Complete Guide to Husqvarna 325L Parts Diagram

In the world of outdoor machinery, knowing the intricate details of various tools is essential for effective maintenance and repair. A comprehensive overview of the individual elements that comprise your device can enhance both its longevity and performance. Familiarizing yourself with these components allows for informed decisions when it comes to servicing and replacements.

Each model is equipped with a unique arrangement of parts that contribute to its functionality. Whether it’s the engine, the cutting mechanism, or the frame, every section plays a pivotal role in ensuring the equipment operates smoothly. By examining these elements closely, users can pinpoint issues and address them proactively, minimizing downtime and maximizing efficiency.

Having access to a detailed visual representation of these components is invaluable. Such resources not only aid in identifying each part but also facilitate understanding of how they interact with one another. This knowledge empowers operators to tackle maintenance tasks with confidence, ensuring their machinery remains in peak condition for years to come.

Understanding the Husqvarna 325L Model

This section delves into the intricacies of a popular outdoor power equipment model, renowned for its efficiency and durability. Recognized among users for its robust performance, this tool serves as a reliable companion for both professional landscapers and home gardeners alike. Its thoughtful design and engineering make it an essential asset for various gardening tasks.

Key Features and Benefits

The featured model boasts a range of functionalities that enhance user experience. One of its standout attributes is the lightweight construction, which facilitates ease of handling during prolonged use. Additionally, the powerful engine ensures that cutting through dense foliage is accomplished with minimal effort. The ergonomic design contributes to user comfort, reducing fatigue during extensive operations.

Maintenance and Care

Proper maintenance is crucial to ensure longevity and optimal performance. Regular cleaning and inspection of components can prevent issues and enhance efficiency. Utilizing genuine replacement elements not only guarantees compatibility but also contributes to the overall lifespan of the equipment. Users are encouraged to refer to the manufacturer’s guidelines for specific care routines, ensuring that the tool remains in peak condition.

Essential Features of the 325L

The machine’s design incorporates a blend of efficiency, durability, and user-friendly controls. Its overall build focuses on ensuring optimal performance in various outdoor tasks, catering to both professional and occasional use. This section outlines key attributes that make the tool reliable for consistent operation.

| Feature | Details |

|---|---|

| Engine Power | Equipped with a high-output motor for handling tough vegetation and extended use. |

| Ergonomics | Designed with a balanced weight distribution and comfortable grip for reduced fatigue during extended sessions. |

| Fuel Efficiency | Built to minimize fuel consumption, offering longer operating times without frequent refills. |

| Durability | Constructed from robust materials, ensuring the equipment withstands harsh working conditions. |

| Maintenance | Engineered for easy access to components, simplifying cleaning and routine upkeep. |

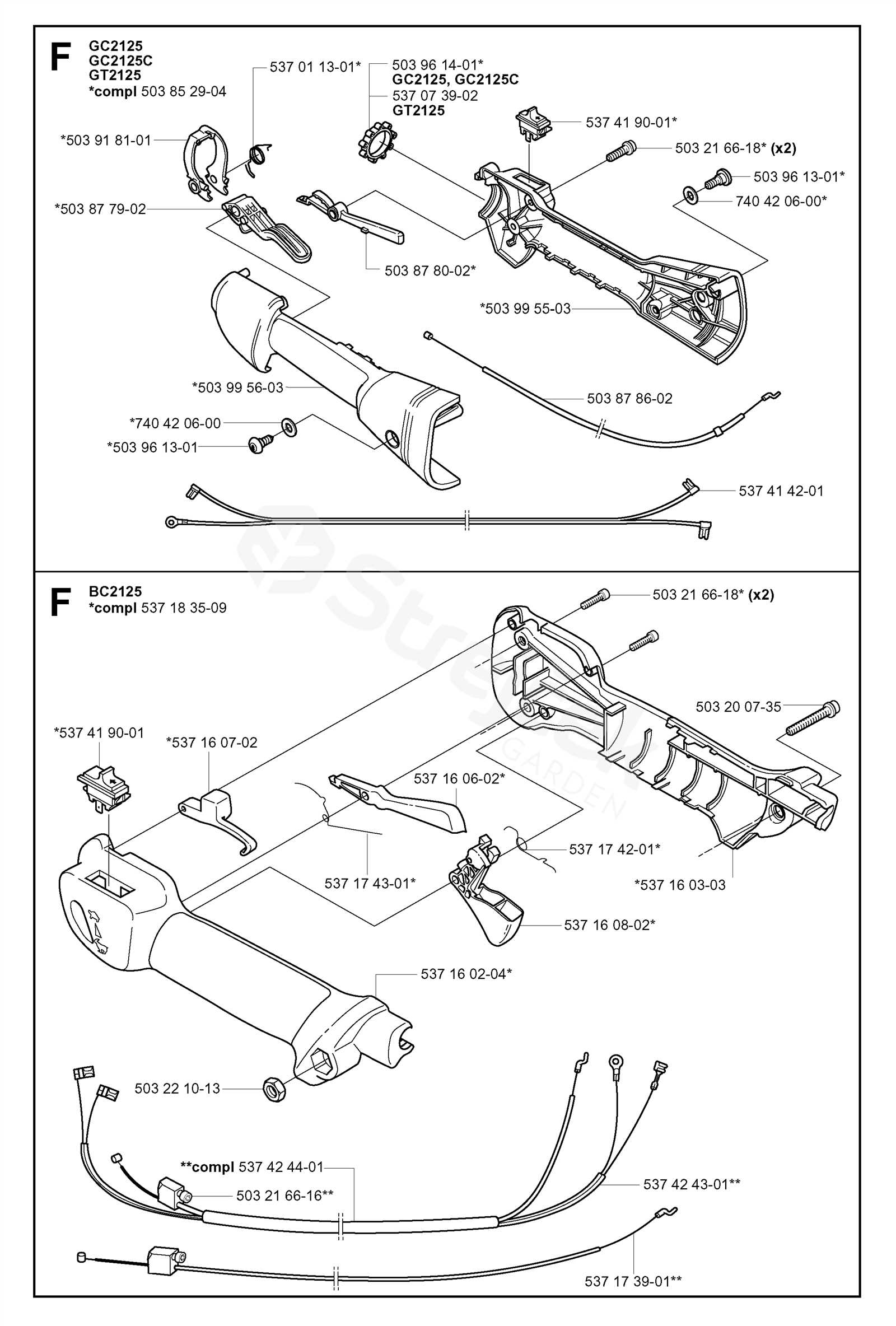

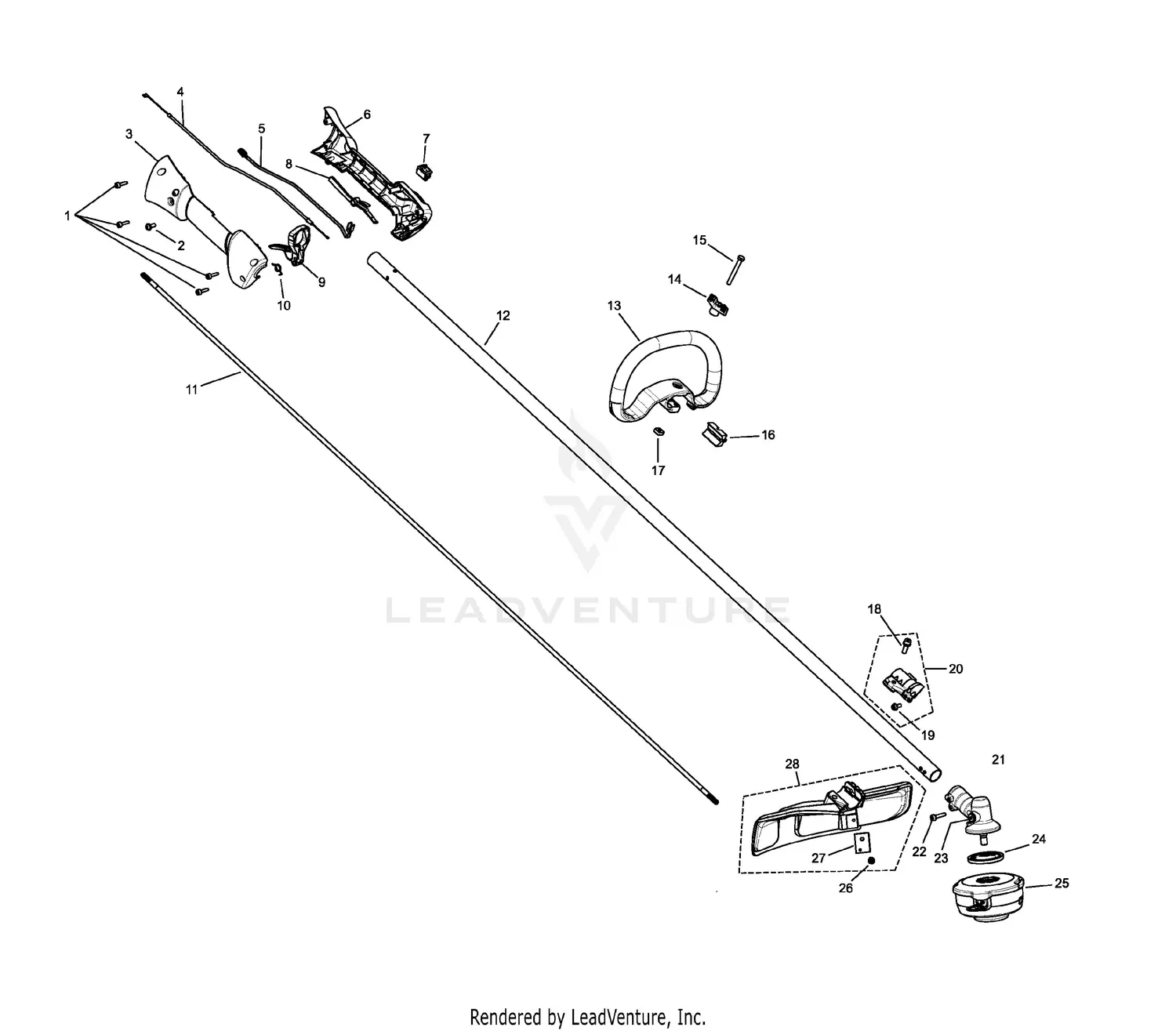

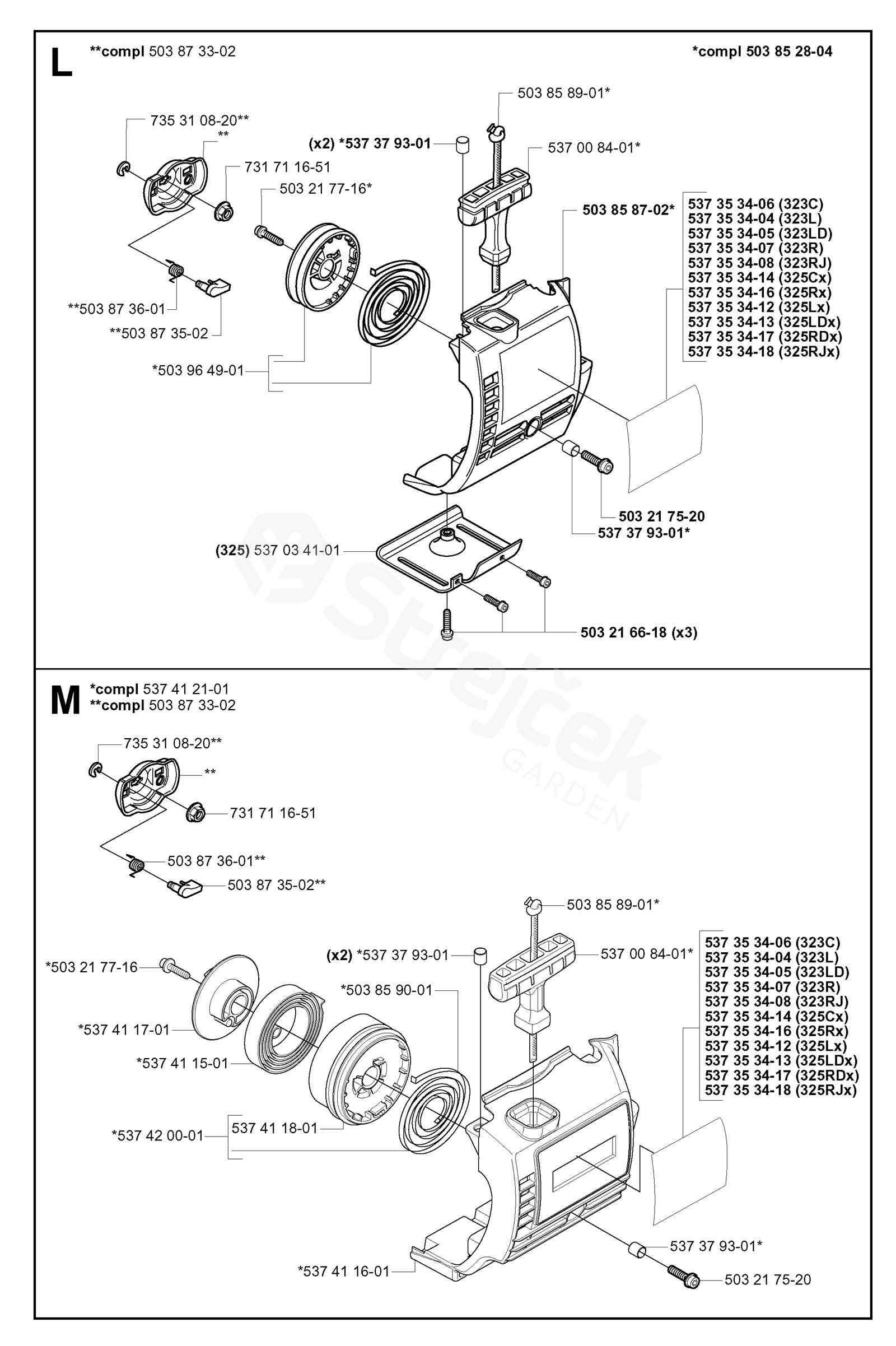

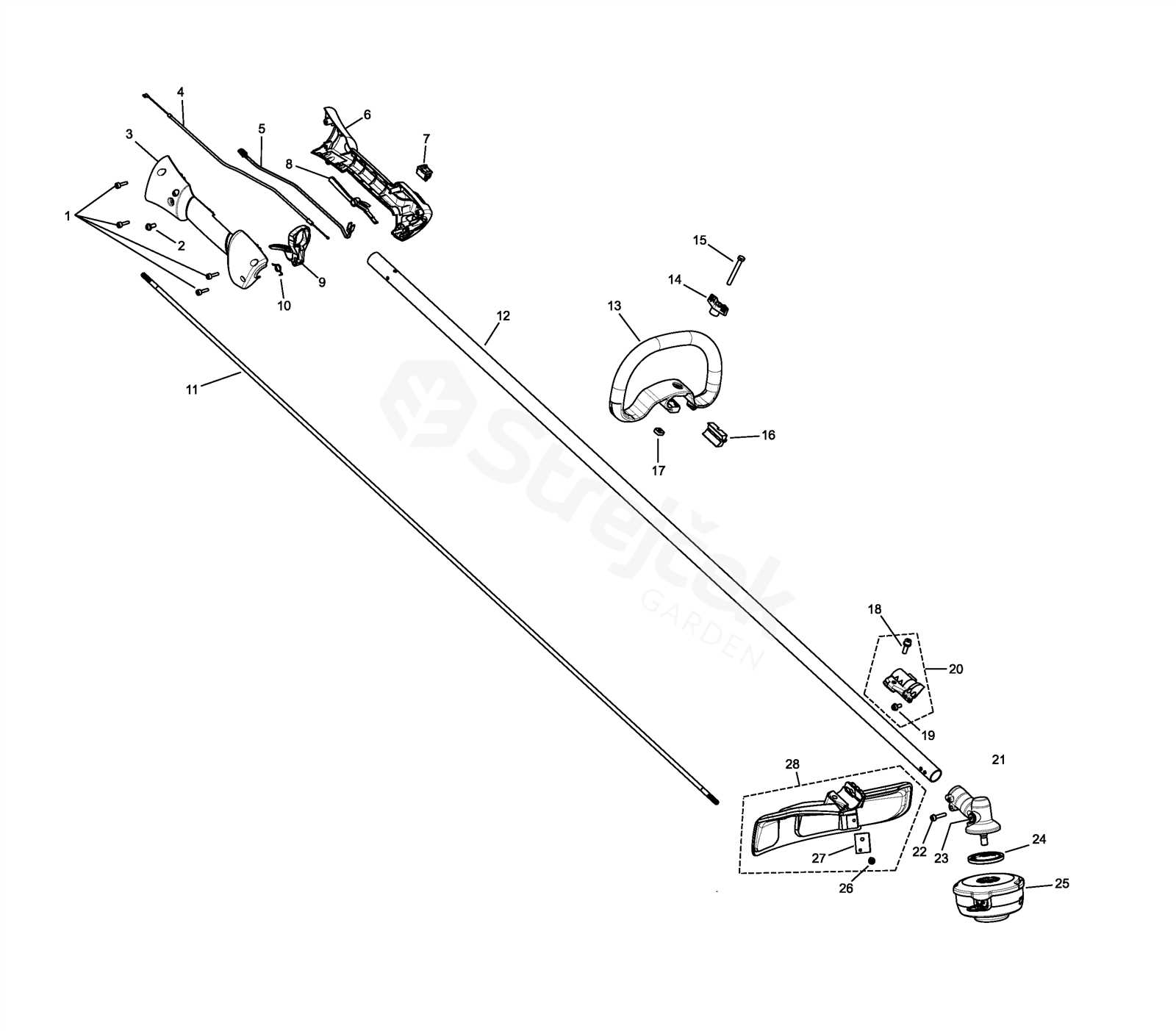

Importance of Parts Diagrams

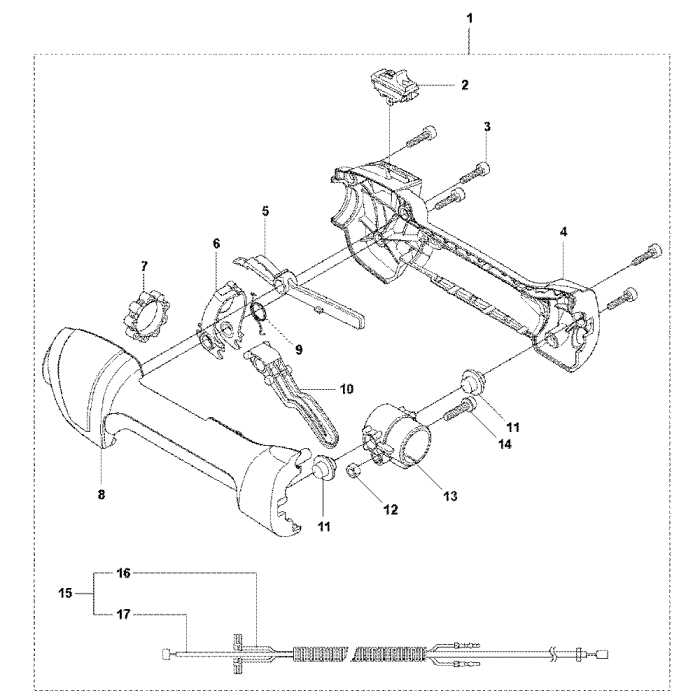

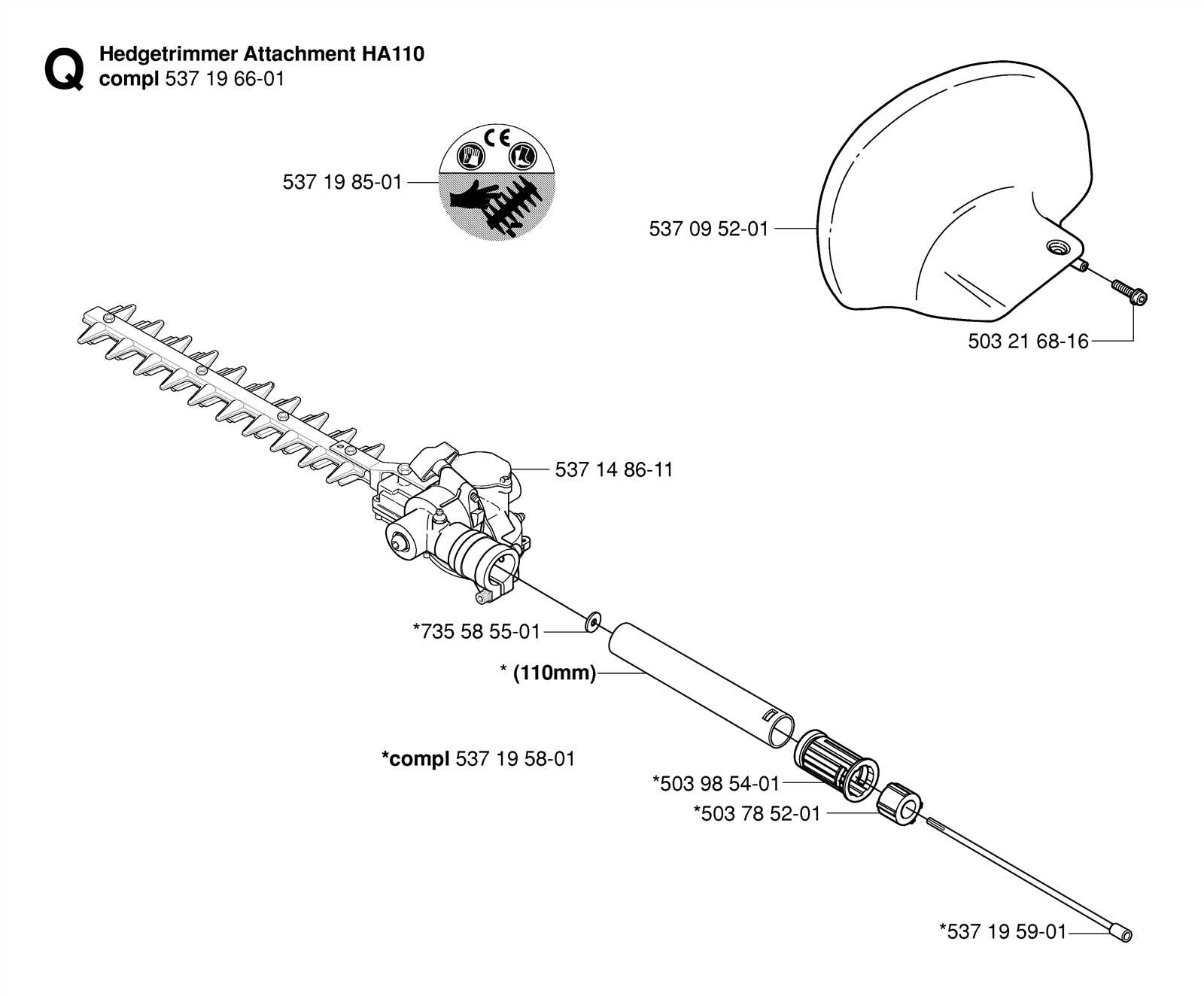

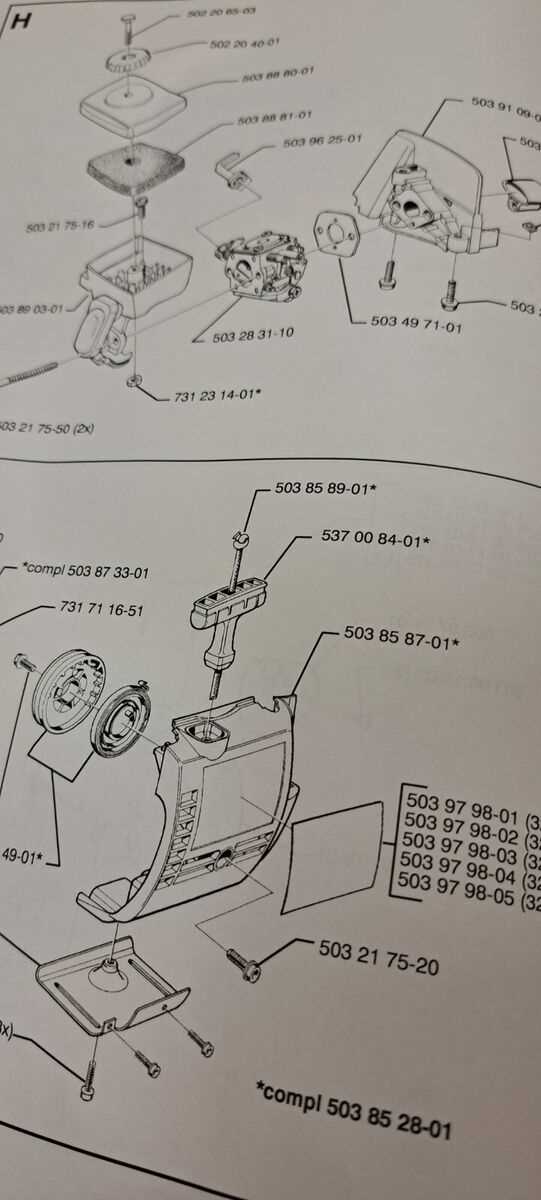

Clear visual representations of equipment components play a crucial role in maintaining and repairing mechanical systems. These detailed illustrations provide users with a comprehensive overview of how individual elements fit together and function as a whole.

Understanding the structure of any machine helps not only in identifying specific issues but also in ensuring that replacements or adjustments are done with precision. Without these diagrams, disassembling or fixing complex machinery could lead to mistakes, further damages, or improper assembly.

By offering step-by-step guidance, these visuals reduce the time needed for troubleshooting and simplify the overall repair process. They are essential tools for both professionals and hobbyists looking to keep their equipment in optimal condition.

Commonly Replaced Components

Regular maintenance ensures the longevity of outdoor equipment, but some parts naturally wear out over time. Knowing which components are most frequently replaced can help prevent sudden breakdowns and keep machinery operating smoothly. Below are several key elements that often require attention due to wear or damage.

- Filters: Air and fuel filters play a critical role in keeping debris out of the engine. Regular inspection and replacement prevent clogging, which can lead to poor performance.

- Drive belts: These components are responsible for transmitting power between the engine and moving parts. Over time, belts can wear down or crack, requiring replacement to maintain efficient operation.

- Spark plugs: Essential for ignition, spark plugs can become fouled with carbon deposits or wear down, leading to difficulties in starting the engine. Routine checks and timely replacement are crucial for reliable performance.

- Blades: Cutting or trimming blades dull over time with regular use, affecting their efficiency.

How to Access the Parts Diagram

Finding detailed information about the components of your equipment is essential for repairs or maintenance. This guide will help you locate the visual reference that displays the structure and arrangement of all the key elements.

- Visit the official website or relevant support page of your equipment’s manufacturer.

- Look for the section dedicated to product documentation or support materials.

- Enter your model number or browse through the categories to find your specific equipment.

- Select the breakdown illustration, typically available as a PDF or interactive image.

- Make sure to download or print the document for future reference during repairs.

Following these steps will ensure you have a reliable visual guide to identify and work with individual components efficiently.

Maintenance Tips for Optimal Performance

To ensure your equipment operates efficiently, regular upkeep is crucial. By following simple yet effective care routines, you can extend the life of your tools and maintain their peak performance. Preventive measures not only improve functionality but also reduce the risk of unexpected breakdowns.

Regular Cleaning

One of the easiest ways to keep your machine in top condition is by cleaning it after each use. Remove any debris that may have accumulated, paying close attention to areas prone to clogging. Regular cleaning prevents long-term buildup and ensures smooth operation.

Inspection and Lubrication

Periodically inspect all moving parts and connections for signs of wear. Lubricate the essential components to reduce friction and enhance overall performance. Well-maintained parts help avoid costly repairs and improve the machine’s longevity.

Identifying Parts by Model Number

Understanding how to locate the correct components for specific equipment models is essential for efficient repairs or maintenance. Knowing the model number allows users to match parts precisely to the machinery they need to service. This section will guide you on how to use model numbers effectively for identifying necessary components.

Where to Find the Model Number

The model number can often be found on a label or plate attached to the equipment. It typically consists of a combination of numbers and letters. Check common locations like the engine cover or the frame. Once identified, this number becomes crucial for finding compatible components.

- Check labels or plates on the equipment

- Look at the engine or frame for identifying marks

- Ensure the model number is entered correctly when searching for parts

Where to Buy Replacement Parts

Finding the correct components for your equipment is crucial for maintaining its performance and extending its lifespan. Whether you’re dealing with wear and tear or a sudden breakdown, having a reliable source for high-quality replacements can make all the difference in keeping your tool in top condition.

Authorized Dealers

One of the best places to purchase original components is through authorized dealers. These stores ensure that you are getting items that meet the manufacturer’s specifications, guaranteeing compatibility and durability. They also offer expert advice and customer support.

Online Retailers

If you’re looking for convenience, online platforms offer a wide range of options for sourcing components. Many retailers provide detailed listings and user reviews, helping you compare prices and find the right fit for your needs. Shopping online can also give you access to hard-to-find items that might not be available locally.

DIY Repair Guide for Beginners

Taking on simple maintenance and fixing tasks can be a rewarding experience for those new to hands-on projects. This guide provides essential tips and steps for tackling common issues, ensuring that even those with little prior knowledge can feel confident in their ability to handle repairs effectively.

Basic Tools You’ll Need

Before starting any project, it’s important to gather the necessary tools. A basic toolkit with a few essential items will suffice for most small repairs. Here’s a quick overview of the key tools:

Tool Purpose Screwdriver Set For tightening or loosening screws Wrench Useful for bolts and nuts Pliers Gripping and pulling components Safety Precautions While Repairing When working on equipment, ensuring personal safety is paramount. Following basic guidelines can help prevent injuries and ensure that repairs are completed without complications.

- Disconnect Power: Always make sure the machine is completely powered off and unplugged before starting any maintenance.

- Wear Protective Gear: Use appropriate protective equipment such as gloves, safety glasses, and sturdy footwear to protect yourself from sharp parts or unexpected hazards.

- Work in a Well-Lit Area: Proper lighting is crucial for clearly seeing all components, reducing the chances of errors or accidents.

- Follow the Manual: Refer to the product manual to understand specific repair procedures and avoid improvising on critical parts.

- Use the Right Tools: Make sure you have the proper tools for the job to avoid damage to components or injury from makeshift solutions.

- Secure the Work Area: Keep your

Understanding Engine Components

The internal structure of a small two-stroke engine is a complex assembly of key elements working together to ensure efficient operation. Each component plays a critical role in powering the machine, transforming fuel into motion through precise mechanical interactions.

- Cylinder and Piston: The cylinder houses the piston, which moves up and down to create the necessary compression for combustion. This process generates the power that drives the engine.

- Crankshaft: Connected to the piston, the crankshaft converts the piston’s linear movement into rotational force, ultimately turning the drive mechanisms.

- Carburetor: This component ensures the proper air-to-fuel mixture is delivered to the combustion chamber, optimizing engine performance and efficiency.

- Spark Plug: The spark plug ignites the fuel-air mixture inside the cylinder, creating the explosion that propels the piston.

- Exhaust System: After combustion, gases are expelled through the exhaust

Tips for Troubleshooting Issues

Troubleshooting mechanical equipment can often feel daunting, but with the right approach, you can identify and resolve common problems effectively. Understanding the essential components and their functions will aid in pinpointing the source of the issue. Here are some practical tips to consider when addressing challenges.

- Consult the Manual: Always start with the user manual. It provides valuable information on specifications, troubleshooting procedures, and maintenance recommendations.

- Visual Inspection: Conduct a thorough visual check of the machine. Look for signs of wear, loose connections, or damaged parts that may affect performance.

- Test All Functions: Operate the equipment while monitoring different functions. This can help isolate the problem to specific components.

- Check Fuel and Oil Levels: Low fuel or oil levels can lead to performance issues. Ensure that these levels are adequate before proceeding with more in-depth troubleshooting.

- Look for Clogs: Inspect air filters, fuel lines, and exhaust systems for blockages that can impede operation. Cleaning or replacing these components can restore functionality.

By following these strategies, you can systematically diagnose and rectify issues, ensuring your equipment runs smoothly and efficiently.

Upgrading Your Equipment Effectively

Enhancing your tools can significantly improve performance and efficiency. Whether you’re looking to boost capabilities or extend the lifespan of your machinery, thoughtful upgrades are essential. By evaluating your current setup and identifying areas for enhancement, you can make informed decisions that lead to better results.

Consider the Compatibility: When selecting new components, ensure they are compatible with your existing systems. Research specifications and consult with manufacturers or experts to avoid issues down the line. This approach helps maintain seamless operation and maximizes the benefits of your upgrades.

Prioritize Quality: Investing in high-quality parts can lead to increased durability and reliability. While it may be tempting to opt for cheaper alternatives, consider the long-term costs associated with frequent replacements or repairs. Premium components often provide better performance and peace of mind.

Stay Informed: Keeping up with the latest advancements in technology can guide your upgrade decisions. Subscribe to industry newsletters, attend workshops, and engage with community forums to learn about new products and innovations. This knowledge will empower you to make upgrades that truly enhance your equipment.

Evaluate Your Needs: Before proceeding with any upgrades, assess your specific requirements. Identify the tasks that challenge your current equipment and prioritize upgrades that address these needs. Tailoring your enhancements to your operational demands will yield the best results.