Understanding the Transformer Parts Diagram for Better Electrical Insights

The intricacies of electrical apparatuses reveal a fascinating interplay of various elements, each playing a critical role in the overall functionality. Grasping the arrangement and interaction of these components is essential for anyone seeking to comprehend how energy is transformed and utilized within different systems.

In this section, we will explore the essential building blocks of such devices, shedding light on their configuration and interrelationships. Each component contributes uniquely, forming a cohesive unit that enhances efficiency and performance.

By delving into the specific roles and arrangements of these critical elements, we aim to provide a clearer picture of their collective impact on energy management. Understanding these aspects will equip readers with the knowledge necessary to navigate the complexities of electrical systems with confidence.

Understanding Transformer Components

In the realm of electrical engineering, the devices responsible for the conversion of voltage levels are essential for efficient energy transmission and distribution. A deep comprehension of their key elements is crucial for both design and troubleshooting processes. Each component plays a vital role in ensuring the smooth operation of these intricate systems.

Core materials form the heart of these devices, serving as a magnetic pathway that facilitates the flow of energy. The choice of material significantly impacts the efficiency and overall performance, making it a critical consideration in design.

Windings are another fundamental aspect, typically composed of conductive wire. These coils are strategically placed around the core and are responsible for generating electromagnetic fields. The number of turns in each winding directly influences voltage transformation ratios.

Insulation is crucial for preventing unwanted electrical contact between components, ensuring safety and functionality. Various types of insulating materials are employed to withstand high voltages and temperature variations.

Lastly, tap changers are utilized for adjusting voltage levels, providing flexibility and adaptability in operation. This feature is particularly important for meeting varying load demands in real-time scenarios.

Understanding these fundamental elements not only enhances the knowledge of energy conversion systems but also aids in optimizing their application across different industries.

Types of Transformers Explained

This section explores the various categories of electrical devices used to alter voltage levels, ensuring efficient power distribution across different applications. Understanding these classifications is essential for selecting the appropriate equipment for specific operational needs.

One major classification includes the distinction between power and distribution units. The former primarily manages high voltage for large-scale energy transmission, while the latter focuses on stepping down voltage for local usage. Each type plays a crucial role in maintaining electrical efficiency and safety.

Another important category involves the configuration of the core and windings, which can be either step-up or step-down. Step-up variants increase voltage, making them suitable for long-distance transmission, whereas step-down types reduce voltage for consumer use. This functional differentiation is key in designing electrical systems.

Additionally, there are specialized versions such as isolation and auto units, which serve unique purposes like protecting circuits and providing automatic voltage adjustments. These designs enhance performance and reliability in various electrical setups.

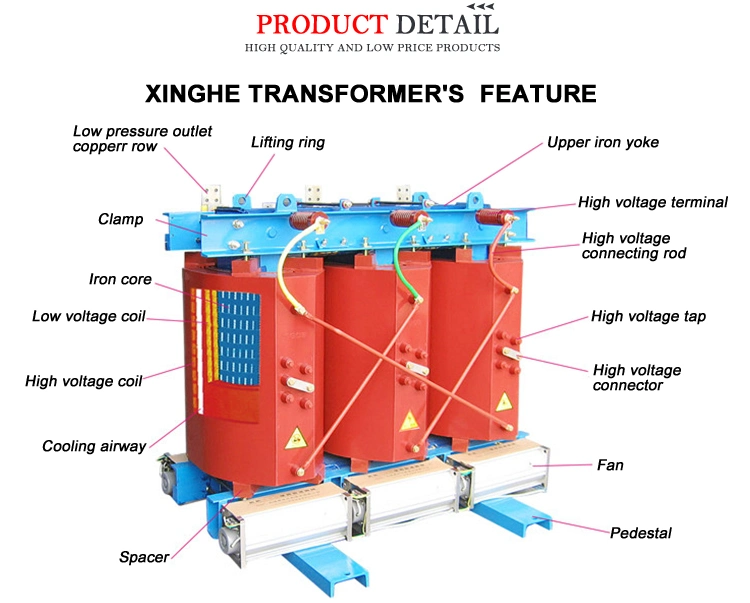

Key Parts of a Transformer

Understanding the fundamental components of this electrical device is crucial for grasping its operation and efficiency. Each element plays a specific role in the overall functionality, contributing to the transformation of energy from one voltage level to another.

Core: The core is made of laminated iron or steel, serving to channel magnetic flux efficiently. Its design minimizes energy losses and enhances performance.

Windings: These are the conductive coils, usually made of copper or aluminum, that generate magnetic fields. The primary and secondary windings differ in the number of turns, determining voltage transformation.

Insulation: Insulating materials are vital for preventing electrical shorts between the windings and the core, ensuring safe operation and longevity.

Taps: Taps are additional connection points on the windings that allow for voltage adjustment. They provide flexibility in various applications, accommodating different load requirements.

Cooling System: To prevent overheating, many designs incorporate a cooling mechanism, which can include oil or air circulation, ensuring optimal functioning and reliability.

Transformer Core Materials Overview

The core of an electromagnetic device plays a crucial role in its efficiency and functionality. The choice of materials used in this component significantly impacts the performance characteristics, such as energy losses and magnetic saturation. Understanding the various options available allows for better design choices tailored to specific applications.

Commonly employed materials include silicon steel, which offers a good balance of magnetic permeability and conductivity, making it a popular choice for many designs. Another alternative is amorphous steel, known for its lower energy losses, particularly at high frequencies. Additionally, ferrites are often utilized in high-frequency applications due to their excellent magnetic properties and minimal eddy current losses.

Each material comes with its own set of advantages and limitations, which must be considered in the context of the desired operational parameters. The selection process often involves a trade-off between cost, weight, and performance requirements. Ultimately, the right material can enhance overall efficiency and longevity in a wide range of electrical applications.

Insulation Systems in Transformers

The effectiveness and reliability of electrical machines heavily depend on the materials and technologies used for their insulation. Proper insulation plays a crucial role in preventing electrical breakdown, ensuring safety, and enhancing the longevity of these systems. Various insulation methods and materials are employed to create barriers against electrical currents, heat, and environmental factors, which are essential for optimal operation.

Types of Insulating Materials

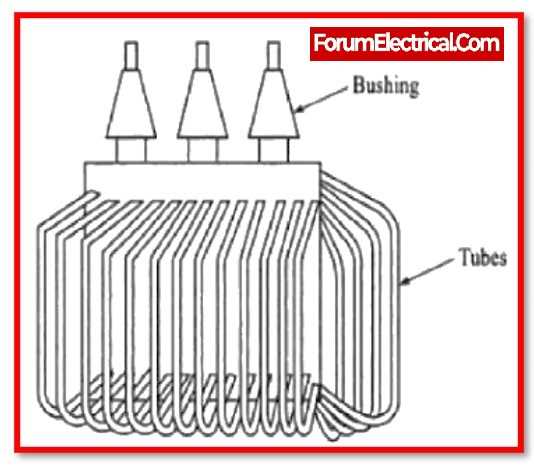

Different classes of insulating materials serve distinct purposes within electrical equipment. Solid, liquid, and gaseous insulators are commonly used, each offering unique properties that cater to specific operational needs. Solid insulators, such as polymers and ceramics, provide structural support and electrical isolation, while liquid insulators, like mineral oils, facilitate heat dissipation and protect against moisture. Gaseous insulators, including sulfur hexafluoride (SF6), are employed in high-voltage applications due to their excellent dielectric strength.

Importance of Proper Insulation Design

Designing an effective insulation system involves careful consideration of thermal, electrical, and mechanical stresses. A well-engineered insulation strategy not only minimizes the risk of failure but also optimizes performance under varying operating conditions. Regular maintenance and monitoring of insulation integrity are vital to identify potential issues before they lead to catastrophic failures, ensuring that the equipment remains functional and safe throughout its operational life.

Cooling Methods for Transformers

Effective temperature management is crucial for the longevity and performance of electrical devices. Excess heat can lead to failures and reduced efficiency, making cooling techniques essential for maintaining optimal operating conditions. Various methods are employed to dissipate heat and ensure reliable functionality.

The primary cooling strategies can be categorized as follows:

- Natural Cooling: Utilizes ambient air or surrounding environment for heat dissipation. It is a simple and cost-effective method, suitable for smaller units.

- Forced Air Cooling: Involves fans or blowers to enhance airflow, improving heat removal. This method is effective in environments with limited natural ventilation.

- Liquid Cooling: Uses fluids, such as water or oil, to absorb and transfer heat away from the source. This method is more efficient for larger devices requiring extensive heat management.

- Heat Exchangers: These systems transfer heat from the internal components to an external environment, often using a secondary fluid. This approach allows for effective cooling in high-load applications.

Each technique has its own advantages and is chosen based on specific operational requirements, environmental conditions, and size constraints. Proper implementation of these cooling methods can significantly enhance the performance and lifespan of electrical equipment.

Winding Configurations in Transformers

The arrangement of coils within electromagnetic devices plays a crucial role in their functionality and efficiency. Different configurations can significantly influence voltage transformation, energy losses, and overall performance. Understanding these setups is essential for optimizing design and application.

Common arrangements include series and parallel configurations, each serving distinct purposes. Series connections enhance voltage levels, while parallel arrangements focus on current capabilities. The choice of configuration impacts the device’s ability to meet specific operational demands.

Additionally, variations such as delta and star configurations are utilized in three-phase systems. The delta setup allows for higher currents and is suitable for heavy loads, while the star configuration provides benefits in voltage regulation and reduced phase currents.

Each of these arrangements has its advantages and considerations, influencing aspects such as harmonics, impedance, and stability. Selecting the appropriate coil configuration is vital for achieving desired electrical characteristics and ensuring reliable operation in various applications.

Transformer Tap Changer Functionality

The mechanism responsible for adjusting voltage levels plays a crucial role in ensuring the stability and efficiency of electrical systems. By modifying the turns ratio of the winding, this device allows for precise control of output voltage, adapting to varying load conditions and maintaining optimal performance across a range of scenarios.

Operational Principles

This adjustment device operates by selecting different connections on the winding. Each connection corresponds to a different number of turns, effectively changing the output voltage. The process is typically automated, allowing for real-time adjustments based on current demand. This not only enhances the reliability of the electrical supply but also protects equipment from voltage fluctuations.

Benefits of Effective Voltage Regulation

Maintaining the desired voltage level is essential for the efficient operation of electrical equipment. Proper regulation minimizes energy losses and extends the lifespan of machinery, while also improving overall system efficiency. Additionally, it contributes to better load management, ensuring that both consumers and providers can operate smoothly in a dynamic environment.

Electrical Connections in Transformers

The efficient operation of electrical devices relies heavily on the intricate network of connections within their structure. These connections ensure that electrical energy is transmitted effectively from one component to another, facilitating the transformation of voltage levels and enhancing overall functionality. Understanding the arrangement and significance of these linkages is crucial for maintenance and troubleshooting.

Types of Connections

There are several common methods employed to establish these crucial linkages. The most prevalent types include winding connections and tap connections. Winding connections involve the configuration of coils that create magnetic fields, while tap connections allow for voltage adjustments, ensuring compatibility with various loads.

Importance of Proper Connections

Maintaining optimal connections is vital for the longevity and efficiency of electrical devices. Poorly executed linkages can lead to issues such as energy losses, overheating, and even complete system failures. Regular inspections and adherence to established standards are essential practices to ensure that these connections remain secure and functional.

Understanding Transformer Ratings

When evaluating electrical devices designed to transfer energy, it’s crucial to grasp the significance of their specifications. These ratings indicate the capabilities and limitations of the equipment, helping users to select the appropriate model for their needs. A thorough understanding ensures efficient operation, safety, and longevity of the apparatus in various applications.

Power Capacity

The power capacity is one of the most critical aspects to consider. It refers to the maximum amount of energy that the unit can handle without overheating or suffering damage. This value is usually expressed in volt-amperes (VA) or kilovolt-amperes (kVA), representing the apparent power in an electrical system. Selecting a device with the right power rating is essential for maintaining system efficiency and preventing overloads.

Voltage Ratings

Another vital specification is the voltage rating, which indicates the acceptable input and output voltage levels. Devices typically come with primary and secondary voltage ratings, denoting the voltages for which they are designed to operate effectively. Understanding these values helps ensure compatibility with existing systems and contributes to the safe and reliable functioning of the electrical setup.

Maintenance of Transformer Parts

Ensuring the longevity and efficiency of electrical equipment requires regular upkeep and inspection. This practice not only extends the lifespan of components but also enhances operational reliability and performance. Effective maintenance strategies involve a thorough understanding of the individual elements and their roles within the system.

Key areas to focus on include:

- Visual inspections to detect wear and tear.

- Cleaning of surfaces to prevent dust and debris accumulation.

- Checking insulation integrity to avoid breakdowns.

- Monitoring temperature levels to prevent overheating.

Implementing a routine maintenance schedule can provide significant benefits:

- Early identification of potential issues.

- Reduction of unexpected failures.

- Improved energy efficiency.

- Cost savings on repairs and replacements.

Additionally, training personnel on best practices is crucial. Knowledgeable staff can effectively execute maintenance tasks and respond swiftly to any abnormalities.

In summary, a proactive approach to maintaining essential components leads to enhanced functionality and safety, ensuring seamless operation in various applications.

Common Issues with Transformer Components

Understanding the frequent challenges faced by key elements in electrical systems is essential for effective maintenance and operation. Various factors can lead to malfunctions, impacting performance and reliability. This section outlines typical problems that may arise, enabling better preparation and response strategies.

Electrical Failures

- Short Circuits: Often caused by insulation breakdown, these can lead to severe damage.

- Overloading: Exceeding design limits can result in overheating and premature wear.

- Voltage Fluctuations: Instabilities can affect efficiency and lead to component failure.

Mechanical Issues

- Vibration: Excessive movement can loosen connections and damage sensitive components.

- Corrosion: Environmental factors can lead to deterioration of metal parts, affecting conductivity.

- Wear and Tear: Regular usage can cause gradual degradation, necessitating timely replacements.

Future Trends in Transformer Design

The evolution of electrical devices continues to pave the way for innovative designs that promise improved efficiency and sustainability. As technology advances, the focus shifts towards creating systems that not only meet current demands but also anticipate future needs. This section explores emerging trends that are set to reshape the landscape of energy conversion systems.

Smart Technologies: The integration of smart technologies is becoming increasingly prevalent. Devices equipped with advanced monitoring and control capabilities can optimize performance, reduce downtime, and enhance predictive maintenance. This shift towards automation is revolutionizing how energy systems operate, making them more responsive and efficient.

Material Advancements: The use of high-performance materials is another significant trend. Innovations in superconductors and advanced alloys are leading to lighter, more efficient configurations that minimize energy loss. These materials enable the design of smaller and more compact units, catering to the growing demand for space-efficient solutions.

Sustainability Initiatives: Environmental considerations are driving the push towards greener technologies. The adoption of eco-friendly materials and energy sources reflects a broader commitment to sustainability. Future designs will likely incorporate recyclable components and energy-efficient processes, aligning with global efforts to reduce carbon footprints.

Decentralization: The move towards decentralized energy systems is reshaping traditional models. With the rise of renewable energy sources and distributed generation, new configurations are being developed to facilitate localized power management. This trend supports greater resilience and flexibility in energy distribution.

Digital Twins: The implementation of digital twin technology is transforming how devices are designed and managed. By creating virtual replicas, engineers can simulate performance under various conditions, leading to enhanced reliability and efficiency. This approach not only accelerates the design process but also aids in ongoing monitoring and optimization.

In conclusion, the future of energy conversion systems is marked by technological advancements, a commitment to sustainability, and a shift towards more intelligent, decentralized solutions. As these trends unfold, they promise to enhance efficiency and reliability while addressing the challenges of a changing energy landscape.