Understanding the Husqvarna Z4822 Parts Diagram

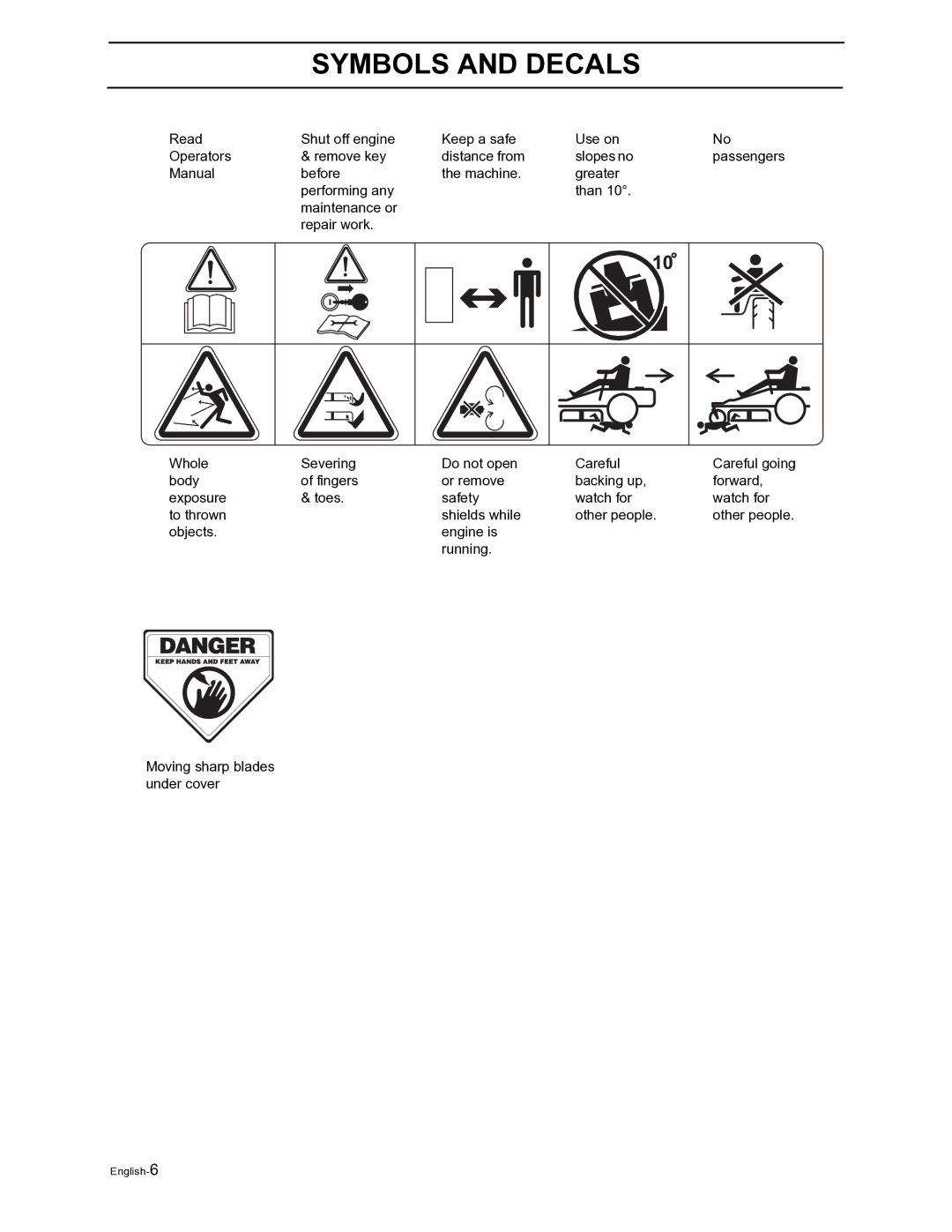

In the world of outdoor machinery, maintaining efficiency and performance is crucial. Knowing the intricate layout of your machine’s components can significantly enhance your ability to service and troubleshoot issues. This knowledge not only ensures longevity but also maximizes productivity during operation.

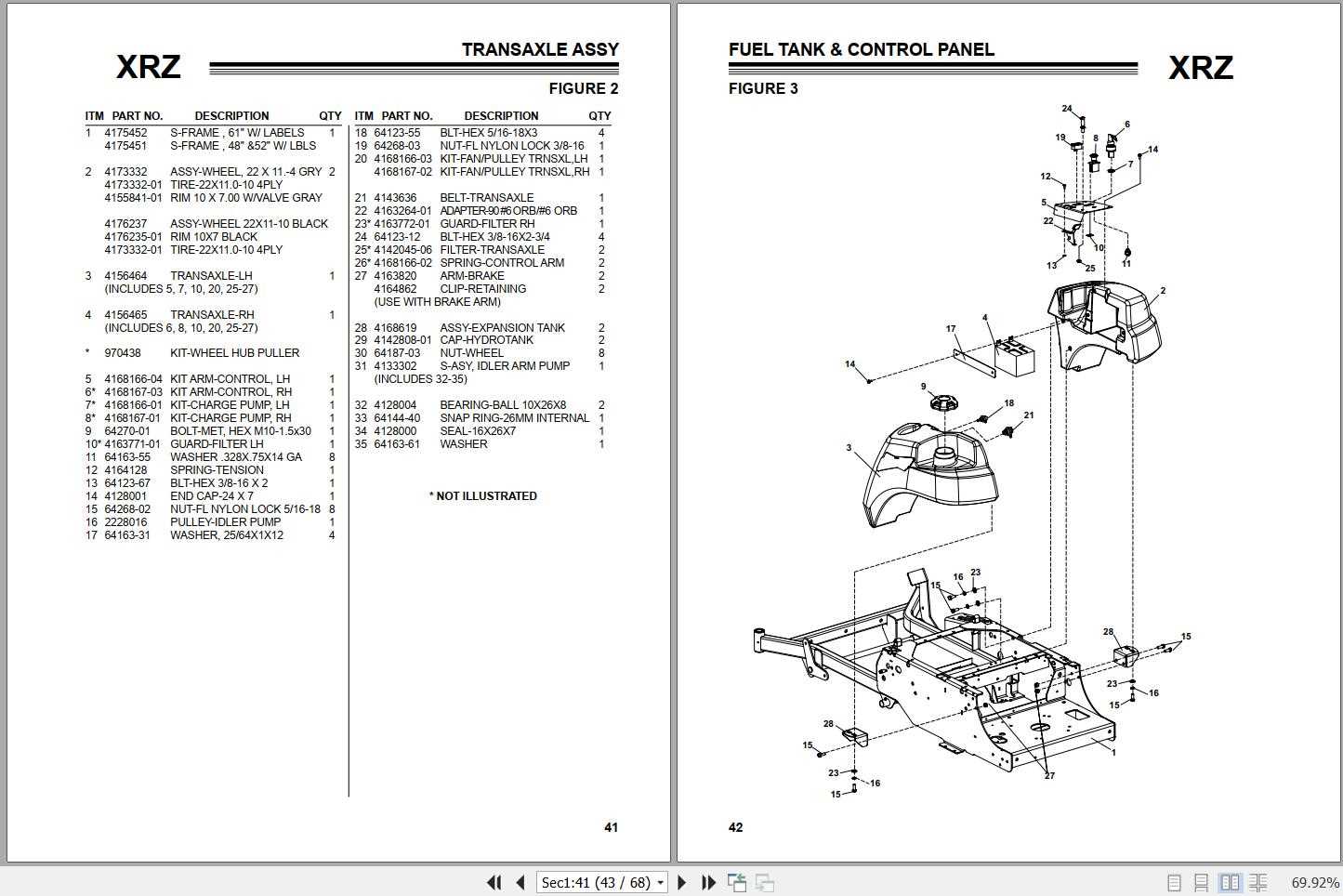

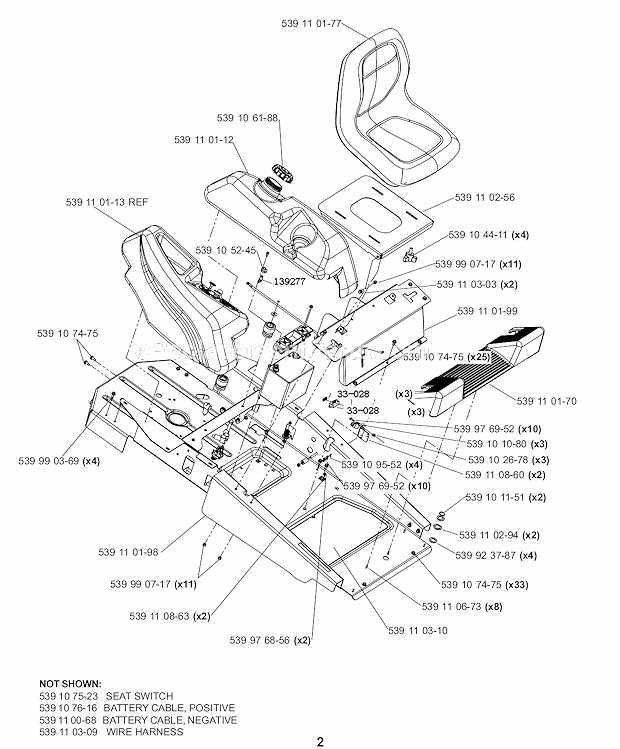

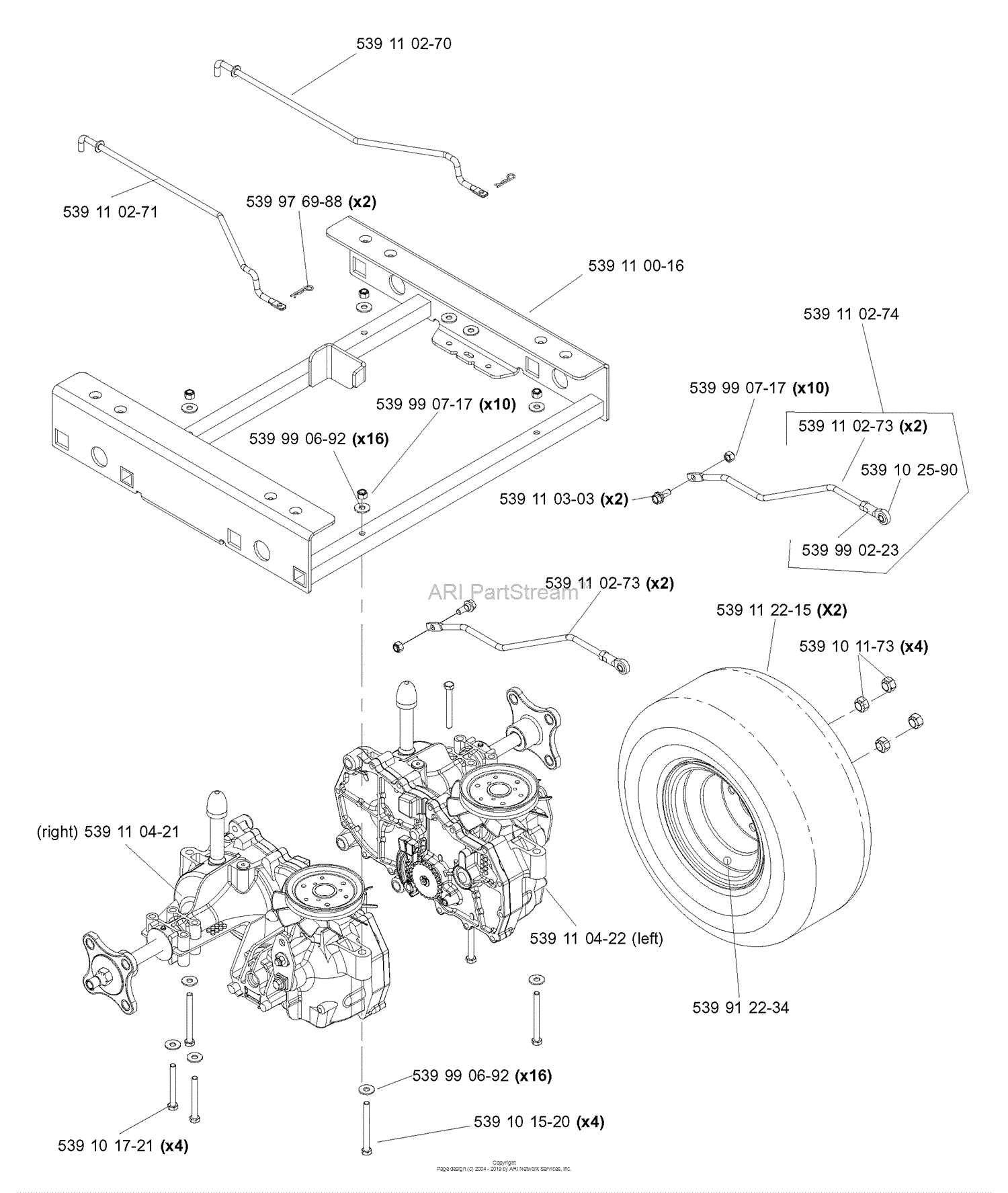

For those seeking to explore the assembly of their equipment, visual representations serve as invaluable tools. They provide a clear overview of the individual elements, highlighting how each piece interacts within the system. By delving into these representations, users can identify parts easily and understand their ultimate functions.

Whether you are a seasoned professional or a dedicated hobbyist, familiarizing yourself with the configuration of your machinery will empower you in maintenance tasks. This insight fosters a deeper appreciation for the technology at your disposal and encourages proactive care of your equipment.

Understanding Husqvarna Z4822 Components

Grasping the intricacies of machinery components is essential for effective maintenance and optimal performance. Each element plays a crucial role in the overall functionality, contributing to a seamless operation.

Key elements to consider include:

- Engine: The heart of the system, providing necessary power.

- Transmission: Facilitates the transfer of energy, allowing for speed and control.

- Deck: Houses cutting blades, essential for efficient grass management.

- Wheels: Ensure mobility and maneuverability across various terrains.

- Controls: User interface for adjusting settings and operation modes.

Understanding these components allows for informed troubleshooting and maintenance, ultimately enhancing longevity and performance.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements not only enhance comprehension but also streamline the process of identifying issues and solutions. Here are key reasons why these illustrations are essential:

- Enhanced Clarity: Visual aids simplify complex assemblies, making it easier to grasp how different pieces interact.

- Efficient Troubleshooting: Quick identification of faulty components accelerates the repair process.

- Improved Communication: Technicians can share insights and recommendations more effectively using standardized visuals.

- Inventory Management: Knowing specific elements helps in maintaining appropriate stock levels for replacements.

- Guided Assembly: Step-by-step visuals assist in reassembling machinery correctly after repairs.

Utilizing these resources not only saves time but also ensures that repairs are done accurately, enhancing the longevity and performance of the equipment.

Common Issues with Z4822 Models

Every machine can experience challenges over time, and certain models are more prone to specific problems. Understanding these common issues can help users maintain optimal performance and extend the lifespan of their equipment.

Starting Difficulties: One frequent concern is trouble with ignition. This may stem from battery issues, faulty spark plugs, or fuel supply problems.

Engine Performance: Users often report reduced power or stalling. This can be attributed to clogged air filters, old fuel, or issues with the carburetor.

Blade Issues: Dull or misaligned blades can lead to poor cutting performance. Regular sharpening and proper alignment are essential for effective operation.

Hydraulic Problems: Leaks or slow response times in hydraulic systems can hinder functionality. Routine checks for leaks and fluid levels are vital for maintenance.

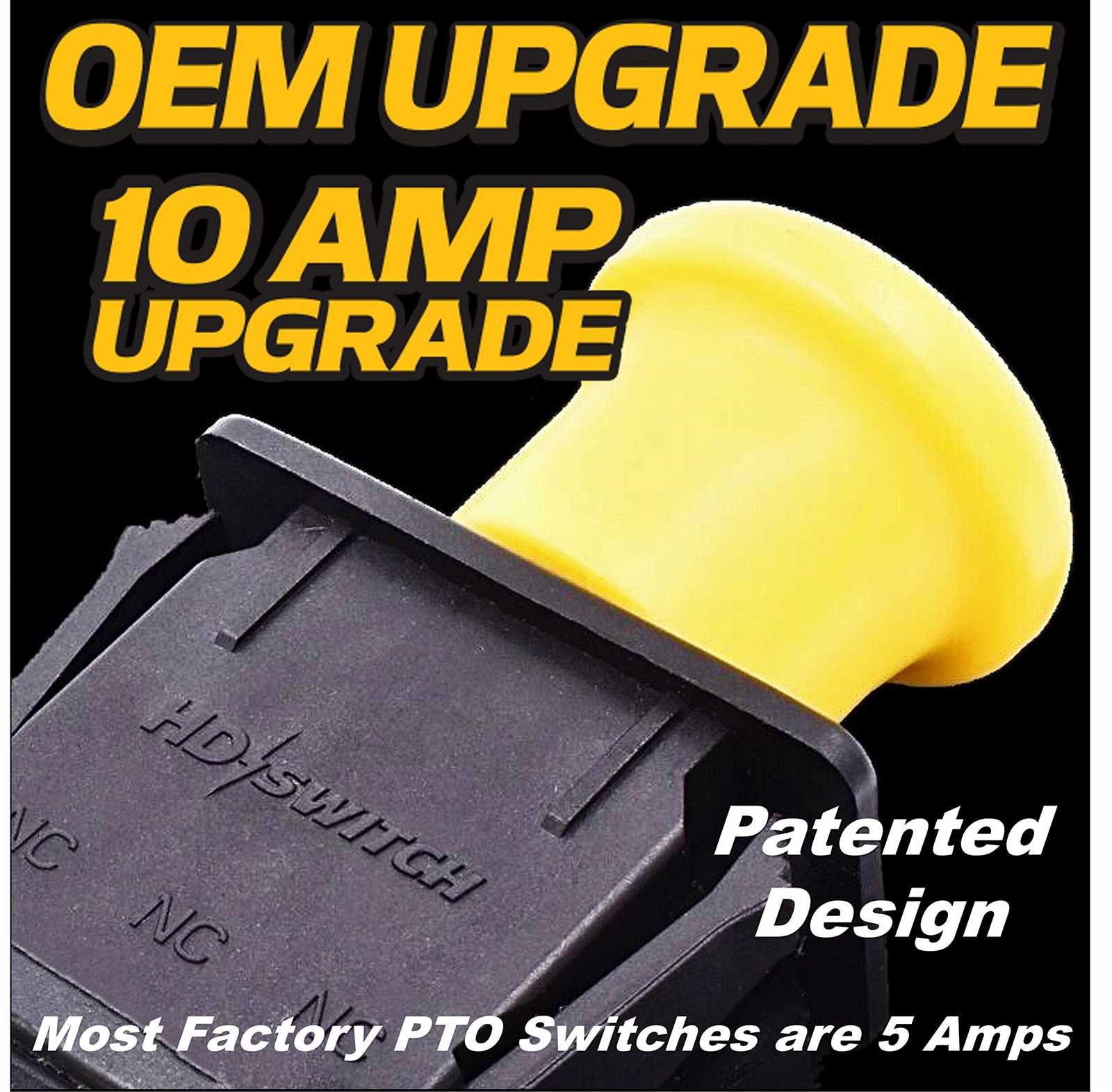

Electrical Failures: Faulty wiring or blown fuses may disrupt operation. Ensuring all connections are secure can prevent unexpected shutdowns.

By being aware of these prevalent challenges, users can proactively address them, ensuring their equipment operates at peak efficiency.

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repairs. These visual representations offer a clear breakdown of components and their relationships, enabling users to identify and locate each part with ease. By familiarizing yourself with these illustrations, you can streamline the process of ordering replacements or performing repairs.

When approaching these visuals, pay attention to the following elements:

| Element | Description |

|---|---|

| Numbers | Each component is typically assigned a unique identifier, making it easier to reference in manuals or parts lists. |

| Lines | Connecting lines often indicate how parts fit together or interact, providing insights into assembly or disassembly. |

| Legend | A key or legend may be included, explaining symbols or color codes used within the representation. |

| Groupings | Components may be grouped by function or assembly, aiding in understanding complex structures. |

By mastering these aspects, you will enhance your ability to effectively interpret these visuals, facilitating a smoother repair experience.

Key Parts of the Z4822

This section highlights essential components of the model, focusing on their functions and significance in overall performance. Understanding these elements is crucial for optimal operation and maintenance.

Engine Assembly

The engine assembly serves as the heart of the machine, providing the necessary power for various tasks. It encompasses key features that enhance efficiency and durability.

Transmission System

The transmission system is vital for transferring power from the engine to the wheels. It allows for smooth operation and adaptability across different terrains, ensuring an ultimate driving experience.

Maintenance Tips for Z4822 Owners

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular attention to various components can prevent issues and enhance efficiency, ultimately resulting in a more satisfying user experience.

Start by routinely checking the engine oil level and replacing it as recommended in the manual. Clean or replace the air filter to ensure smooth airflow and engine performance. Inspect the blades for sharpness and damage, sharpening or replacing them as needed to maintain cutting efficiency.

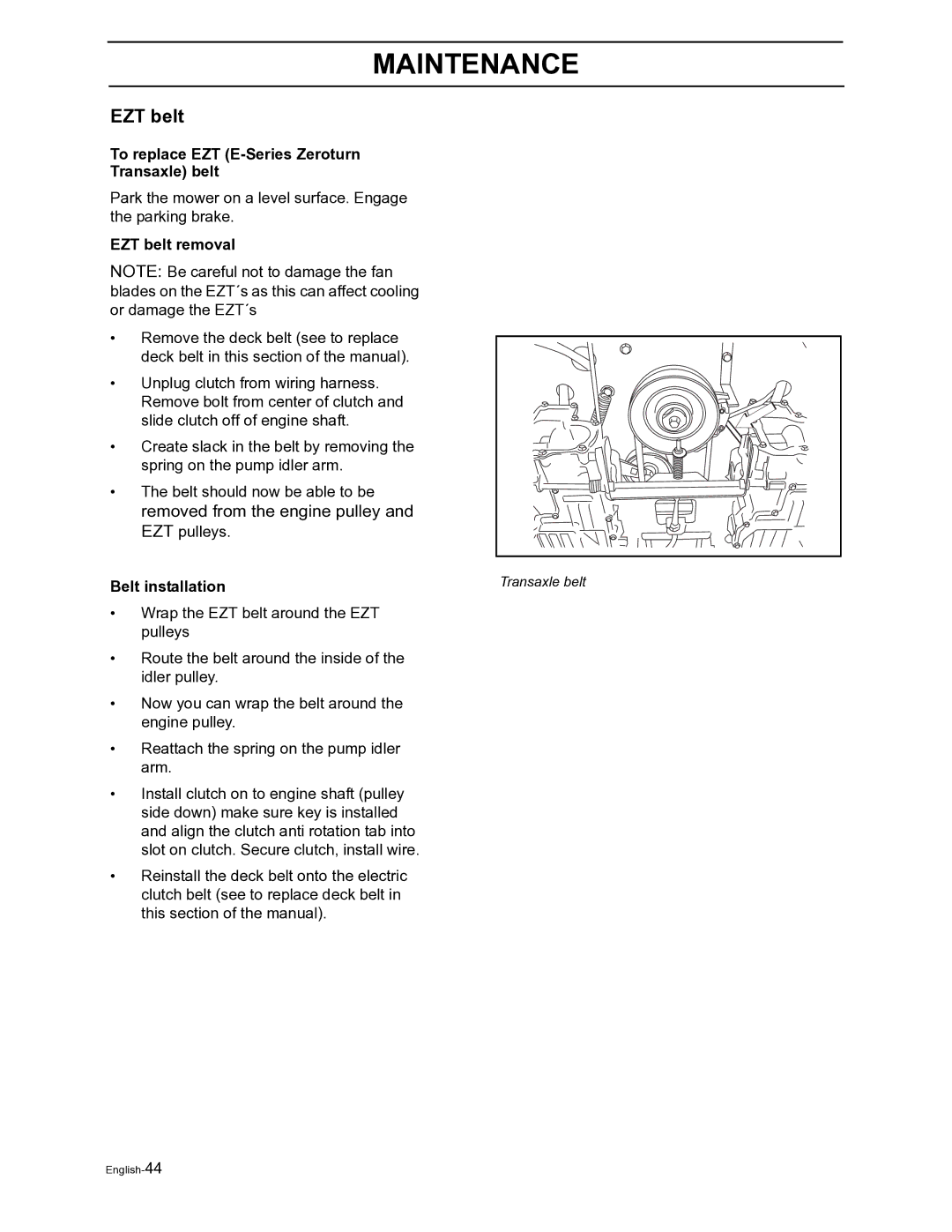

Additionally, examine belts and cables for signs of wear and tear, and adjust or replace them if necessary. Keeping the fuel system clean will prevent clogging; consider using a fuel stabilizer during off-seasons. Lastly, regularly clean the exterior to remove debris and dirt, which can hinder performance.

Where to Find Replacement Parts

When it comes to sourcing components for your equipment, knowing where to look can make all the difference. Various options exist to help you secure the necessary elements to keep your machinery running smoothly.

- Authorized Dealers: Visit local dealerships that specialize in your brand for genuine components.

- Online Retailers: Explore e-commerce platforms that offer a wide selection of aftermarket and original items.

- Manufacturer’s Website: Check the official site for a comprehensive catalog and purchasing options.

- Local Repair Shops: Consult with nearby repair services, as they often have a stock of commonly needed elements.

- Forums and Community Groups: Join online communities where enthusiasts share information on sourcing and troubleshooting.

By exploring these avenues, you can effectively acquire the components necessary for maintenance and repairs.

Benefits of OEM vs. Aftermarket Parts

When it comes to maintaining equipment, the choice between original components and alternatives can significantly impact performance and longevity. Understanding the differences between these options is crucial for making informed decisions that affect both efficiency and reliability.

Advantages of OEM Components

- Designed specifically for your equipment, ensuring a perfect fit.

- Manufactured to meet strict quality standards, enhancing durability.

- Often backed by warranties, providing peace of mind for users.

- Maintains resale value by preserving the original specifications.

Benefits of Aftermarket Options

- Typically more affordable, allowing for budget-friendly repairs.

- Variety of choices, offering enhancements or modifications.

- Availability can be wider, making it easier to find alternatives.

- Some brands may offer improved performance features over originals.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to troubleshooting and fixing mechanical equipment, ensuring a systematic resolution of common issues. Each step is designed to enhance understanding and promote effective repair techniques, making the process manageable for users of all skill levels.

| Step | Description |

|---|---|

| 1 | Identify the issue by observing performance and checking for any unusual sounds or behaviors. |

| 2 | Gather necessary tools and materials to facilitate the repair process. |

| 3 | Carefully disassemble the relevant components, noting the arrangement for reassembly. |

| 4 | Inspect each part for wear and damage, replacing any faulty components as needed. |

| 5 | Reassemble the equipment, ensuring all parts are securely fitted and aligned correctly. |

| 6 | Test the machinery to confirm the repair was successful and that it operates smoothly. |

Customer Support Resources

Access to reliable assistance is essential for maintaining equipment effectively. Whether you are facing technical issues or need guidance on usage, various resources are available to ensure you receive the help you need promptly.

Here are some key support avenues to explore:

- Official Website: Most manufacturers provide comprehensive information, including FAQs, manuals, and troubleshooting guides.

- Customer Service Hotline: A dedicated support team can assist you directly with any inquiries or concerns. Look for the contact number on the official site.

- Email Support: For less urgent matters, emailing the support team allows for detailed communication. Expect a response within a few business days.

- Online Forums: Community-driven platforms often host discussions where users share experiences and solutions. Engaging in these forums can provide insights and tips.

- Social Media Channels: Many companies utilize social media for customer engagement. You can reach out with questions or follow for updates and support information.

Utilizing these resources can enhance your experience and ensure your equipment operates smoothly. Don’t hesitate to reach out for assistance whenever needed.

Frequently Asked Questions about Z4822

This section addresses common inquiries related to the model in question, providing clarity and insights for users and enthusiasts alike. Whether you are a seasoned operator or a newcomer, understanding these key aspects can enhance your experience and maintenance practices.

What are the key features of this model?

This model is equipped with a range of advanced features designed for efficiency and ease of use. From robust cutting systems to user-friendly controls, it offers a comprehensive solution for various landscaping tasks.

How do I perform routine maintenance?

Regular upkeep is crucial for optimal performance. This typically involves checking fluid levels, inspecting blades, and cleaning air filters. Following the manufacturer’s guidelines will ensure longevity and reliability.

Where can I find replacement components?

Replacement parts can be sourced from authorized dealers, online retailers, or specialty stores. It’s important to ensure compatibility with your specific model to avoid any performance issues.

What are common troubleshooting steps?

If you encounter issues, start by checking the power source and connections. Consult the user manual for specific troubleshooting advice, as it provides detailed guidance on resolving common problems.

Is there a warranty available?

Typically, a warranty is offered that covers manufacturing defects and certain repairs. Review the warranty details for your model to understand the coverage and duration.