Comprehensive Guide to John Deere CS56 Chainsaw Parts Diagram

When it comes to maintaining and operating your cutting equipment, a thorough grasp of its individual elements is essential. Each component plays a crucial role in the overall performance and efficiency of the device. Familiarity with these elements not only enhances the user experience but also aids in troubleshooting potential issues that may arise during usage.

Exploring the intricate layout of your equipment’s structure can reveal important insights into its functionality. By studying the arrangement and relationship of various components, operators can better appreciate how each part contributes to the machine’s effectiveness. This knowledge empowers users to make informed decisions regarding maintenance and repairs.

Moreover, having access to a comprehensive visual representation of the machinery allows for a clearer understanding of how to address specific problems. Such illustrations serve as valuable references, guiding users through assembly, disassembly, and replacement processes. This resource ultimately promotes a more efficient and safer operational experience.

Understanding the CS56 Chainsaw Components

Exploring the various elements of a cutting tool can enhance your knowledge of its functionality and maintenance. Each component plays a vital role in ensuring the equipment operates efficiently and safely. Familiarizing yourself with these parts allows for better troubleshooting and repairs.

Below is a table highlighting key components along with their functions:

| Component | Function |

|---|---|

| Engine | Powers the unit, converting fuel into mechanical energy. |

| Guide Bar | Serves as a track for the cutting chain, providing stability during operation. |

| Cutting Chain | Features sharp teeth for efficient cutting through wood. |

| Throttle Trigger | Regulates the engine speed and cutting power by controlling fuel flow. |

| Air Filter | Prevents dirt and debris from entering the engine, ensuring optimal performance. |

| Fuel Tank | Holds the fuel necessary for engine operation. |

Understanding these components can lead to improved performance and longevity of your equipment, as well as a safer operating experience.

Overview of John Deere Chainsaw Models

This section provides a comprehensive look at the various models offered by a renowned manufacturer known for its high-quality outdoor power equipment. These models are designed to cater to a wide range of users, from casual hobbyists to professional arborists, each with unique features and specifications that enhance performance and efficiency.

Features and Innovations

The highlighted equipment boasts several innovative technologies aimed at improving usability and safety. Features such as advanced fuel systems, ergonomic designs, and automatic lubrication contribute to a smoother operation. These enhancements not only optimize performance but also reduce user fatigue during prolonged use.

Choosing the Right Model

When selecting the ideal model, it’s essential to consider factors such as intended use, power requirements, and maintenance ease. The diverse lineup allows customers to find a suitable option that meets their specific needs, whether for light yard work or heavy-duty logging tasks.

Key Parts of CS56 Chainsaw Explained

Understanding the essential components of a cutting tool can significantly enhance its performance and maintenance. Each section plays a crucial role in ensuring efficient operation and longevity, making it vital for users to familiarize themselves with these elements.

Here are some of the fundamental components:

- Engine: Powers the tool, providing the necessary force for cutting through various materials.

- Guide Bar: The elongated metal piece that supports the cutting chain and helps guide it during operation.

- Cutting Chain: Features sharp teeth designed to slice through wood effectively, crucial for achieving clean cuts.

- Throttle Trigger: Allows the user to control the engine’s speed and, consequently, the cutting performance.

- Fuel Tank: Stores the fuel needed to power the engine, essential for operation.

- Oil Reservoir: Holds lubrication fluid that keeps the chain and bar functioning smoothly and prevents wear.

- Chain Brake: A safety feature that stops the chain from moving in case of kickback, ensuring user protection.

Each of these elements contributes to the overall effectiveness and safety of the equipment. Regular inspection and maintenance of these components will lead to optimal performance and a longer lifespan of the tool.

Importance of Proper Maintenance

Key benefits of maintaining your equipment include:

| Benefit | Description |

|---|---|

| Enhanced Performance | Regular inspections and servicing help maintain peak efficiency, ensuring smooth operation. |

| Extended Lifespan | Consistent care can significantly prolong the life of the tool, delaying the need for replacement. |

| Improved Safety | Well-maintained equipment reduces the risk of accidents and injuries during use. |

| Cost Savings | Preventive maintenance is often less expensive than repairing or replacing damaged components. |

Implementing a regular maintenance schedule will not only improve functionality but also provide peace of mind during operation. Investing time in upkeep is an investment in efficiency and safety.

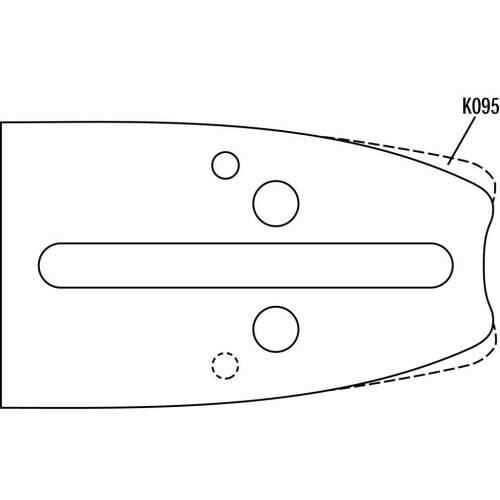

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repairs. These illustrations provide a clear representation of components, helping users identify specific elements and their relationships within a machine. Familiarity with these visuals can significantly enhance the repair process and ensure proper reassembly.

1. Familiarize Yourself with Symbols

Each schematic uses unique symbols to represent different components. Take time to learn what each symbol signifies to avoid confusion during the repair process. Often, the legend accompanying the illustration will clarify these symbols.

2. Follow the Layout

These visuals are generally organized in a logical manner, often following the assembly sequence. Start from the top or left and proceed systematically to understand how components fit together. This approach helps in visualizing the overall structure.

3. Identify Key Components

Focus on locating critical elements first, such as the engine or main housing. Once these are understood, it becomes easier to relate smaller parts to the overall assembly. Highlighting or marking these key components can aid in your understanding.

4. Reference the Parts List

Often, a list accompanies the visual, detailing each component’s name and specifications. Use this list to confirm the correct part numbers and descriptions, ensuring you procure the right replacements during repairs.

5. Practice Regularly

The more you engage with these schematics, the more intuitive they will become. Regular practice will enhance your ability to quickly identify parts and understand their functions, making the repair process more efficient and less daunting.

Common Issues with CS56 Components

Understanding the frequent challenges encountered with various components is essential for maintaining optimal performance. Each element plays a crucial role, and when one part fails, it can affect the entire system. Identifying these common issues can help in timely troubleshooting and enhance longevity.

Frequent Problems

- Fuel Delivery Issues: Blockages in the fuel line can lead to inadequate fuel flow, causing the engine to stall.

- Electrical Failures: Malfunctions in the ignition system can prevent starting, often due to worn spark plugs or faulty wiring.

- Chain Tension Difficulties: An improperly adjusted chain can lead to excessive wear or even detachment during operation.

Signs of Wear and Tear

- Unusual noises during operation can indicate a misalignment or damaged components.

- Difficulty in starting may suggest issues with the carburetor or ignition.

- Inconsistent cutting performance often signals dull or damaged blades.

Regular inspections and maintenance can help mitigate these issues, ensuring that each component functions effectively and efficiently.

Finding Replacement Parts Online

Locating suitable components for your equipment can be a straightforward task with the right approach. The internet offers a wealth of resources where enthusiasts and professionals alike can discover various options, ensuring that machinery remains in optimal condition. Whether you need a specific item or are exploring alternatives, online platforms provide convenience and accessibility.

Utilizing Specialized Websites

Many websites focus exclusively on offering components for various machinery. These platforms often feature comprehensive catalogs, allowing users to search by model or type. By using filters and categories, you can easily narrow down your options and find what you need quickly.

Community Forums and Groups

Engaging with online communities can also be invaluable. Forums and social media groups dedicated to equipment maintenance often have experienced members who can recommend trusted sources for acquiring necessary items. Additionally, these spaces allow for sharing insights and tips about ensuring longevity and performance.

Step-by-Step Assembly Instructions

Assembling your equipment can be a straightforward task if you follow a structured approach. This section provides a detailed guide to ensure all components are correctly fitted together, allowing for optimal performance and longevity.

-

Gather all necessary components and tools. Ensure you have:

- All parts specified in the manual

- A suitable work surface

- Required tools such as wrenches and screwdrivers

-

Begin with the main body. Secure the base section to ensure stability during assembly.

-

Attach the power unit to the main body:

- Align the power unit with the designated slots

- Fasten with screws or bolts provided

-

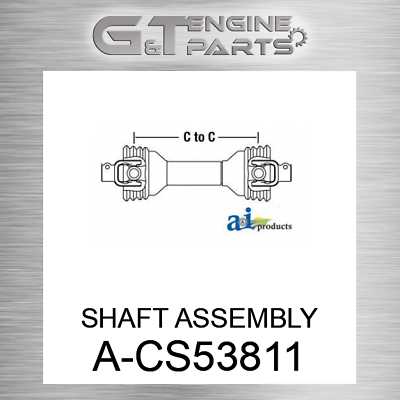

Install the guide bar:

- Position the guide bar in place

- Ensure it is aligned correctly with the power unit

- Tighten the securing mechanism

-

Connect the chain:

- Thread the chain around the guide bar

- Make sure it is fitted correctly in the sprocket

- Check the tension and adjust as necessary

-

Finalize the assembly:

- Inspect all connections for security

- Ensure that all tools and leftover parts are removed from the workspace

- Perform a functionality check before use

By following these steps meticulously, you can ensure that your equipment is assembled correctly and ready for use.

Safety Tips for Using Chainsaws

Operating power tools can be both rewarding and hazardous. Proper precautions are essential to ensure a safe experience. This section outlines key recommendations to minimize risks while maximizing efficiency during usage.

Pre-Use Preparation

Before engaging with any cutting equipment, it is crucial to assess your surroundings and prepare adequately. Always wear appropriate protective gear, including a helmet, eye protection, gloves, and sturdy footwear. Ensure the working area is clear of obstacles and bystanders. Familiarize yourself with the equipment’s manual and inspect the tool for any signs of damage or wear.

Safe Operation Practices

Maintain a firm grip on the tool with both hands while in operation. Keep a stable stance and position your body to avoid potential kickback. Never attempt to cut above shoulder height, as this increases the likelihood of accidents. Always be aware of your environment, particularly the location of others, and communicate clearly if you are working in a team.

Remember: Safety should always be your top priority. Taking the time to follow these guidelines can help prevent injuries and ensure a successful task.

Essential Tools for Repairs

Maintaining and fixing outdoor power equipment requires a selection of specific instruments that ensure efficient and effective repairs. Having the right tools at hand not only simplifies the process but also enhances the longevity and performance of the machinery.

Basic hand tools, such as screwdrivers, pliers, and wrenches, form the foundation of any repair toolkit. These instruments allow for the adjustment and removal of various components, making it easier to access internal parts. Additionally, a good set of sockets is invaluable for tackling different sizes of bolts and nuts.

Power tools, including drills and impact drivers, can significantly speed up the repair process. They are particularly useful for tasks that require repeated fastening or removal of screws and bolts. Furthermore, having a quality set of replacement blades and filters can prevent downtime during maintenance activities.

Safety gear, such as gloves and goggles, is crucial when undertaking repairs. Protecting oneself from potential hazards is as important as the tools used in the process. Lastly, keeping a clean workspace with organizational tools will ensure that all instruments are easily accessible and accounted for, streamlining repairs and enhancing productivity.

Comparing CS56 to Other Models

When evaluating different models of cutting equipment, it’s essential to recognize the unique features and specifications that set each apart. The comparative analysis provides insights into performance, durability, and usability, helping users make informed decisions based on their specific needs.

One notable aspect to consider is engine power. Some models boast higher horsepower, enabling quicker cuts and better efficiency during intensive tasks. In contrast, others may prioritize lightweight designs, making them more suitable for extended use without fatigue.

Another critical factor is the design and ergonomics. Certain variants are crafted with enhanced grip and balance, reducing user strain during operation. This can significantly impact the overall experience, especially for those engaged in lengthy projects.

Additionally, the availability of accessories and customization options varies among models. Some equipment allows for a range of attachments that enhance versatility, while others might offer limited compatibility, affecting adaptability to different tasks.

Ultimately, comparing these characteristics can guide users toward selecting the most suitable equipment for their cutting endeavors, ensuring they achieve optimal results with maximum comfort and efficiency.

Upgrades and Modifications for Performance

Enhancing the efficiency and effectiveness of your equipment can significantly improve its overall performance. By implementing various upgrades and modifications, you can optimize functionality, extend longevity, and adapt the machine to meet specific tasks or challenges. This section explores several options that can lead to noticeable improvements in operation.

Engine Enhancements

One of the primary areas to focus on is the engine. Upgrading to a high-performance air filter can increase airflow, leading to better combustion and power output. Additionally, tuning the carburetor ensures that the fuel-air mixture is optimal for enhanced performance. Regular maintenance combined with these upgrades can further contribute to a smoother and more efficient operation.

Bar and Chain Modifications

Another critical component is the cutting system. Switching to a higher-quality bar and chain can result in improved cutting speed and precision. Consider using a different gauge or length that suits your specific needs better. Additionally, sharpening the chain regularly will maximize its effectiveness. These modifications not only enhance performance but also provide a more enjoyable user experience.

Resources for Further Learning

Expanding your knowledge in the realm of outdoor power equipment can significantly enhance your skills and efficiency. Whether you are looking to understand maintenance, repair techniques, or operational best practices, there are numerous resources available to assist you in your journey.

- Online Forums: Engage with communities of enthusiasts and professionals. Websites like Reddit and specialized forums offer a wealth of shared experiences and troubleshooting tips.

- YouTube Channels: Visual learners can benefit from various channels that provide detailed tutorials and demonstrations on equipment use and upkeep.

- Manufacturer Websites: Explore official sites for comprehensive manuals, FAQs, and product specifications that can enhance your understanding of specific models.

- Books and Guides: Consider reading publications focused on outdoor equipment maintenance. Libraries and bookstores often carry resources that delve deep into practical techniques.

By leveraging these resources, you can deepen your expertise and ensure you are well-equipped to handle any challenges that arise in the field.