Kubota T1570 Parts Diagram for Easy Identification

In the realm of machinery, comprehending the intricate relationships between various elements is crucial for maintaining efficiency and longevity. This section aims to provide insights into the essential components that contribute to the seamless operation of these robust machines. By exploring the configurations and interactions of each piece, users can enhance their understanding and ensure their equipment runs smoothly.

Whether you are a seasoned professional or a newcomer, grasping the layout of these vital elements can lead to better troubleshooting and maintenance practices. With a clearer vision of how everything fits together, one can easily pinpoint potential issues and implement effective solutions. This guide delves into the complexities of each component, offering an ultimate resource for anyone looking to deepen their knowledge.

Ultimately, having a solid grasp of the mechanical framework is not just beneficial; it is essential for achieving peak performance. By investing time in understanding these details, users can take proactive steps to safeguard their investment and maximize productivity in their operations.

Kubota T1570 Overview

This section provides a comprehensive look at a specific model of compact tractors, highlighting its features, capabilities, and overall design. With a focus on user experience and performance, the insights here aim to guide potential users in understanding the value and functionality of this machine.

Key Features

This model is designed with efficiency and versatility in mind. Equipped with a powerful engine, it ensures reliability across various tasks. Its ergonomic design enhances user comfort, making it suitable for both professional and residential use.

Specifications

| Feature | Specification |

|---|---|

| Engine Type | 4-Cycle, Diesel |

| Power Output | 25 HP |

| Transmission | Hydrostatic |

| Weight | 1500 lbs |

| Fuel Capacity | 6.5 gallons |

Importance of Parts Diagrams

Understanding the layout of components in machinery is crucial for effective maintenance and repair. Visual representations enhance clarity, allowing users to quickly identify and locate each element.

Benefits of these visual aids include:

- Facilitating efficient troubleshooting by pinpointing specific areas.

- Streamlining the ordering process for replacements.

- Enhancing the learning experience for new technicians.

- Providing a reference for assembly and disassembly procedures.

Ultimately, clear illustrations lead to better upkeep and prolonged lifespan of equipment.

Key Components of Kubota T1570

This section highlights the essential elements that contribute to the efficient functioning of a compact utility machine. Understanding these components is crucial for maintenance and performance optimization, ensuring that the equipment operates smoothly and reliably in various tasks.

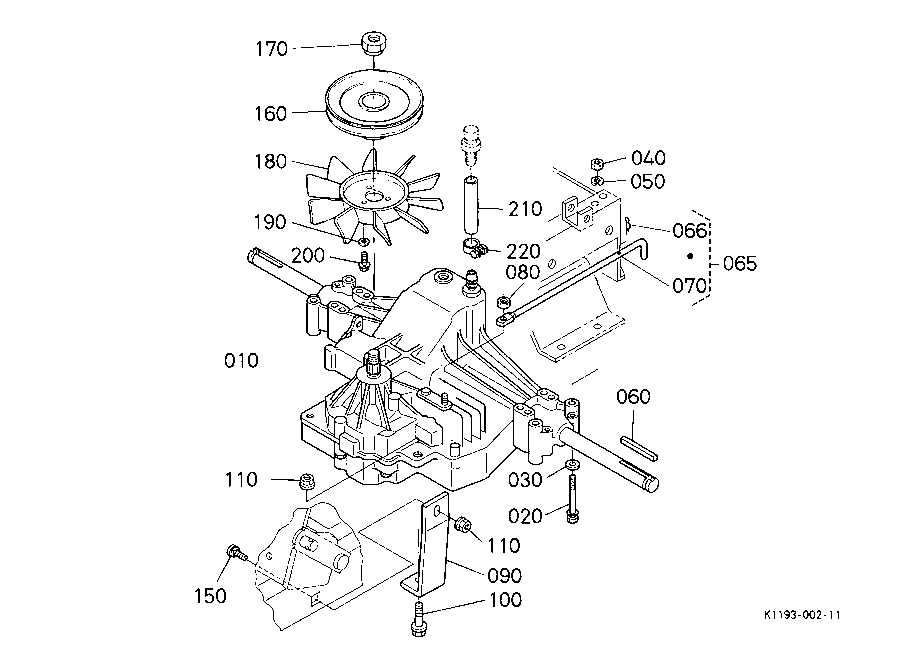

Engine and Transmission

The heart of any machinery lies in its engine and transmission system. These components work in harmony to provide the necessary power and control. The engine converts fuel into mechanical energy, while the transmission system transfers this energy to the wheels, allowing for smooth movement across different terrains.

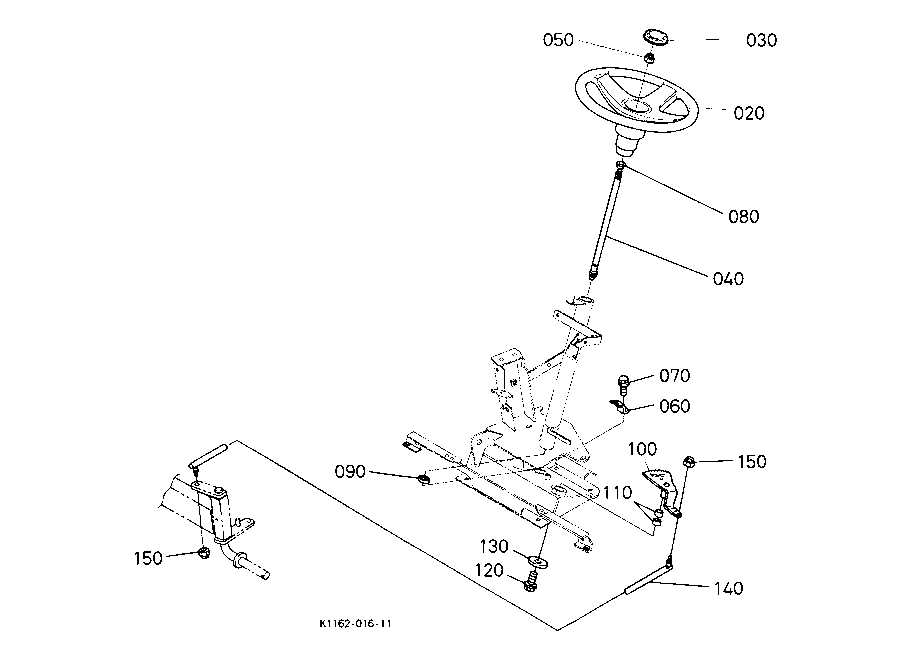

Chassis and Steering Mechanism

The structural framework and steering system play a pivotal role in stability and maneuverability. A robust chassis supports various attachments and ensures durability, while the steering mechanism allows for precise handling, enhancing the operator’s control during operation.

Understanding Engine Parts Layout

Gaining insight into the arrangement of components within an engine is crucial for effective maintenance and troubleshooting. Each element plays a significant role in the overall functionality, and understanding their positioning aids in identifying issues and enhancing performance.

The layout typically includes various key sections, such as the combustion chamber, intake and exhaust systems, and cooling mechanisms. A clear comprehension of how these sections interconnect is essential for any operator or technician.

| Component | Description | Function |

|---|---|---|

| Combustion Chamber | Space where fuel and air mix and ignite | Generates power through combustion |

| Intake System | Involves ducts and valves for air entry | Ensures proper air supply for efficient combustion |

| Exhaust System | Pathway for burnt gases to exit | Reduces back pressure and expels exhaust |

| Cooling Mechanism | Includes radiators and cooling fluids | Maintains optimal operating temperature |

By familiarizing oneself with these arrangements, operators can better diagnose issues and implement repairs, ultimately ensuring that the machinery runs smoothly and efficiently.

Common Issues with Kubota T1570

Many users encounter various challenges with their machinery, impacting performance and longevity. Identifying and addressing these common problems is crucial for maintaining optimal functionality and preventing costly repairs.

Engine Overheating: One prevalent issue is overheating, often caused by insufficient coolant levels or a clogged radiator. Regular maintenance and monitoring can mitigate this risk.

Battery Drain: Frequent battery issues may arise from faulty connections or parasitic draws. Ensuring secure connections and checking for electrical leaks is vital.

Poor Starting: Difficulties in starting may result from worn spark plugs or a failing starter motor. Routine inspections can help detect these issues early.

Transmission Problems: Users often report shifting difficulties, typically linked to low fluid levels or contaminated transmission fluid. Regular checks can prevent these complications.

Uneven Cutting: Some operators notice uneven cutting patterns, which can be attributed to dull blades or improper tire pressure. Regular blade maintenance and tire checks are recommended.

How to Use Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to maintain and repair machinery. These illustrations provide a detailed look at each element, making it easier to identify, order, and replace parts as needed.

Identifying Components

Start by familiarizing yourself with the layout. Each section typically highlights specific assemblies, allowing you to pinpoint the items relevant to your repair. Pay attention to the labels and numbers associated with each part, as these references are crucial for ordering replacements.

Ordering Replacements

Once you have identified the necessary elements, you can move on to procuring replacements. Utilize the reference numbers to ensure accuracy when communicating with suppliers. This practice minimizes errors and speeds up the repair process, allowing you to get your machinery back in operation promptly.

Finding Replacement Parts Easily

Locating suitable components for your machinery can be a straightforward process if you know where to look. Understanding the various resources available and the right approach can save you time and effort when searching for the necessary items to keep your equipment in top condition.

Utilizing Online Resources

Many websites specialize in offering a wide range of components for various machinery. Here are some strategies to make the most of these online platforms:

- Search by model number to filter results effectively.

- Use trusted marketplaces to ensure quality and authenticity.

- Read customer reviews to gauge the reliability of sellers.

Consulting Local Dealers

Reaching out to nearby dealerships can provide personalized assistance and access to genuine components. Consider the following:

- Build a relationship with a local dealer for expert advice.

- Ask about special orders if specific items are not in stock.

- Inquire about any available discounts or promotions.

By leveraging both online and local resources, you can efficiently find the components you need, ensuring your equipment remains operational and efficient.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent care and attention. By following a few essential practices, you can significantly extend the lifespan of your equipment and maintain optimal performance. Regular maintenance not only prevents costly repairs but also enhances reliability during operation.

First, always adhere to the manufacturer’s recommended service schedule. This includes routine checks and timely replacement of vital components. Monitoring fluid levels and replacing them when necessary will help keep the engine and other systems functioning smoothly.

Additionally, keep your machinery clean. Debris and dirt accumulation can lead to overheating and mechanical failure. Regularly washing and inspecting your equipment will help identify potential issues before they escalate.

Pay attention to the tires and tracks, ensuring they are properly inflated and aligned. This prevents uneven wear and improves traction, which is crucial for safe and efficient operation.

Finally, don’t underestimate the importance of using quality replacement parts. Investing in high-grade components ensures that your equipment remains in peak condition, reducing the risk of breakdowns and enhancing overall performance.

Comparing T1570 with Other Models

This section aims to explore the distinctions and similarities between a specific model and its counterparts within the same category. By examining various attributes such as performance, design, and functionality, we can gain insights into how this particular machine measures up against others, enhancing our understanding of its ultimate advantages and potential drawbacks.

When considering operational efficiency, this model stands out with its robust engine capabilities compared to similar machines, providing superior power and torque. In contrast, other models may offer lighter weight, which can be beneficial for maneuverability in tight spaces. Evaluating these factors allows users to select the most suitable option based on their specific needs.

Another significant aspect is the comfort and usability of the operator’s environment. While some alternatives prioritize advanced features and technology, this model maintains a focus on simplicity, making it user-friendly for both novices and experienced operators alike. This balance can be crucial for those who prefer a straightforward approach to operation.

Additionally, maintenance requirements vary across different machines. While some models demand more frequent servicing, this particular variant is designed for ease of upkeep, allowing for longer intervals between maintenance sessions. This factor not only saves time but also reduces long-term costs, making it an appealing choice for budget-conscious users.

Resources for Technical Support

When navigating the complexities of machinery maintenance and repair, having access to reliable resources can be crucial. Support networks can provide valuable insights and solutions for troubleshooting various issues. Utilizing the right tools and information ensures optimal performance and longevity of your equipment.

Online Forums: Participating in specialized online communities allows users to share experiences, seek advice, and exchange tips on resolving specific challenges. These platforms often feature seasoned professionals who can offer practical guidance.

User Manuals: Comprehensive manuals are indispensable for understanding operational guidelines and maintenance procedures. These documents typically include troubleshooting sections, making them a vital resource for quick reference.

Manufacturer Support: Reaching out to the manufacturer’s customer service can provide direct assistance. They often have knowledgeable staff ready to address inquiries and provide detailed technical support.

Local Dealers: Authorized dealers are another excellent source of assistance. They can supply original components and offer expert advice tailored to specific models, ensuring you receive the best possible care for your equipment.

Videos and Tutorials: Online video tutorials can be particularly h