Understanding the John Deere 648R Parts Diagram

When it comes to heavy machinery, having a clear understanding of the various components and their organization is essential for optimal performance and maintenance. Each machine comprises numerous elements that work in unison, and grasping their arrangement can significantly aid in troubleshooting and repairs. This knowledge not only enhances efficiency but also extends the lifespan of the equipment.

In this section, we delve into the intricate relationships between different mechanical parts. By exploring how each element fits into the overall framework, operators and technicians can better appreciate the engineering behind the machinery. A comprehensive visualization of these components helps demystify the complexities involved in operation and upkeep.

Equipped with detailed illustrations and descriptions, users will find it easier to identify individual parts and understand their functions. This clarity is crucial for both routine maintenance and addressing specific issues that may arise during operation. Ultimately, such insights contribute to smoother workflows and reduced downtime.

Understanding John Deere 648R Parts

When it comes to maintaining and repairing machinery, a comprehensive grasp of components is essential. This knowledge enables operators to ensure their equipment functions smoothly and efficiently. Familiarity with individual elements can significantly enhance performance and longevity.

Key elements of these machines include:

- Hydraulic systems

- Transmission units

- Frame structures

- Engine components

- Electrical systems

Each of these categories encompasses various sub-components that play a vital role in the overall operation. Understanding these parts allows for:

- Effective troubleshooting

- Streamlined maintenance

- Informed decision-making when replacing elements

For optimal performance, it is important to refer to detailed visual representations of these components. Such resources can aid in identifying specific parts and their functions, ensuring that users can efficiently address any issues that may arise.

In conclusion, a solid understanding of these crucial elements fosters better maintenance practices, enhances operational efficiency, and ultimately contributes to the longevity of the equipment.

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for efficient maintenance and repair processes. Such illustrations facilitate a better understanding of the relationships between various elements, helping users identify the necessary items for replacements or repairs. This clarity not only streamlines tasks but also reduces the likelihood of errors that could lead to further complications.

Enhancing Efficiency

When individuals can easily reference well-organized schematics, they can complete their work more quickly. This efficiency is particularly important in environments where time is of the essence. Technicians can swiftly pinpoint what needs attention, ensuring that machines are back in operation with minimal downtime.

Reducing Costs

Accurate visual aids contribute to cost savings in several ways. First, they help prevent the purchase of incorrect items, thereby minimizing waste. Second, they assist in identifying issues early, which can prevent more significant and expensive repairs in the future. Overall, clear and detailed illustrations serve as a valuable resource for both professionals and enthusiasts alike.

| Benefit | Description |

|---|---|

| Time-saving | Speeds up identification of needed components. |

| Error reduction | Minimizes mistakes in selecting and replacing items. |

| Cost efficiency | Decreases unnecessary expenditures on incorrect parts. |

| Enhanced understanding | Provides clear insights into the assembly and function of components. |

Key Components of 648R Equipment

This section delves into the essential elements that contribute to the functionality and efficiency of this particular machinery. Understanding these components allows operators to maintain optimal performance and enhance the longevity of the equipment.

| Component | Description | Function |

|---|---|---|

| Engine | A robust power unit designed for high performance. | Drives the machine and powers various systems. |

| Hydraulic System | Consists of pumps, cylinders, and valves. | Facilitates the movement and operation of attachments. |

| Transmission | Gearbox responsible for speed and torque management. | Enables smooth operation and control of the vehicle. |

| Chassis | The structural framework that supports all components. | Provides stability and durability to the equipment. |

| Control System | User interface for operating the machinery. | Allows precise handling and monitoring of functions. |

Familiarity with these key components empowers users to effectively manage maintenance tasks and troubleshoot potential issues, ensuring the machinery operates at peak efficiency.

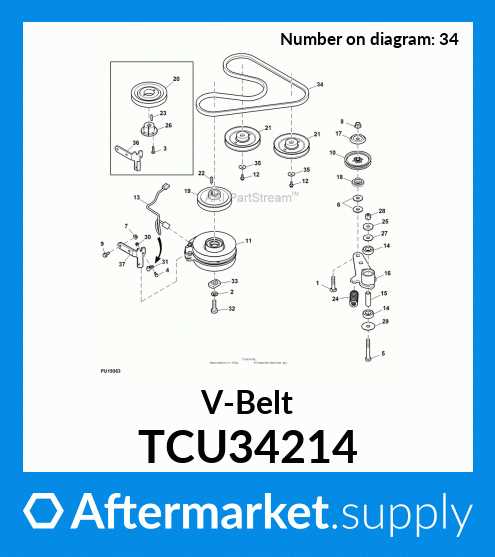

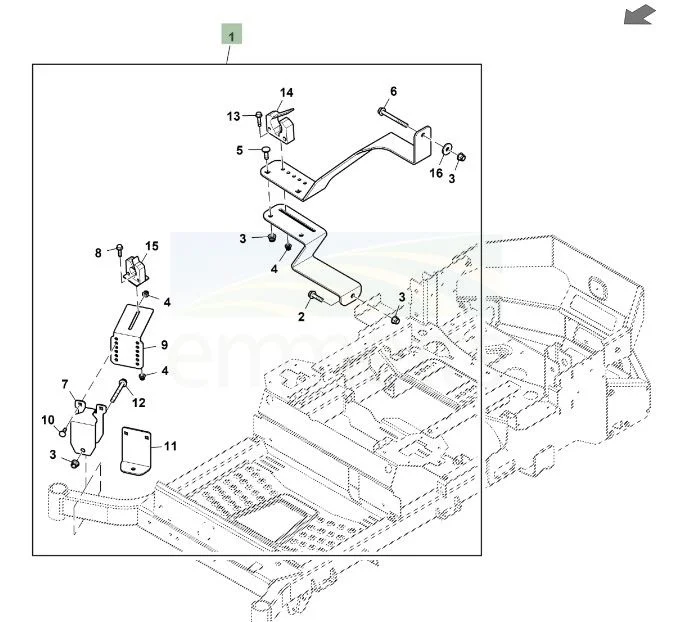

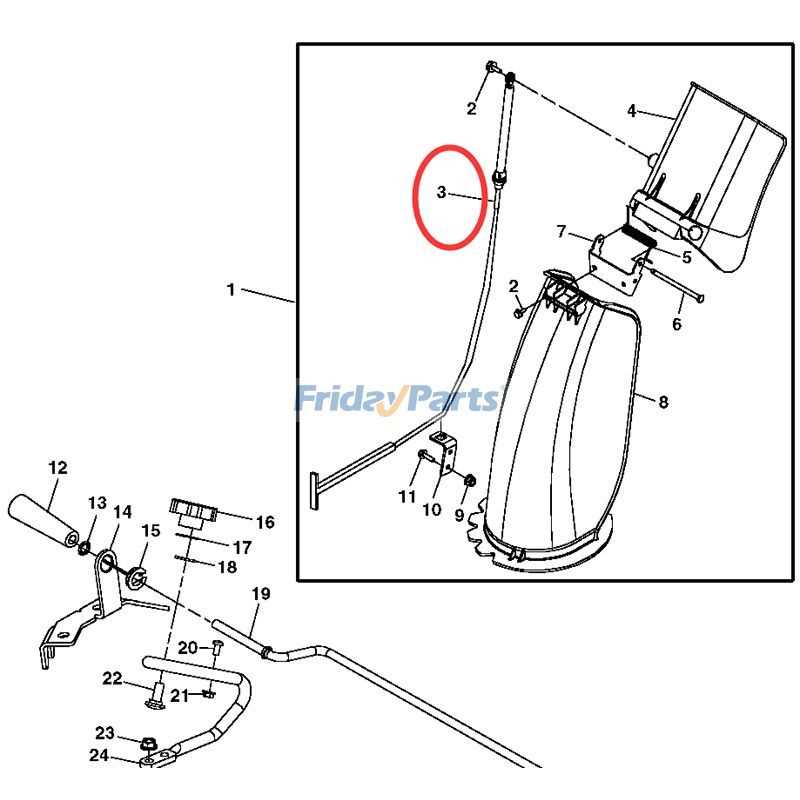

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide insights into the assembly and relationships between various elements, allowing users to identify and locate necessary pieces efficiently.

Key Elements to Identify

Focus on the labels and numbers that correspond to specific components. Each symbol often represents a unique part, making it easier to pinpoint what is needed for replacements or repairs.

Understanding Relationships

Pay attention to lines and connections that show how different elements interact. Recognizing these links can help you understand the overall structure and functionality, ultimately guiding you in troubleshooting and assembly processes.

Common Issues with John Deere Parts

When it comes to equipment maintenance, certain challenges frequently arise that can affect performance and longevity. Understanding these common problems can help users mitigate issues and ensure smoother operation.

Wear and Tear: Regular use can lead to gradual degradation of components. Over time, parts may lose their effectiveness, requiring timely replacements to maintain optimal functionality.

Compatibility Problems: Not all components fit perfectly across different models. Users may encounter difficulties when trying to install aftermarket or used items, which can result in improper function.

Quality Variations: The market offers a range of options, but the quality can vary significantly. Choosing inferior items may lead to early failures and increased maintenance costs.

Installation Challenges: Some components require specific tools or expertise for proper installation. Incorrect fitting can lead to further complications and damage to other areas of the machinery.

Supply Chain Issues: Availability of certain components can sometimes be problematic, especially during peak seasons. Delays in obtaining necessary items can hinder repair timelines and productivity.

Ordering Replacement Parts Efficiently

Efficient procurement of components is essential for maintaining optimal functionality in machinery. Understanding the process can save time and resources, ensuring swift repairs and minimal downtime. This section explores strategies to streamline the ordering process.

Identify Your Needs: Begin by clearly defining what you require. Accurate identification of the specific components can prevent misorders and delays.

Utilize Reliable Sources: Engage with trusted suppliers or platforms known for their comprehensive catalogs. This ensures access to high-quality alternatives and compatibility.

Organize Information: Keep a detailed list of part numbers and descriptions. This facilitates faster searches and helps maintain organization during the ordering process.

Leverage Technology: Consider using online tools and apps designed for tracking and managing orders. These resources can significantly enhance efficiency.

Plan for the Future: Anticipate future needs by maintaining a stock of commonly used components. This proactive approach minimizes delays during critical repairs.

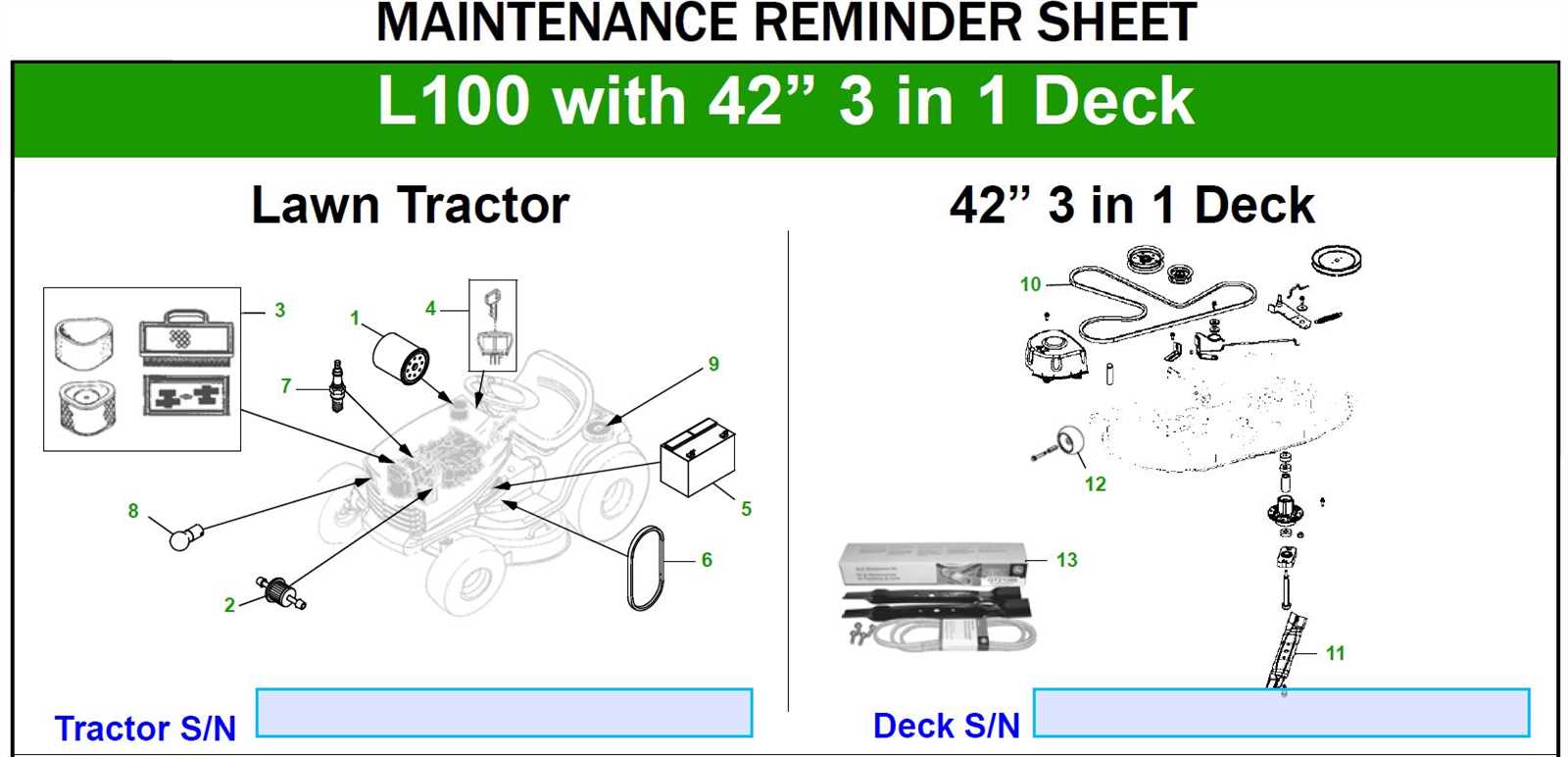

Maintenance Tips for 648R Machinery

Regular upkeep of heavy equipment is essential for optimal performance and longevity. Ensuring that each component functions smoothly not only enhances productivity but also prevents costly repairs. Following a systematic maintenance routine will help you achieve these goals.

1. Regular Inspections: Conduct frequent checks of the machinery to identify any signs of wear and tear. Look for leaks, unusual noises, and any changes in performance. Early detection can save time and resources.

2. Cleanliness is Key: Keeping the equipment clean prevents dirt and debris from causing damage. Regularly wash the exterior and ensure that all moving parts are free from contaminants.

3. Lubrication: Proper lubrication of all moving components is crucial. Use high-quality lubricants to minimize friction and wear. Refer to the manufacturer’s recommendations for specific lubrication points.

4. Filter Replacement: Regularly check and replace filters to maintain air and fluid quality. Clogged filters can lead to decreased efficiency and potential engine damage.

5. Monitor Fluid Levels: Regularly check oil, coolant, and hydraulic fluid levels. Maintaining the correct levels is vital for the smooth operation of machinery.

6. Schedule Professional Servicing: Even with diligent maintenance, periodic professional servicing is necessary. Certified technicians can perform in-depth inspections and address issues that may go unnoticed.

7. Keep Documentation: Maintain detailed records of all maintenance activities. This documentation can help track performance over time and is useful for future reference or resale.

By following these maintenance tips, you can ensure that your machinery operates efficiently, providing reliable service for years to come.

Where to Find Official Diagrams

Accessing accurate and detailed illustrations for equipment can significantly enhance maintenance and repair efforts. These visuals provide essential insights into component arrangements and functionalities, ensuring that users can effectively troubleshoot and replace parts as needed.

Official Manufacturer Resources

One of the most reliable sources for these illustrations is the official website of the manufacturer. Here are steps to locate them:

- Visit the manufacturer’s homepage.

- Navigate to the support or resources section.

- Look for a category related to service manuals or technical documentation.

- Utilize the search function to find specific models or equipment.

Authorized Dealers and Service Centers

Authorized dealers often have access to exclusive resources and can provide valuable support:

- Contact local dealers directly for assistance.

- Request printed or digital copies of relevant illustrations.

- Inquire about any training sessions or workshops that might include visual aids.

Utilizing these channels ensures that you have the most accurate and up-to-date information for your machinery.

Comparing 648R with Other Models

This section explores the differences and similarities between a specific model and its counterparts in the same category. Understanding these variations can aid in making an informed decision when considering which machine best suits particular needs. Each model offers unique features, performance capabilities, and design elements that cater to various applications.

Performance: One of the primary distinctions lies in performance metrics such as horsepower and operational efficiency. While some models excel in power delivery, others may focus on fuel economy, providing options for users with varying priorities.

Durability: Constructed with different materials and engineering approaches, each machine showcases varying levels of durability and longevity. Users should assess how often they plan to use the equipment and under what conditions to select the most resilient option.

Features: Technological advancements play a significant role in differentiating models. Features such as advanced hydraulic systems, user-friendly controls, and integrated safety mechanisms can enhance productivity and user experience. Comparing these attributes can reveal which model aligns best with individual preferences.

Cost: Budget considerations are crucial when evaluating different machines. Prices can vary widely based on brand reputation, features, and capabilities. It’s essential to balance the initial investment with long-term value, factoring in maintenance and operating costs.

In conclusion, a thorough comparison between this model and its competitors can illuminate the best choice for prospective buyers, ensuring that they select a machine that meets their specific requirements and expectations.

Impact of Quality Parts on Performance

The significance of using high-quality components in machinery cannot be overstated. Superior materials and precise engineering play a crucial role in enhancing the functionality, durability, and overall efficiency of equipment. When reliable elements are utilized, operators can expect improved performance and reduced downtime.

Benefits of High-Quality Components

- Enhanced Durability: Quality materials withstand wear and tear, extending the lifespan of machinery.

- Improved Efficiency: Precision-engineered components ensure optimal performance, leading to better fuel consumption and reduced energy costs.

- Reduced Maintenance Needs: Reliable elements require less frequent replacements, saving time and resources.

- Increased Safety: Well-manufactured parts minimize the risk of failure, ensuring a safer working environment.

Impact on Operational Costs

Investing in quality components can significantly influence operational expenses. Although the initial cost may be higher, the long-term savings often outweigh this investment.

- Lower repair costs due to fewer breakdowns.

- Decreased labor costs from reduced maintenance time.

- Higher resale value, as equipment with quality components retains its worth better.

Ultimately, choosing superior elements not only enhances performance but also promotes a more sustainable and economically viable operation.

FAQs About John Deere 648R Parts

This section addresses common inquiries regarding components and maintenance for a popular equipment model. Understanding these aspects can enhance the longevity and performance of your machinery, ensuring it operates smoothly.

What are the most frequently replaced components?

Regular wear and tear often affects items such as belts, filters, and bearings. These parts are crucial for optimal functioning and may need periodic inspection and replacement.

Where can I find replacement components?

Replacement items can typically be sourced from authorized dealers, specialized retailers, or online marketplaces that focus on agricultural machinery. Ensure that the quality meets the manufacturer’s standards.

How can I identify the correct components for my model?

Referencing the owner’s manual is the best practice. Additionally, many manufacturers provide online resources that list specifications and compatible components based on serial numbers.

Are aftermarket options reliable?

Aftermarket alternatives can be cost-effective, but quality varies. It’s advisable to research the brand and read reviews to ensure reliability and compatibility with your specific model.

What maintenance practices can prolong the life of my equipment?

Regular inspections, timely replacements, and adhering to the maintenance schedule outlined in the owner’s manual are essential. Keeping the machinery clean and lubricated also contributes to its durability.

Can I perform repairs myself, or should I seek professional help?

Simple repairs and replacements can often be done independently if you possess the necessary skills and tools. However, complex issues are best handled by trained professionals to avoid further damage.