Comprehensive Parts Diagram for John Deere Snowblower 1330SE

Effective winter maintenance relies heavily on the right tools and knowledge. When facing heavy snowfall, having a reliable machine is essential for homeowners and businesses alike. This guide aims to enhance your understanding of the components involved in these powerful devices, allowing you to maintain and optimize their performance.

With a comprehensive overview of the essential elements that contribute to the functionality of your equipment, you can ensure that it operates smoothly throughout the chilly months. Familiarity with the various components will not only assist in troubleshooting but will also facilitate proper upkeep and repairs, making your winter preparation more efficient.

Utilizing detailed illustrations can significantly simplify the process of identifying and sourcing the necessary components. By exploring these visual aids, you’ll gain clarity on how each piece interconnects, enabling you to make informed decisions regarding maintenance and replacements. This knowledge empowers you to tackle winter challenges with confidence and ease.

Understanding the John Deere 1330SE

This section delves into the essential features and components of a popular winter equipment model. Designed to tackle harsh weather conditions, this machine showcases a blend of efficiency and durability. Users often appreciate its robust construction and ease of use, making it a preferred choice for clearing pathways and driveways during heavy snowfall.

Key Attributes: The equipment is engineered with powerful mechanisms that enhance performance in various snow depths. Its intuitive controls provide an accessible user experience, ensuring that both seasoned operators and novices can handle it with confidence.

Maintenance Considerations: Regular upkeep is crucial for sustaining optimal functionality. Familiarity with the various elements and their roles can aid in effective maintenance, reducing the likelihood of breakdowns and prolonging the lifespan of the machinery.

Understanding the components and their interplay can significantly enhance operational efficiency, leading to a smoother experience in winter conditions.

Key Features of the Snow Clearing Equipment

This equipment is designed to tackle challenging winter conditions with efficiency and reliability. Equipped with advanced technology and thoughtful engineering, it offers a range of features that enhance its performance and ease of use, making it an essential tool for maintaining clear pathways during snowstorms.

Powerful Engine

- High-performance engine ensures efficient snow removal.

- Reliable starting system for immediate use in cold weather.

- Durable construction for prolonged life and dependability.

Enhanced Maneuverability

- Adjustable chute for precise snow direction control.

- Ergonomic design for comfortable operation.

- Large tires provide stability and traction on slippery surfaces.

Overall, these features combine to create a robust solution for handling winter’s challenges effectively.

Importance of Maintenance for Longevity

Proper upkeep is essential for extending the life of any machinery. Regular attention to maintenance tasks can prevent costly repairs and ensure that equipment operates efficiently. By following a consistent maintenance routine, users can enhance performance and reliability, ultimately leading to a more satisfying experience.

Benefits of Routine Care

Engaging in routine care provides numerous advantages. It not only reduces the likelihood of unexpected breakdowns but also helps in identifying potential issues before they escalate. Regular inspections and timely replacements of worn components can significantly enhance operational efficiency. Moreover, well-maintained equipment often retains higher resale value, benefiting owners in the long run.

Best Practices for Equipment Maintenance

Adopting effective practices is vital for ensuring longevity. Always refer to the manufacturer’s guidelines for specific maintenance intervals and procedures. Regularly checking fluid levels, cleaning filters, and examining belts can prevent minor problems from turning into major failures. Emphasizing cleanliness and lubrication also plays a crucial role in maintaining optimal performance and durability.

Common Replacement Parts for the 1330SE

Maintenance and repair are essential for keeping any outdoor equipment in top condition. Certain components may require replacement over time to ensure optimal performance and longevity. Identifying these key elements can greatly enhance the efficiency of your machine.

Essential Components

When it comes to servicing your equipment, some elements are more prone to wear and tear than others. Below are common components that often need attention:

| Component | Description |

|---|---|

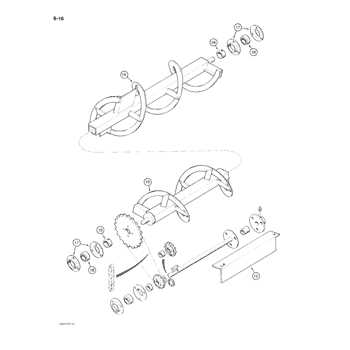

| Auger | Used for moving snow effectively; often requires replacement due to wear. |

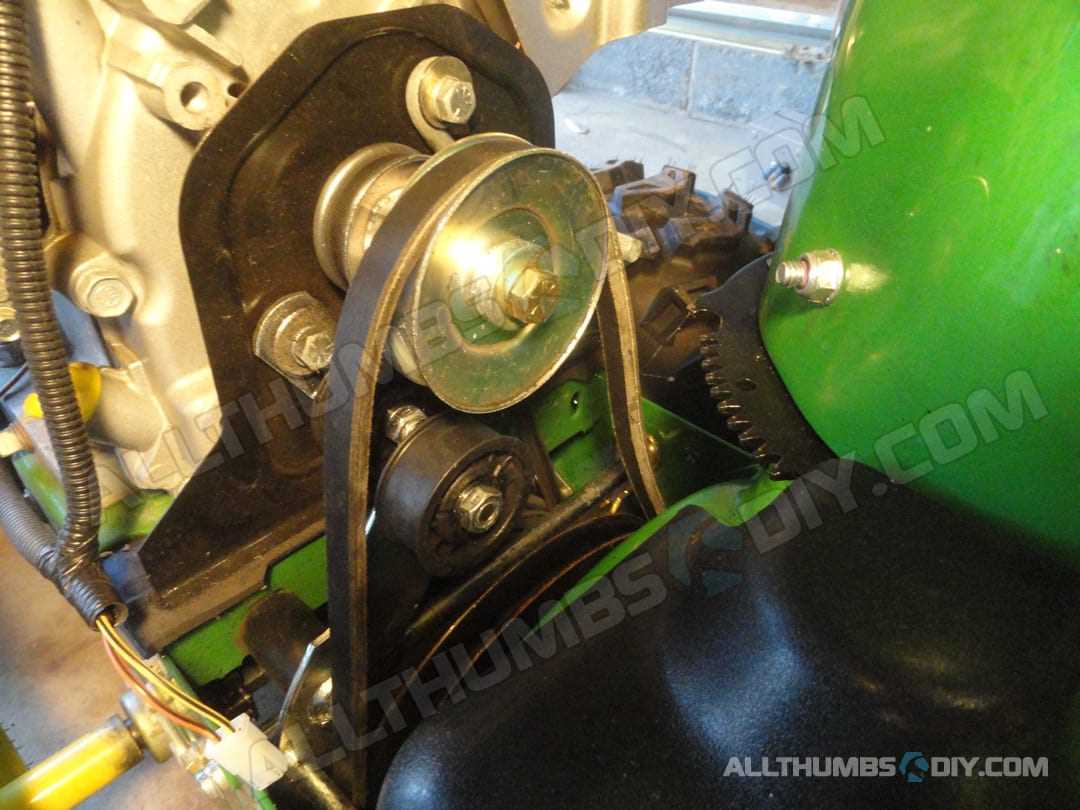

| Drive Belt | Transmits power from the engine to the auger and wheels; may stretch or break over time. |

| Shear Pins | Designed to protect the auger and engine; can break under stress and need replacing. |

| Skid Shoes | Help adjust the height of the machine from the ground; wear out from contact with surfaces. |

Conclusion

Regular checks and timely replacements of these critical components can prevent larger issues down the line. Staying proactive ensures that your equipment continues to operate smoothly and effectively.

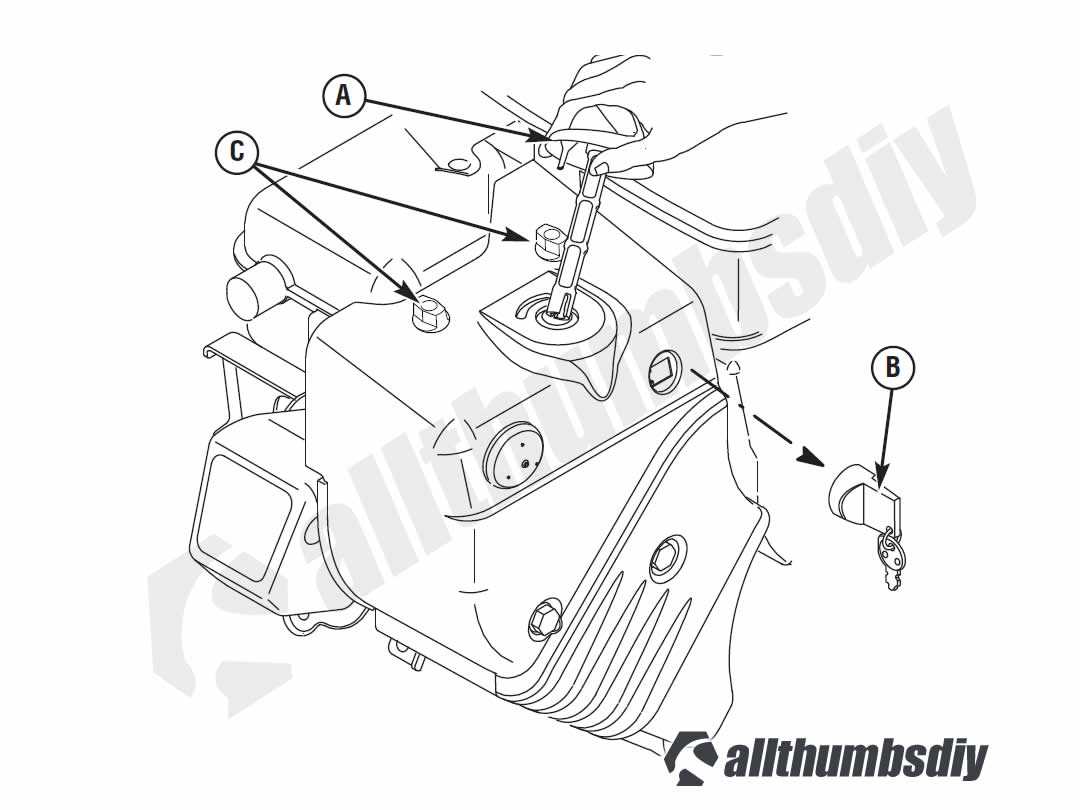

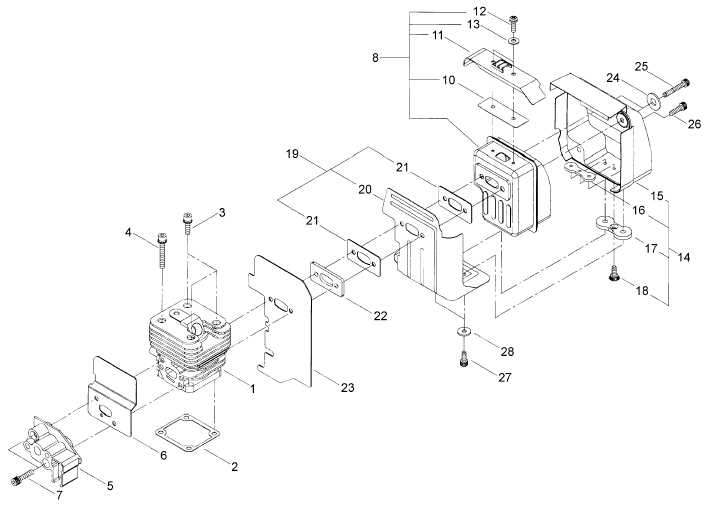

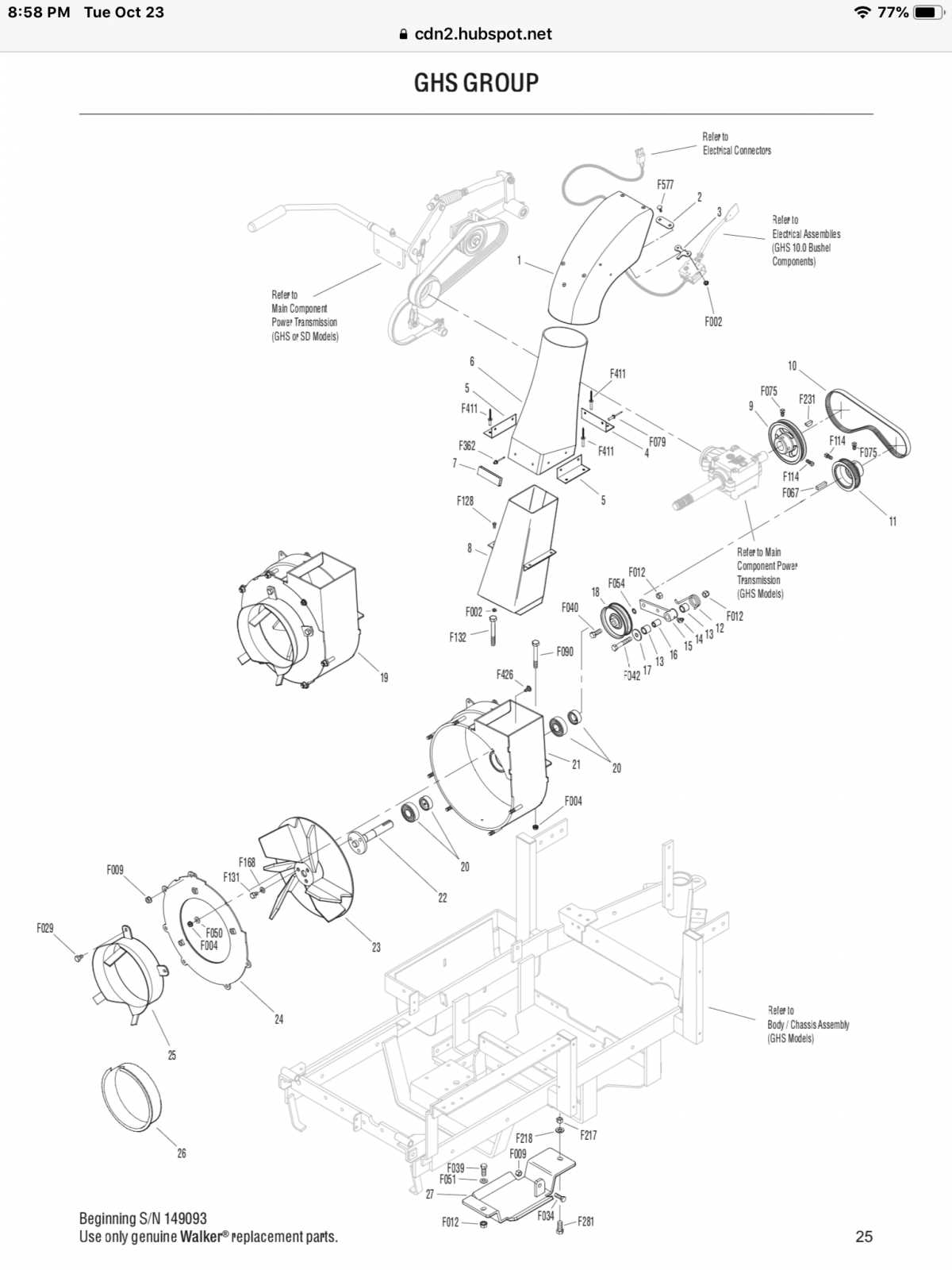

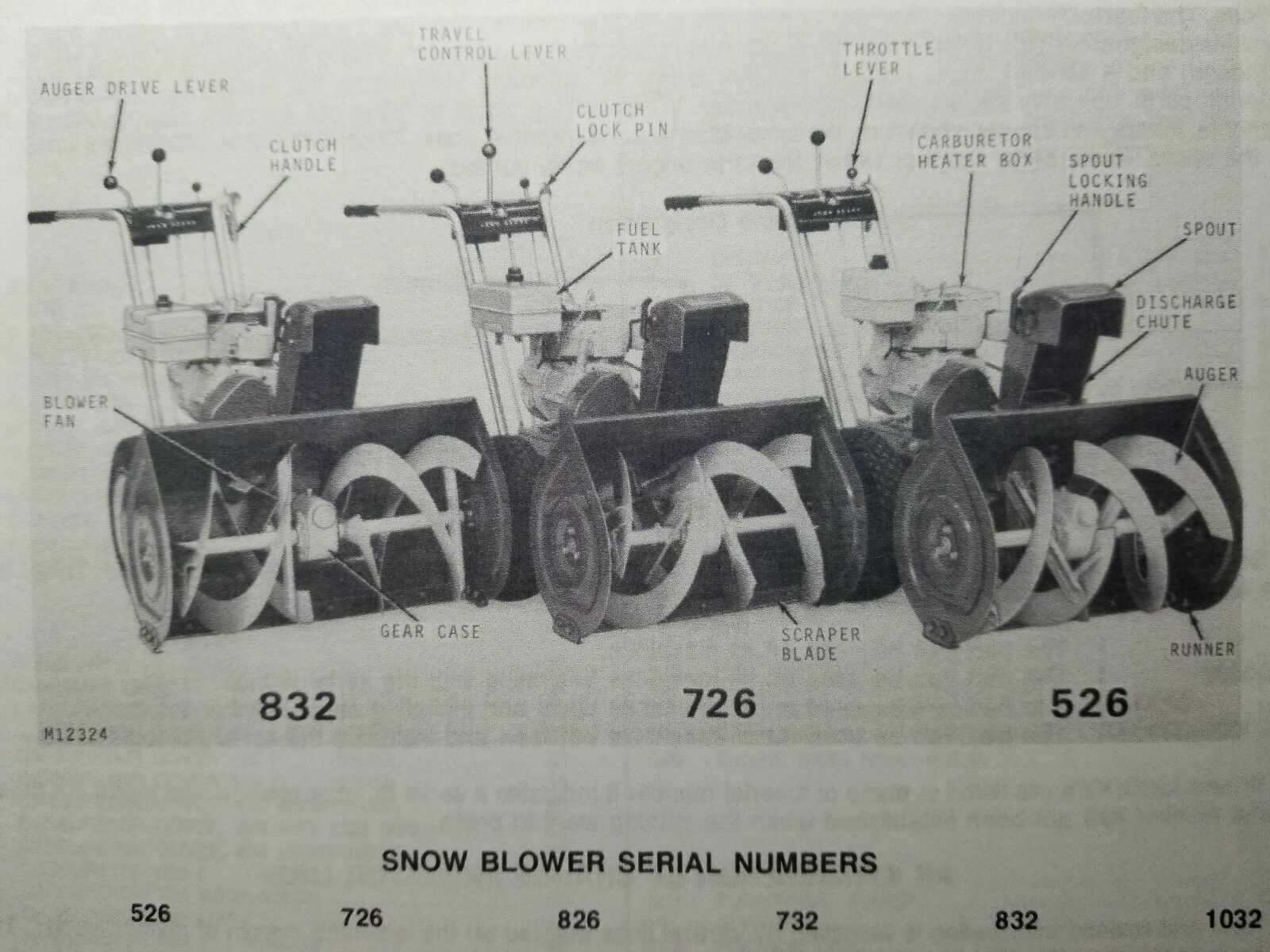

How to Read Parts Diagrams

Understanding visual schematics can greatly enhance your ability to identify components and their relationships within complex machinery. These illustrations serve as a vital resource, providing clarity on the assembly and disassembly of equipment. By familiarizing yourself with the structure and symbols used in these visuals, you can streamline maintenance and repair tasks effectively.

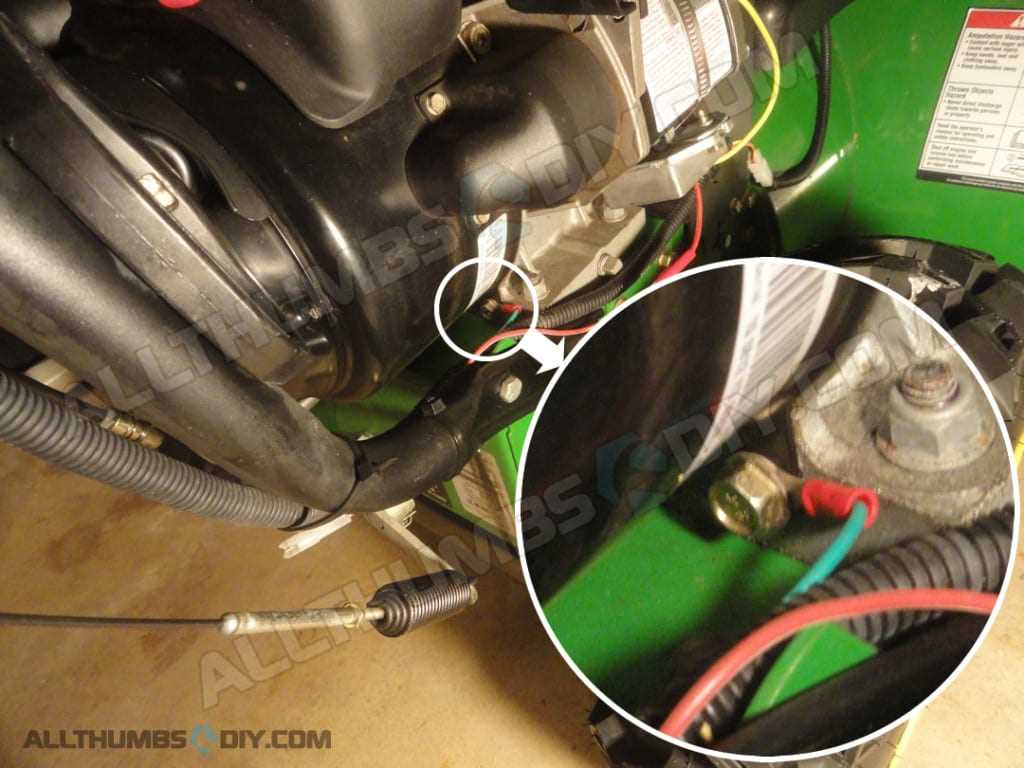

To begin, pay attention to the layout of the illustration. Most visuals will categorize elements into sections, often grouping related items together. This organizational method helps in quickly locating specific components. Additionally, each item will typically be labeled with a unique identifier, which correlates with a list or legend elsewhere in the documentation. Familiarize yourself with these identifiers to facilitate easy reference.

Next, observe the connections depicted between various elements. Lines or arrows often indicate how components are linked or interact with one another. Understanding these relationships is crucial, especially when disassembling or replacing parts. It can also provide insight into the overall functioning of the machinery.

Finally, take note of any special symbols or color codes used in the illustration. These can signify important details, such as the type of material or specific assembly instructions. Being aware of these nuances will ensure that you interpret the information accurately, leading to more efficient repairs and maintenance.

Identifying Essential Components Easily

Understanding the critical elements of your equipment is fundamental for effective maintenance and troubleshooting. This knowledge ensures that you can quickly locate and recognize individual parts, making repairs and upgrades more manageable.

To assist in the identification process, consider the following strategies:

- Reference Manuals: Always keep the user guide handy. It provides valuable information about component functions and locations.

- Online Resources: Utilize websites and forums dedicated to machinery. They often feature comprehensive breakdowns and user experiences.

- Visual Aids: Diagrams and images can significantly enhance your understanding. Look for labeled illustrations that show each part clearly.

Moreover, familiarizing yourself with common terminologies associated with your equipment can help in pinpointing specific elements when seeking assistance or purchasing replacements. Here are some key areas to focus on:

- Engine Components: Familiarize yourself with the engine’s major sections, including the carburetor and air filter.

- Drive System: Understanding belts, gears, and drive assemblies can aid in diagnosing issues related to movement and power transfer.

- Control Mechanisms: Knowing the layout of levers, switches, and controls is crucial for efficient operation.

By employing these techniques, you can simplify the process of identifying essential elements, leading to more effective upkeep and enhanced performance.

Where to Find Authentic Parts

Finding genuine components for your equipment is crucial for maintaining its performance and longevity. Authentic replacements not only ensure compatibility but also enhance the overall efficiency of your machinery. There are several reliable sources where you can locate these essential elements.

Official Dealers

One of the best ways to ensure you are acquiring original components is by visiting authorized dealerships. These establishments specialize in the brand and typically stock a comprehensive range of items. Their staff can offer expert advice and guarantee the quality of what you purchase.

Online Retailers

The internet offers a plethora of options for sourcing genuine elements. Reputable online platforms provide detailed descriptions and specifications, making it easier to find the exact replacements you need. Always check for customer reviews and ratings to verify the authenticity of the products before making a purchase.

Top Resources for Repair Guides

Finding reliable resources for maintenance and repair can significantly enhance the efficiency and longevity of your equipment. Numerous guides and manuals are available online, offering detailed instructions and diagrams that simplify the troubleshooting process. Accessing these materials not only empowers you to perform repairs confidently but also helps you understand your machinery better.

Online Forums and Communities: Engaging with fellow enthusiasts and experts through dedicated forums can provide valuable insights. Many users share their experiences, tips, and even troubleshooting techniques that may not be found in traditional manuals. This collaborative knowledge can be invaluable for resolving specific issues.

Manufacturer Websites: Official websites often provide downloadable manuals and guides. These resources typically contain accurate specifications and step-by-step instructions tailored to your model, ensuring you have the most relevant information at your fingertips.

YouTube Tutorials: Video content is an excellent resource for visual learners. Many creators post comprehensive walkthroughs, demonstrating repairs and maintenance procedures in real-time. These videos can clarify complex tasks, making them easier to follow.

DIY Repair Blogs: Numerous blogs focus on home and equipment repairs. These platforms often feature detailed articles, tips, and recommendations for tools, enhancing your repair skills and knowledge base. Regular updates from seasoned DIYers can keep you informed about the latest techniques and products.

By utilizing these resources, you can streamline your repair process and ensure your equipment operates at its best, ultimately saving time and money.

Benefits of OEM vs. Aftermarket Parts

When it comes to maintenance and repair of machinery, the choice between original equipment manufacturer (OEM) components and those produced by third-party vendors can significantly impact performance and longevity. Understanding the advantages of each option helps users make informed decisions tailored to their needs.

OEM components are designed specifically for the equipment they serve, ensuring a perfect fit and optimal performance. This precision often leads to enhanced reliability, as these items are tested rigorously to meet the original specifications set by the manufacturer. Additionally, using these components can help maintain warranty coverage and ensure compliance with any safety regulations.

On the other hand, aftermarket alternatives often provide cost savings and a wider variety of options. Many third-party manufacturers produce high-quality components that can match or even exceed the performance of OEM parts, especially for users seeking budget-friendly solutions. Furthermore, these products may offer unique features or enhancements that appeal to specific user needs.

In summary, the choice between OEM and aftermarket components hinges on factors such as performance expectations, budget considerations, and specific application requirements. Evaluating these elements allows users to select the best option for their particular situation.

Troubleshooting Common Issues

Addressing problems with your equipment can be essential for maintaining optimal performance during harsh winter conditions. Common malfunctions often stem from a few identifiable sources, and understanding these can help you efficiently resolve issues and minimize downtime.

1. Difficulty Starting

If the machine struggles to start, check the fuel level and quality. Stale or contaminated fuel can lead to ignition issues. Additionally, inspect the spark plug for wear and ensure it is properly connected.

2. Uneven Snow Clearing

When the clearing process is inconsistent, inspect the blades for damage or obstructions. Debris lodged in the chute can hinder performance, so ensure everything is free of blockages. Also, check the height settings to ensure they are appropriately adjusted for the surface.

3. Loss of Power

A noticeable drop in power may indicate a clogged air filter. Regularly cleaning or replacing the filter can help maintain efficiency. Furthermore, ensure that the engine is not overheating, as this can significantly affect performance.

4. Excessive Vibrations

Excessive shaking can be a sign of misaligned components. Examine the auger and impeller for balance and proper attachment. Tightening loose screws or bolts can also help reduce vibrations.

5. Frequent Stalling

If your machine frequently stalls during operation, it may be a sign of a fuel delivery issue. Inspect the fuel lines for kinks or leaks and verify that the fuel filter is not obstructed. Proper maintenance can prevent many of these issues from arising.

By systematically addressing these common challenges, you can extend the life of your equipment and ensure reliable operation throughout the winter season.