Comprehensive Guide to John Deere Z355R Parts Diagram

The maintenance and repair of lawn care equipment can often seem daunting. However, having a clear visual representation of the various components is crucial for both novice and experienced users. This guide aims to provide insights into the intricate design and functionality of essential mower elements, allowing for a smoother maintenance experience.

By exploring the specific configurations and placements of each part, users can enhance their understanding of how to effectively troubleshoot issues. This knowledge not only aids in repairs but also contributes to extending the lifespan of the machinery. Identifying these components can be the ultimate key to ensuring optimal performance.

Moreover, a comprehensive examination of these layouts empowers operators to take charge of their equipment. With the right information, even the most complex repairs become manageable, leading to a more rewarding gardening experience. Embrace the opportunity to delve into this essential topic and elevate your lawn care game.

Understanding John Deere Z355R Parts

This section delves into the essential components of a popular lawn maintenance machine, highlighting their significance in ensuring optimal performance and longevity. Recognizing the various elements that constitute this equipment can empower users to make informed decisions regarding maintenance and repairs.

Key Components Overview

Each machine is made up of numerous vital parts that work in harmony to achieve efficient operation. From the cutting mechanism to the propulsion system, understanding the functionality of these elements can help users troubleshoot issues more effectively. Regular inspection and timely replacement of worn-out components are crucial for maintaining performance standards.

Maintenance Tips for Longevity

To ensure that your equipment runs smoothly over the years, adopting a proactive maintenance approach is essential. Regularly check and clean filters, lubricate moving parts, and replace any damaged components promptly. Keeping a close eye on the performance of each element not only extends the life of the machine but also enhances its overall efficiency.

By familiarizing oneself with the intricate details of each section, operators can significantly improve their lawn care experience while reducing the risk of unexpected breakdowns.

Overview of Z355R Components

This section provides a detailed look at the various elements that make up this advanced lawn care machine. Understanding these components is essential for effective maintenance and optimal performance.

| Component | Description |

|---|---|

| Engine | A powerful unit designed for reliable performance and efficiency. |

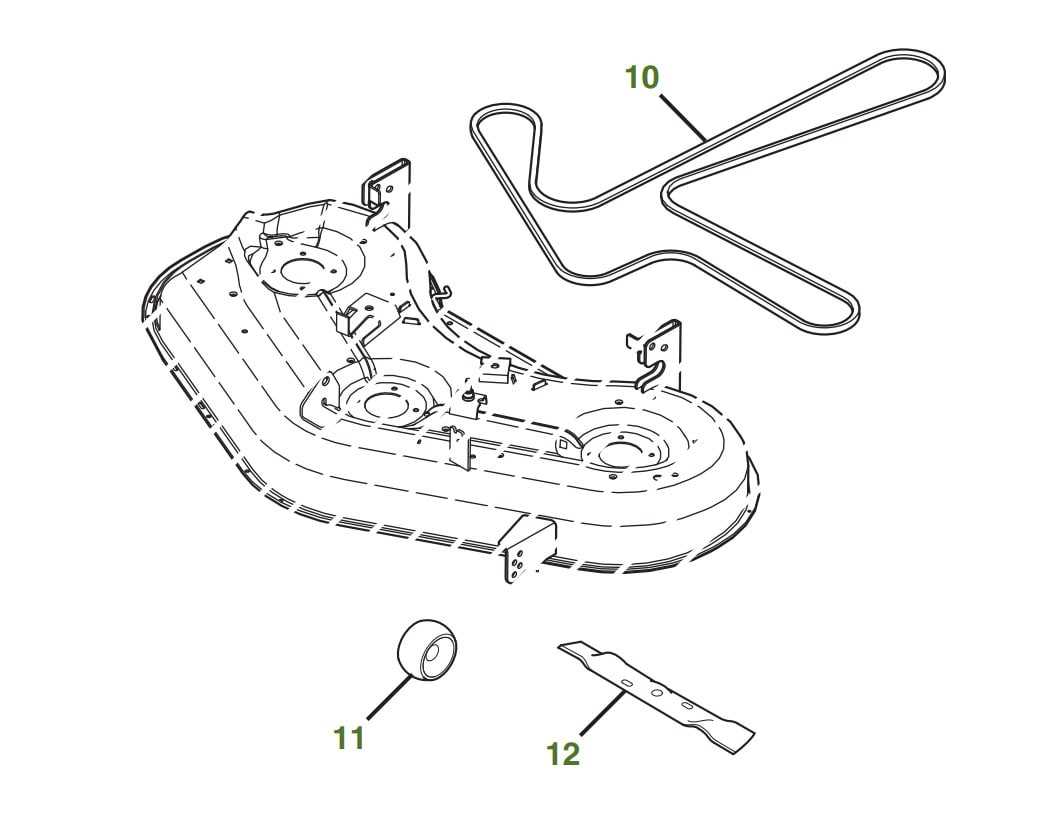

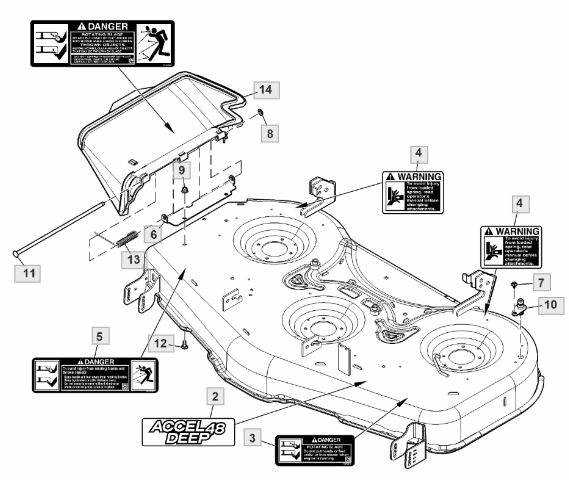

| Deck | The cutting platform that houses the blades, ensuring a clean and even cut. |

| Wheels | Durable and designed for stability and traction on various terrains. |

| Transmission | Facilitates smooth movement and speed control for user convenience. |

| Control Panel | Interface for the operator to manage functions and settings easily. |

Importance of Parts Diagrams

Understanding the intricacies of machinery requires a visual representation that simplifies complex components and their interrelations. Such illustrations serve as essential tools for both novice and experienced users, facilitating easier navigation through various elements of equipment.

These visual guides offer several key advantages:

- Enhanced Clarity: Clear depictions help users identify specific components quickly, reducing the likelihood of errors during repairs or maintenance.

- Improved Efficiency: By having a structured view of parts, individuals can locate and obtain necessary items swiftly, minimizing downtime.

- Better Communication: They provide a common language for technicians, enabling better collaboration and understanding when discussing repairs or upgrades.

- Facilitates Learning: Beginners can learn about the functionality and placement of each component, enhancing their overall knowledge and skills.

In summary, visual representations are invaluable resources that contribute to effective maintenance, repair, and understanding of machinery, ultimately leading to improved performance and longevity.

Key Features of Z355R Model

This model stands out in the realm of lawn maintenance equipment, delivering an exceptional blend of performance, comfort, and advanced technology. Designed for both residential and commercial use, it offers a variety of innovative attributes that enhance user experience and efficiency in outdoor tasks.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a robust engine, this unit ensures reliable performance for a variety of mowing conditions. |

| Cutting Width | The ample cutting deck allows for wider swathes, reducing the time needed for mowing large areas. |

| Comfortable Seating | Designed with ergonomics in mind, the seating provides comfort during extended use, reducing fatigue. |

| Adjustable Cutting Height | The cutting height can be easily adjusted to suit different grass types and conditions, promoting healthier lawn growth. |

| Easy Maneuverability | Features a compact design that allows for tight turns and easy navigation around obstacles in the yard. |

Overall, this model combines innovative technology with practical features to meet the diverse needs of lawn care enthusiasts and professionals alike.

Common Replacement Parts Explained

When it comes to maintaining outdoor machinery, understanding the essential components that may require replacement is crucial. Each element plays a significant role in ensuring optimal performance and longevity, making it important to recognize which parts are prone to wear and how to address them effectively.

| Component | Description |

|---|---|

| Blades | These are vital for cutting efficiency and may dull over time, necessitating regular inspection and replacement. |

| Filters | Air and fuel filters ensure clean operation, preventing debris from causing damage; they should be changed periodically. |

| Batteries | A reliable power source is essential; old batteries can lead to starting issues and should be replaced when performance declines. |

| Tires | Worn or damaged tires can impact traction and stability; regular checks can help maintain proper functionality. |

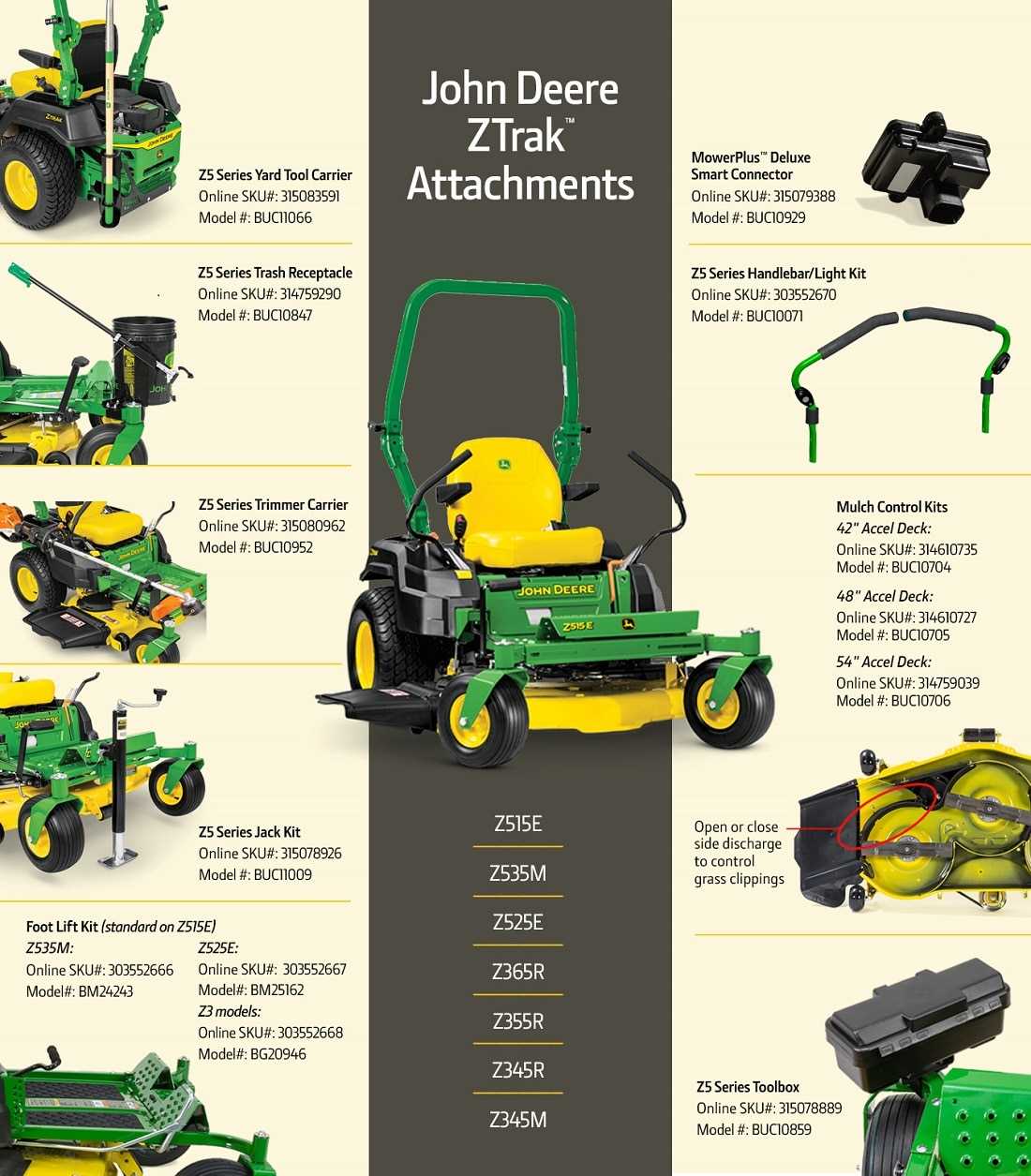

How to Access Parts Diagrams

Finding technical illustrations for machinery components can greatly enhance your understanding of assembly and maintenance. These visual aids serve as valuable resources for identifying parts and ensuring correct installations.

Online Resources

- Manufacturer’s Official Website

- Dedicated Equipment Forums

- Parts Retailer Platforms

Physical Manuals

- Check the owner’s manual

- Request printed illustrations from your dealer

- Utilize service manuals available at libraries

By utilizing these avenues, you can delve into the specifics of your machinery and streamline your repair processes.

Maintenance Tips for Z355R

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Adopting a systematic approach to maintenance not only enhances performance but also prevents costly repairs in the long run.

1. Check Fluid Levels: Regularly inspect and top up oil, coolant, and fuel levels. Maintaining appropriate fluid levels is crucial for optimal operation.

2. Clean the Air Filter: A clean air filter allows for better airflow, enhancing engine performance. Replace or clean the filter according to the manufacturer’s guidelines.

3. Inspect the Blades: Dull or damaged blades can affect cutting efficiency. Sharpen or replace blades as needed to maintain a clean cut.

4. Battery Maintenance: Check battery connections and clean any corrosion. Ensure the battery is charged and replace it if it shows signs of wear.

5. Tire Pressure: Maintain proper tire pressure for better traction and handling. Regularly check and adjust as needed.

6. Seasonal Maintenance: Before each season, perform a thorough inspection to identify any wear and tear. This proactive approach helps avoid issues during peak usage.

By following these tips, you can ensure your machine remains in top condition, ready to tackle any task effectively.

Finding Authentic John Deere Parts

Ensuring the quality and longevity of your equipment requires sourcing genuine components. Authentic elements not only enhance performance but also guarantee reliability and safety. Identifying these original items can significantly impact maintenance and operational efficiency.

Why Choose Genuine Components?

Opting for original pieces provides several advantages, including superior fit, increased durability, and enhanced safety. Imitations may seem appealing due to lower costs, but they often lack the performance and longevity of authentic options.

How to Identify Authentic Parts

To ensure you’re purchasing genuine items, consider the following tips:

| Tip | Description |

|---|---|

| Check Packaging | Authentic items usually come in branded packaging with quality seals. |

| Verify Part Numbers | Cross-reference numbers with official documentation or trusted sources. |

| Consult Authorized Dealers | Purchase from recognized vendors or dealerships for guaranteed quality. |

Tools Needed for Repairs

When it comes to maintenance and fixing equipment, having the right instruments on hand is crucial. A well-equipped toolkit not only streamlines the repair process but also ensures safety and efficiency. Below is a list of essential tools that will help you tackle various tasks effectively.

- Wrenches: A set of adjustable and socket wrenches will allow you to handle different bolt sizes.

- Screwdrivers: Both flathead and Phillips head screwdrivers are necessary for various screws.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires.

- Jack Stands: These provide stability when working under heavy machinery.

- Torque Wrench: Ensures that bolts are tightened to the specified torque, preventing damage.

- Multimeter: Useful for diagnosing electrical issues and testing components.

Having these tools at your disposal will not only enhance your repair capabilities but also prolong the lifespan of your equipment. Always ensure that your toolkit is organized and that each tool is in good condition for optimal performance.

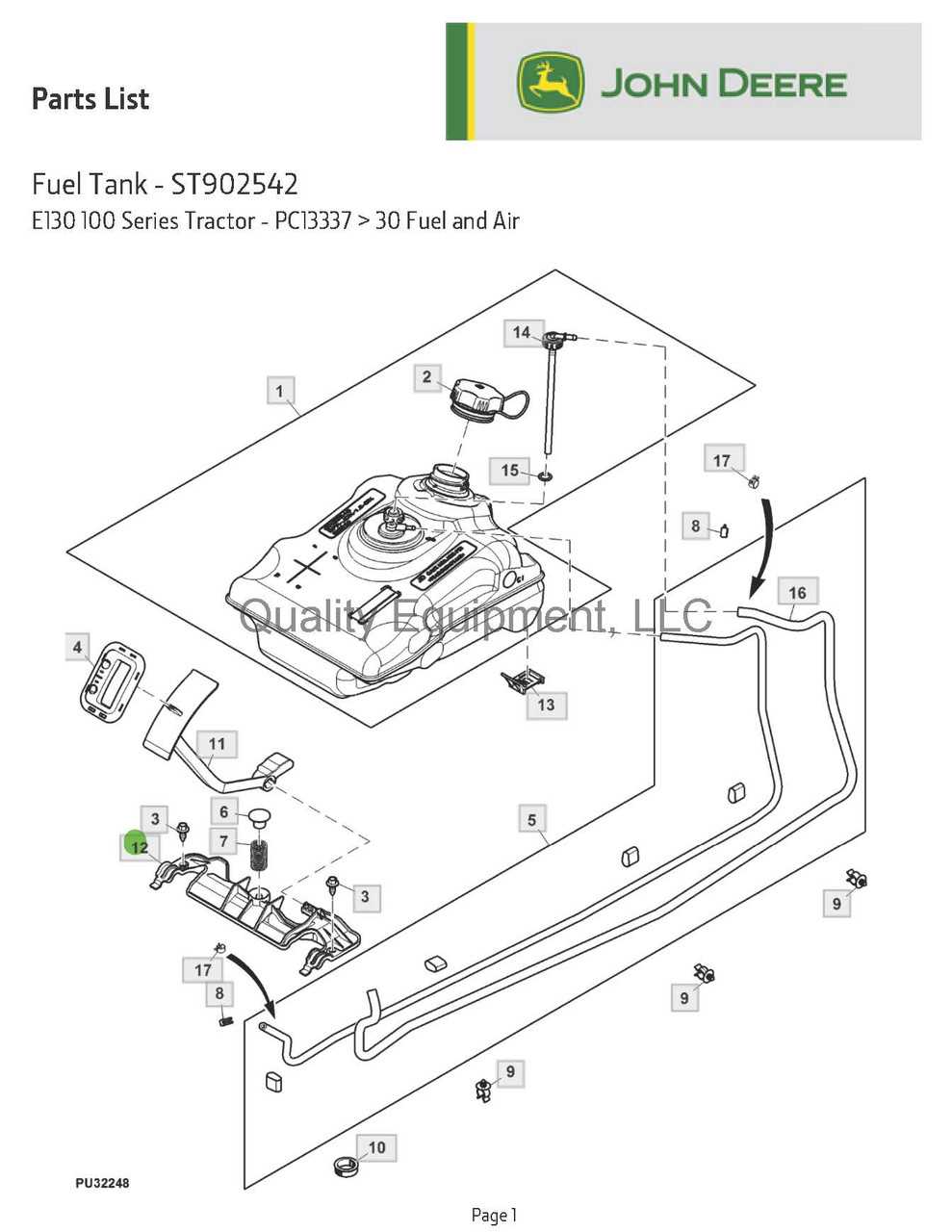

Identifying Parts by Model Number

Understanding the components of your equipment is essential for effective maintenance and repair. By focusing on specific identification codes associated with each model, users can ensure they select the correct elements for their machinery. This knowledge minimizes downtime and enhances operational efficiency.

Importance of Model Numbers

Model identifiers serve as a unique reference point, simplifying the search for appropriate components. By using these codes, individuals can quickly access information about suitable replacements, thus avoiding confusion and ensuring compatibility.

How to Locate Model Numbers

Typically, the identification number can be found in various locations on the machinery, including the frame or beneath the engine. It’s advisable to refer to the owner’s manual for precise locations, allowing for a straightforward identification process when seeking necessary components.

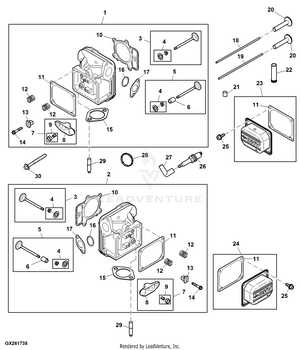

Assembly Instructions for Key Components

This section provides detailed guidance for the assembly of essential components within your machinery, ensuring optimal performance and longevity. Following these instructions will help you correctly piece together critical elements with precision.

Preparation Steps

- Gather all necessary tools and components.

- Review the component specifications for compatibility.

- Ensure a clean and organized workspace to facilitate assembly.

Assembly Process

- Begin by aligning the main structure and securing it with bolts.

- Attach the drive system, making sure to follow the torque specifications.

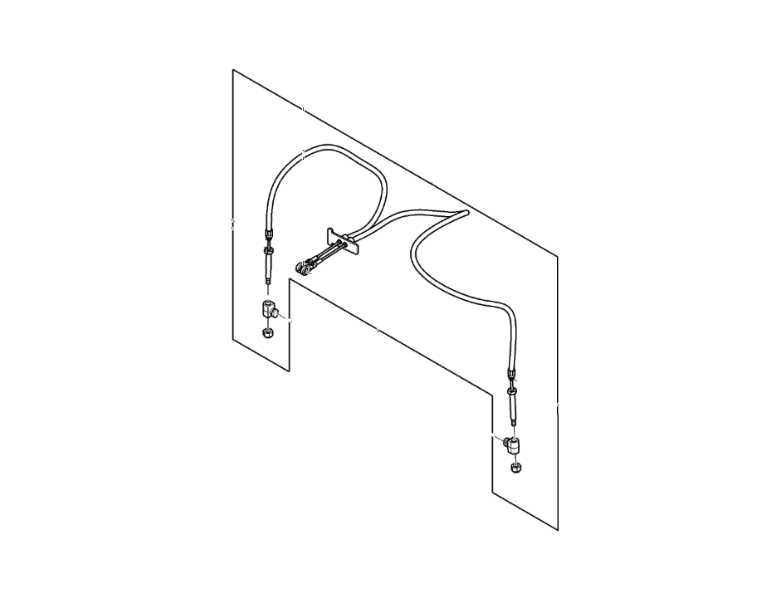

- Connect the electrical wiring, ensuring proper insulation and routing.

- Final checks: Inspect all connections and ensure everything is tight.

Troubleshooting Common Issues

When operating any lawn care equipment, encountering problems is not uncommon. Identifying the source of these issues can enhance performance and prolong the lifespan of the machinery. This section focuses on typical challenges users may face and offers guidance on how to resolve them effectively.

Engine Problems

One of the most frequent concerns involves engine functionality. Symptoms such as difficulty starting, unusual noises, or stalling can indicate underlying issues that need attention. Below is a table highlighting common engine-related problems and their potential solutions.

| Issue | Possible Cause | Solution |

|---|---|---|

| Won’t Start | Faulty battery or fuel supply | Check connections and refill fuel. |

| Stalling | Clogged air filter | Clean or replace the air filter. |

| Excessive Noise | Loose components | Tighten any loose bolts or parts. |

Cutting Issues

Another common area of concern relates to the cutting performance of the equipment. Uneven cuts or ineffective grass management can be frustrating. The following table outlines potential cutting-related issues along with suggested fixes.

| Issue | Possible Cause | Solution |

|---|---|---|

| Uneven Cutting | Uneven tire pressure | Check and adjust tire pressure. |

| Grass Clumping | Dull blades | Sharpen or replace the cutting blades. |

| Streaking | Improper height setting | Adjust cutting height to appropriate level. |

Resources for Further Information

To enhance your understanding and find additional insights into machinery components, several valuable sources are available. These resources provide comprehensive knowledge, from manuals to expert forums, ensuring you stay informed about maintenance and repairs.

Official Manuals

Manufacturer documentation is essential for obtaining accurate specifications and maintenance guidelines. Look for downloadable manuals on official websites to ensure you have the most reliable information.

Online Communities

Engaging with online forums and social media groups dedicated to equipment enthusiasts can be incredibly beneficial. These platforms allow users to share experiences, ask questions, and gain practical advice from seasoned professionals and hobbyists alike.