified mower model, highlighting its efficiency and functionality. Designed for optimal performance, it integrates cutting-edge technology and user-friendly design, making it suitable for a variety of landscaping tasks.

Key Features

With a focus on durability and ease of use, this mower boasts several standout features that enhance the overall mowing experience. Here are some of the most notable attributes:

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust engine that ensures reliable performance and efficiency. |

| Ergonomic Design | Engineered for comfort, allowing operators to navigate with ease during extended use. |

| Cutting Deck | Features a wide cutting deck for quicker mowing and a clean finish on lawns. |

| Adjustable Height | Offers multiple height settings to accommodate various grass types and preferences. |

Benefits of Enhanced Technology

The incorporation of advanced technology not only improves cutting precision but also enhances the overall user experience. From intuitive controls to efficient fuel consumption, these innovations make lawn maintenance simpler and more effective.

Common Issues with Z465 Parts

When maintaining outdoor machinery, various challenges can arise that impact performance and longevity. Recognizing and addressing these issues promptly is essential to ensure efficient operation and prevent further complications.

| Issue | Description | Solution |

|---|---|---|

| Wear and Tear | Components can degrade over time, leading to inefficiency. | Regular inspections and timely replacements are crucial. |

| Corrosion | Exposure to moisture may cause rust and deterioration. | Use protective coatings and store in a dry place. |

| Misalignment | Parts can become misaligned, resulting in operational issues. | Routine checks and adjustments help maintain alignment. |

| Clogging | Debris can obstruct pathways, affecting performance. | Regular cleaning and maintenance minimize this risk. |

Where to Find Replacement Parts

Finding suitable components for your equipment is crucial for maintaining optimal performance and longevity. There are various avenues to explore that can lead you to reliable sources for quality replacements.

Online Resources

- Manufacturer Websites: Official sites often provide catalogs and direct purchasing options.

- Online Marketplaces: Platforms like Amazon or eBay feature numerous sellers and customer reviews.

- Specialized Retailers: Websites focusing on agricultural machinery can offer expert advice and a wide selection.

Local Options

- Authorized Dealers: Local dealers provide genuine components and professional support.

- Auto Parts Stores: Many carry a range of equipment components, including aftermarket options.

- Salvage Yards: These can be treasure troves for hard-to-find items at a lower cost.

Step-by-Step Maintenance Guide

Maintaining your machinery is essential for optimal performance and longevity. This guide offers a structured approach to ensure that your equipment operates smoothly and efficiently. By following these steps, you can prevent issues and extend the life of your investment.

1. Regular Inspection: Begin by examining the equipment thoroughly. Look for any signs of wear or damage, including frayed belts or leaking fluids. Regular checks can help catch problems early.

2. Cleanliness is Key: Keep the machine clean. Remove dirt and debris from critical areas, especially around the engine and air filters. A clean environment reduces the risk of overheating and mechanical failure.

3. Fluid Levels: Check all fluid levels regularly, including oil, coolant, and hydraulic fluid. Maintaining proper levels is crucial for performance and avoiding damage.

4. Filter Replacement: Replace filters as per the manufacturer’s recommendations. Clean filters ensure that your equipment operates efficiently and prevents contaminants from causing harm.

5. Lubrication: Properly lubricate moving parts to reduce friction and wear. Use the recommended lubricants and apply them in the right amounts.

6. Battery Care: Inspect the battery connections and clean any corrosion. Ensure that the battery is charged and functioning well to avoid starting issues.

7. Seasonal Preparation: Prepare your equipment for seasonal changes. This includes winterizing machinery before cold weather and ensuring proper cooling in hot months.

By following this maintenance guide, you can delve deeper into the intricacies of your machinery, ensuring it remains in top condition for the ultimate performance.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right equipment is crucial for achieving optimal performance. Proper tools not only facilitate efficient repairs but also ensure safety and accuracy during the process.

Here are some essential tools to consider:

- Wrenches: A variety of sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types for different screw types.

- Pliers: Useful for gripping, bending, and cutting wires.

- Socket Set: Ideal for reaching hard-to-access fasteners.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Grease Gun: Essential for lubrication to maintain smooth operation.

- Measuring Tape: For precise measurements during repairs.

- Safety Gear: Gloves and goggles to protect against debris and injury.

Having these tools on hand will streamline the repair process, making it easier to address issues promptly and effectively.

Comparing OEM and Aftermarket Parts

When it comes to equipment maintenance, the choice between original manufacturer components and third-party alternatives is crucial. Understanding the distinctions can influence performance, cost-effectiveness, and longevity.

| Aspect | OEM | Aftermarket |

|---|---|---|

| Quality | Generally higher, built to specific standards | Varies widely; some are high-quality, others may be subpar |

| Price | Usually more expensive | Typically more affordable |

| Availability | Limited to specific retailers | Widely available from various sources |

| Warranty | Often includes a warranty | May or may not include a warranty |

| Compatibility | Designed for precise fit | Compatibility can vary; may require modifications |

Identifying Specific Part Numbers

Understanding the intricacies of machinery components is crucial for maintenance and repairs. Recognizing unique identifiers associated with each element can greatly enhance efficiency when sourcing replacements or conducting upgrades. This section aims to clarify how to locate and interpret these identifiers effectively.

Utilizing Manufacturer Resources

Manufacturers often provide comprehensive catalogs that include detailed lists of identifiers. These resources typically feature clear images and descriptions, allowing users to cross-reference specific components easily. Accessing these materials is essential for accurate identification.

Cross-Referencing with Online Databases

Online databases serve as valuable tools for finding specific identifiers. Many websites compile extensive lists that allow users to search by dimensions, features, or compatibility. Engaging with these platforms can streamline the process of finding the correct item needed for repair or replacement.

Benefits of Using Diagrams for Repairs

Utilizing visual aids during maintenance tasks can significantly enhance the repair process. These illustrations provide clarity, making it easier to identify components and understand assembly procedures.

- Improved Understanding: Visual representations clarify complex systems, enabling technicians to grasp how parts interact.

- Efficiency: Quick reference guides streamline the repair process, reducing downtime.

- Accuracy: Detailed visuals help prevent errors, ensuring components are reassembled correctly.

- Training Aid: New technicians benefit from diagrams, as they illustrate workflows and troubleshooting steps effectively.

- Cost-Effectiveness: Reducing mistakes can lead to savings on both time and resources.

Incorporating illustrations into repair workflows ultimately leads to more successful outcomes and enhances overall productivity.

How to Interpret Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair. These representations provide valuable information about components and their interconnections, enabling users to identify necessary replacements and assembly procedures.

To effectively interpret these visuals, follow these steps:

- Familiarize Yourself with Symbols: Each icon represents a specific part. Learning these symbols is crucial for accurate identification.

- Study the Layout: Observe how elements are arranged. This can indicate the relationship between various components.

- Check the Legend: A legend often accompanies schematics, explaining each symbol and line type, enhancing understanding.

- Identify Groups: Look for clusters of components that work together. This can help in recognizing system functions.

- Follow the Flow: Understanding how parts interact can guide troubleshooting and repair strategies.

By practicing these techniques, anyone can become proficient in navigating these essential resources.

Enhancing Longevity of Z465 Mower

Maximizing the lifespan of your mowing equipment involves several essential practices. These steps ensure that the machinery remains efficient and performs at its best throughout its service life.

Regular maintenance is crucial for sustaining the operational efficiency of your mower. Consider implementing the following practices:

- Routine Cleaning: After each use, clean the machine thoroughly to remove grass clippings and debris that can cause corrosion and rust.

- Oil Changes: Regularly change the oil to keep the engine well-lubricated and prevent wear.

- Blade Sharpening: Keep the cutting blades sharp for clean cuts, which reduces strain on the engine.

- Tire Maintenance: Check tire pressure regularly and maintain proper inflation to ensure stability and performance.

Storing your mower properly is also vital for its longevity. Follow these guidelines for optimal storage:

- Choose a dry, sheltered location to protect against weather elements.

- Consider using a cover to shield from dust and moisture.

- Before storage, drain fuel to prevent degradation and potential engine issues.

By adhering to these maintenance and storage practices, you can significantly enhance the durability and performance of your mowing equipment, ensuring it remains a reliable tool for years to come.