Comprehensive Guide to EB802RT Parts Diagram

In the realm of machinery and technology, comprehending the configuration of individual elements is crucial for effective maintenance and repair. A thorough grasp of how each piece interrelates within the whole can significantly enhance operational efficiency and longevity of equipment. Whether you’re troubleshooting or upgrading, familiarizing yourself with these layouts is an essential step towards success.

Detailed schematics serve as invaluable resources, offering insights into the arrangement and functionality of various components. These visual aids not only facilitate a clearer understanding but also empower users to identify potential issues and streamline their interventions. By studying these representations, one can quickly pinpoint the necessary actions for optimal performance.

Moreover, having access to clear representations enables technicians and enthusiasts alike to foster a deeper connection with the technology they work with. It transforms abstract concepts into tangible understanding, allowing for more informed decisions when it comes to repairs or enhancements. This foundational knowledge ultimately leads to greater confidence in handling complex systems.

Understanding EB802RT Components

Exploring the various elements that comprise a complex system reveals the intricate relationships and functionalities that drive its performance. Each component plays a crucial role, contributing to the overall efficiency and reliability of the device.

To grasp the significance of each part, it is essential to consider their unique functions and how they interact with one another. Here are some key aspects to keep in mind:

- Functionality: Each element has a specific purpose, whether it’s managing power, facilitating communication, or ensuring stability.

- Compatibility: Understanding how components work together is vital for optimal performance and preventing potential issues.

- Durability: The materials used in construction affect longevity and the ability to withstand varying conditions.

By examining these characteristics, one can better appreciate the complexity of the system and make informed decisions regarding maintenance and upgrades.

- Identify individual components and their roles.

- Assess compatibility with other system parts.

- Evaluate performance metrics based on usage.

In conclusion, a comprehensive understanding of these elements is fundamental for anyone looking to enhance their knowledge and skills in managing sophisticated technologies.

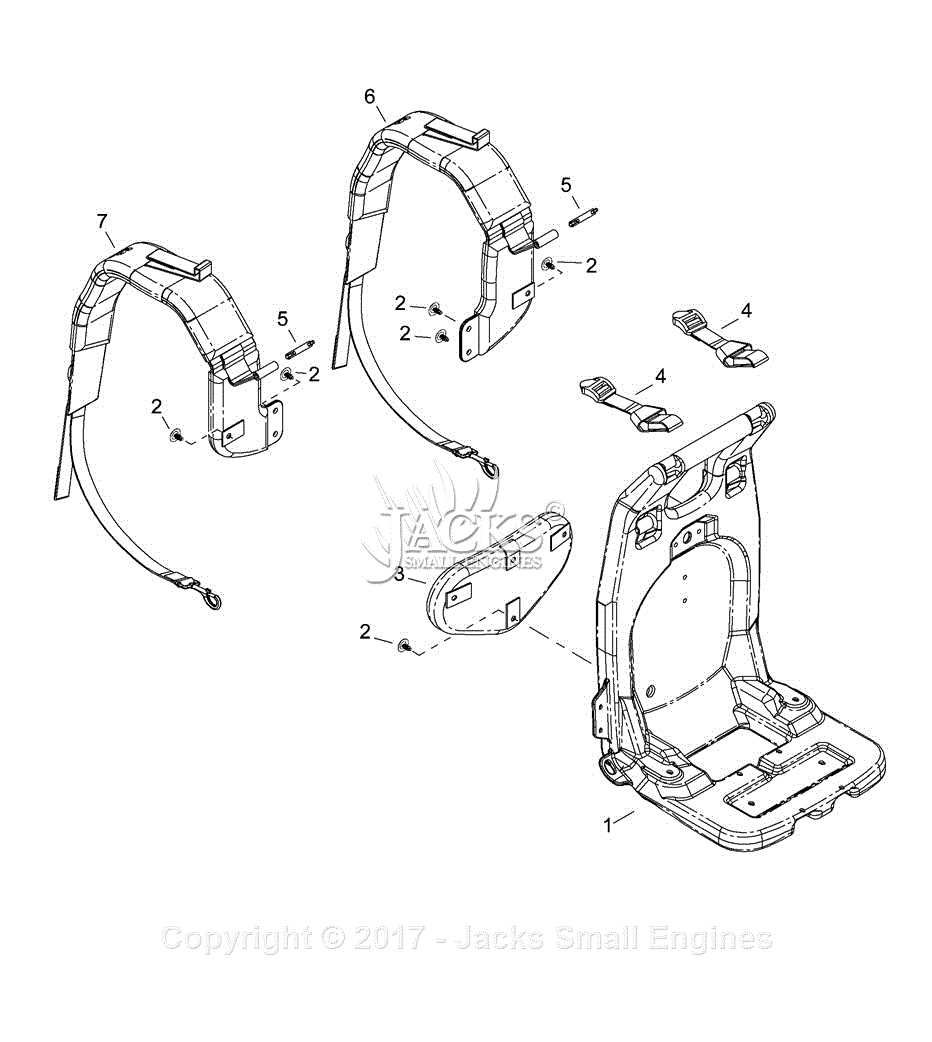

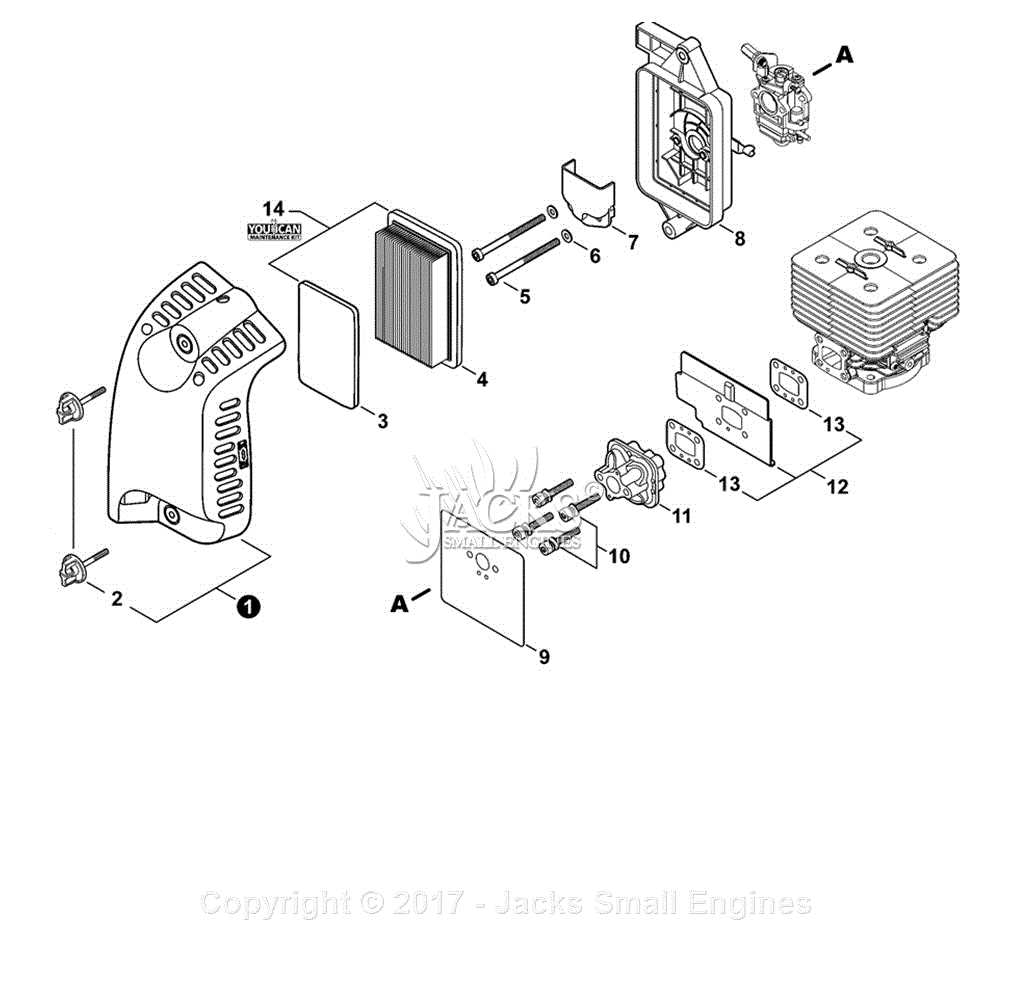

Overview of Parts Diagram

This section provides a comprehensive understanding of the various components and their arrangements within a specific system. By analyzing the visual representation, one can gain insights into the interconnections and functionalities of each element, facilitating effective maintenance and troubleshooting.

Such visual guides are invaluable tools for technicians and engineers alike. They allow for quick identification of individual elements, enhancing the efficiency of repairs and upgrades. Moreover, a well-structured representation simplifies the learning curve for new users, providing a clear roadmap of the system’s architecture.

| Component | Description |

|---|---|

| Element A | Main functional unit responsible for operation. |

| Element B | Supportive structure that enhances stability. |

| Element C | Interface for user interaction and control. |

| Element D | Connector enabling communication between units. |

Common Issues with EB802RT Parts

When dealing with components of a specific model, users often encounter a variety of challenges that can impact performance and longevity. Understanding these issues is crucial for maintenance and effective troubleshooting.

Wear and Tear: Over time, various elements may experience degradation due to regular usage. This can lead to reduced efficiency or even failure. Regular inspections can help identify signs of wear early.

Compatibility Problems: Sometimes, not all elements function harmoniously together. Incompatible components can cause malfunctions or hinder overall performance. It’s essential to ensure that all items are suited for each other.

Installation Errors: Incorrect installation can lead to a range of issues, including improper operation and potential damage. Following the manufacturer’s guidelines is vital for a successful setup.

Environmental Factors: External conditions such as humidity, temperature fluctuations, and dust can affect the functionality of various elements. Implementing protective measures can mitigate these risks.

Lack of Maintenance: Neglecting regular upkeep can result in diminished performance and shorten the lifespan of components. Establishing a routine maintenance schedule is beneficial for ensuring optimal function.

By being aware of these common challenges, users can take proactive steps to enhance the performance and reliability of their equipment.

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to identify and work with mechanical systems. This section will guide you through the essential steps to interpret such illustrations effectively, enabling you to locate parts and comprehend their relationships within the assembly.

Key Elements to Focus On

When examining a visual layout, pay attention to several critical elements that provide insight into the structure:

| Element | Description |

|---|---|

| Labels | Names or numbers associated with each component that help in identification. |

| Connections | Lines or arrows indicating how parts are linked or interact with one another. |

| Legend | A section that explains symbols used in the illustration, enhancing clarity. |

Steps to Interpretation

To effectively decode the visual layout, follow these steps:

- Start by reviewing the legend to familiarize yourself with the symbols.

- Identify the main components using the labels provided.

- Observe how the elements connect, noting any dependencies or interactions.

- Refer to supplementary materials, such as manuals or guides, for further clarification if needed.

Maintenance Tips for EB802RT

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By following a few key practices, you can significantly enhance its reliability and efficiency. This section provides valuable insights into routine care, troubleshooting, and preventive measures to keep your machinery in top condition.

1. Regular Cleaning: Keeping the exterior and interior components clean prevents dust and debris from causing damage. Use appropriate cleaning agents and tools to maintain surfaces without causing wear.

2. Lubrication: Apply lubricant to moving parts as per the manufacturer’s guidelines. Proper lubrication reduces friction, minimizes wear, and prolongs the life of the machinery.

3. Check Fluid Levels: Monitor and maintain fluid levels regularly. Low or contaminated fluids can lead to overheating and other operational issues.

4. Inspect Electrical Components: Regularly examine wiring and connections for signs of wear or damage. Promptly address any issues to avoid electrical failures.

5. Schedule Professional Servicing: Arrange for periodic check-ups by a qualified technician. Professional assessments can catch potential problems early, ensuring safe and efficient operation.

6. Keep an Eye on Performance: Pay attention to any changes in performance. Unusual noises, vibrations, or changes in efficiency can be early indicators of underlying issues that need to be addressed.

By implementing these practices, you can maintain optimal functionality and extend the lifespan of your equipment, ensuring it continues to perform effectively for years to come.

Identifying Key Components

Understanding the essential elements of any machinery is crucial for effective maintenance and troubleshooting. By recognizing each component’s function, users can enhance their ability to operate the system efficiently and address potential issues promptly. This knowledge not only facilitates repairs but also improves overall performance and longevity.

Major Elements to Focus On

When analyzing a system, attention should be directed towards the major elements that play pivotal roles in its operation. These include mechanisms responsible for power distribution, control systems that regulate performance, and safety features that ensure secure usage. Familiarity with these parts can significantly reduce downtime during maintenance tasks.

Common Challenges in Identification

Identifying components may present challenges due to their intricate designs and the overlap of functions. Users often encounter difficulties in distinguishing between similar-looking elements. Documentation and user manuals can serve as valuable resources to navigate these complexities, providing insights into the specific roles and characteristics of each part.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a straightforward task if you know where to look. Numerous sources offer a variety of options, catering to different needs and budgets. From specialized retailers to online marketplaces, you can discover both new and refurbished items that meet your specifications.

Start by checking authorized dealers who provide genuine replacements, ensuring compatibility and quality. Additionally, exploring local hardware stores can yield surprising results, as they often carry common parts or can order them for you. For those comfortable with online shopping, e-commerce platforms boast extensive selections, often featuring user reviews that can help guide your decision.

Don’t overlook forums and community groups related to your equipment. Enthusiasts frequently share valuable insights and may even offer leads on where to find hard-to-source items. Lastly, consider reaching out to repair shops that may have spare components available or can assist in locating what you need.

Impact of Component Quality

The quality of individual elements within a system plays a crucial role in determining overall performance and reliability. High-quality components ensure that systems operate efficiently and withstand various operating conditions, whereas inferior parts can lead to failures, inefficiencies, and increased maintenance costs. Understanding the significance of material quality is essential for optimizing both functionality and longevity of any assembly.

Factors Influencing Quality

| Factor | Description |

|---|---|

| Manufacturing Processes | Techniques and technologies used during production that can affect precision and durability. |

| Material Selection | The choice of raw materials that determine strength, weight, and resistance to wear. |

| Quality Control | Measures taken to ensure that components meet specific standards throughout the production cycle. |

Long-Term Benefits

Assembly Instructions for EB802RT

Proper assembly is crucial for optimal performance and longevity of your device. This section provides a clear and concise guide to help you through the assembly process, ensuring that all components are correctly integrated and functioning effectively.

Before starting, gather all necessary tools and materials. Familiarize yourself with the individual components to streamline the assembly procedure. Follow the steps outlined below to ensure a successful setup.

- Start by organizing all the components on a clean, flat surface.

- Refer to the assembly list to verify that you have all required items.

- Begin with the base unit:

- Secure the feet to the bottom using the provided screws.

- Ensure all connections are tight and aligned.

- Carefully position the housing over the base.

- Align the mounting points and insert screws to secure it in place.

- Connect the power supply to the designated input.

- Attach any additional circuit boards as specified.

- Ensure all internal parts are tucked away securely.

- Fasten the cover with the provided clips or screws.

After completing the assembly, perform a thorough inspection to confirm that all parts are securely attached. This will help avoid potential issues during operation. Once you are satisfied with the assembly, proceed to the initial setup and testing phase.

Comparing EB802RT to Similar Models

When evaluating the features and performance of various models in the same category, it’s essential to understand their similarities and differences. This comparison allows potential users to make informed decisions based on their specific needs and preferences.

Key aspects to consider include:

- Design and Build Quality: Assessing the materials used and overall durability can indicate long-term performance.

- Functionality: Comparing the range of functions offered by each model can reveal which best suits your requirements.

- Performance Metrics: Looking at output specifications, efficiency ratings, and reliability helps gauge the effectiveness of each option.

- Ease of Use: User interfaces and setup processes can significantly impact user experience.

- Price Point: Evaluating cost versus features will aid in identifying the best value among the alternatives.

By focusing on these elements, users can identify which device aligns best with their expectations and operational needs. Each model offers unique advantages that cater to different preferences, making thorough comparisons crucial for optimal selection.

Frequently Asked Questions about EB802RT

This section addresses common inquiries related to the subject matter, providing clarity and insights for users seeking detailed information. Whether you are looking for guidance on functionality, compatibility, or maintenance, the following FAQs aim to assist you in navigating the intricacies of this specific model.

What are the key features of this model?

The primary attributes of this unit include advanced functionality, user-friendly design, and robust performance. Users often appreciate its reliability and efficiency, which make it suitable for various applications. Understanding these features can enhance your overall experience.

How can I troubleshoot common issues?

If you encounter challenges, start by checking the basic connections and settings. Often, minor adjustments can resolve issues quickly. For more complex problems, consulting the user manual or seeking assistance from customer support may be necessary. Maintaining regular updates and following proper guidelines will also prevent many common complications.