Comprehensive Guide to Lucknow Snowblower Parts Diagram

The efficient functioning of winter machinery relies heavily on the precise arrangement and interaction of its components. This section aims to illuminate the intricacies involved in the assembly of these essential devices, highlighting the various elements that contribute to their operational effectiveness.

Grasping how each piece fits into the larger framework can significantly enhance maintenance and repair efforts. By examining the layout and roles of individual components, users can better appreciate the engineering behind these powerful tools.

Ultimately, a thorough understanding of this machinery not only aids in troubleshooting but also empowers users to optimize performance. With clear insights into the configuration, one can confidently navigate the complexities of winter equipment and ensure its reliability during harsh conditions.

Understanding Snowblower Components

In the world of winter equipment, comprehending the various elements that contribute to the efficient operation of a clearing machine is essential. Each component plays a vital role in ensuring optimal performance, making it crucial for users to familiarize themselves with their functions and interactions.

| Component | Description |

|---|---|

| Engine | Provides the necessary power to drive the entire machine, converting fuel into mechanical energy. |

| Auger | Designed to gather and break up snow, facilitating its movement toward the discharge chute. |

| Impeller | Works in conjunction with the auger to propel the cleared material out of the chute at high speed. |

| Chassis | The framework that supports all components, providing stability and structural integrity. |

| Controls | Enable the operator to manage speed, direction, and other functions, ensuring ease of use. |

| Discharge Chute | Directs the expelled snow away from the cleared area, preventing re-accumulation. |

| Skids | Adjustable elements that help maintain an optimal height for effective clearing without damaging surfaces. |

Understanding these elements not only enhances operational efficiency but also aids in maintenance and troubleshooting, leading to a more effective experience in tackling winter conditions.

Importance of Diagrams in Repairs

Visual representations play a crucial role in the repair process, serving as essential tools for understanding complex systems. They simplify intricate mechanisms, making it easier for technicians and DIY enthusiasts to identify issues and execute solutions effectively.

Enhancing Understanding

Illustrations provide clarity, breaking down components into manageable parts. This not only aids in troubleshooting but also boosts confidence among those undertaking repairs.

Streamlining the Repair Process

By using visual aids, individuals can efficiently follow procedures, minimizing the risk of errors. This leads to quicker repairs and improved outcomes.

| Benefit | Description |

|---|---|

| Clarity | Helps in understanding the assembly and function of parts. |

| Efficiency | Reduces time spent on repairs by providing clear instructions. |

| Confidence | Encourages users to attempt repairs by demystifying processes. |

Common Parts of Lucknow Snowblowers

Understanding the essential components of these machines is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring the equipment performs optimally during winter conditions.

Main Components

- Engine: Powers the entire system and determines performance capabilities.

- Auger: Responsible for gathering and moving snow towards the discharge chute.

- Discharge Chute: Directs the snow away from the machine, allowing for effective clearing.

- Skid Shoes: Help adjust the height of the unit and protect the base from wear.

- Drive Belts: Transfer power from the engine to various moving parts.

Additional Elements

- Control Panel: Allows the operator to manage functions such as speed and chute direction.

- Wheels or Tracks: Provide mobility across different surfaces, ensuring stability.

- Fuel System: Ensures the engine receives the necessary energy to operate.

- Cabinets or Housings: Protect internal components from external elements and debris.

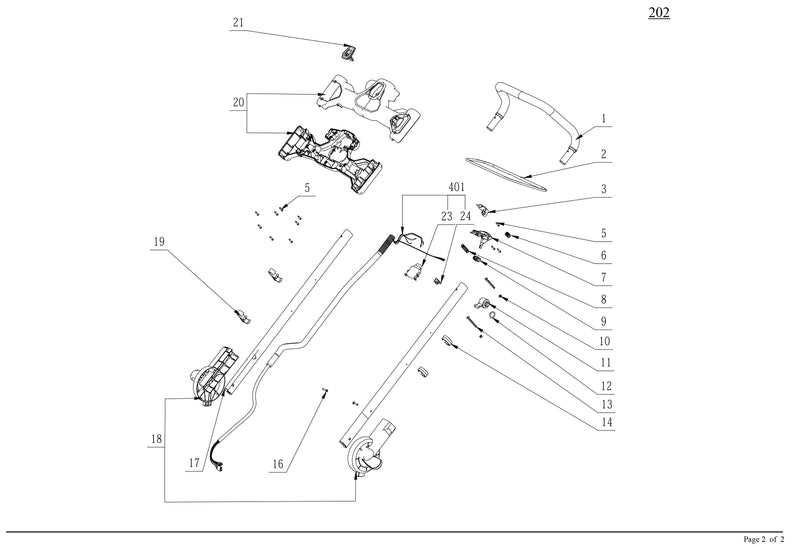

How to Read a Parts Diagram

Understanding an assembly illustration can significantly enhance your maintenance and repair skills. By familiarizing yourself with the layout and symbols, you can easily identify components and their functions, streamlining your troubleshooting process.

Key Elements to Note

- Labels: Pay attention to the naming conventions used for each element.

- Numbering: Look for a sequential numbering system that helps you track components easily.

- Connection Lines: Observe how different parts are interconnected, indicating their relationship.

Steps to Interpret Effectively

- Start by reviewing the legend or key that explains symbols.

- Identify the main components first before diving into details.

- Cross-reference with your product manual for clarification.

Identifying Snowblower Issues

Understanding the common problems that can arise with your outdoor equipment is crucial for maintaining its performance. Identifying these issues early can prevent further damage and ensure smooth operation during the winter season. Regular inspections and awareness of potential faults can significantly extend the life of your machine.

Common Symptoms of Malfunction

- Difficulty starting the engine

- Unusual noises during operation

- Inconsistent throwing of snow

- Leaking fluids

- Reduced power or stalling

Steps to Diagnose Problems

- Check the fuel level and quality.

- Inspect the ignition system for wear.

- Examine belts and cables for fraying or damage.

- Look for blockages in the chute or auger.

- Test the control mechanisms to ensure responsiveness.

By systematically addressing these areas, you can effectively diagnose and resolve issues, keeping your equipment in optimal condition for winter challenges.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of your outdoor equipment. By implementing a few straightforward practices, you can extend the lifespan and efficiency of your machine, minimizing costly repairs and enhancing reliability.

Regular Cleaning

Keeping the unit clean prevents the buildup of debris that can cause wear and tear. Regularly inspect and remove any dirt or materials that may accumulate during use.

Lubrication and Inspection

Regular lubrication of moving components is crucial for smooth operation. Periodic inspections help identify potential issues before they escalate.

| Task | Frequency |

|---|---|

| Clean exterior | After each use |

| Inspect belts and cables | Monthly |

| Change oil | Every season |

| Sharpen blades | As needed |

Finding Replacement Parts Easily

Locating the necessary components for your equipment can often be a daunting task. However, with the right approach and resources, you can simplify the process significantly. Here are some strategies to help you find what you need quickly and efficiently.

- Online Retailers: Explore various e-commerce platforms that specialize in outdoor equipment. They often have extensive inventories and detailed descriptions.

- Manufacturer Websites: Check the official websites of the brands you trust. They usually provide manuals, support pages, and direct links to order components.

- Local Dealers: Visit or contact local distributors or repair shops. They can provide valuable insights and may have the items in stock.

Additionally, consider joining online forums or community groups focused on outdoor machinery. These platforms allow you to connect with other users who may share their experiences and recommendations for sourcing specific items.

- Utilize Search Engines: Use specific search terms related to your requirements to find relevant resources quickly.

- Check Auction Sites: Websites that facilitate auctions may offer second-hand options at competitive prices.

- Social Media Groups: Engage with communities on platforms like Facebook or Reddit, where enthusiasts often share leads on where to find essential items.

By employing these methods, you can streamline the process of acquiring the necessary components, ensuring your equipment remains in optimal condition.

Tools Needed for Snowblower Repairs

Performing maintenance and repairs on winter machinery requires a specific set of tools to ensure efficiency and effectiveness. Having the right instruments not only simplifies the process but also enhances safety while working. Below are essential implements that can help you tackle various tasks with confidence.

Basic Hand Tools

Every repair enthusiast should have a well-equipped toolbox. Wrenches, screwdrivers, and pliers are fundamental for loosening and tightening components. Additionally, an adjustable wrench can be invaluable for reaching awkward spaces and accommodating different sizes of fasteners.

Specialized Equipment

In some cases, you may require tools tailored for specific tasks. A torque wrench is crucial for applying the correct amount of force to bolts, preventing damage to sensitive components. Moreover, having a multimeter allows for effective electrical diagnostics, ensuring that all systems function correctly. Lastly, a parts washer can help keep your components clean, promoting longevity and optimal performance.

Assembling a Snowblower Step-by-Step

Putting together a powerful outdoor tool requires attention to detail and a methodical approach. This process not only enhances performance but also ensures safety during operation. Following a structured guide will help streamline the assembly and contribute to a successful setup.

Gathering Your Tools and Components

Before starting, ensure you have all necessary components and tools at hand. Common items needed include wrenches, screwdrivers, and protective gear. Organizing the pieces will save time and reduce frustration. Familiarize yourself with each component by consulting the provided manuals or schematics.

Step-by-Step Assembly Process

Begin by laying out the base unit and attaching the framework according to the instructions. Secure each part with the appropriate fasteners, checking for tightness as you proceed. Next, connect the operational elements, ensuring all wiring and controls are correctly aligned. Once assembled, perform a thorough inspection to confirm that everything is in place before testing the equipment.

Expert Tips for Troubleshooting

When faced with operational issues, understanding the underlying mechanisms can be crucial. This section provides guidance to help you identify and resolve common challenges effectively.

- Begin with a thorough inspection of the equipment to identify visible signs of wear or damage.

- Refer to the manufacturer’s manual for specific guidance on maintenance and repair procedures.

- Test electrical components with a multimeter to ensure proper functionality.

- Check for blockages in the intake or discharge areas that could hinder performance.

By systematically approaching each potential issue, you can enhance efficiency and extend the lifespan of your equipment.

Snowblower Safety Precautions

Ensuring safety during winter maintenance tasks is crucial. Adhering to specific guidelines can help prevent accidents and injuries while operating machinery designed for clearing snow. Awareness and preparation are key components in fostering a secure environment for both the user and bystanders.

Pre-Operation Guidelines

Before engaging the equipment, it’s essential to conduct a thorough inspection. Check for any visible damage and ensure that all safety features are functional. It’s also advisable to familiarize yourself with the operator’s manual to understand the specific requirements for safe usage.

Operational Safety Tips

During operation, maintain a safe distance from others and never allow children or pets near the area of work. Additionally, avoid wearing loose clothing that could become entangled in moving parts.

| Safety Tip | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and appropriate footwear to protect against cold and injuries. |

| Stay Alert | Be attentive to your surroundings and the condition of the equipment at all times. |

| Clear Blockages Safely | Turn off the machine before attempting to clear any clogs to prevent accidental starts. |

Seasonal Maintenance Checklist for Users

Proper upkeep is essential for ensuring optimal performance and longevity of your equipment. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns. Here’s a comprehensive checklist to guide you through seasonal care.

- Inspection of Components:

- Check belts for wear and tear.

- Examine the blades for sharpness and damage.

- Inspect the fuel lines and connections for leaks.

- Fluid Checks:

- Change the oil according to the manufacturer’s recommendations.

- Ensure the fuel is fresh and clean.

- Check and refill hydraulic fluid if necessary.

- Cleaning Procedures:

- Remove any debris from the exterior surfaces.

- Clear out the intake and exhaust areas.

- Wash the unit to prevent rust and corrosion.

- Battery Maintenance:

- Inspect terminals for corrosion and clean if needed.

- Ensure the battery is fully charged.

- Check for any signs of swelling or leaks.

- Safety Features:

- Test the emergency stop switch.

- Examine all safety guards and shields for proper installation.

- Ensure that warning labels are visible and legible.

By adhering to this checklist, users can ensure their machinery is well-prepared for the upcoming season, ultimately enhancing performance and safety.