Comprehensive Guide to Mercruiser Parts Diagram

When it comes to maintaining and troubleshooting your aquatic power system, having a clear visual reference of the individual elements can significantly enhance your understanding and efficiency. A comprehensive overview of these components not only aids in identifying specific parts but also streamlines the process of repairs and upgrades.

Each segment of the engine plays a crucial role in its overall functionality, and recognizing how these pieces fit together is essential for any boating enthusiast or professional. A detailed illustration can serve as a valuable tool, providing insights into the intricate relationships between various components.

By familiarizing yourself with the layout and function of these essential items, you can approach maintenance tasks with greater confidence. This knowledge empowers you to tackle issues independently, ensuring your vessel remains in peak condition for all your maritime adventures.

Understanding Mercruiser Engine Components

The efficient functioning of marine power units relies on a variety of interconnected elements, each serving a specific purpose. Familiarity with these components is essential for both maintenance and troubleshooting, ensuring that your engine performs at its best in aquatic environments. This section delves into the critical elements of these propulsion systems, highlighting their roles and significance.

Core Components

At the heart of any marine engine lies the engine block, which houses the cylinders and provides the foundation for other parts. Connected to this structure are the pistons, which move up and down to create power through combustion. Additionally, the cylinder head plays a vital role in sealing the combustion chamber and facilitating the intake and exhaust of gases.

Supporting Systems

Beyond the core elements, various auxiliary systems are crucial for optimal performance. The cooling system ensures that the engine operates within safe temperature ranges, while the fuel delivery mechanism regulates the flow of fuel to maintain efficiency. Moreover, the ignition system ignites the air-fuel mixture at the precise moment, allowing for smooth operation and maximum power output.

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial in the realm of machinery and equipment maintenance. These illustrations serve as essential guides for technicians, enabling them to identify, locate, and understand the function of each element within a system. Without accurate depictions, the risk of errors during repairs increases significantly, potentially leading to further complications.

Clarity in these representations ensures that individuals can quickly grasp the layout and interconnections of various elements. This understanding is vital for effective troubleshooting and enhances the overall efficiency of maintenance tasks. Additionally, clear visuals help reduce downtime by allowing for quicker identification of required replacements and facilitating smoother workflows.

Moreover, relying on well-crafted visuals can enhance safety during repairs. Technicians can better understand the potential hazards associated with different components, ensuring they follow the correct procedures. Ultimately, the significance of having reliable and detailed visual aids cannot be overstated, as they play a fundamental role in maintaining operational integrity and prolonging the lifespan of the equipment.

Common Mercruiser Engine Models

This section delves into popular powertrain configurations that have become staples in the boating community. These engine types are recognized for their reliability, performance, and versatility across various marine applications.

One widely used model is the 4.3L V6, known for its compact size and efficient fuel consumption. Ideal for smaller vessels, it provides a balance of power and agility, making it a favorite among recreational boaters.

Another notable option is the 5.0L V8. This engine is celebrated for its robust output and smooth operation, making it suitable for a range of activities, from cruising to water sports. Its ability to handle heavier loads makes it a popular choice for larger boats.

The 7.4L V8 is a powerhouse, designed for those who demand maximum performance. It excels in speed and acceleration, catering to thrill-seekers and those looking to navigate rough waters with ease.

Lastly, the 6.2L V8 combines advanced technology with impressive power, featuring fuel injection systems that enhance efficiency while delivering exceptional performance. This model is often found in premium vessels, reflecting a blend of innovation and capability.

How to Read Parts Diagrams

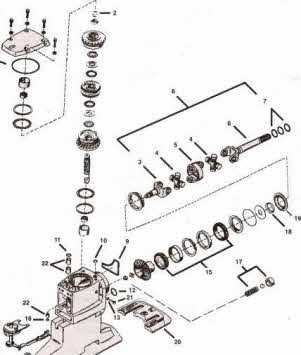

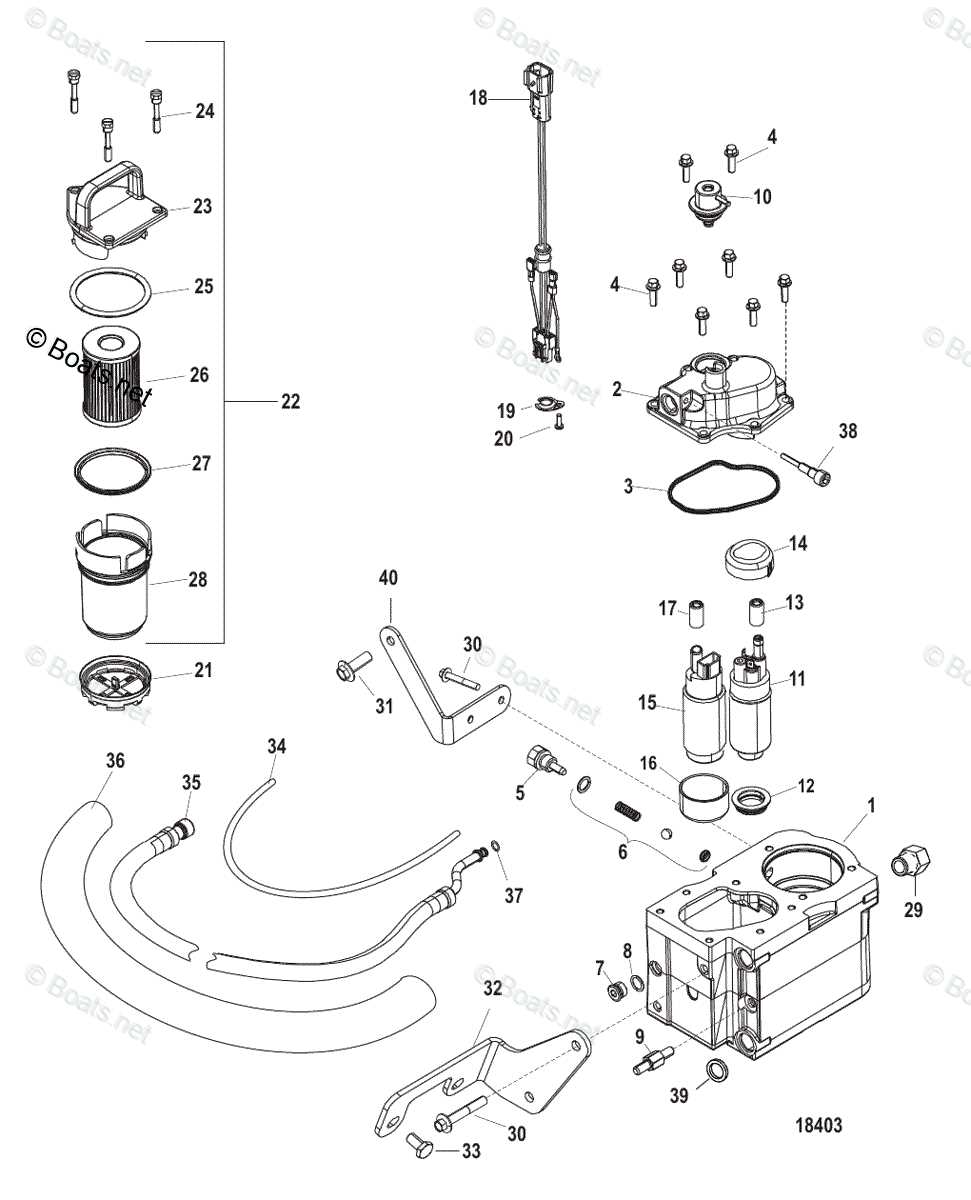

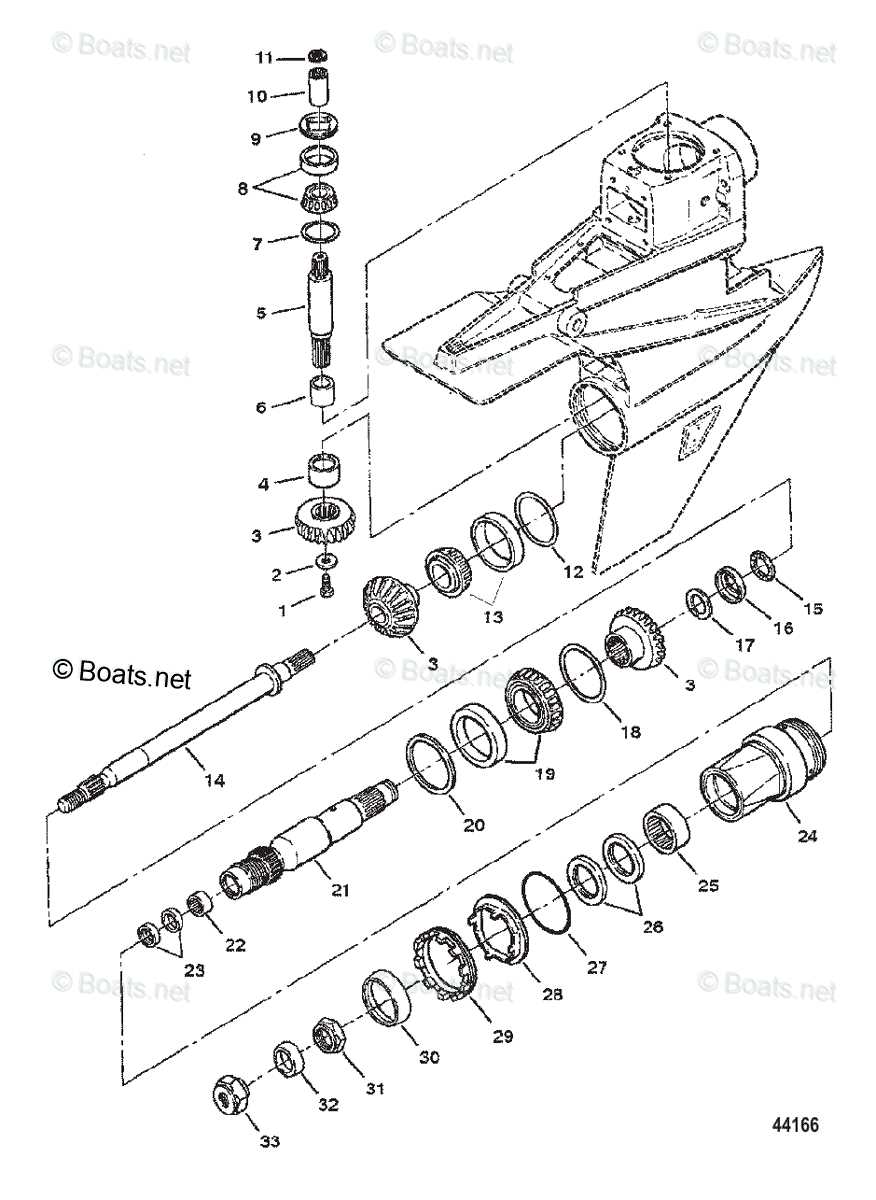

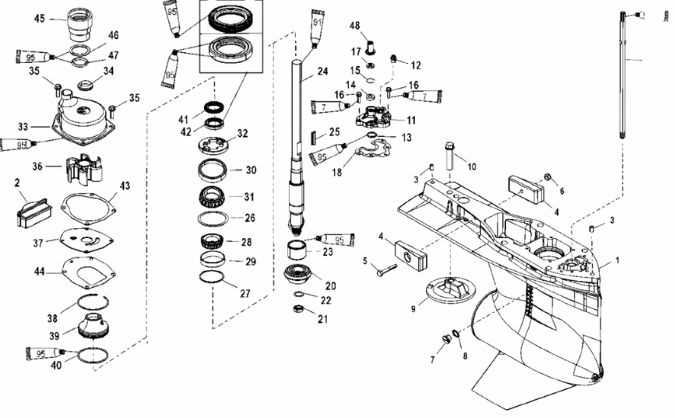

Understanding schematics is essential for effectively maintaining and repairing marine engines. These visual representations provide a comprehensive overview of various components, their relationships, and functionalities. By familiarizing yourself with these illustrations, you can identify individual elements and their roles within the overall system.

To begin, pay attention to the labels and numbers associated with each component. These identifiers are crucial for locating the correct items when ordering replacements. Additionally, observe how the parts are arranged; their positioning often indicates how they fit together in the physical assembly.

Next, examine the connections between different sections. Lines and arrows usually represent pathways for fluids or electrical signals, guiding you on how systems interact. Understanding these pathways can enhance your troubleshooting skills and help diagnose potential issues.

Finally, make note of any accompanying legends or notes that clarify specific functions or installation tips. These annotations can provide valuable insights and simplify complex assemblies, ensuring you approach repairs with confidence and accuracy.

Essential Tools for Maintenance

Proper upkeep of your marine engine requires a well-equipped toolkit. Having the right instruments not only ensures efficient repairs but also prolongs the life of your machinery. Below is a curated list of essential items that every boat owner should have for effective maintenance.

Basic Hand Tools

- Wrenches: Various sizes are necessary for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are essential for accessing different components.

- Socket Set: A versatile set will help in reaching tight spaces more easily.

- Pliers: Useful for gripping and manipulating small parts.

Specialized Tools

- Torque Wrench: Ensures that bolts are tightened to the correct specifications.

- Compression Tester: Assesses engine compression levels for diagnostics.

- Multimeter: Essential for electrical troubleshooting and ensuring proper functionality.

- Grease Gun: Keeps moving parts lubricated for optimal performance.

Having these tools at your disposal will enable you to perform regular maintenance tasks with confidence and precision, ensuring your vessel operates smoothly for years to come.

Where to Find Official Diagrams

Accessing authentic schematics is crucial for anyone involved in maintenance or repair tasks. These visual guides not only enhance understanding but also streamline the process of identifying components and their relationships. Whether you are a seasoned professional or a novice, knowing where to locate reliable resources can significantly impact your efficiency and success.

Manufacturer’s Website

The primary source for official illustrations is often the manufacturer’s own website. These platforms typically provide a wealth of information, including downloadable files and interactive tools. Exploring the support or resources section can lead you to comprehensive visual references tailored to specific models.

Authorized Dealers and Distributors

Another excellent avenue is reaching out to authorized dealers or distributors. They frequently maintain archives of official materials and can offer personalized assistance. Consulting with these professionals not only ensures access to accurate information but also allows for inquiries about parts compatibility and recommendations for your particular situation.

Identifying Worn Parts in Diagrams

Recognizing components that have experienced wear and tear is crucial for maintaining the performance and longevity of any mechanical system. Understanding the layout and function of various elements in a visual representation can help in pinpointing which pieces require attention. By analyzing these illustrations, one can determine signs of deterioration and make informed decisions regarding repairs or replacements.

Common Signs of Wear

Several indicators can reveal whether a component is reaching the end of its service life. Look for cracks, discoloration, or unusual wear patterns in the visual guides. Additionally, deformation or looseness in connection points often suggests that an element may need to be replaced. Familiarity with these signs can enhance your ability to maintain overall system health.

Utilizing Visual Guides for Maintenance

When studying illustrations, it’s beneficial to compare current conditions with reference images of new or well-maintained components. This practice can highlight discrepancies and help in making precise assessments. Regularly consulting these resources ensures that you remain vigilant about potential issues, ultimately contributing to a more efficient operation.

Frequently Replaced Components Explained

In the world of marine engines, certain elements are more prone to wear and tear due to their exposure to harsh environments and operational stresses. Understanding these components can help boat owners maintain their vessels effectively and prolong their lifespan.

Commonly Worn Items

Several key components often require replacement during routine maintenance. These parts not only affect performance but also influence safety and reliability. Regular checks can identify these items early, preventing more significant issues down the line.

| Component | Symptoms of Wear | Recommended Maintenance |

|---|---|---|

| Fuel Filter | Reduced engine power, stalling | Replace every season |

| Water Pump | Overheating, reduced cooling | Inspect annually, replace every 2-3 years |

| Spark Plugs | Hard starting, poor acceleration | Check and replace every 100 hours |

| Oil Filter | Low oil pressure, engine noise | Change with every oil change |

Preventive Strategies

To minimize the frequency of replacements, implementing a proactive maintenance schedule is essential. Regular inspections and timely replacements can significantly enhance the overall performance of the engine, ensuring a smoother and safer boating experience.

Benefits of Using OEM Parts

Choosing original equipment manufacturer components offers numerous advantages that contribute to the longevity and reliability of your vessel. These components are specifically designed to meet the exact specifications of your engine, ensuring optimal performance and compatibility.

One of the primary benefits is the assurance of quality. OEM components undergo rigorous testing and quality control processes, which guarantees that they meet high standards. This not only enhances the safety of your vessel but also reduces the likelihood of failures or malfunctions.

Another significant advantage is the availability of warranties. Using original components often comes with a manufacturer’s warranty, providing peace of mind and protection against defects. This can save you money on repairs in the long run, as you won’t have to deal with unexpected issues that arise from inferior alternatives.

Additionally, opting for OEM solutions can maintain the resale value of your vessel. Potential buyers often prefer equipment that has been maintained with original parts, as it reflects a commitment to quality and care. This can make a substantial difference when it comes time to sell or trade-in.

Lastly, sourcing original components simplifies the replacement process. They are designed to fit seamlessly with existing systems, reducing installation time and effort. This ensures that your vessel gets back on the water faster, allowing you to enjoy your time on the water with minimal disruption.

Tips for Ordering Replacement Parts

When it comes to acquiring new components for your marine engine, there are several key considerations to ensure a smooth and successful transaction. Understanding the nuances of what you need can save you time, money, and frustration.

1. Identify the Exact Component: Before making a purchase, it’s crucial to know precisely what you need. Check the model number and any specifications associated with the item to avoid mistakes.

2. Use Reputable Suppliers: Choose well-established vendors known for their quality and reliability. Reading reviews and seeking recommendations can help you find trustworthy sources.

3. Compare Prices: Don’t settle for the first option you find. Compare prices from multiple retailers to ensure you’re getting the best deal. However, be cautious of prices that seem too good to be true.

4. Ask Questions: If you’re unsure about a specific item, reach out to customer service for clarification. A knowledgeable representative can help guide you toward the correct selection.

5. Consider Compatibility: Ensure that the component you intend to order is compatible with your existing setup. Verify that it matches the required specifications to avoid compatibility issues.

6. Review Return Policies: Before completing your purchase, familiarize yourself with the return policy. Understanding the process for returns or exchanges can provide peace of mind.

7. Keep Documentation Handy: Maintain records of your previous purchases and any relevant documentation. This information can be helpful for future orders and troubleshooting.

Common Installation Mistakes to Avoid

When working on marine engines, precision and attention to detail are crucial. Many individuals overlook key aspects during installation, leading to issues that can affect performance and safety. Recognizing these common pitfalls can save time and resources, ensuring a smoother process and better outcomes.

Neglecting to Follow Manufacturer Guidelines

One of the most frequent errors is failing to adhere to the specified instructions provided by the manufacturer. Each engine model has unique requirements, and ignoring these can lead to improper assembly and operational problems.

Using Incorrect Tools and Fasteners

Utilizing the wrong tools or fasteners is another mistake that can compromise the integrity of the installation. Always ensure that you are equipped with the right equipment and components to maintain the engine’s functionality.

| Mistake | Consequence | Solution |

|---|---|---|

| Ignoring torque specifications | Leaking fluids, component damage | Use a torque wrench |

| Inadequate cleaning of surfaces | Poor seal and potential leaks | Thoroughly clean all contact areas |

| Improper alignment of components | Increased wear and tear | Double-check alignment before securing |

Upgrading Your Mercruiser Engine

Enhancing your marine powertrain can significantly improve performance, efficiency, and longevity. Whether you’re aiming for more horsepower, better fuel economy, or improved reliability, a few strategic upgrades can make a substantial difference. This section explores various options available to elevate your vessel’s capabilities.

Performance Enhancements

One effective way to boost performance is by upgrading the intake and exhaust systems. A high-flow intake allows your engine to breathe more freely, resulting in increased power output. Similarly, a performance exhaust system reduces back pressure, enhancing exhaust flow and optimizing engine efficiency. Additionally, tuning the engine management software can further refine performance, ensuring that every component works harmoniously.

Durability Improvements

To extend the life of your power unit, consider enhancing its durability through upgraded components. High-quality gaskets and seals can prevent leaks and maintain optimal pressure. Upgrading to a more robust cooling system can also prevent overheating, especially during extended use. Investing in better-quality lubricants and filters will ensure that all moving parts remain protected and perform at their best.

Resources for Further Learning

Exploring comprehensive materials can significantly enhance your understanding of marine engine components and their functionality. Various resources, including manuals, online forums, and educational videos, provide valuable insights into maintenance and troubleshooting practices.

Official manufacturer websites often offer downloadable manuals that contain detailed information about specific models and their assemblies. These documents serve as a great starting point for anyone looking to deepen their knowledge.

Online communities and forums are also excellent platforms for sharing experiences and tips among enthusiasts. Engaging with fellow users can lead to discovering practical advice and innovative solutions to common issues.

Additionally, video tutorials on platforms like YouTube can provide step-by-step guidance on repairs and installations, making complex tasks more approachable. These visual aids can help bridge the gap between theoretical knowledge and practical application.

Lastly, consider enrolling in workshops or courses dedicated to marine technology. These educational opportunities can provide hands-on experience and professional insights, further enriching your understanding of engine systems.