Toro 22210 Parts Diagram Overview

Exploring the intricacies of machinery is essential for effective maintenance and operation. Knowing how various elements interact enhances performance and longevity, allowing users to achieve optimal results in their tasks. This section aims to unravel the complexities behind these vital components.

In any mechanical system, the arrangement and functionality of each piece play a pivotal role. By visualizing how parts fit together, one can better appreciate their significance and troubleshoot potential issues. This understanding serves as the foundation for efficient repairs and replacements.

Moreover, having access to a detailed representation of these components can greatly aid both novice and experienced users. It empowers them to identify specific elements quickly, fostering confidence in their ability to manage equipment effectively. With this knowledge, the ultimate goal of seamless operation becomes attainable.

Parts Overview

This section provides an insightful look into the essential components of a specific model, detailing their functions and significance. Understanding the various elements involved enhances both maintenance and operation, ensuring optimal performance.

Key Components are integral to the machinery’s efficiency. Each element, from the drive system to the cutting mechanism, plays a crucial role in the overall functionality. Proper knowledge of these parts aids users in troubleshooting and repair, minimizing downtime.

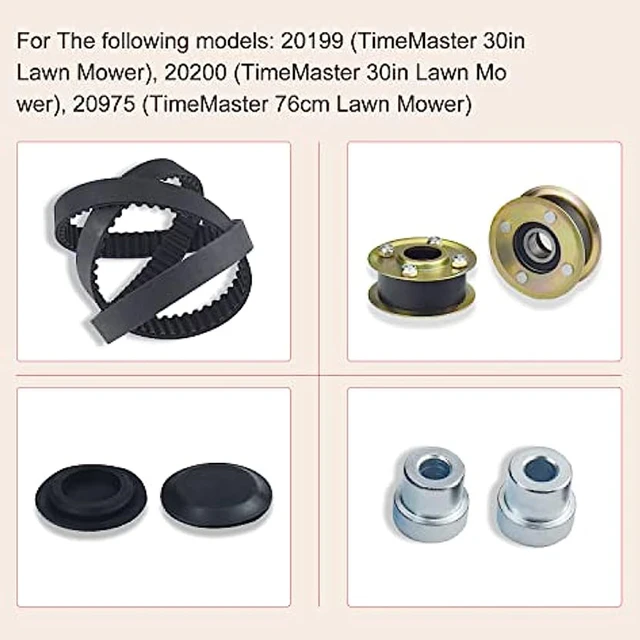

Replacement Options are available for various elements, ensuring longevity and reliability. It is essential to choose high-quality substitutes to maintain the integrity of the equipment. Familiarity with the component specifications can guide users in selecting the right parts for their needs.

Regular Maintenance Practices are vital for sustaining the performance of each element. Periodic inspections and timely replacements can prevent significant issues, contributing to the longevity of the entire system.

By gaining a comprehensive understanding of the various components and their functions, users can enhance their experience and ensure the machinery operates at peak efficiency.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding how different elements interact within a system. They provide clarity, allowing users to identify and locate specific items effortlessly. This understanding is essential for maintenance, repairs, and upgrades.

Benefits of Visual Representations

- Enhances comprehension of complex systems

- Facilitates efficient troubleshooting and repairs

- Helps in identifying compatible components for replacements

- Assists in streamlining assembly processes

Applications in Various Fields

- Manufacturing: Streamlining production lines

- Automotive: Assisting in repairs and servicing

- Electronics: Guiding assembly and maintenance

- Aerospace: Ensuring precision in component integration

Key Components of Toro 22210

Understanding the essential elements of a specific lawn maintenance tool is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance, reliability, and longevity of the equipment. This section highlights the fundamental parts that contribute to the functionality of this machine.

Major Elements

Among the critical components, the engine and cutting mechanism are paramount. These parts work in tandem to provide the necessary power and precision for lawn care tasks. Additionally, the control system enhances user interaction, ensuring a smooth and effective experience.

Functionality Overview

| Component | Function |

|---|---|

| Engine | Drives the machine, providing power for operation. |

| Cutting Blade | Ensures precise cutting of grass to desired lengths. |

| Control Panel | Allows the operator to adjust settings and monitor performance. |

| Wheels | Facilitate movement across various terrains. |

| Frame | Supports all components and provides stability. |

Recognizing these key elements not only aids in better understanding the tool but also ensures proper care and maintenance practices are followed.

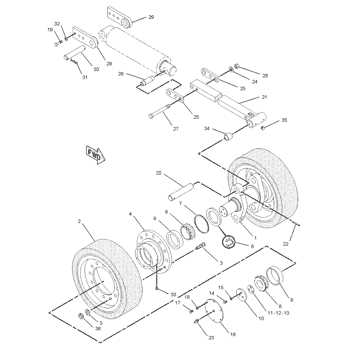

How to Read Parts Diagrams

Understanding visual schematics is essential for identifying components and their interrelations in various equipment. These illustrations serve as a roadmap, helping users locate necessary elements for maintenance or repair. Grasping the structure and symbols used in these visuals will enhance your efficiency and accuracy during tasks.

Familiarizing with Symbols

Every illustration employs specific icons and notations to represent different pieces. Take time to study the legend or key provided, as it will clarify what each symbol denotes. Recognizing these can drastically reduce confusion when seeking replacements or understanding assembly.

Tracing Connections

Another crucial aspect is following the links between components. Observe the lines and arrows that indicate how items fit together or function in conjunction. This will provide insight into the overall operation, assisting in effective troubleshooting and ensuring optimal performance.

Common Replacement Parts Explained

Understanding the components that may require replacement is crucial for maintaining equipment efficiency. Many users encounter specific items that wear out over time, affecting overall performance. This section delves into the most frequently needed elements and their functions.

| Component | Function | Signs of Wear |

|---|---|---|

| Air Filter | Filters debris and particles from the air intake. | Reduced airflow, visible dirt buildup. |

| Spark Plug | Ignites the fuel-air mixture for combustion. | Hard starting, misfiring, or poor acceleration. |

| Blades | Cuts grass or other vegetation efficiently. | Uneven cuts, noticeable damage or dullness. |

| Belt | Transfers power from the engine to the cutting mechanism. | Squeaking noises, visible cracks, or fraying. |

| Fuel Filter | Prevents contaminants from entering the engine. | Engine stalling, poor acceleration, fuel leaks. |

Maintenance Tips for Toro 22210

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. By following some simple practices, you can enhance efficiency and prevent potential issues down the line. These strategies will help you keep your machine in top condition, ensuring reliable operation throughout its lifespan.

Routine Checks

Perform frequent inspections of critical components, including the blades, belts, and filters. Cleaning debris and ensuring proper lubrication can significantly extend their life. Additionally, checking for any signs of wear or damage will allow for timely repairs before they escalate into larger problems.

Seasonal Maintenance

At the beginning of each season, give your machine a thorough review. Replace worn-out parts, sharpen blades, and change fluids as needed. This proactive approach will help you tackle any challenges head-on and ensure that your equipment performs at its best when you need it most.

Finding Genuine Toro Parts

When it comes to maintaining equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Using original items not only guarantees compatibility but also enhances reliability, ultimately providing peace of mind during operation.

Researching Authorized Dealers is an effective way to access quality components. Many manufacturers have a network of certified retailers who can offer the genuine articles you need. Always verify the dealer’s credentials to avoid counterfeit products.

Online Resources are invaluable tools for finding the right items. Manufacturer websites often have dedicated sections for replacement goods, complete with specifications and compatibility information. Additionally, reputable marketplaces may have sections for verified products, ensuring you receive what you ordered.

Consulting User Manuals can provide essential insights into the specific components required for your equipment. These manuals typically list part numbers and specifications, making it easier to identify and order the right items.

Lastly, community forums and discussion groups can offer recommendations and experiences from other users, helping you navigate the selection process and find reliable sources for authentic components.

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right equipment at your disposal is essential. The appropriate tools not only facilitate the repair process but also ensure safety and efficiency. Below is a list of common implements you will need for various tasks.

Essential Hand Tools

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for removing and securing screws.

- Wrenches: Adjustable and socket wrenches help in loosening or tightening nuts and bolts.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Hammer: For driving nails or breaking apart components that are stuck.

Specialized Equipment

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Multimeter: Essential for diagnosing electrical issues and measuring voltage, current, and resistance.

- Jack Stands: Provide stability when working under heavy machinery.

- Safety Gear: Includes gloves, goggles, and masks to protect yourself during repairs.

Online Resources for Parts Information

When it comes to maintaining and repairing various mechanical equipment, having access to detailed breakdowns of components is essential. Many platforms offer extensive databases that help identify and locate the necessary items for repair. These resources are crucial for anyone looking to ensure their equipment remains in optimal working condition.

Specialized Websites for Component Details

Numerous websites provide comprehensive catalogs that allow users to search for specific equipment models and view detailed illustrations. These online tools are especially helpful for understanding the assembly and disassembly process, as they typically include diagrams that map out each component. They also provide information on where to source the required items, ensuring users can find what they need efficiently.

Manufacturer and Vendor Platforms

Official manufacturer websites and vendor platforms often offer user-friendly search functions for locating specific details. These platforms are typically well-organized and frequently updated, offering not only basic information but also compatibility data, ensuring that users can easily find the correct replacements for their equipment.

Frequently Asked Questions

This section addresses some of the most common inquiries about maintaining and servicing lawn equipment. It provides helpful information to ensure users can keep their machines running efficiently and troubleshoot basic issues.

| Question | Answer |

|---|---|

| What regular maintenance is required? | Routine checks such as oil changes, air filter replacements, and blade sharpening should be done periodically to ensure optimal performance. |

| How can I troubleshoot starting issues? | Check the fuel level, spark plug condition, and battery. Clean any debris from key components to ensure proper function. |

| What is the recommended cleaning process? | After each use, clean the underside of the machine, remove grass clippings, and inspect for any wear or damage to avoid long-term issues. |

Comparing Toro Models and Parts

When analyzing various lawn equipment models, it’s essential to recognize the differences in their features and components. Each model is designed with specific tasks in mind, making the comparison between them crucial for selecting the right machine for your needs. Understanding these variations can help in identifying which features align with your specific requirements.

- Performance – Different machines offer varying levels of power and efficiency, suited for different lawn sizes and terrains.

- Durability – Some models are built with heavier-duty materials, designed for long-term use and demanding conditions.

- Maintenance – Ease of upkeep can vary, with some equipment requiring simpler adjustments or replacements than others.

- Versatility – Certain models may come with adaptable features or be compatible with a wider range of accessories and extensions.

By considering these factors, it’s easier to pinpoint the model that best meets your performance and maintenance expectations.

Understanding Warranty Coverage

Warranty coverage is essential for protecting your investment in equipment. It offers assurance that any potential issues will be addressed by the manufacturer within a specified period. This section will help you navigate the basics of what is typically covered, as well as any limitations or conditions that may apply.

- Duration of Coverage: Warranties usually provide protection for a certain number of years or operational hours, whichever comes first.

- Covered Components: Many warranties cover specific parts of the equipment, often focusing on the most critical elements like the engine, drivetrain, or electrical systems.

- Exclusions and Limitations: It’s important to understand what is not covered. Damage due to misuse, improper maintenance, or unauthorized repairs may void the warranty.

- Claim Process: To take advantage of the warranty, you will need to follow the manufacturer’s claim procedure, which typically involves providing proof of purchase and a detailed description of the issue.

By understanding these key points, you can ensure that you are prepared in case

Customer Support for Toro Products

Effective customer assistance is vital for ensuring users can maximize the use of their equipment. Comprehensive support services include troubleshooting, technical advice, and product care information. These services provide customers with detailed guidance, helping them maintain and operate their devices efficiently.

Users can access various forms of help, such as online resources, manuals, and dedicated hotlines. The goal is to offer easy access to expert assistance, ensuring smooth and reliable use of equipment for both beginners and experienced users. Regular updates and personalized support further enhance the customer experience.