Kubota BX23 Parts Diagram Overview

In the realm of compact machinery, having a clear overview of the components is essential for effective maintenance and operation. Each element plays a pivotal role in ensuring the seamless functionality of your equipment, and recognizing how these parts interact can greatly enhance performance.

Utilizing a visual representation of these components not only simplifies the identification process but also assists in troubleshooting and repairs. This knowledge empowers operators to make informed decisions and carry out necessary adjustments or replacements with confidence.

Whether you are a seasoned professional or a novice user, mastering the intricacies of your machine’s anatomy is invaluable. It fosters a deeper understanding of its capabilities and ensures longevity through proper care and attention to detail.

Kubota BX23 Overview

This section provides an insightful look into a versatile compact tractor that excels in various tasks. Its robust design and functionality make it a valuable asset for landscaping, farming, and construction activities.

Key features include:

- Powerful engine for efficient performance.

- Compact size for maneuverability in tight spaces.

- Multiple attachment options to enhance versatility.

The equipment is engineered for durability and ease of use, making it suitable for both professionals and enthusiasts alike. Its intuitive controls and comfortable seating ensure an enjoyable operating experience.

Notable specifications consist of:

- Engine type and horsepower ratings.

- Hydraulic system capabilities.

- Weight and dimensions for transportation and storage.

In summary, this machine stands out for its combination of power, agility, and user-friendly design, making it a reliable choice for a variety of applications.

Key Features of the BX23 Model

This compact utility vehicle is designed to offer versatility and efficiency, making it a valuable asset for various landscaping and agricultural tasks. Its innovative design combines power and maneuverability, ensuring that users can tackle a wide range of projects with ease.

Powerful Engine Performance

The machine is equipped with a robust engine that delivers impressive horsepower, allowing it to handle demanding tasks such as digging, lifting, and transporting materials. The advanced engineering ensures optimal fuel efficiency, making it cost-effective for long-term use.

User-Friendly Controls and Comfort

With ergonomic controls and a spacious operator station, this vehicle enhances user comfort and productivity. The intuitive layout of the controls allows for seamless operation, reducing fatigue during extended periods of work. Additionally, the adjustable seating ensures that operators of all sizes can find their ideal position.

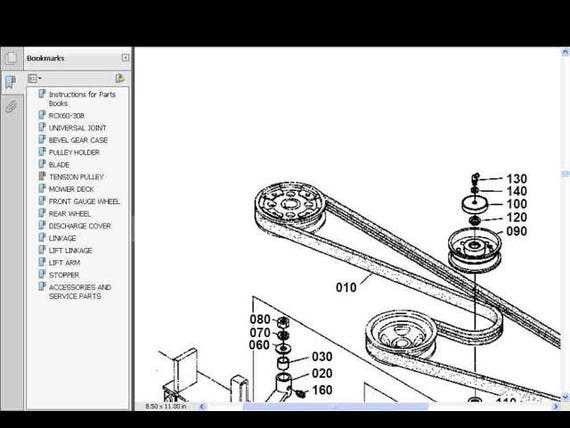

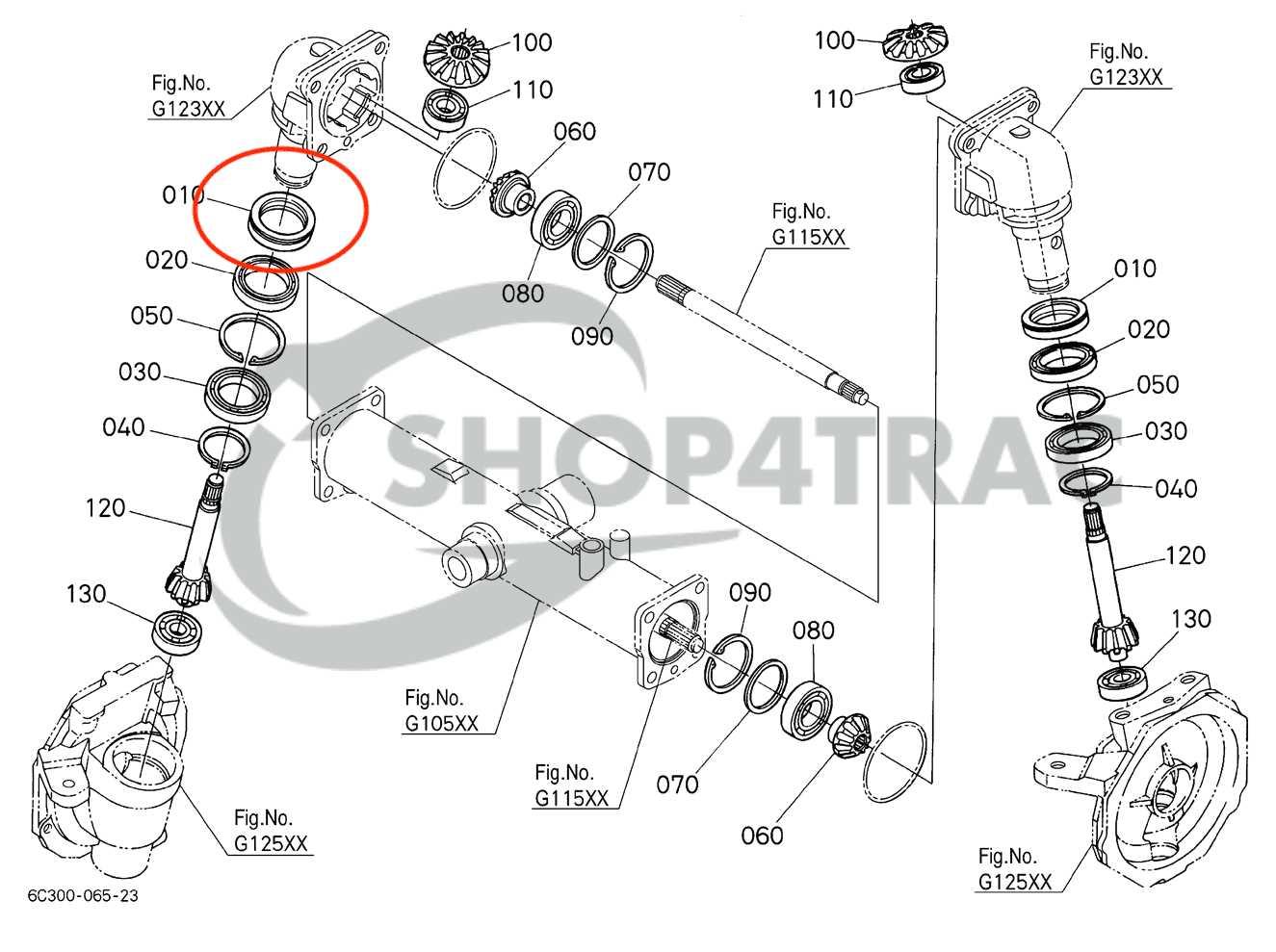

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations play a vital role in simplifying the identification and organization of these elements, enabling users to grasp the overall structure and functionality of their equipment.

Such illustrations enhance the troubleshooting process by providing clear insights into the arrangement and interaction of various parts. When issues arise, having access to these visuals allows for quicker diagnosis, ensuring that problems are addressed promptly and efficiently.

Moreover, these representations serve as valuable references for assembling and disassembling machinery. They guide users through complex procedures, reducing the likelihood of errors and ensuring that all components are handled correctly. This not only saves time but also contributes to the longevity of the equipment.

In addition, detailed visuals can assist in inventory management, helping users keep track of necessary components and making it easier to order replacements when needed. Overall, the significance of these illustrative guides cannot be overstated, as they are essential tools for anyone involved in the upkeep of mechanical systems.

How to Read the Diagram

Understanding a visual representation of components can greatly enhance your ability to maintain and repair machinery. These illustrations serve as valuable guides, providing insight into the arrangement and relationship between various elements.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols:

Each illustration uses specific symbols to denote different components. Take time to learn what each symbol represents.

- Identify Key Sections:

Most representations are divided into sections based on function. Recognizing these areas will help you navigate the visual more efficiently.

- Follow the Lines:

Lines connecting symbols indicate relationships or pathways. Trace these connections to understand how components interact.

- Refer to the Legend:

A legend often accompanies the visual, providing definitions for symbols and color codes. Use it as a reference to clarify any confusion.

- Practice with Examples:

Look for sample visuals and practice interpreting them. Hands-on experience will reinforce your understanding.

By following these guidelines, you’ll gain a deeper comprehension of the visual layout, enabling you to tackle maintenance tasks with confidence and precision.

Common BX23 Replacement Parts

Maintaining machinery requires occasional updates to essential components to ensure optimal performance. Knowing which elements frequently need replacing can save time and enhance efficiency. Below are some commonly replaced items that are crucial for keeping equipment running smoothly.

- Filters

- Oil filters

- Fuel filters

- Air filters

- Belts

- Seals and gaskets

- Blades and cutting tools

- Batteries

- Hydraulic hoses

Regular inspection and timely replacement of these elements can greatly enhance the lifespan of the machinery and ensure it operates at peak efficiency.

Identifying Parts by Diagram

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as valuable tools for recognizing individual elements, allowing users to efficiently locate and assess each section. By utilizing such illustrations, one can ensure proper handling and replacement, minimizing the risk of errors during servicing.

Utilizing Visual References

Visual references break down complex systems into manageable parts. Each section is labeled, making it easier to identify specific elements. This clarity aids both novice and experienced technicians in navigating intricate assemblies, fostering a smoother repair process.

Benefits of Visual Identification

Employing these visual aids not only streamlines repairs but also enhances overall understanding of the machinery’s structure. Efficiency is improved as users can quickly pinpoint the required components. Furthermore, this method reduces the likelihood of incorrect installations, leading to longer-lasting performance and increased safety.

Where to Find Genuine Parts

Locating authentic components for your machinery is crucial for maintaining its performance and longevity. Utilizing reliable sources ensures that you receive high-quality items that fit perfectly and function as intended. This section will guide you on where to find these essential elements.

Authorized Dealers: One of the best places to start your search is through official dealers. These establishments are directly connected to the manufacturer and typically offer a wide range of original equipment. Their staff can provide expert advice and assistance in selecting the correct components.

Online Retailers: Numerous reputable e-commerce platforms specialize in selling genuine components. Look for websites that have positive reviews and a good track record in delivering quality products. Always check for authenticity guarantees before making a purchase.

Local Repair Shops: Many local mechanics and repair facilities have access to authentic components. Establishing a relationship with these professionals can also help you gain insights into maintenance and repair best practices.

Manufacturer’s Website: Often, the manufacturer’s official website offers a catalog of components. Here, you can find detailed information and sometimes even purchase directly. This is a reliable way to ensure you are getting the correct items.

Trade Shows and Expos: Attending industry events can provide an excellent opportunity to connect with suppliers and discover genuine items. These gatherings often showcase the latest offerings and technologies in the field.

In summary, utilizing a combination of authorized dealers, trusted online platforms, local experts, and official resources will help you find the authentic components you need to keep your machinery running smoothly.

DIY Maintenance Tips for BX23

Regular upkeep of your compact utility machine is essential to ensure its longevity and optimal performance. Engaging in simple maintenance tasks not only enhances efficiency but also helps you identify potential issues before they escalate. Here are some practical tips for maintaining your equipment effectively.

| Task | Frequency | Notes |

|---|---|---|

| Check Engine Oil Level | Every 10 hours of operation | Ensure the oil is clean and at the correct level. |

| Clean Air Filter | Every 25 hours of operation | A clean filter improves airflow and engine performance. |

| Inspect Battery | Monthly | Check for corrosion and ensure connections are secure. |

| Sharpen Blades | Every 50 hours of use | Sharp blades promote cleaner cuts and reduce engine strain. |

| Check Tire Pressure | Before each use | Proper pressure ensures better traction and fuel efficiency. |

By adhering to these maintenance practices, you can keep your machinery in peak condition and extend its operational life. Always consult your owner’s manual for specific recommendations tailored to your model.

Understanding the Warranty Coverage

Warranty coverage is an essential aspect of ownership that provides peace of mind to users. It outlines the protections available against manufacturing defects and issues that may arise during regular use. Familiarizing oneself with the specifics of this coverage can help in making informed decisions regarding maintenance and repairs.

The terms of warranty often vary, including duration, components covered, and the types of damage that are eligible for repair or replacement. Here is a breakdown of common warranty features:

| Feature | Description |

|---|---|

| Duration | Length of time the warranty is valid, usually specified in months or years. |

| Coverage Type | Indicates whether the warranty covers parts, labor, or both. |

| Exclusions | Details any conditions or damages that are not covered. |

| Transferability | Specifies if the warranty can be transferred to a new owner. |

| Claim Process | Steps required to file a claim for warranty service. |

Understanding these elements is crucial for maximizing the benefits of warranty protection and ensuring that any potential issues are addressed promptly and effectively.

Frequently Asked Questions

This section aims to address common inquiries related to equipment components and maintenance. Here, you’ll find helpful information to enhance your understanding and assist in troubleshooting.

Common Inquiries

| Question | Answer |

|---|---|

| Where can I find a comprehensive list of components? | You can usually obtain a complete inventory through the manufacturer’s official website or authorized dealers. |

| How do I identify specific components for replacement? | Reference the user manual or consult a parts catalog that corresponds to your model for accurate identification. |

| What should I do if a part is difficult to locate? | If you encounter challenges, consider reaching out to customer support or searching online marketplaces for availability. |

| Are there universal components I can use? | While some parts may be interchangeable, it’s essential to ensure compatibility with your specific model for optimal performance. |

Maintenance Tips

Regular inspections and timely replacements can prolong the lifespan of your machinery. Always follow the recommended maintenance schedule to ensure optimal functionality.