Kubota B2601 Parts Diagram Comprehensive Guide

In the world of compact machinery, a comprehensive understanding of the various components is essential for efficient operation and maintenance. Every piece of equipment consists of intricate parts that work together to ensure optimal performance. Recognizing how these elements interact can greatly enhance the user experience and prolong the lifespan of the machine.

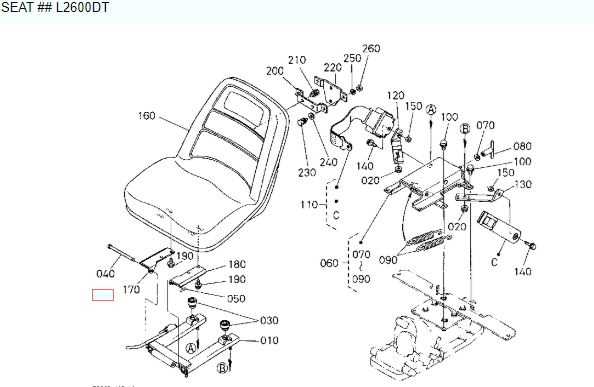

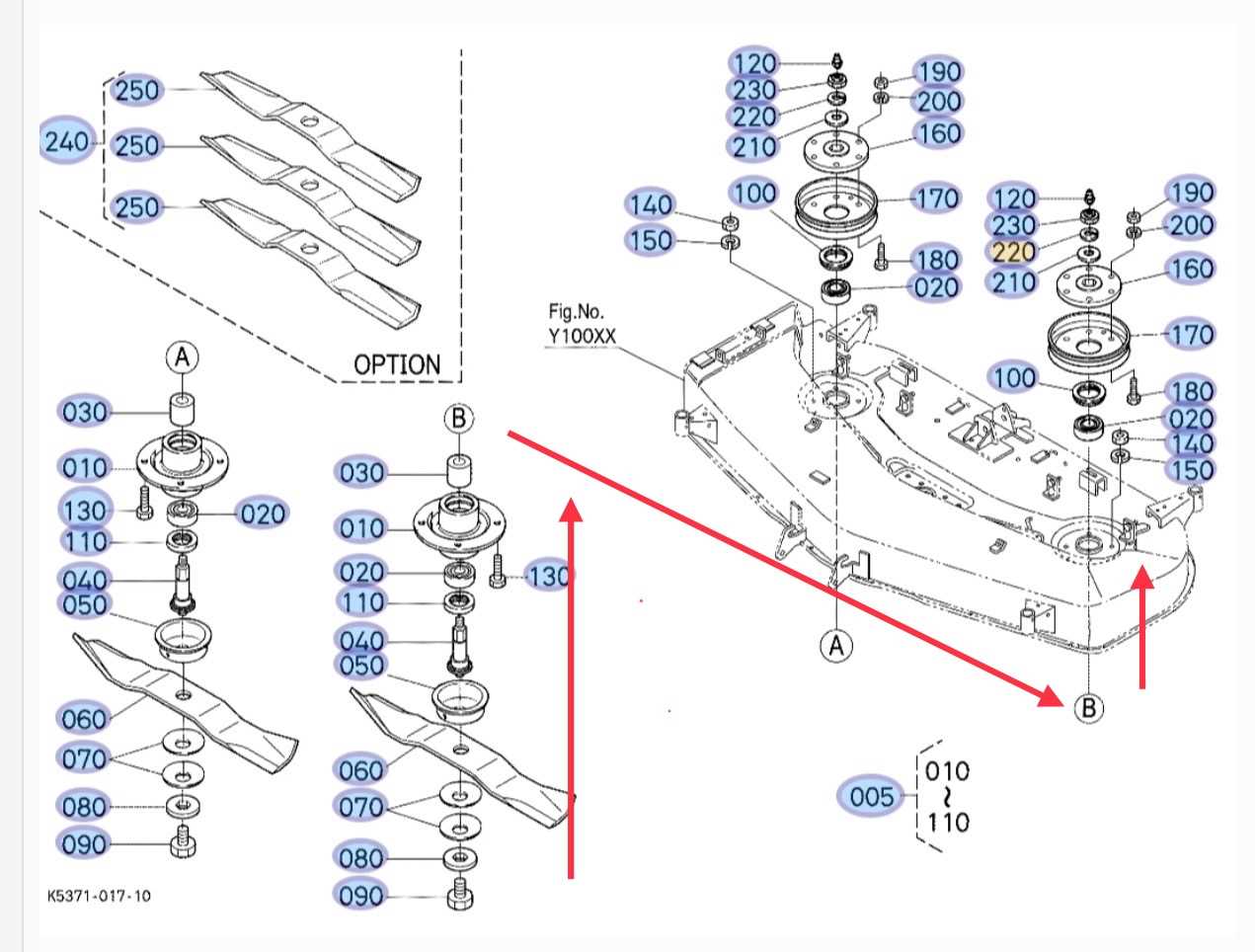

For anyone involved in the upkeep of such machinery, visual representations can be invaluable. They provide clarity and insight into the arrangement and function of each component, allowing for easier troubleshooting and repair. Knowing where each element fits within the larger assembly is crucial for anyone looking to maintain or restore functionality.

Whether you are a seasoned technician or a novice operator, familiarizing yourself with the layout of these essential components will empower you to tackle maintenance tasks with confidence. This guide serves as a resource to help you navigate the complexity of your machinery, ensuring that you can keep it running smoothly for years to come.

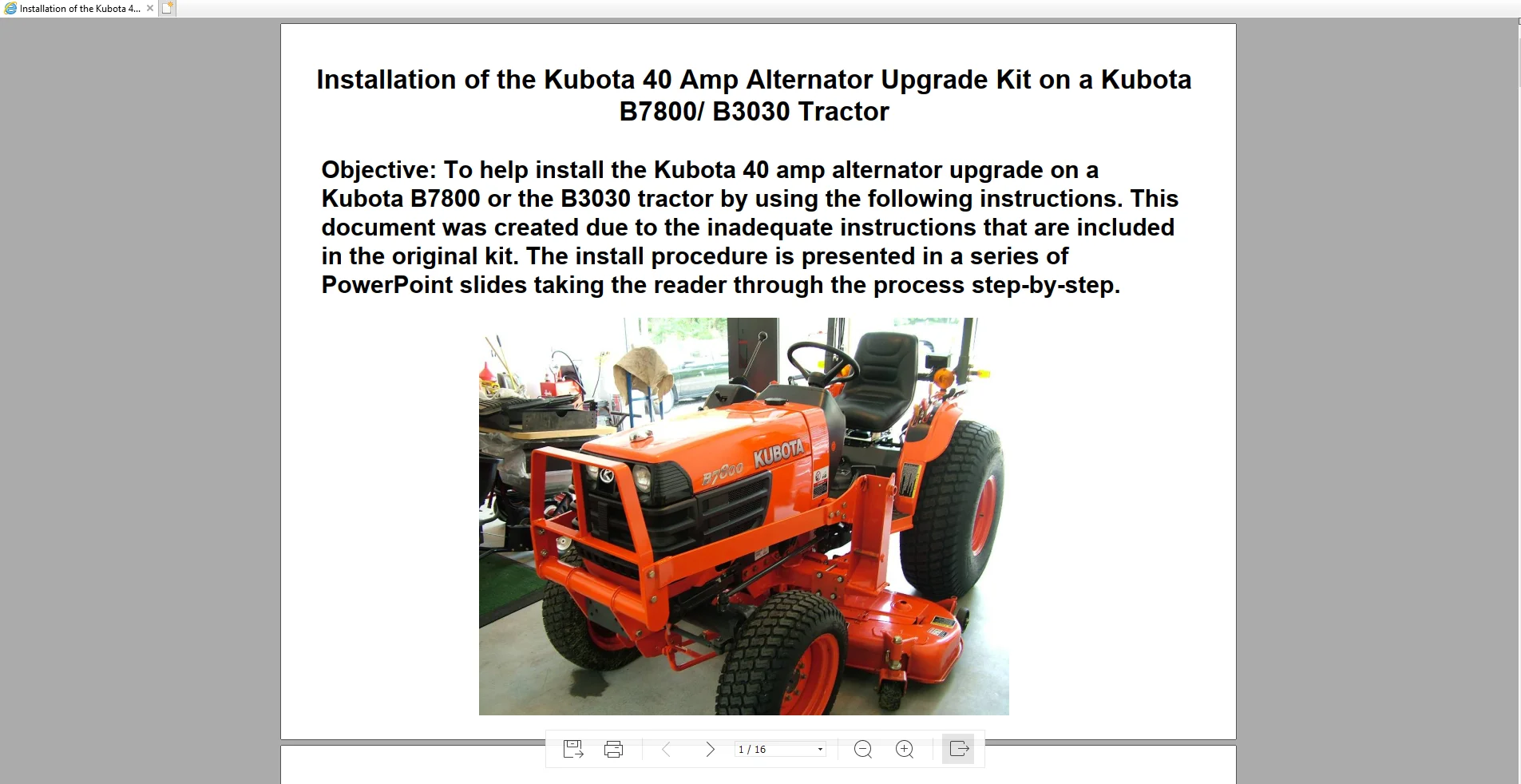

Kubota B2601 Overview

This section provides an insightful look into a versatile and powerful compact machine designed for various agricultural and landscaping tasks. With its efficient design and robust capabilities, it stands out as an essential tool for both professionals and enthusiasts.

Featuring a compact size, this equipment is ideal for maneuvering in tight spaces while delivering impressive performance. Its user-friendly interface ensures that operators can easily navigate through various functions, making it suitable for users of all skill levels.

- Engine Performance: The unit is powered by a reliable engine that ensures optimal productivity, offering excellent torque and fuel efficiency.

- Hydraulic System: Equipped with a powerful hydraulic system, it enables seamless operation of attachments, enhancing versatility.

- Comfortable Operation: The ergonomic design of the operator’s area allows for extended use without discomfort.

- Durability: Built with high-quality materials, it withstands tough conditions, ensuring longevity and dependability.

Overall, this compact machine serves as an invaluable asset for a wide range of applications, making it a popular choice among users looking for reliability and efficiency in their work.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for maintenance and repair. Visual representations serve as essential guides, allowing users to identify and locate specific elements quickly.

- Enhances troubleshooting efficiency

- Facilitates proper assembly and disassembly

- Minimizes the risk of errors during repairs

By providing a clear overview, these illustrations empower users to delve deeper into their understanding of mechanical systems.

- Improves communication between technicians

- Assists in inventory management

- Streamlines the repair process

Ultimately, utilizing these visual aids can lead to better performance and longevity of equipment.

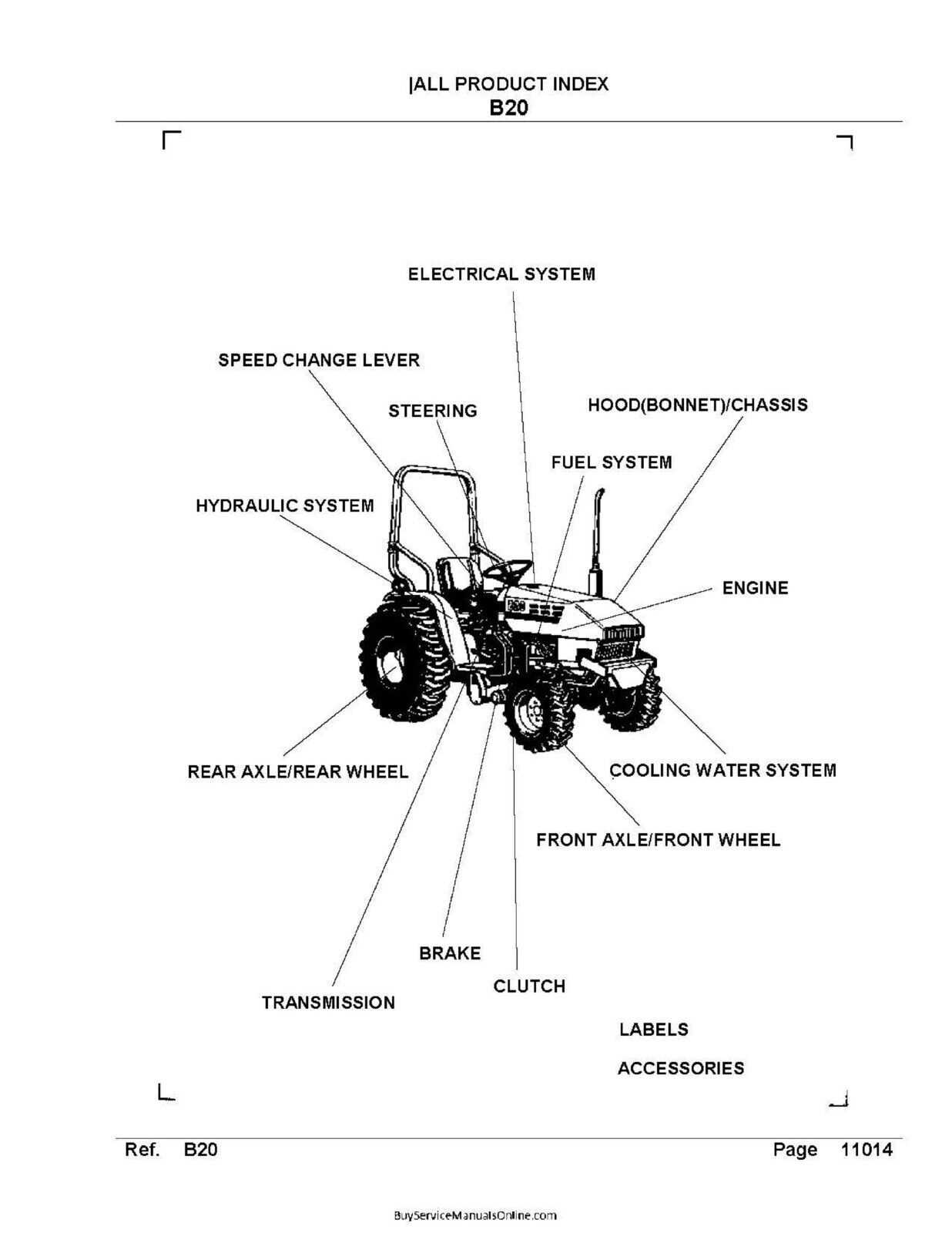

Key Components of B2601

This section explores the essential elements that contribute to the functionality and performance of the machine. Each component plays a pivotal role in ensuring optimal operation and efficiency. Understanding these parts is crucial for maintenance and effective usage.

The engine serves as the heart, providing the necessary power to drive various tasks. The transmission system facilitates smooth gear shifts, enhancing maneuverability. Additionally, the hydraulic system enables precise control over attachments, making it versatile for different applications.

The chassis provides structural integrity and stability, supporting various components and ensuring durability during operation. Finally, the electrical system powers essential features, enhancing user experience and functionality. Together, these elements form a cohesive unit, allowing the machine to perform effectively in diverse conditions.

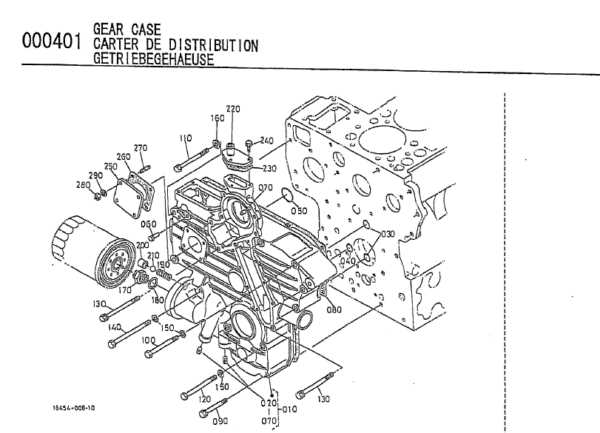

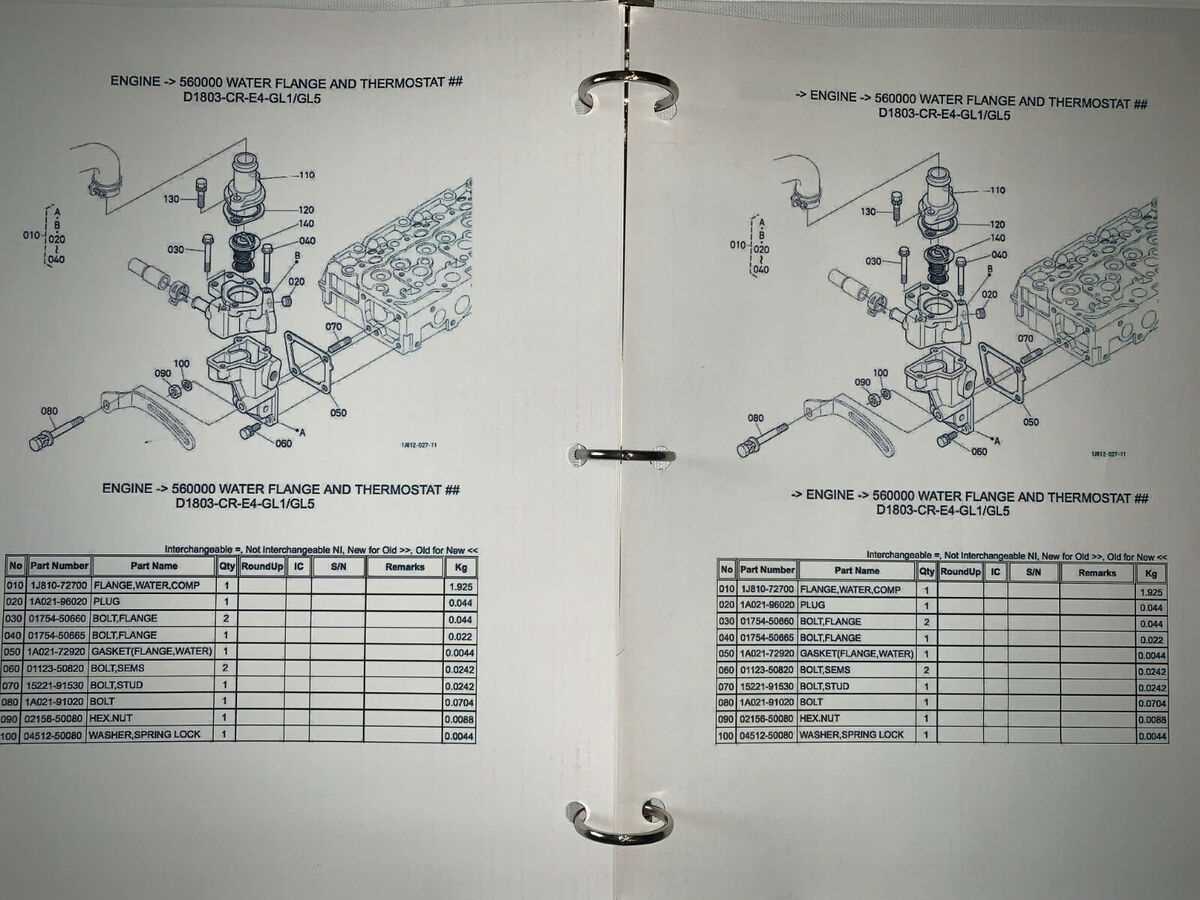

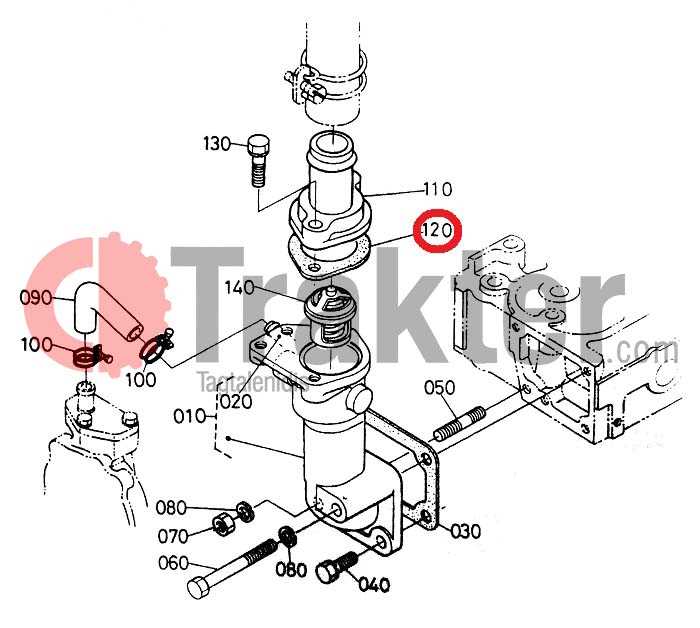

Understanding Engine Parts Layout

Grasping the configuration of engine components is essential for effective maintenance and troubleshooting. Each element plays a critical role in the overall functionality, working in harmony to ensure optimal performance. A clear comprehension of their arrangement allows for quicker diagnostics and more efficient repairs.

Typically, an engine comprises several key segments, including the combustion chamber, crankshaft, and timing mechanism. The combustion chamber is where the fuel-air mixture ignites, driving the pistons. The crankshaft converts the linear motion of the pistons into rotational movement, crucial for powering the vehicle. The timing mechanism, often linked to the crankshaft, ensures that the engine operates in perfect synchrony.

Understanding how these components are positioned and interact is vital. For instance, a misaligned timing mechanism can lead to severe operational issues, highlighting the importance of proper assembly. Regular inspections and familiarity with the layout can prevent costly breakdowns and extend the lifespan of the engine.

In summary, a thorough understanding of the layout of engine components is indispensable for anyone involved in engine care. Recognizing the function and placement of each part not only aids in efficient repairs but also enhances the overall reliability of the machinery.

Common Issues and Solutions

Understanding the frequent challenges that arise with machinery is essential for effective maintenance and operation. Addressing these problems promptly can enhance performance and extend the lifespan of the equipment.

Typical Problems

- Engine Overheating

- Poor Fuel Efficiency

- Hydraulic System Failures

- Electrical Malfunctions

Effective Solutions

- Regularly check and clean the cooling system to prevent overheating.

- Monitor fuel quality and replace filters to improve efficiency.

- Inspect hydraulic fluid levels and lines for leaks.

- Ensure battery connections are secure and test electrical components regularly.

Where to Find Genuine Parts

Locating authentic components for machinery can significantly enhance performance and longevity. Ensuring that replacements are sourced from reputable suppliers is crucial for maintaining optimal function and safety.

Here are some reliable sources for acquiring original components:

| Source | Description |

|---|---|

| Authorized Dealers | These suppliers provide certified components, ensuring quality and compatibility. |

| Online Retailers | Many reputable websites specialize in machinery components, offering detailed descriptions and customer reviews. |

| Manufacturer’s Website | Direct purchases from the official site guarantee authenticity and may include additional support. |

| Local Repair Shops | Many shops maintain a stock of genuine components or can order them directly from manufacturers. |

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires regular care and attention. By adhering to a structured maintenance routine, you can prevent potential issues and enhance overall performance. Simple practices can make a significant difference in efficiency and durability.

1. Regular Inspections: Conduct frequent checks for wear and tear. Look for any signs of damage or unusual noises, which can indicate underlying problems.

2. Fluid Changes: Maintain optimal performance by regularly replacing fluids. This includes engine oil, hydraulic fluids, and coolant, which are vital for smooth operation.

3. Cleanliness: Keep your equipment clean to prevent debris buildup. Regularly washing and clearing dirt from components can help maintain functionality.

4. Proper Storage: Store machinery in a sheltered environment to protect it from harsh weather conditions. This can significantly reduce wear over time.

5. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and guidelines provided by the manufacturer. These recommendations are tailored for the best performance and longevity.

By implementing these strategies, you can ensure that your equipment remains in top condition, ultimately maximizing its lifespan and efficiency.

Comparative Analysis with Similar Models

In the world of compact machinery, understanding how different models stack up against each other is crucial for making informed decisions. This section delves into a comparative evaluation, highlighting the key attributes and functionalities of machines in the same category. By examining their specifications, performance metrics, and user experiences, we can uncover which options best meet specific operational needs.

Performance Efficiency: When analyzing machines in this segment, one must consider their power output and torque capabilities. Some models may offer enhanced horsepower, enabling them to handle heavier loads and more demanding tasks. In contrast, others might excel in fuel efficiency, providing longer operational times without frequent refueling.

Durability and Build Quality: Another vital aspect is the construction quality. Machines built with robust materials can withstand rigorous conditions, ensuring longevity and reducing maintenance costs. It is essential to compare the frame design and component materials to identify the most durable options available.

Versatility and Attachments: The ability to adapt to various tasks through attachments is a significant advantage. Some models come with a wider range of compatible implements, enhancing their utility on diverse job sites. Analyzing the attachment options can reveal which machines offer greater flexibility for different applications.

User Experience and Ergonomics: Comfort and ease of use also play a critical role in overall satisfaction. Features such as seat comfort, control layout, and visibility can greatly affect operational efficiency. Gathering feedback from users can provide valuable insights into the practical aspects of handling each machine.

By conducting a thorough comparative analysis, potential buyers can make educated choices, aligning their equipment selection with their specific requirements and preferences.

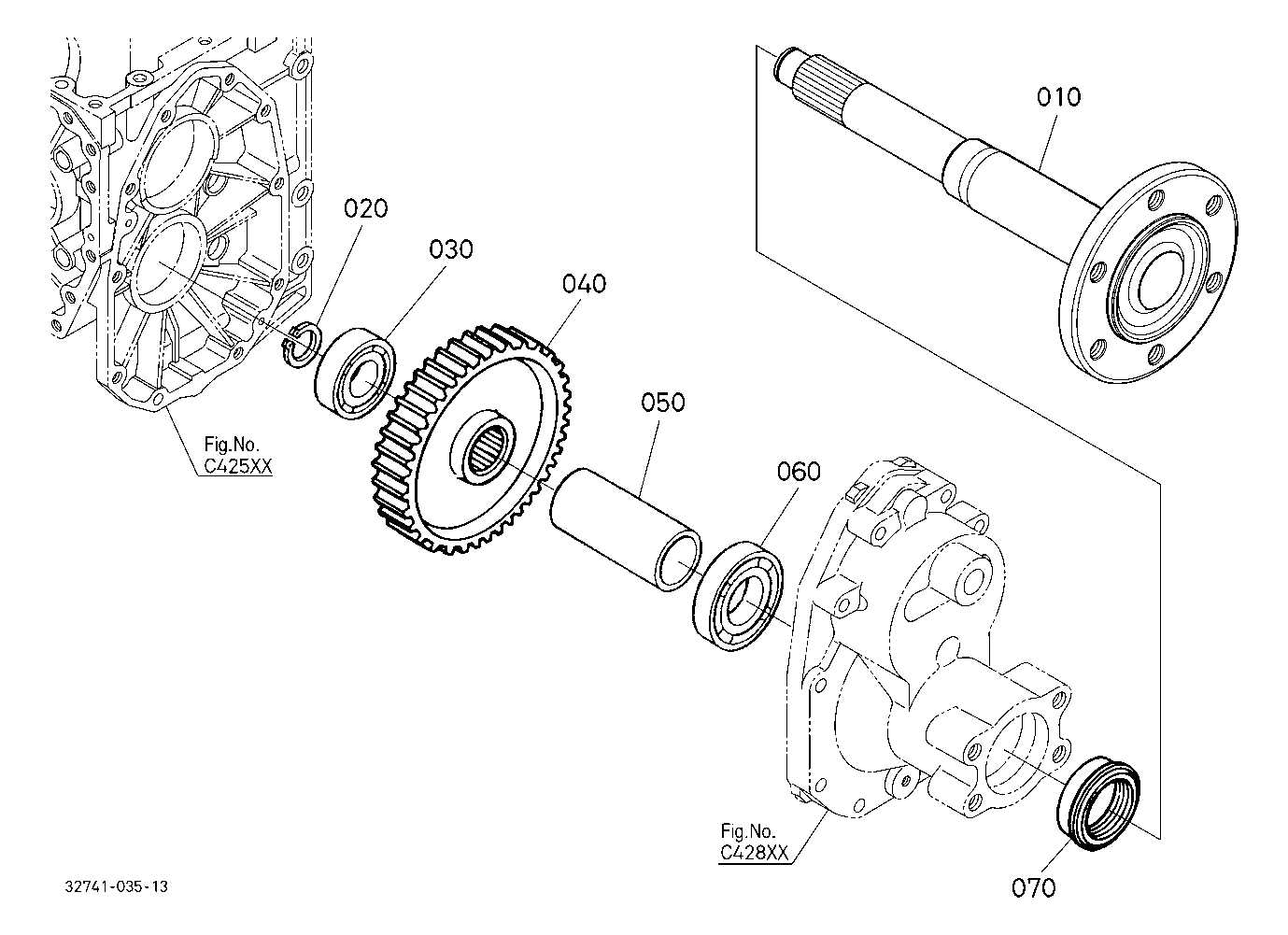

Assembly and Disassembly Guide

This section provides essential information for the proper assembly and disassembly of various components within your machinery. Understanding these processes is crucial for maintenance, repairs, and ensuring optimal performance.

Preparation Steps

- Gather all necessary tools and equipment.

- Ensure a clean, organized workspace.

- Review the manufacturer’s manual for specific guidelines.

Disassembly Process

- Turn off the equipment and disconnect power sources.

- Carefully remove external attachments and coverings.

- Label each part as you remove it to facilitate reassembly.

- Store small components in labeled containers to avoid loss.

Following these guidelines will help you effectively manage the assembly and disassembly of your machinery, ensuring longevity and performance.

Using Diagrams for Troubleshooting

Visual representations of components can significantly enhance the troubleshooting process. By providing a clear overview of system layouts and connections, these illustrations serve as valuable tools for identifying issues quickly and effectively.

Benefits of Visual Aids

- Clarifies complex systems

- Highlights potential failure points

- Facilitates faster repairs

- Improves understanding of machinery

Steps to Utilize Visual Representations

- Examine the illustration to understand the layout.

- Identify the area of concern.

- Compare with the actual system to locate discrepancies.

- Consult maintenance guides for specific troubleshooting steps.