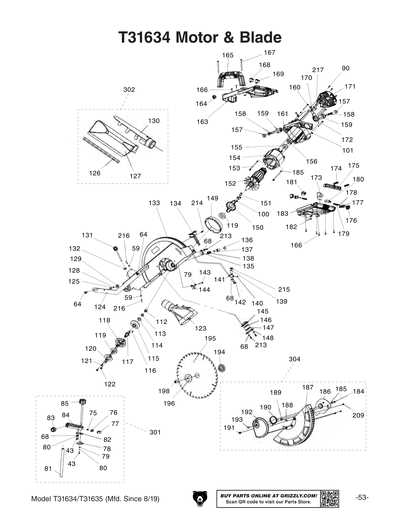

Gear system for

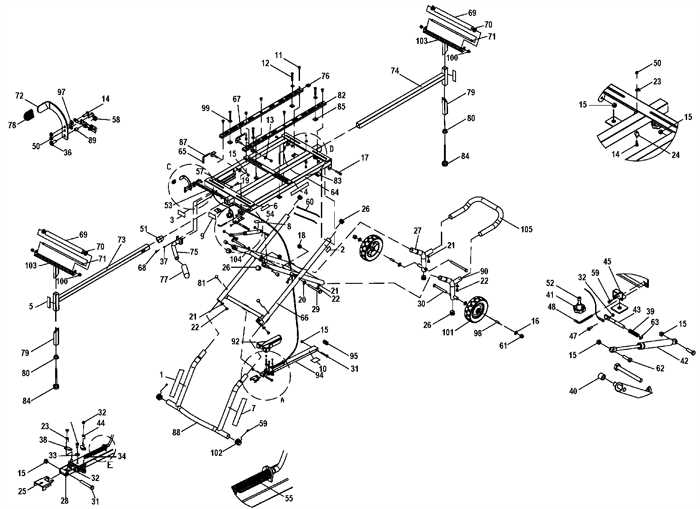

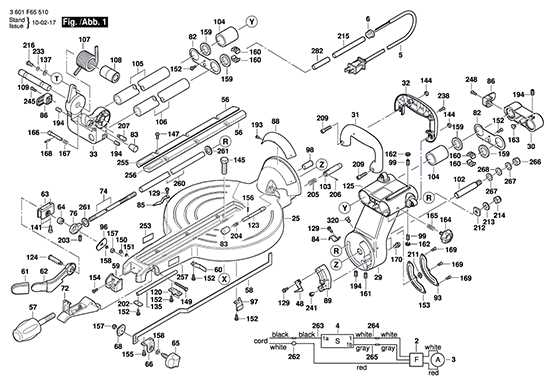

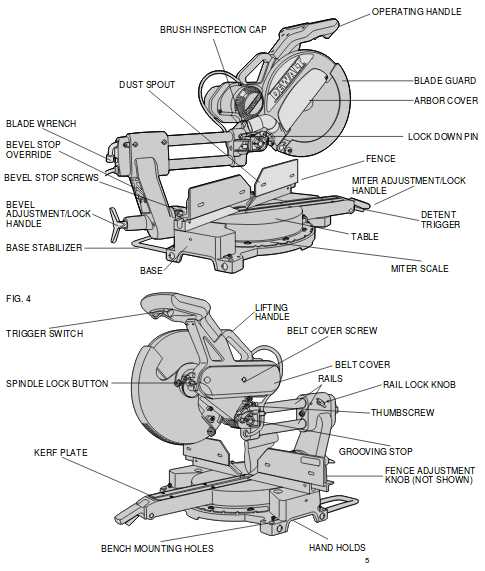

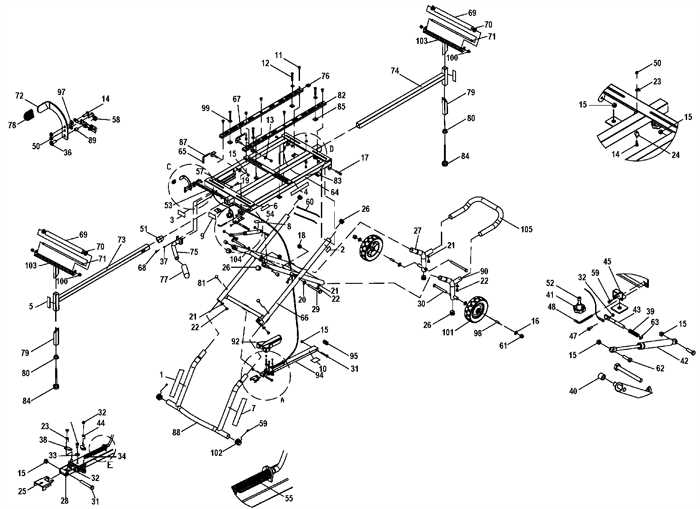

Base and Table Construction Details

The foundation and surface of this tool play a crucial role in ensuring stability and precision during operations. A sturdy base provides the necessary support for accurate cuts, while the table ensures that materials can be securely positioned for optimal performance. Understanding the construction elements of these components is key to maximizing efficiency and ensuring long-term durability.

Base Structure

The foundation is typically made from durable materials designed to withstand heavy loads and minimize vibrations. The base often includes non-slip features or adjustable feet to enhance stability, especially on uneven surfaces. This solid structure helps maintain balance and prevents unwanted movement during use, contributing to safer and more precise operations.

Table Design

The table is crafted to provide ample space for working with various materials, allowing for smooth and consistent positioning. It often includes measurement guides or grooves that facilitate accurate adjustments and alignments. The smooth surface ensures that workpieces can slide easily into place, while any locking mechanisms present allow for secure fixing during

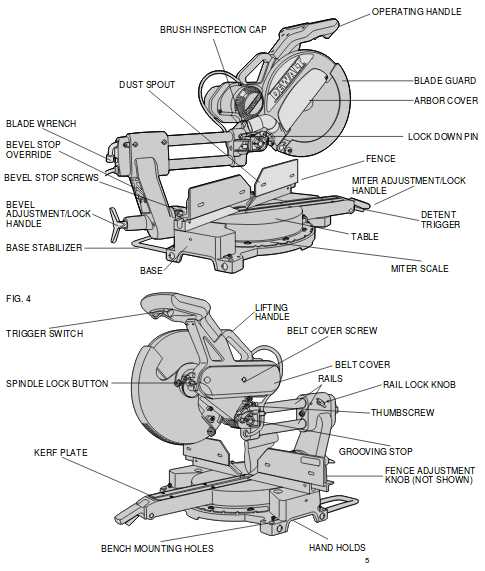

Fence System for Precision Cutting

The fence mechanism plays a crucial role in ensuring accurate and consistent cuts. It provides a stable reference point, allowing the material to be positioned correctly for various cutting tasks. With the right setup, this system can help enhance the precision and quality of each cut, especially for intricate or repetitive work.

Adjustability and Stability

A well-designed fence system offers both adjustability and stability. These features allow for fine-tuning the position of the workpiece while maintaining a rigid structure to prevent unwanted movement during operation. This is essential for achieving consistent results in different types of cutting scenarios.

Enhanced Support for Long Materials

The system also provides additional support when working with longer materials. By extending the fence or using auxiliary extensions, users can handle larger pieces with greater control, minimizing the risk of inaccuracies. This support is particularly beneficial for large-scale projects that require precise alignment over extended

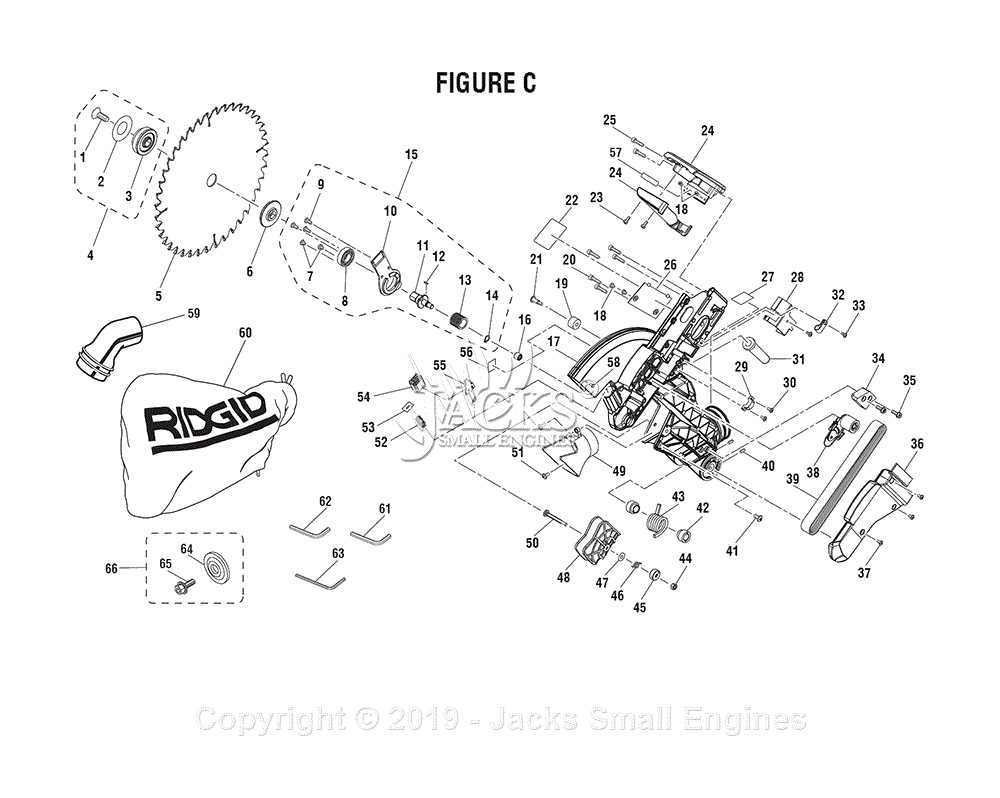

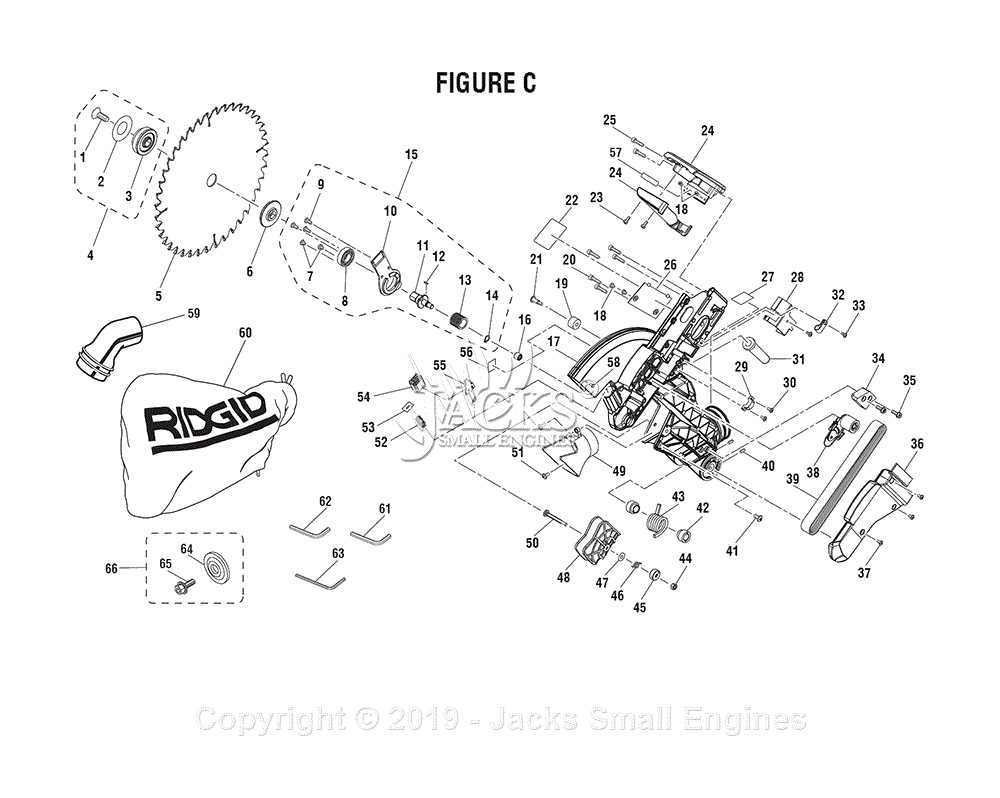

Dust Collection System Explained

A reliable dust collection system is essential for maintaining a clean and safe workspace. These systems efficiently capture and remove debris generated during cutting and shaping operations, minimizing airborne particles and ensuring a healthier environment for users. Understanding the components and functionality of these systems can enhance their effectiveness and prolong the life of tools.

Key Components

Dust collection systems typically consist of a few critical elements, including a collection hood, ductwork, and a filtration mechanism. The collection hood is strategically positioned to capture dust at the source, while the ductwork transports the particles to a designated container. Effective filtration ensures that even the smallest particles are captured, preventing them from being released back into the air.

Maintenance and Efficiency

Regular maintenance of the dust collection system is crucial for optimal performance. This includes checking and cleaning filters, inspecting ductwork for clogs, and ensuring the collection container is emptied frequently. By keeping these components in top condition, users can improve the system’s efficiency, leading to a cleaner workspace and reduced health risks.

Handle and Control Features

The design and functionality of a cutting tool greatly depend on its handling and control elements. These features play a crucial role in ensuring user comfort, precision, and overall efficiency during operation. A well-structured handle and intuitive control setup can enhance the experience, allowing for more accurate cuts and reduced fatigue over extended use.

Ergonomic Design

Ergonomics is vital in the construction of handling mechanisms. An ergonomic handle allows users to maintain a secure grip while minimizing strain on the hands and wrists. This design consideration is essential for professionals who require prolonged usage, as it promotes better posture and reduces the risk of injuries.

Control Mechanisms

Control features are designed to provide users with seamless adjustments and enhanced safety. This includes easy-to-reach levers and switches that enable quick changes in settings, allowing for precise operations. The incorporation of safety locks further ensures that the tool remains secure when not in use, preventing accidental activation.

Safety Mechanisms and Their Importance

In any power tool, the incorporation of safety features is essential for protecting users from potential hazards. These mechanisms are designed to minimize the risk of accidents and ensure that equipment operates smoothly under various conditions. Understanding the importance of these systems can significantly enhance user confidence and safety during operation.

One of the primary roles of safety mechanisms is to prevent unintended activation of the equipment. Features such as blade guards and trigger locks are vital in safeguarding against accidental startups, which can lead to serious injuries. These precautions are particularly crucial when tools are not in use, as they help maintain a secure environment.

Moreover, safety systems also play a critical role during operation. Features like emergency shut-off switches allow users to quickly disable the tool in case of an emergency, reducing the likelihood of injury. Additionally, protective guards help contain debris and ensure that the working area remains safe, contributing to overall operational efficiency.

In conclusion, prioritizing safety mechanisms in power tools not only protects the user but also fosters a culture of safety in the workplace. By understanding and utilizing these features, operators can significantly reduce risks and enhance their overall experience with the equipment.

Maintenance Tips for Longevity

To ensure the lasting performance of your cutting tool, regular upkeep is essential. Implementing a consistent maintenance routine not only enhances efficiency but also extends the lifespan of the equipment. Below are key practices to consider for optimal care.

1. Regular Cleaning: Keeping the tool free from dust and debris is crucial. After each use, wipe down the surfaces and remove any accumulated sawdust. This prevents build-up that can affect performance.

2. Lubrication: Apply appropriate lubricants to moving parts periodically. Proper lubrication reduces friction, ensuring smoother operation and minimizing wear on components.

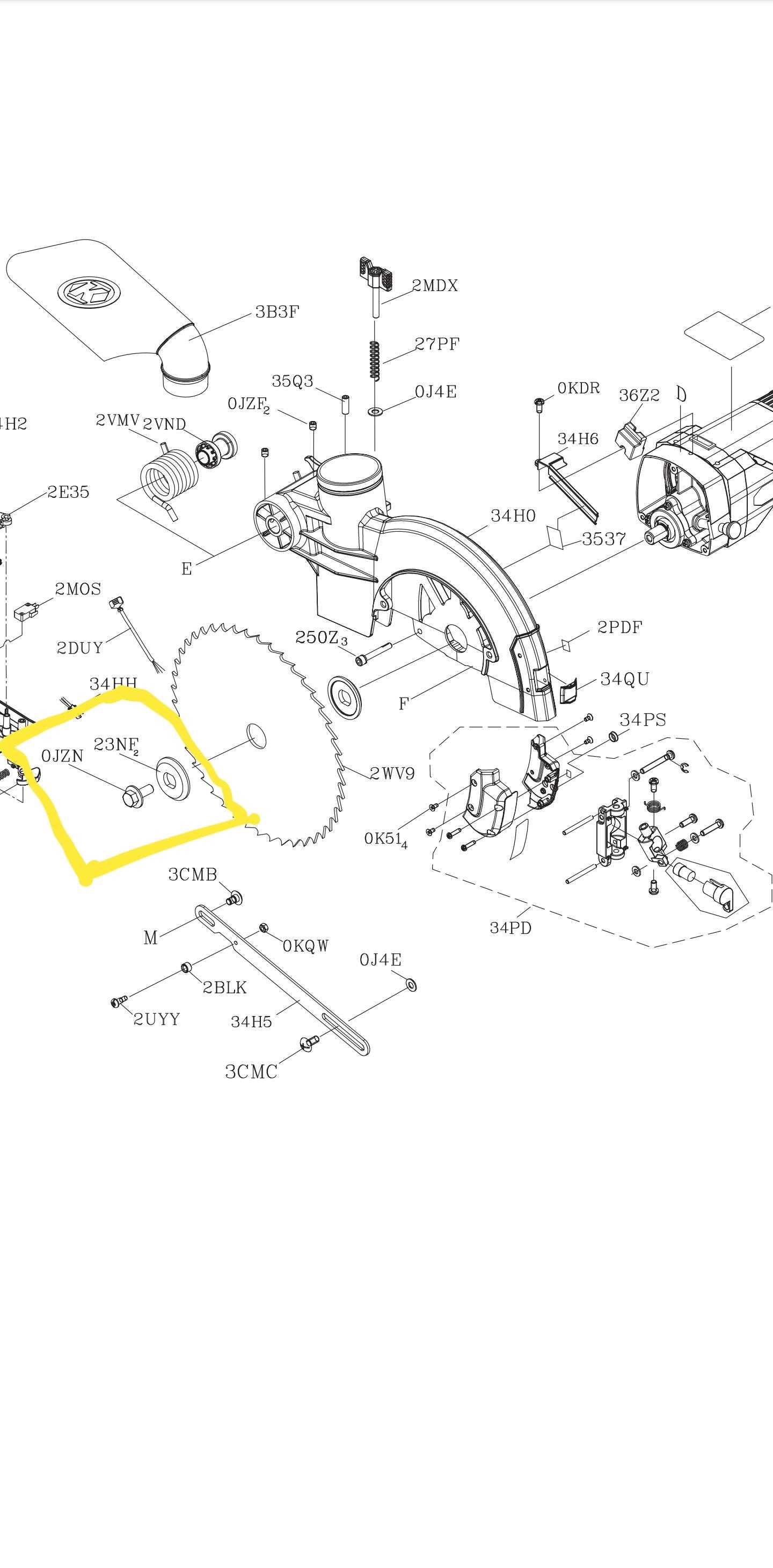

3. Blade Inspection: Frequently check the cutting blade for signs of damage or dullness. A well-maintained blade not only improves cutting accuracy but also reduces the risk of accidents.

4. Calibration: Regularly verify the alignment and accuracy of the tool. Proper calibration ensures precise cuts and can prevent unnecessary strain on the motor.

5. Safe Storage: Store the equipment in a dry, protected environment when not in use. Using a cover can shield it from moisture and dust, helping to maintain its condition.

By following these maintenance tips, you can enhance the reliability and efficiency of your cutting tool, ensuring it remains a valuable asset for years to come.

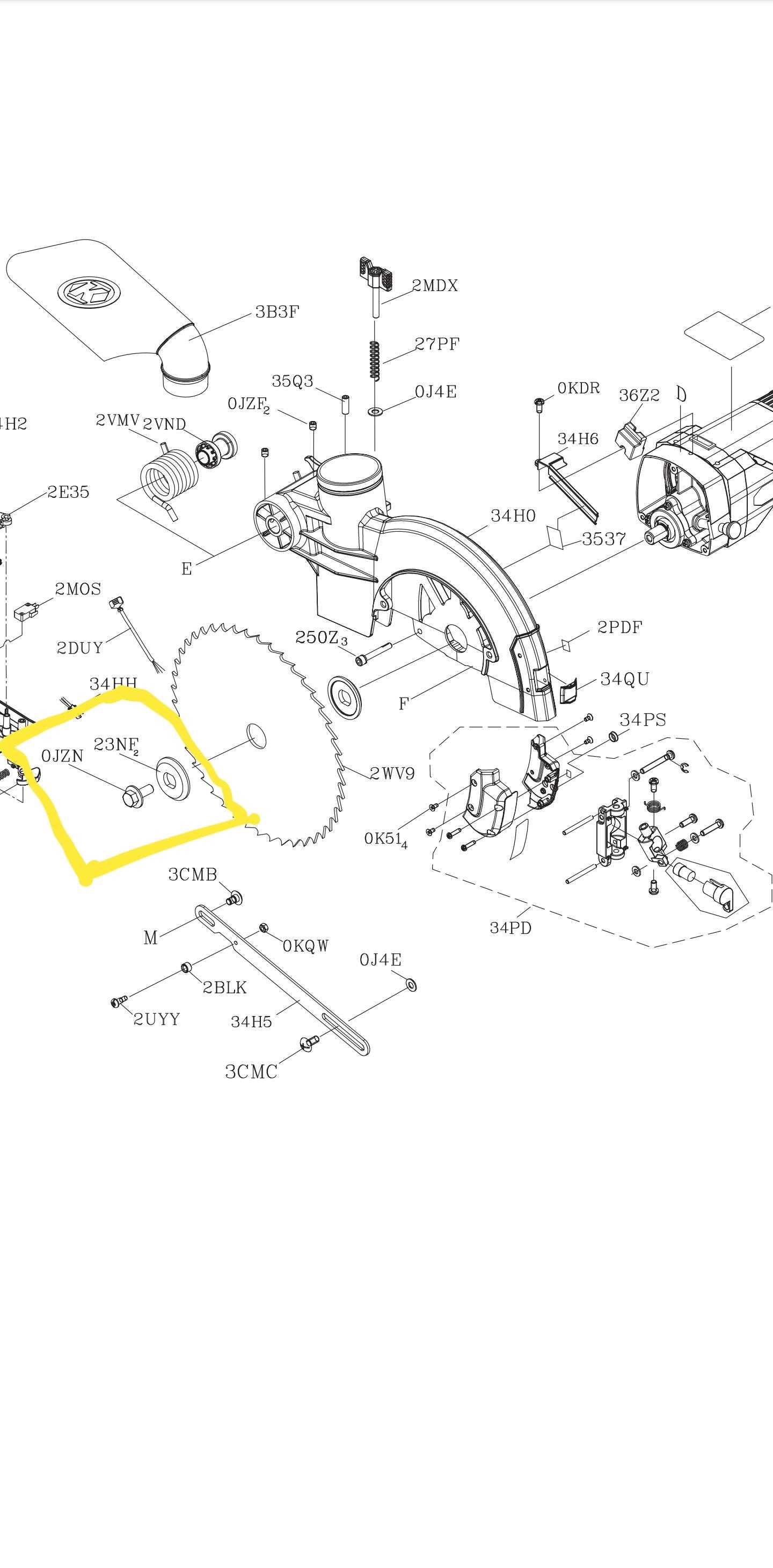

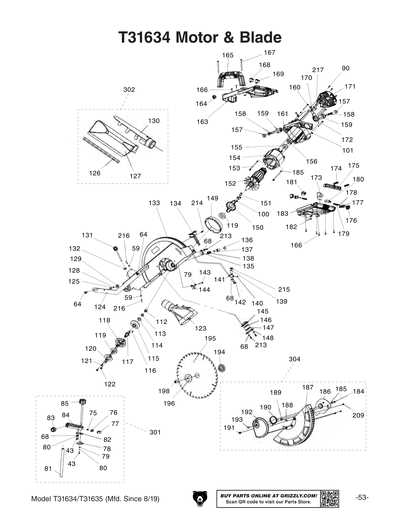

Common Replacement Parts and Availability

Understanding the essential components of your equipment is crucial for ensuring optimal performance and longevity. Knowing which elements may require replacement can help users maintain their tools effectively. This section will explore frequently replaced components and their availability in the market.

Essential Components

- Blades: A critical element for achieving clean cuts, these are often the first to show signs of wear.

- Bushings: Essential for smooth operation, these small but vital pieces can degrade over time.

- Switches: Ensuring safe operation, faulty switches necessitate prompt replacement to prevent accidents.

- Handles: Often subjected to significant wear, these can become uncomfortable or unsafe to use.

Finding Replacement Parts

When looking for components, consider the following sources:

- Authorized Dealers: They provide genuine replacements and expert advice.

- Online Retailers: Websites dedicated to tools often stock a wide variety of components.

- Local Hardware Stores: Many carry essential parts for popular equipment.

Ensuring you have access to quality replacements is key to keeping your machinery in top condition.

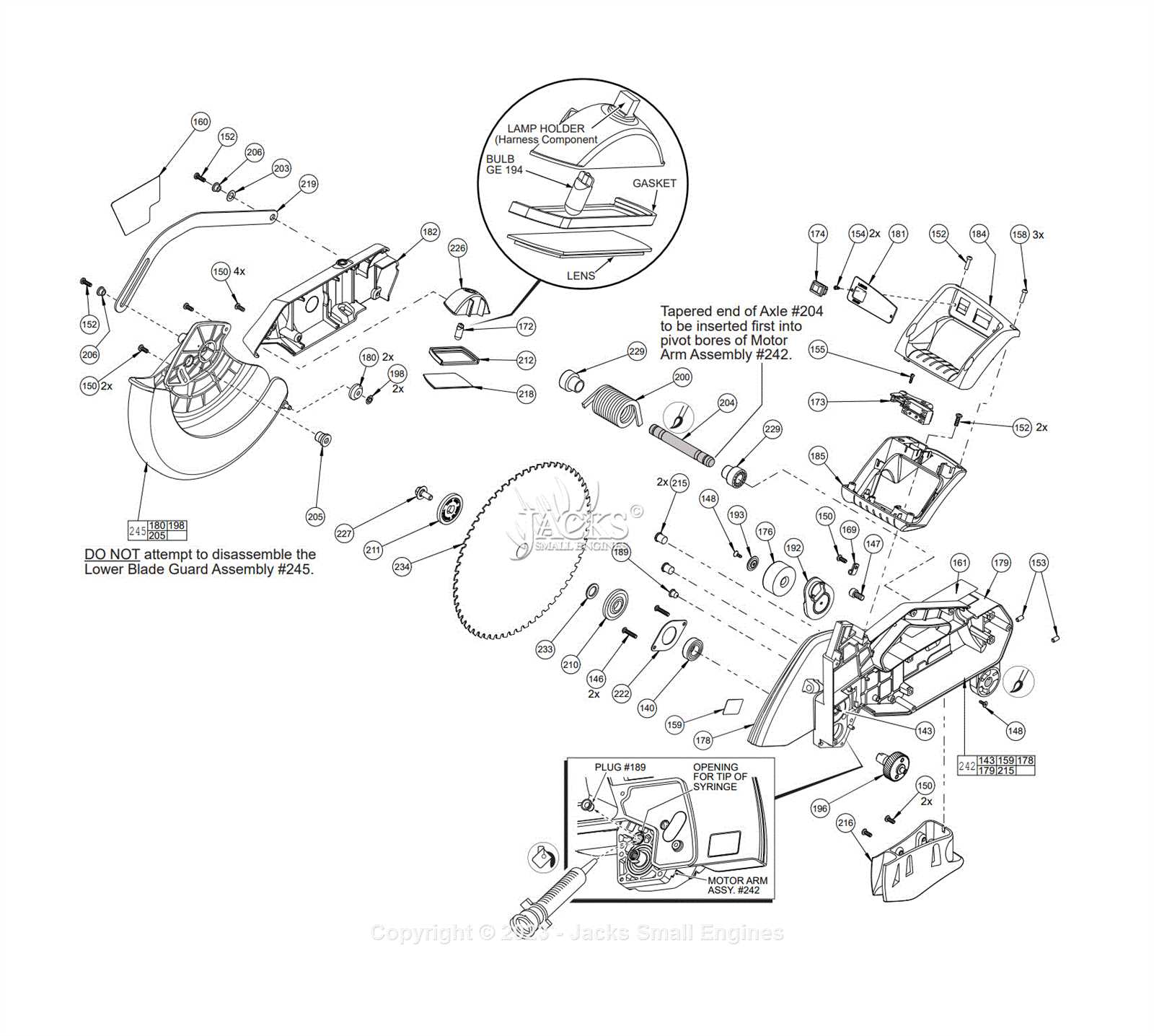

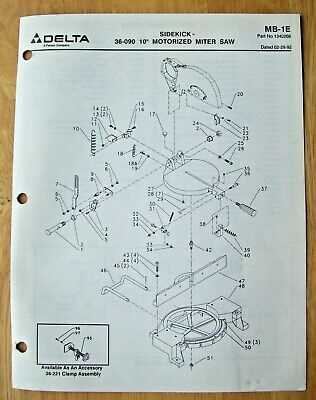

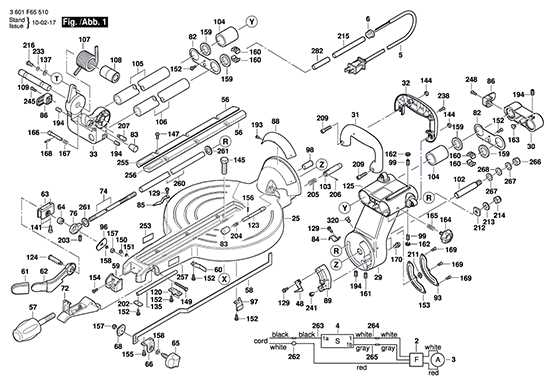

Assembly and Disassembly Instructions

This section provides essential guidance on the correct methods for assembling and disassembling your tool. Proper handling is crucial for maintaining performance and ensuring safety during use.

Follow these steps for assembly:

- Start by gathering all necessary components and tools. Ensure you have a clean workspace to prevent misplacing any parts.

- Begin with the base; secure it firmly to prevent movement during operation.

- Attach the arm mechanism to the base, ensuring all screws are tightened properly.

- Connect the blade holder, making sure it is aligned correctly with the motor assembly.

- Finally, double-check all connections and ensure safety features are operational.

For disassembly, adhere to the following guidelines:

- Unplug the tool to ensure safety before starting any disassembly process.

- Begin by removing the blade, taking care to follow safety precautions.

- Loosen and detach the arm from the base carefully to avoid damage.

- Remove the motor assembly, ensuring to keep all screws and components organized.

- Store all parts in a labeled container for easy reassembly later.

Always refer to your user manual for specific instructions related to your model, ensuring compliance with safety regulations.