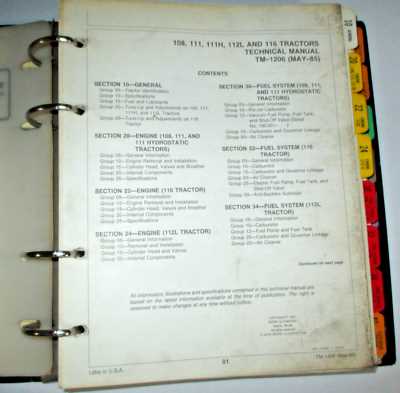

John Deere 112L Parts Breakdown and Components Guide

The world of mechanical equipment relies heavily on the proper functioning of each element within a machine. Understanding how different components interact is crucial for maintaining the performance and longevity of any device. Every small element plays a vital role in ensuring smooth operation and efficiency, especially in equipment designed for demanding tasks.

Reliable equipment maintenance often begins with having a detailed understanding of each component. When every part is in its correct place, systems run more smoothly and require less frequent repairs. Identifying key elements can help troubleshoot issues, prevent wear, and extend the lifespan of any mechanical tool.

Learning about the layout of various elements and their technical relationships is an important step for anyone looking to enhance their equipment’s performance. In-depth knowledge of this subject will lead to more informed decisions regarding repairs and upgrades.

John Deere 112L Parts Overview

Understanding the components of a riding mower is essential for its maintenance and long-term performance. This section provides a detailed exploration of the key elements that make up a robust and reliable lawn care machine.

Below are the main sections of this equipment, highlighting their importance and functionality:

- Engine: The core of the machine, providing power to the entire system and enabling smooth operation across varying terrains.

- Transmission: Responsible for transferring power from the motor to the wheels, ensuring consistent movement and control.

- Blades: Precision-engineered to deliver clean and even cuts, enhancing the quality of lawn care.

- Steering System: Allows for accurate maneuvering, especially in tight or complex spaces, ensuring efficiency and ease of use.

- Chassis: The structural foundation that supports all other parts, designed for durability and stability during use.

Each of these sections plays a critical role in the overall performance, and knowing their function helps in both regular upkeep and identifying

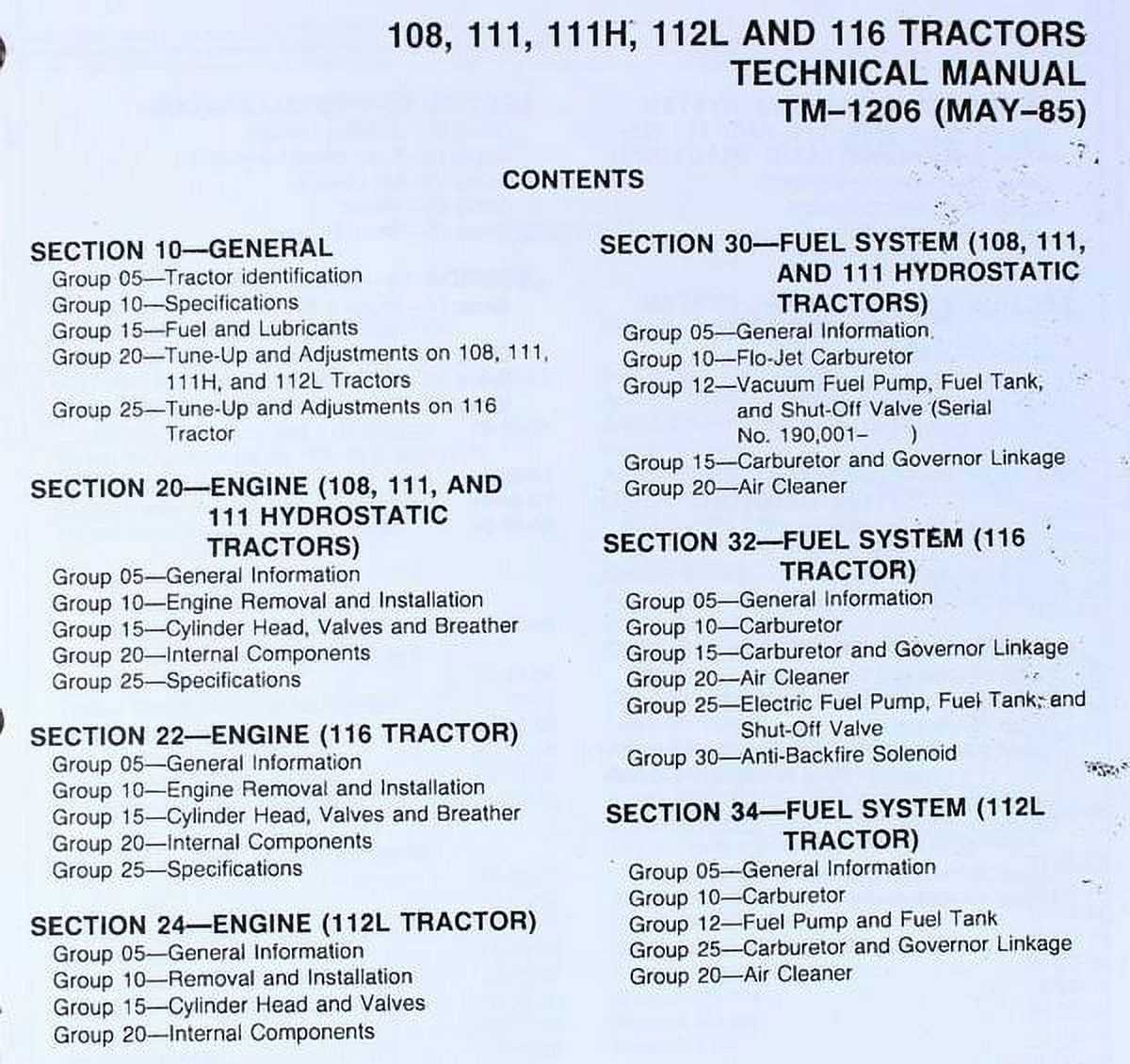

Engine Components and Their Functions

The engine is a complex assembly of various elements that work together to ensure optimal performance. Understanding the roles of each component can help with maintenance and troubleshooting, as well as improving the overall efficiency of the machine.

Key Elements of the Engine

Several essential parts play a crucial role in the engine’s functionality. From fuel systems to internal moving parts, every component has its specific purpose. Below is a brief overview of some of the critical engine elements and their primary tasks:

| Component | Function |

|---|---|

| Cylinder | The core chamber where fuel combustion occurs, powering the machine. |

| Piston | A moving part inside the cylinder that helps to convert the expanding gas into mechanical energy. |

| Crankshaft | Transforms the piston’s linear motion into rotational force to drive other components. |

| Carburetor | Regulates the air and fuel mixture for optimal combustion. |

Supporting Systems

Beyond the core engine parts, there are several supporting systems that ensure smooth operation. These include cooling mechanisms, lubrication pathways, and exhaust systems, all working to maintain efficiency and longevity.

Transmission and Drive System Breakdown

The operation of the transmission and drive mechanism plays a crucial role in ensuring the smooth movement and power delivery of any equipment. Understanding how the system works and identifying its main components can significantly aid in maintenance and troubleshooting.

Main Transmission Components

- Clutch: Connects and disconnects the engine from the transmission to allow gear shifting.

- Gearbox: Contains the gears that modify the speed and torque sent to the wheels.

- Driveline: Transmits power from the gearbox to the axles, ensuring efficient power distribution.

Drive System Overview

The drive system, responsible for controlling movement, works in harmony with the transmission. Key elements such as the axle, differential, and driveshaft collaborate to ensure that the power from the engine is directed to the wheels or tracks in a balanced manner.

- Axles: Support the weight and allow the wheels to rotate smoothly.

- Differential: Enables the wheels to turn at different speeds while maintaining traction.

- Driveshaft: Transfers torque from the transmission to the axles.

By understanding these components, one can ensure proper maintenance and quickly address any operational issues that arise in the system.

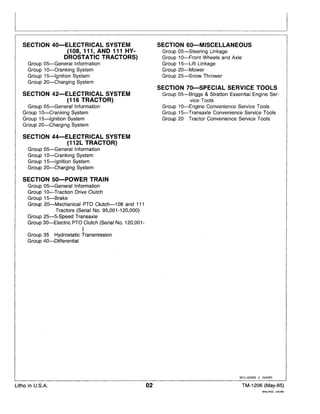

Electrical System Parts and Wiring

The electrical system plays a crucial role in ensuring the reliable operation of various components. A well-organized network of cables and connectors delivers power to essential functions, supporting smooth performance and safety.

Key Components in the system include wiring harnesses, which efficiently route electrical currents to different areas, and various connectors that link critical elements, such as the ignition and lighting circuits. Maintaining these elements is essential for uninterrupted functionality.

Additionally, fuses and relays act as safeguards, preventing overloads and ensuring that the system remains operational under various conditions. Proper upkeep of these components helps prevent malfunctions and enhances longevity.

Steering Mechanism and Adjustments

The steering system plays a crucial role in ensuring precise control and maneuverability of the vehicle. A well-maintained mechanism allows for smoother turns and more stable handling, which is essential for safe operation. Regular inspections and timely adjustments are key to preventing wear and ensuring optimal performance.

To maintain the effectiveness of the steering, it’s important to monitor the alignment and ensure all components are free from excessive play. Adjustments may be needed to correct steering wheel responsiveness or to address any signs of misalignment, such as uneven movement or difficulty in turning.

In cases where the steering becomes stiff or unresponsive, checking the linkage and ensuring proper lubrication can resolve minor issues. However, for more complex concerns, recalibration of the system might be required to restore proper functionality.

Deck Assembly and Cutting Blades

The assembly of the cutting deck is crucial for ensuring optimal performance and efficiency in lawn care. A well-constructed deck not only supports the cutting mechanism but also contributes to a clean and precise cut. Understanding the various components involved in this assembly helps in maintaining and troubleshooting the system effectively.

Cutting blades are essential elements of the deck assembly, designed to deliver a sharp and even cut. These blades come in different shapes and sizes, each tailored for specific mowing conditions and grass types. Regular inspection and replacement of dull or damaged blades are necessary to maintain cutting effectiveness.

Additionally, proper alignment and fastening of the cutting deck are vital for smooth operation. Ensuring that all components are securely attached minimizes vibration and wear during use. By prioritizing maintenance and understanding the deck’s structure, users can achieve a well-groomed lawn year-round.

Fuel System Components and Maintenance

The fuel system plays a vital role in ensuring the efficient operation of any engine. It comprises various elements that work together to store, filter, and deliver fuel to the engine, contributing to optimal performance and longevity. Regular maintenance of these components is essential to prevent issues that could lead to reduced efficiency or costly repairs.

Key Components

Essential elements of the fuel system include the fuel tank, fuel pump, fuel filter, and injectors. The fuel tank stores the fuel, while the fuel pump is responsible for transferring it to the engine under the right pressure. The fuel filter cleans the fuel before it reaches the injectors, which atomize the fuel for combustion. Each of these components must be in good working condition for the system to function effectively.

Maintenance Tips

Regular inspection and maintenance can help extend the life of the fuel system. It is advisable to check the fuel filter periodically and replace it as needed to ensure clean fuel flow. Additionally, monitoring the fuel pump for any signs of wear or malfunction can prevent potential breakdowns. Keeping the fuel tank clean and free from contaminants also plays a crucial role in maintaining overall system health.

Hydraulics and Fluid Reservoirs

The hydraulic system plays a crucial role in the operation of various machinery, utilizing pressurized fluid to facilitate movement and power different components. Understanding the mechanics behind these systems is essential for efficient maintenance and functionality.

Fluid reservoirs serve as storage units for hydraulic fluid, ensuring a consistent supply to the system. These reservoirs must be designed to withstand varying pressures while providing easy access for monitoring fluid levels and performing necessary maintenance. Proper maintenance of these units is vital for the overall performance of the hydraulic system.

Components such as pumps, filters, and hoses are integral to the hydraulic circuit, each fulfilling a specific function. Regular checks and replacements of these parts can prevent system failures and prolong the lifespan of the equipment.

Tires, Wheels, and Axle Setup

The configuration of wheels, tires, and axles plays a crucial role in the overall performance and functionality of any outdoor equipment. Proper selection and maintenance of these components ensure optimal traction, stability, and maneuverability. Understanding the interconnections and specifications can enhance the longevity and efficiency of the machinery.

Choosing the Right Tires

Selecting appropriate tires is essential for maximizing performance. Consider the following factors:

- Tread Pattern: Different tread designs cater to various terrains and conditions.

- Size: Ensure compatibility with the equipment’s specifications for optimal fit.

- Material: Choose tires made from durable materials to withstand wear and tear.

Wheel and Axle Alignment

Correct alignment of wheels and axles is vital for ensuring smooth operation. Follow these guidelines:

- Check for any visible wear on axles and replace if necessary.

- Regularly inspect the alignment to avoid uneven tire wear.

- Ensure that all fasteners are tightened to prevent any loosening during operation.

Chassis and Frame Structure Details

The chassis and frame form the foundation of any vehicle, providing essential support and stability during operation. Understanding their composition and arrangement is vital for maintenance and repair processes. This section delves into the fundamental aspects of the structural components, highlighting their significance in the overall performance and durability of the machine.

Structural Composition

The framework is typically constructed from robust materials designed to withstand various stresses encountered during operation. The choice of material and design influences the vehicle’s weight, handling, and resilience. Key components include:

| Component | Material | Function |

|---|---|---|

| Main Frame | Steel or Aluminum | Supports the weight of the vehicle and components. |

| Subframe | Steel | Houses additional components and enhances structural integrity. |

| Cross Members | Steel | Provides lateral support and stability. |

Importance of Maintenance

Regular inspection and maintenance of the chassis and frame are crucial for ensuring the longevity and safe operation of the vehicle. Any signs of wear, corrosion, or damage should be addressed promptly to prevent further issues and maintain optimal performance.

Cooling System and Airflow Components

The efficiency of an engine is significantly influenced by its cooling mechanism and airflow management. Properly functioning components in these systems ensure optimal temperature regulation, preventing overheating and maintaining performance. This section will explore the essential elements that contribute to effective cooling and airflow in machinery.

Key Components of the Cooling System

- Radiator: Responsible for dissipating heat from the engine coolant.

- Water Pump: Circulates coolant throughout the engine and radiator.

- Thermostat: Regulates the coolant temperature by controlling its flow.

- Cooling Fan: Enhances airflow through the radiator, aiding in heat dissipation.

Airflow Management Elements

- Intake Ducts: Direct air into the engine for combustion.

- Air Filters: Remove impurities from incoming air, ensuring clean airflow.

- Exhaust System: Facilitates the exit of combustion gases, allowing for better airflow.

- Ventilation Grills: Improve air circulation within the engine compartment.