Comprehensive Guide to John Deere 827E Parts Diagram

In the realm of heavy equipment, grasping the intricacies of the structural assembly is crucial for effective maintenance and repair. A detailed representation of the various elements that make up these robust machines serves as an invaluable tool for operators and technicians alike. Such visual aids enhance comprehension and facilitate a smoother workflow when addressing mechanical issues.

When working with complex machinery, knowing the specific configuration of each element can prevent costly errors and downtime. By referring to an organized schematic, users can quickly identify the location and function of individual components. This not only streamlines repairs but also fosters a deeper understanding of the machine’s operation, empowering users to troubleshoot problems more effectively.

Whether you are a seasoned professional or a newcomer in the industry, familiarizing yourself with the layout of key components is essential. The ability to visualize how each part interacts within the system can enhance your skills and confidence. Ultimately, such knowledge translates into improved performance and longevity for the equipment you rely on.

Understanding John Deere 827E Parts

When it comes to machinery maintenance, comprehending the components and their functions is essential for optimal performance and longevity. Every element plays a crucial role in the overall operation, ensuring efficiency and reliability during tasks. By familiarizing oneself with these components, operators can make informed decisions regarding repairs and upgrades.

Essential Elements are the building blocks of any equipment, from the engine to the hydraulic systems. Each piece has a specific function, contributing to the seamless operation of the entire system. Understanding how these elements interact can help in diagnosing issues and performing routine maintenance effectively.

Maintenance and Replacement are vital aspects of equipment ownership. Knowing when to replace a worn-out component or how to maintain it properly can save time and resources. Regular checks and timely interventions can prevent minor issues from escalating into major repairs, ensuring that the machine remains in peak condition.

In summary, gaining insight into the various components of your machinery not only enhances operational efficiency but also promotes a proactive approach to maintenance, ultimately leading to better performance and durability.

Key Components of 827E Model

The efficiency and functionality of heavy machinery rely on various essential elements that work in harmony. Understanding these crucial components is vital for optimal performance and maintenance. Each part plays a specific role, contributing to the overall capability and reliability of the equipment.

Engine: The powerhouse of the machine, the engine delivers the necessary energy to operate all functions. Its design emphasizes durability and efficiency, ensuring that it can handle demanding tasks.

Transmission System: This component is responsible for transferring power from the engine to the wheels or tracks. A well-engineered transmission system allows for smooth operation and adaptability across different terrains.

Hydraulic System: A key feature that enhances maneuverability and lifting capabilities, the hydraulic system utilizes fluid power to facilitate various movements. Its reliability is crucial for executing precise tasks.

Chassis: Serving as the foundational framework, the chassis supports all other components and provides stability. Its robust construction is designed to withstand heavy loads and challenging working conditions.

Control Mechanisms: These elements allow operators to manage the machine’s functions efficiently. Ergonomically designed controls improve usability and precision, enhancing overall productivity.

Each of these components is integral to the machine’s performance, and understanding their functions aids in effective maintenance and operation.

Importance of Parts Diagrams

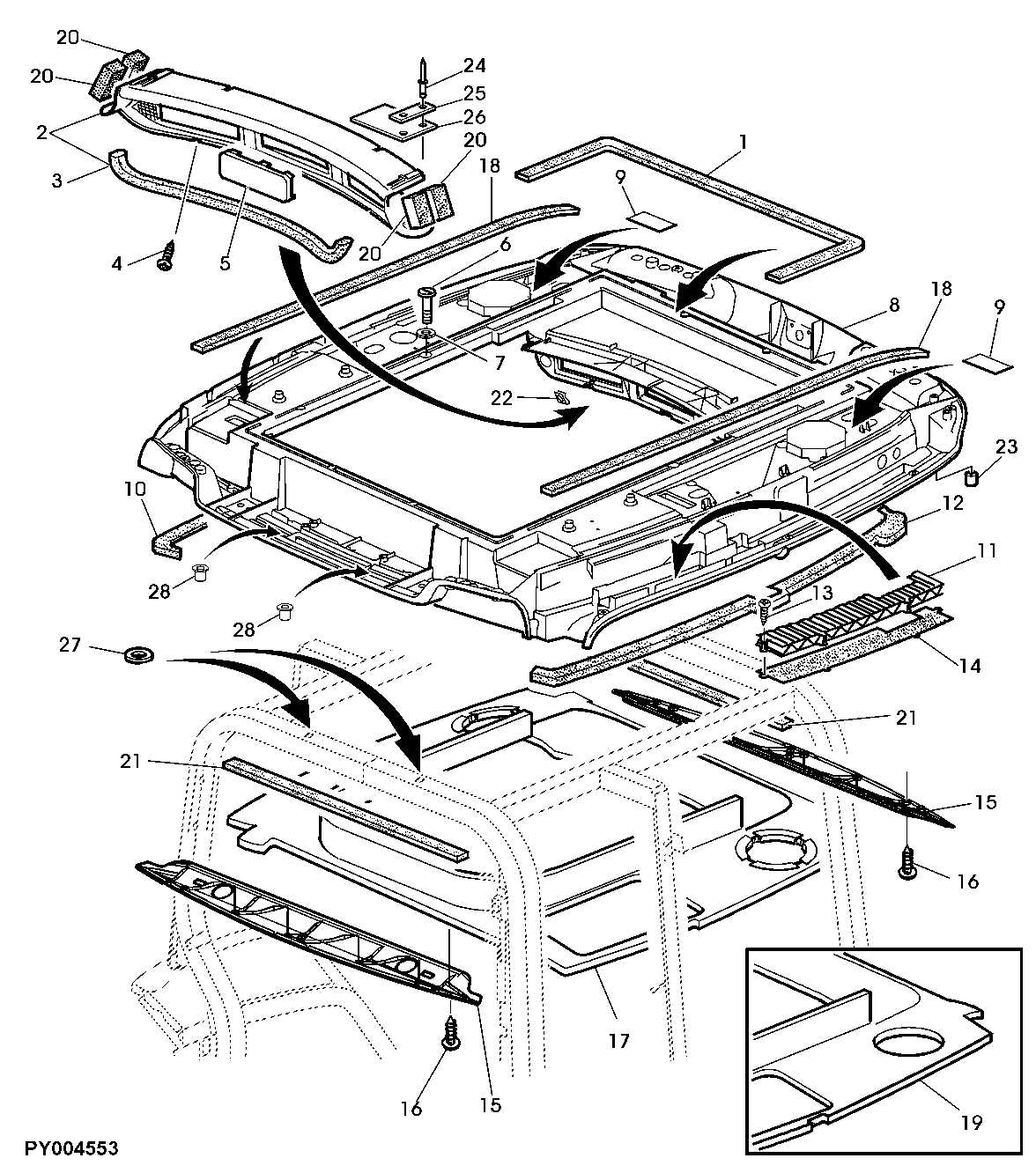

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide a clear overview of individual elements, allowing users to identify, locate, and understand each piece’s function within the system. This clarity helps streamline troubleshooting and enhances the efficiency of repairs.

These illustrations are particularly valuable for both novice and experienced technicians. They serve as a reference point, enabling users to follow assembly instructions or replacement procedures with greater accuracy. A well-structured visual guide can significantly reduce the time spent searching for specific elements, ultimately improving productivity.

| Benefits | Description |

|---|---|

| Clarity | Provides a visual reference that simplifies understanding of complex systems. |

| Efficiency | Speeds up repair processes by reducing guesswork and improving accuracy. |

| Training Aid | Assists in training new technicians by providing clear, visual explanations of components. |

| Inventory Management | Helps in tracking and organizing components, facilitating better inventory control. |

In summary, these visual aids are essential tools for anyone involved in the upkeep of equipment. Their ability to enhance understanding and streamline processes underscores their importance in the industry.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of machinery. These visual guides serve as a roadmap, helping users identify components, their relationships, and the order of assembly. By mastering the art of interpreting these visuals, you can streamline the repair process and ensure the longevity of your equipment.

First, familiarize yourself with the legend or key, as it typically contains symbols and markings that indicate specific elements and their functions. Each component is usually numbered or labeled, allowing for easy cross-referencing with lists or catalogs. Pay attention to the lines connecting different elements; these indicate how parts fit together or interact within the system.

Next, observe the layout carefully. Components are often organized logically, reflecting their physical arrangement within the machinery. This organization helps you visualize where each piece belongs and understand the assembly sequence. Take note of any highlighted or shaded areas that might indicate special instructions or critical parts that require extra attention.

Finally, practice makes perfect. Spend time reviewing various illustrations to build your confidence in recognizing different components and their roles. With experience, you’ll find it easier to navigate these guides and efficiently tackle any maintenance or repair tasks.

Common Issues with 827E Parts

Understanding the frequent challenges associated with specific components is essential for effective maintenance and optimal performance. Many users encounter similar malfunctions that can impede functionality and lead to costly repairs if not addressed promptly.

Typical Problems

Users often report a variety of issues that stem from wear and tear, incorrect installation, or inferior quality of replacement components. These problems can manifest as reduced efficiency or complete failure of the equipment.

Common Component Failures

| Component | Issue | Possible Solution |

|---|---|---|

| Hydraulic System | Leaking | Check seals and hoses for wear. |

| Engine Parts | Overheating | Inspect coolant levels and radiator condition. |

| Transmission | Slipping | Examine fluid levels and replace filters. |

Where to Find Replacement Parts

When searching for components to restore machinery, it’s essential to explore various avenues for obtaining reliable substitutes. From authorized dealers to online marketplaces, there are multiple resources available to help you locate the necessary items.

Authorized retailers often provide genuine components that ensure compatibility and durability. These locations typically offer expert advice and support, making them a valuable option for those unfamiliar with specific requirements.

Additionally, online platforms have become increasingly popular for sourcing equipment. Websites specializing in machinery supplies can provide a vast selection, often at competitive prices. Remember to check customer reviews and ratings to ensure quality.

Lastly, consider connecting with local repair shops or machinery forums. Enthusiasts and professionals in these communities can offer insights into where to find sought-after items and may even have leads on second-hand options.

Benefits of Genuine John Deere Parts

Using authentic components for machinery ensures optimal performance and longevity. These elements are specifically designed to meet the highest standards, resulting in enhanced reliability and efficiency.

Quality Assurance

- Manufactured to strict specifications.

- Thoroughly tested for durability.

- Consistent performance across various conditions.

Cost-Effectiveness

- Reduces the likelihood of costly repairs.

- Minimizes downtime through reliable operation.

- Maximizes the lifespan of machinery.

Aftermarket vs. Original Parts

The choice between alternative and manufacturer-specific components is crucial for maintaining machinery. Each option presents unique advantages and drawbacks that can significantly influence performance, longevity, and cost-effectiveness.

Original components are typically designed to meet exact specifications set by the manufacturer. This often ensures compatibility and reliability, but may come with a higher price tag. Conversely, aftermarket alternatives can offer cost savings and a wider variety of options. However, the quality and fit may vary, requiring careful consideration.

Ultimately, the decision should be guided by factors such as budget, usage, and the desired level of assurance regarding performance. It’s essential to delve into reviews and experiences to make an informed choice that best meets individual needs.

Maintenance Tips for 827E

Regular upkeep is essential to ensure optimal performance and longevity of your machinery. Implementing a systematic maintenance routine can prevent unexpected breakdowns and enhance efficiency. Focus on key areas such as lubrication, inspection, and timely replacements to keep your equipment running smoothly.

Lubrication and Fluid Checks

Proper lubrication is crucial for minimizing wear and tear. Regularly check oil levels and replace fluids as needed. Pay attention to grease points to ensure all moving parts operate seamlessly, reducing friction and extending the lifespan of components.

Inspection and Replacement

Conduct frequent inspections of vital components to identify signs of wear. Replace any damaged parts promptly to avoid further issues. Keeping an eye on filters and belts can prevent larger mechanical problems and ensure efficient operation.

Identifying Part Numbers Easily

Locating specific identifiers for machinery components can streamline maintenance and repair processes. Understanding the nuances of these identifiers is crucial for effective sourcing and inventory management.

- Consult Manufacturer Resources: Most manufacturers provide catalogs that detail various components and their corresponding identifiers.

- Utilize Online Databases: Numerous websites offer searchable databases that can quickly match components with their identifiers.

- Join User Forums: Engaging with online communities can yield insights and shared experiences regarding specific identifiers.

- Keep a Reference List: Maintain a personal record of commonly used identifiers to enhance efficiency during future tasks.

By employing these strategies, you can effectively navigate the landscape of component identification and ensure you always have the right information at hand.

Online Resources for Parts Diagrams

Accessing detailed visual guides for machinery components is essential for efficient maintenance and repair. Numerous online platforms provide valuable resources to help users identify and locate various elements of their equipment. These digital tools enhance understanding and streamline the process of sourcing necessary items.

Manufacturer Websites: Official manufacturer websites often host comprehensive catalogs, including clear visuals and specifications. These resources are reliable and up-to-date, making them a primary choice for users seeking accurate information.

Online Forums and Communities: Participating in online forums can be incredibly beneficial. Enthusiasts and professionals share their experiences, tips, and even scanned manuals, fostering a collaborative environment for troubleshooting and advice.

Third-Party Retailers: Various retailers specialize in equipment and accessories, often featuring interactive tools that allow users to explore components in detail. These platforms may also offer comparison tools to aid in making informed purchasing decisions.

YouTube Tutorials: Video content can provide visual guidance on disassembly and assembly processes. Many creators demonstrate how to identify specific elements, making complex tasks more approachable for users with varying levels of expertise.

Utilizing these online resources empowers users to navigate the intricacies of their equipment effectively, ensuring longevity and optimal performance.

Cost Considerations for Repairs

When it comes to maintaining heavy machinery, understanding the financial implications of repairs is crucial. Several factors can influence the overall cost, including labor, components, and unexpected complications. A thorough assessment can help in budgeting effectively and ensuring minimal downtime.

Key elements to consider when evaluating repair costs include:

| Factor | Description |

|---|---|

| Labor Expenses | Costs associated with skilled technicians and the time required for repairs. |

| Replacement Components | Price of new or refurbished parts necessary for restoration. |

| Downtime | Potential revenue loss due to the machinery being out of operation during repairs. |

| Warranty Considerations | Impact of warranties on certain repairs, which may reduce out-of-pocket expenses. |

| Preventive Maintenance | Investment in regular maintenance that can lower the likelihood of costly repairs. |

By taking these factors into account, operators can make informed decisions that will ultimately lead to better financial management and prolonged equipment life.

Frequently Asked Questions About 827E

This section addresses common inquiries regarding the specific machinery model, focusing on its components, functionality, and maintenance. Here, we aim to provide clear and concise answers to enhance understanding and support users in their operations.

- What types of components are essential for optimal performance?

Key components include:

- Engine system

- Transmission

- Hydraulic units

- Electrical systems

- How can I identify the correct replacement items?

To find the right replacements, consider the following:

- Refer to the equipment manual

- Check serial numbers

- Consult with authorized dealers

- What maintenance practices should be followed regularly?

Regular maintenance includes:

- Oil changes

- Filter replacements

- Routine inspections of key systems

- Are there common issues associated with this model?

Users have reported issues such as:

- Hydraulic leaks

- Electrical failures

- Engine performance problems

- Where can I find detailed technical assistance?

For technical support, consider:

- Manufacturer’s website

- Local service centers

- Online forums and user groups