Kubota SVL95 Parts Diagram Overview

The intricate design of heavy equipment relies on a well-organized arrangement of its various elements. Recognizing how these components interact is crucial for effective maintenance and optimal performance. A detailed representation serves as a valuable resource for operators and technicians alike, offering insights into assembly and functionality.

Such visual aids enhance the understanding of each segment’s role within the overall machinery framework. By examining these layouts, one can identify specific areas that may require attention, thus streamlining the repair process. Clarity in these illustrations helps ensure that all parts are correctly aligned and functioning in harmony.

Moreover, familiarizing oneself with the structure of these operational units can lead to improved efficiency in troubleshooting. This knowledge not only supports timely interventions but also fosters a deeper appreciation for the engineering behind modern equipment. Mastering the intricacies of these designs is essential for anyone involved in the upkeep of heavy machinery.

Kubota SVL95 Overview

This section provides a comprehensive understanding of a powerful and versatile machine designed for various tasks in construction and agriculture. Known for its robust performance and reliability, this compact vehicle is essential for operators looking to maximize productivity on the job site.

Key Features

The machine boasts a powerful engine, advanced hydraulic systems, and superior maneuverability, making it ideal for digging, grading, and lifting. Its compact size allows for easy navigation in tight spaces while maintaining high levels of stability and traction on diverse terrains.

Applications

This equipment is widely used in landscaping, excavation, and material handling. Its adaptability to different attachments enhances its functionality, allowing users to tackle a variety of tasks efficiently. From site preparation to snow removal, this versatile machine proves invaluable in numerous applications.

Importance of Parts Diagrams

Understanding the assembly and components of machinery is crucial for effective maintenance and repair. Visual representations that detail the individual elements and their relationships serve as valuable tools for technicians and operators alike. These illustrations enhance comprehension, enabling users to navigate complex systems with ease.

Clarity is one of the primary benefits of these visual aids. They provide a clear view of how parts fit together, reducing the likelihood of errors during disassembly or reassembly. This is particularly important in intricate machinery where even minor mistakes can lead to significant issues.

Moreover, such representations facilitate efficient troubleshooting. By identifying specific components, users can quickly locate potential problems and address them without unnecessary delay. This streamlined approach not only saves time but also minimizes downtime, which is essential in operational settings.

Additionally, these visuals are invaluable for training purposes. New technicians can refer to them as they learn the intricacies of the equipment, building a solid foundation of knowledge. Over time, familiarity with these illustrations can lead to greater confidence and proficiency in handling repairs.

In summary, these visual tools are essential resources that enhance understanding, efficiency, and training in the maintenance and repair of machinery. Their role in promoting effective practices cannot be overstated.

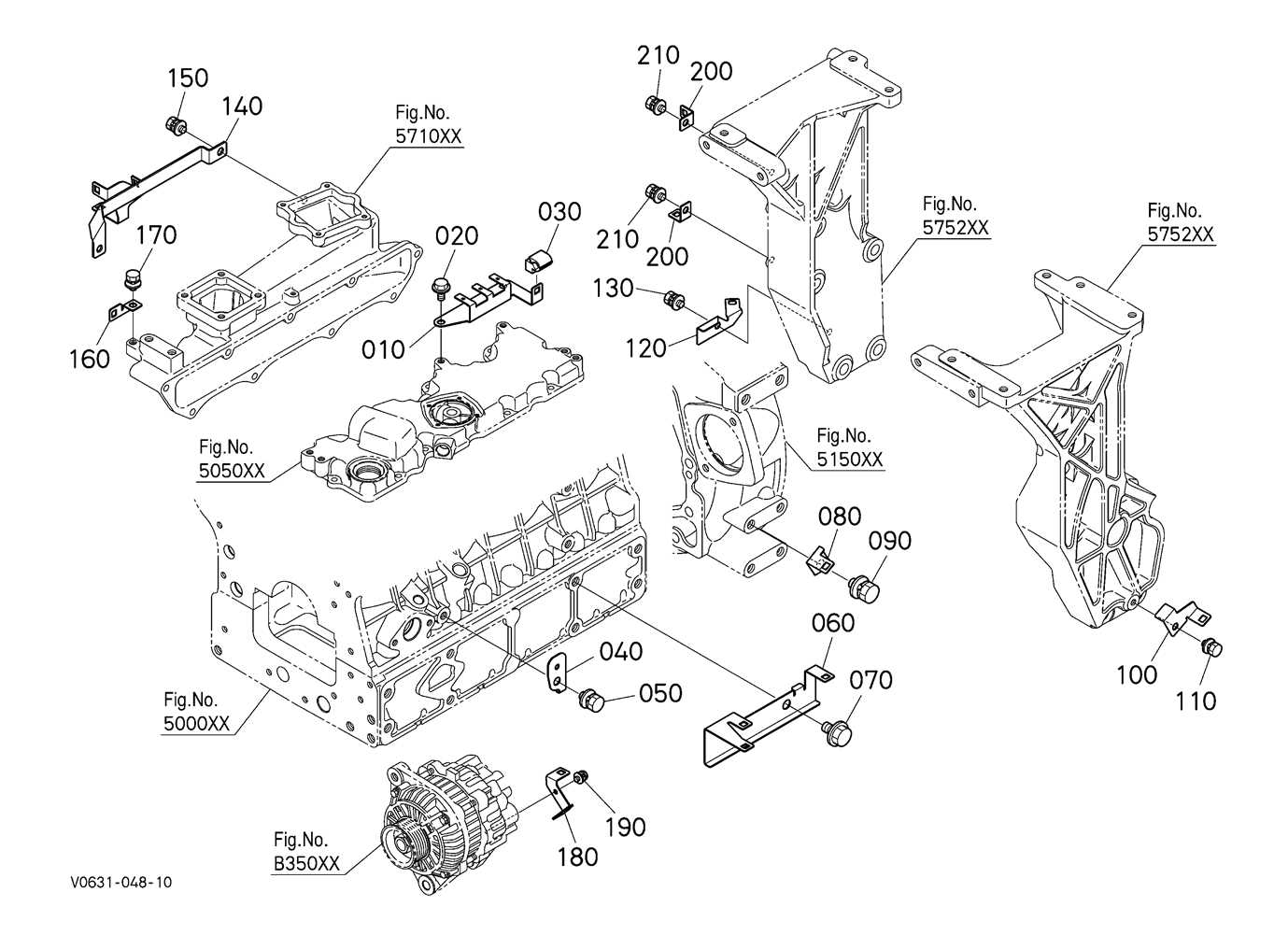

Key Components of SVL95

This section delves into the essential elements that contribute to the functionality and performance of the machine. Understanding these key components is crucial for effective maintenance and optimal operation.

Engine and Transmission

The heart of the machine lies in its engine and transmission system, which work in unison to provide power and efficiency. A robust engine ensures that the unit can handle various tasks, while the transmission system enables smooth operation across different terrains.

Hydraulic System

The hydraulic system is vital for executing various functions, from lifting to pushing. It converts the engine’s power into hydraulic energy, allowing for precise control over attachments and enhancing overall productivity.

| Component | Function |

|---|---|

| Engine | Provides power for operation |

| Transmission | Facilitates smooth movement |

| Hydraulic Pump | Generates hydraulic pressure |

| Control Valve | Regulates hydraulic flow |

Understanding the Hydraulic System

The hydraulic system is a vital component of heavy machinery, providing the necessary force and control for various functions. This intricate system utilizes fluid power to perform tasks such as lifting, digging, and pushing, making it essential for efficient operation.

At its core, the hydraulic system consists of several key elements that work together to generate and transmit power:

- Hydraulic Pump: Converts mechanical energy into hydraulic energy, moving fluid through the system.

- Hydraulic Fluid: The medium that transmits power, ensuring smooth operation and cooling of components.

- Actuators: Devices such as cylinders and motors that convert hydraulic energy back into mechanical energy to perform work.

- Valves: Control the flow and direction of the hydraulic fluid, allowing for precise movements and functions.

- Reservoir: Stores hydraulic fluid and helps maintain consistent pressure within the system.

Understanding how these components interact is crucial for maintenance and troubleshooting. Regular checks can prevent issues and prolong the lifespan of the system. Key areas to monitor include:

- Fluid levels and quality.

- Signs of leaks or wear on hoses and fittings.

- Performance of the pump and actuators.

- Functionality of valves and control mechanisms.

By gaining insight into the hydraulic system’s workings, operators can enhance performance and ensure reliable operation in various tasks.

Common Wear and Tear Parts

Every piece of heavy machinery is subject to natural deterioration over time, especially components that experience constant friction and stress during operation. Understanding which elements typically need replacement can enhance maintenance strategies and extend the lifespan of the equipment.

Key components that often show signs of wear include:

- Tracks: Continuous exposure to rough terrains leads to gradual degradation.

- Belts: These are crucial for power transmission and can fray or crack under heavy use.

- Filters: Air and hydraulic filters can clog, reducing efficiency and performance.

- Seals: O-rings and gaskets may degrade, causing leaks and loss of fluid pressure.

- Hydraulic Hoses: Frequent bending and exposure to pressure can lead to cracks and leaks.

Regular inspections can help identify these vulnerable elements before they lead to more significant issues, ensuring optimal functionality and safety.

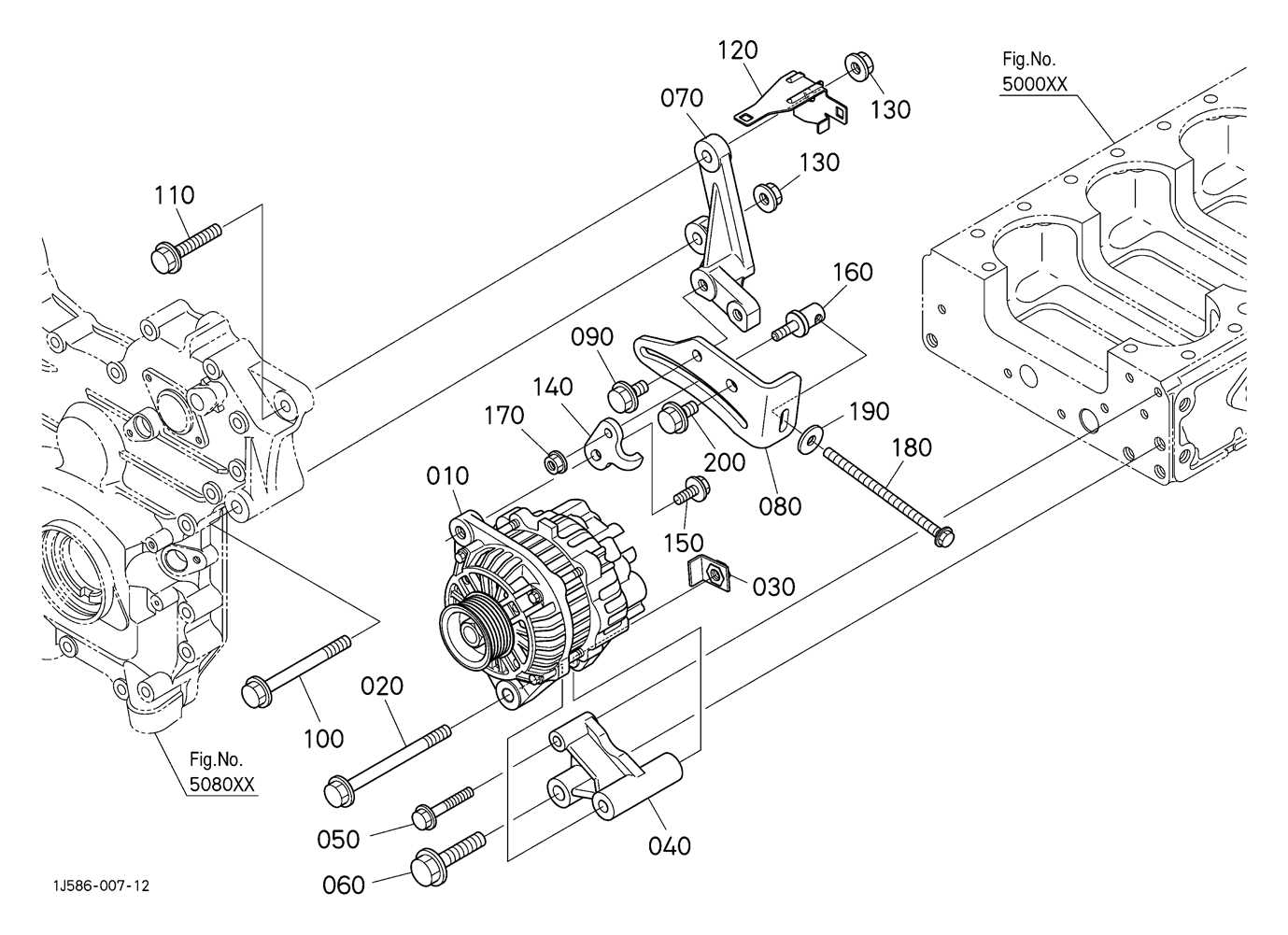

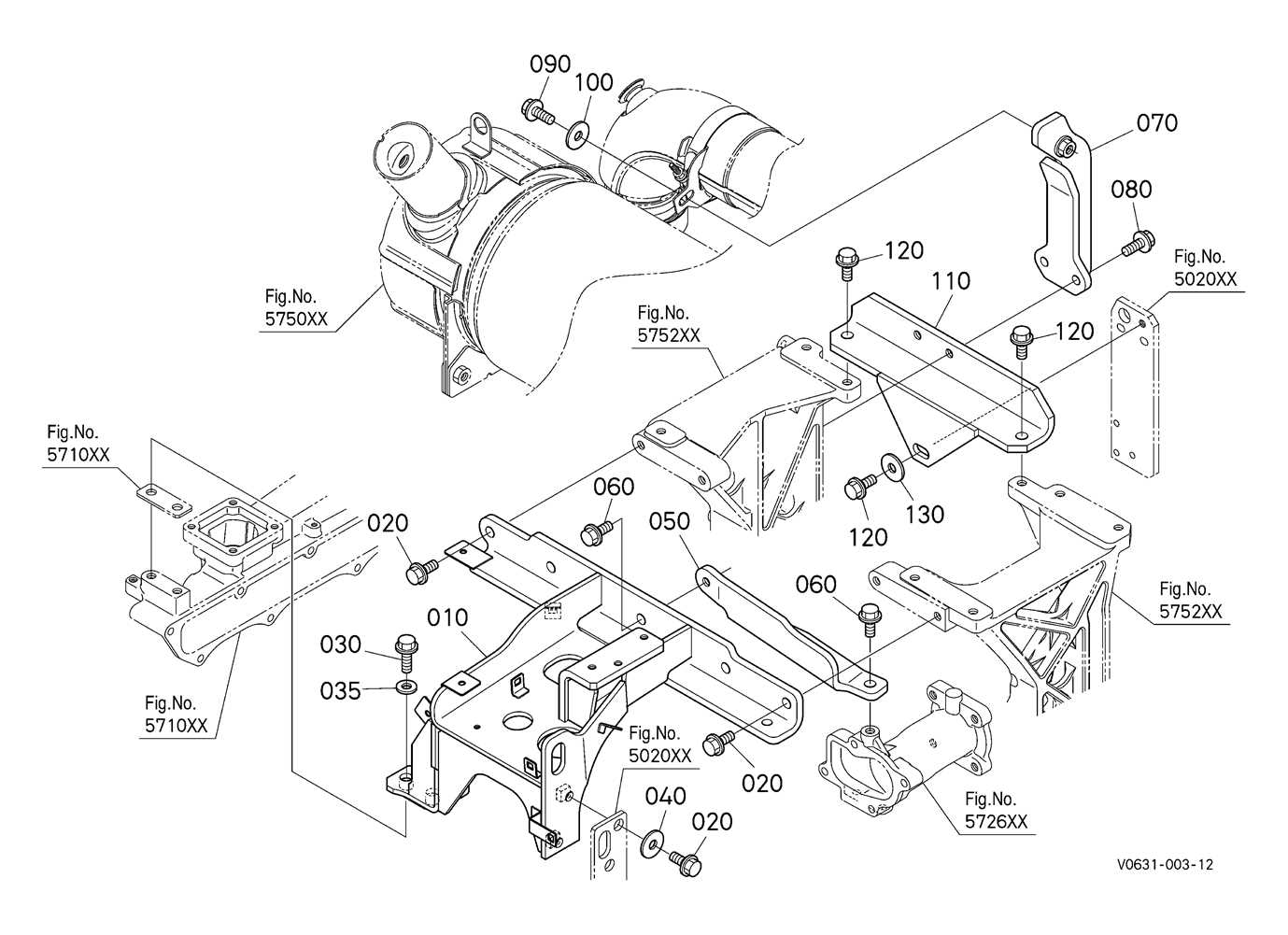

Identifying Parts with Diagrams

Understanding machinery components can often be challenging, but visual aids serve as invaluable resources. By examining illustrations, users can quickly identify various elements, leading to more effective maintenance and repairs. These visual representations break down complex structures into manageable segments, making it easier to pinpoint specific areas of interest.

Benefits of Using Visual Aids

- Enhanced clarity in identifying components

- Quick reference for troubleshooting issues

- Improved efficiency during maintenance tasks

- Better understanding of assembly and disassembly processes

How to Effectively Use Illustrations

- Familiarize yourself with the overall layout before diving into specifics.

- Cross-reference labeled parts with their functions for deeper understanding.

- Take note of any associated parts that may require simultaneous attention.

- Utilize these visuals as a guide during the repair or replacement process.

Maintenance Tips for SVL95

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. Implementing a consistent maintenance routine can prevent costly repairs and enhance productivity. Here are some key recommendations to keep your equipment in peak condition.

- Regular Inspections: Conduct frequent checks of the machine to identify any wear or potential issues early on.

- Fluid Checks: Monitor hydraulic and engine oils, coolant levels, and fuel quality to ensure they are within acceptable ranges.

- Filter Replacement: Replace air, oil, and fuel filters as per the manufacturer’s schedule to maintain efficiency and performance.

- Cleaning: Keep the exterior and undercarriage clean to prevent dirt buildup, which can affect cooling and component function.

- Tire and Track Maintenance: Inspect tires and tracks for wear and proper tension; ensure they are inflated and adjusted as necessary.

Implementing these practices can significantly enhance the reliability and efficiency of your machine, ensuring it performs at its best throughout its service life.

Where to Find Replacement Parts

When it comes to maintaining heavy machinery, sourcing quality components is crucial for optimal performance and longevity. Identifying reliable suppliers and understanding where to locate essential elements can make a significant difference in ensuring your equipment runs smoothly. This section will guide you through various avenues to acquire the necessary replacements.

One effective option is to explore authorized dealerships that specialize in your specific equipment brand. These locations typically offer genuine components and knowledgeable staff who can assist you with your requirements. Additionally, visiting manufacturer websites can provide insights into recommended suppliers and current inventory.

Another alternative is to search for reputable online retailers that focus on machinery components. These platforms often feature extensive catalogs, allowing you to compare prices and find the exact items you need. Be sure to check customer reviews to ensure reliability before making a purchase.

Furthermore, local salvage yards can be valuable resources for finding second-hand elements at a reduced cost. While the quality may vary, you might discover hard-to-find items that are still in good condition. Networking with fellow operators and industry professionals can also lead to recommendations for trusted sources.

Lastly, consider joining forums or social media groups dedicated to machinery enthusiasts. These communities often share tips on where to find specific components and can connect you with sellers who specialize in aftermarket options.

Benefits of Genuine Kubota Parts

When it comes to maintaining and enhancing the performance of your machinery, opting for original components offers numerous advantages. These authentic elements are designed specifically for your equipment, ensuring optimal compatibility and functionality. By choosing these high-quality items, you not only safeguard your investment but also enhance the overall longevity of your machine.

Reliability is one of the key benefits of using original components. They undergo rigorous testing and meet stringent quality standards, which means you can trust their performance under various working conditions. This reliability translates to reduced downtime, allowing you to complete tasks efficiently without unexpected interruptions.

Another significant advantage is performance optimization. Authentic elements are engineered to work seamlessly with your equipment, ensuring that every part operates in harmony. This results in improved efficiency, allowing your machinery to perform at its best, which is crucial for achieving optimal productivity.

Additionally, utilizing original components can lead to cost savings in the long run. While generic alternatives may seem more economical initially, they often lack durability and can result in frequent replacements. This can lead to increased maintenance costs and potential damage to your equipment, negating any initial savings.

Finally, selecting genuine components often comes with warranty benefits. Many manufacturers provide warranties on their original parts, offering peace of mind and protection against defects. This assurance is invaluable, as it ensures that your investment is safeguarded for years to come.

Using Online Resources Effectively

In today’s digital age, accessing information has never been easier. However, the challenge lies in utilizing these resources to their fullest potential. By employing effective strategies, individuals can navigate the vast landscape of online content, ensuring they find the most relevant and accurate information for their needs.

Start with Reputable Sources: Always prioritize trustworthy websites and databases. Academic institutions, government sites, and established industry platforms are typically more reliable than user-generated content. This helps ensure the information you gather is credible and up-to-date.

Utilize Search Filters: Many search engines offer advanced filtering options. By refining your search with specific keywords, publication dates, or content types, you can quickly zero in on the material that is most pertinent to your inquiry.

Leverage Community Forums: Engaging in online communities can provide invaluable insights. Platforms where professionals share experiences and advice can help clarify complex topics, offering practical solutions that you may not find in traditional sources.

Bookmark and Organize: As you discover valuable resources, keep them organized for easy access later. Bookmarking tools or digital note-taking applications can help you compile information systematically, making it easier to reference when needed.

Stay Updated: The online landscape is constantly evolving. Subscribing to newsletters, following relevant blogs, or joining professional groups can keep you informed about the latest developments in your area of interest.

By implementing these strategies, you can enhance your online research skills and effectively gather the information necessary to support your projects and decisions.