Comprehensive Guide to John Deere F510 Parts Diagram

Maintaining machinery involves a clear grasp of its components and their functionalities. Proper knowledge allows operators to ensure efficient performance and longevity of their tools. This section aims to shed light on the intricate design and essential elements that contribute to the overall operation.

By exploring the various segments and their interactions, users can better navigate the complexities of their equipment. Recognizing how each piece fits into the larger mechanism not only enhances understanding but also aids in troubleshooting and maintenance. Illustrative resources play a crucial role in visualizing these relationships.

Ultimately, this guide serves as a valuable resource for anyone looking to delve into the specifics of their machinery, facilitating informed decisions and effective care strategies. Empower yourself with knowledge to maximize the functionality of your tools and tackle any challenges with confidence.

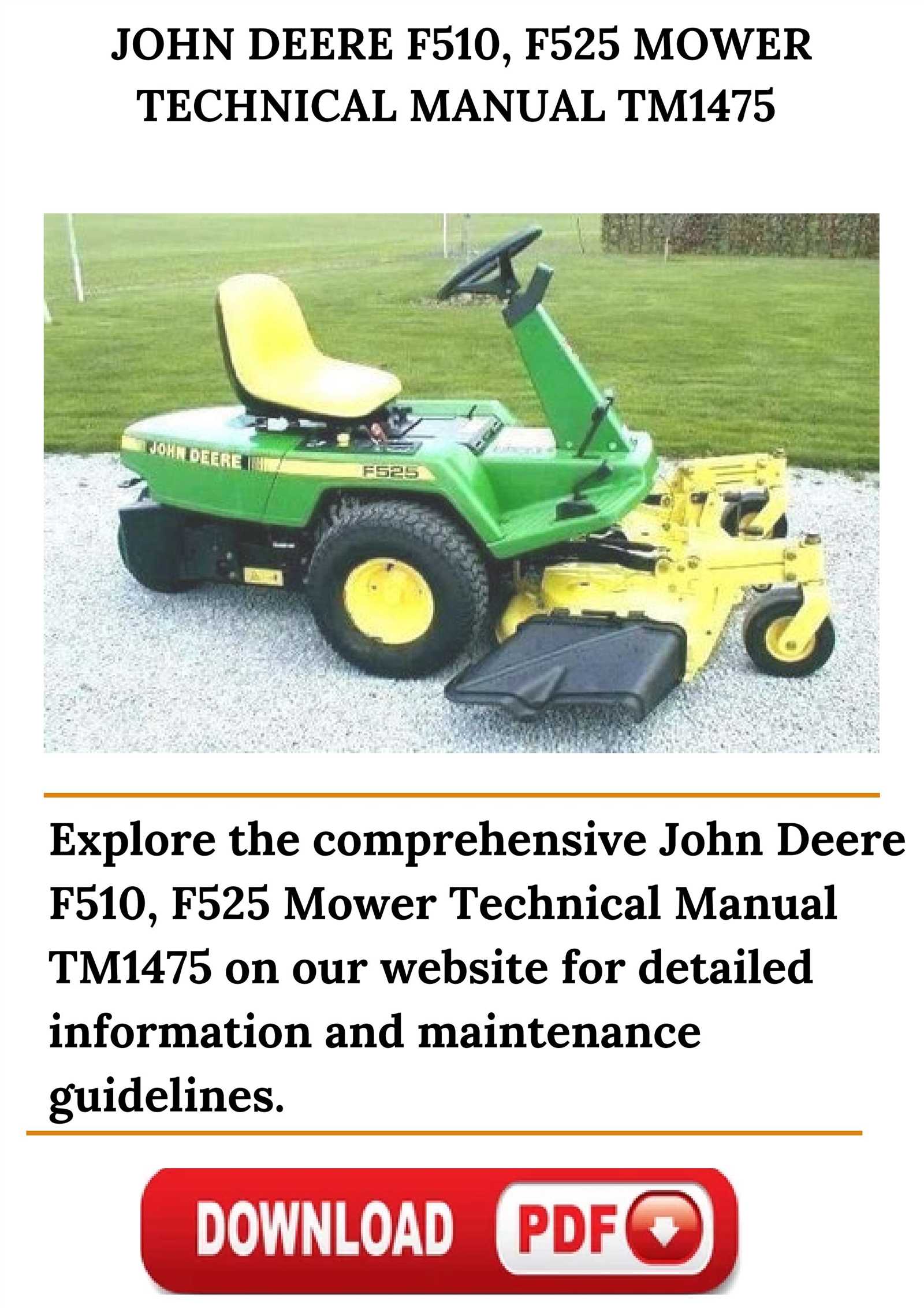

Overview of John Deere F510

This section provides a comprehensive look at a popular model known for its reliability and efficiency in outdoor tasks. With a focus on robust design and user-friendly features, it has become a staple for both enthusiasts and professionals alike.

The machine is engineered to deliver exceptional performance in various terrains, making it suitable for a wide range of applications. Its powerful engine and advanced technology ensure smooth operation and ease of maintenance.

Users appreciate the ergonomic design, which enhances comfort during prolonged use, as well as the versatile attachments that can be integrated for specialized functions. This adaptability contributes to its reputation as an ultimate choice for many outdoor tasks.

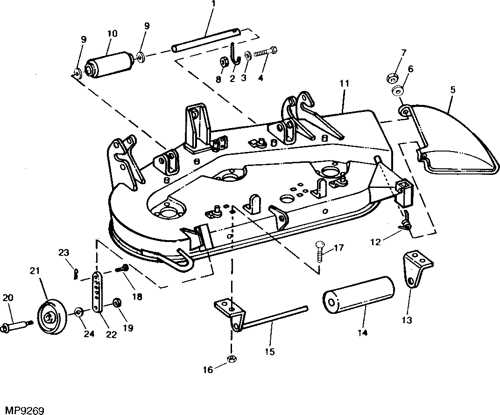

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide clear guidance, helping users to understand the intricate relationships and functions of various elements within a system. This understanding is essential for efficient troubleshooting and restoration tasks.

Benefits of Visual Representations

- Clarity: Diagrams simplify complex assemblies, making it easier to identify parts and their locations.

- Efficiency: Having a visual reference speeds up the repair process by allowing users to quickly locate necessary components.

- Accuracy: Detailed visuals reduce the risk of errors during disassembly and reassembly, ensuring that everything is put back together correctly.

- Education: They serve as valuable tools for training new technicians, enhancing their understanding of the machinery.

Enhancing Maintenance Practices

- Fosters systematic troubleshooting by providing a roadmap of potential failure points.

- Encourages regular inspections and proactive maintenance by highlighting critical components.

- Facilitates effective communication among team members by providing a shared reference point.

- Improves overall safety by ensuring that technicians are aware of all parts and their functions.

Incorporating visual guides into maintenance practices is essential for optimizing performance and prolonging the lifespan of machinery.

Common Parts for F510 Model

This section provides an overview of essential components for a popular mowing machine. Understanding these elements can enhance maintenance and ensure optimal performance, making your tasks easier and more efficient.

Key Components

- Engine assembly

- Transmission system

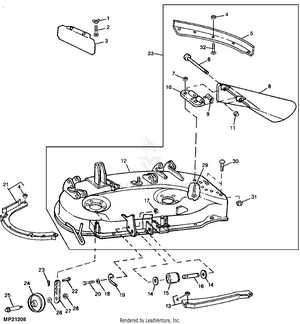

- Cutting blades

- Wheels and tires

- Battery

Maintenance Essentials

- Oil filter

- Air filter

- Fuel filter

- Belts and pulleys

- Deck hardware

Identifying F510 Components Easily

Understanding the various elements of your equipment is essential for efficient maintenance and operation. Recognizing these components can streamline repairs and enhance your ability to troubleshoot issues effectively. This section will guide you in identifying the critical parts, ensuring you can manage your machinery with confidence.

To facilitate the identification process, consider the following steps:

- Familiarize yourself with the layout of the equipment.

- Use a reliable reference to understand the function of each part.

- Keep a checklist of common components to simplify your search.

When examining the machinery, pay attention to these key areas:

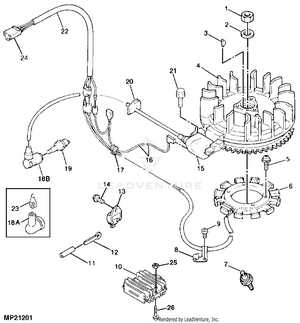

- Engine Assembly: Look for the main components such as the cylinder head and crankshaft.

- Transmission System: Identify gears, belts, and housing elements.

- Chassis and Frame: Note structural components that support the entire system.

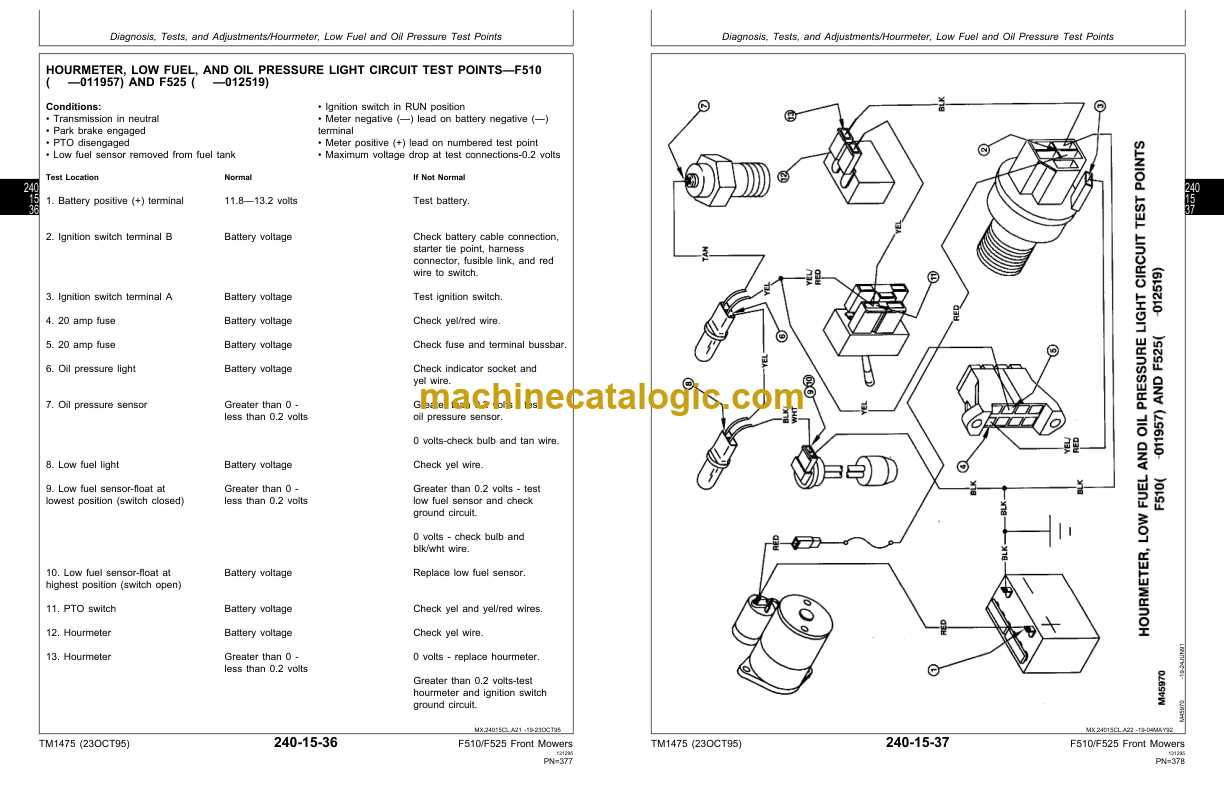

- Control Systems: Locate levers, pedals, and wiring that enable operation.

By following these tips, you can easily navigate through the essential elements of your machinery, leading to better maintenance practices and improved functionality.

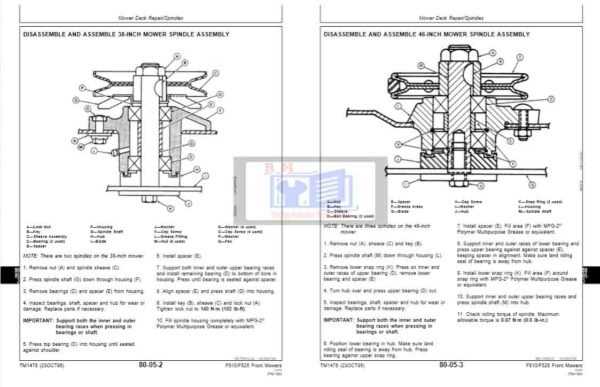

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual guides offer a clear representation of components, helping users identify and locate each item needed for servicing. By grasping the layout and symbols used, one can ensure accurate assembly and replacement tasks.

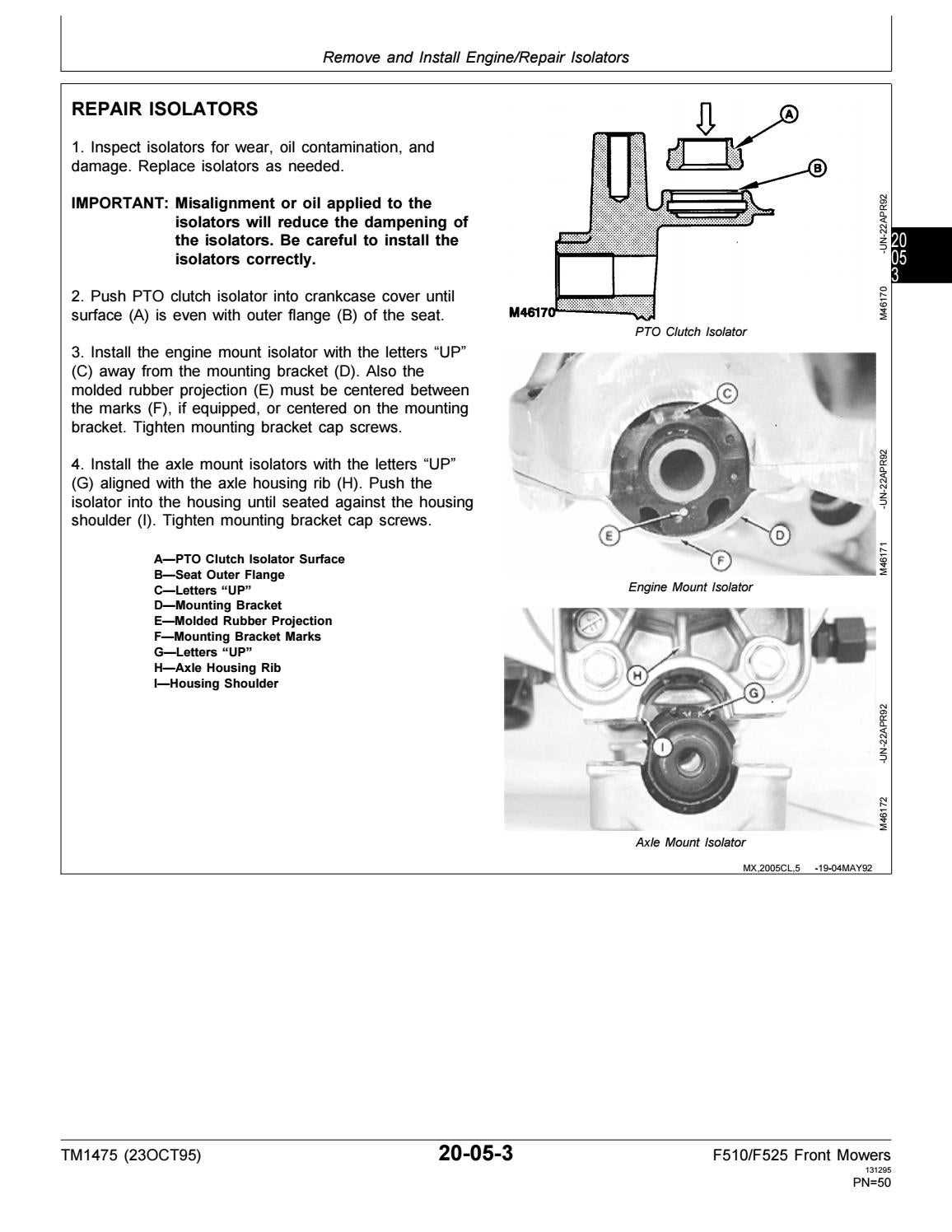

Identifying Key Components

Each illustration typically labels specific elements. Look for legends or annotations that clarify the function of each item. Familiarity with common symbols can enhance your ability to quickly navigate the image.

Understanding Relationships

Pay attention to how different components are connected. Lines often indicate how parts interact or fit together. Recognizing these relationships is crucial for successful repairs and ensuring all pieces work in harmony.

Where to Find Replacement Parts

Locating essential components for machinery can be a straightforward process when you know where to look. There are several reliable sources that cater to various needs, ensuring that you can keep your equipment running smoothly.

Online Retailers

- Specialized e-commerce platforms often provide a wide selection of items.

- Manufacturer websites may offer direct sales and detailed specifications.

- Marketplaces like eBay and Amazon feature both new and used options.

Local Suppliers

- Visit nearby hardware or equipment stores for immediate availability.

- Authorized dealers may carry original components and offer expert advice.

- Check with local salvage yards for cost-effective alternatives.

Maintaining Your John Deere F510

Regular upkeep of your machinery is essential for optimal performance and longevity. A well-maintained device not only enhances efficiency but also reduces the likelihood of costly repairs.

- Check oil levels frequently to ensure smooth operation.

- Inspect the air filter and replace it as necessary to maintain airflow.

- Sharpen or replace blades regularly for effective cutting.

- Examine belts and cables for signs of wear or damage.

- Clean the exterior and undercarriage to prevent rust and buildup.

Establish a maintenance schedule to help you stay on top of these tasks. Keeping records of service can also assist in identifying patterns that may require attention.

Troubleshooting Common Issues

Identifying and resolving frequent problems is essential for maintaining optimal performance in any machinery. By understanding the typical challenges that may arise, operators can take proactive measures to ensure smooth operation. This section will explore common issues, providing insights on their potential causes and solutions.

Engine Performance Problems

One of the most prevalent concerns is engine performance. Symptoms such as difficulty starting, stalling, or reduced power can indicate underlying issues. Fuel delivery problems, such as clogged filters or low fuel levels, may be to blame. Additionally, inspect the ignition system for worn spark plugs or faulty wiring, which can hinder proper operation.

Steering and Mobility Issues

Another area that often requires attention is the steering and mobility of the equipment. If steering feels unresponsive or there is unusual noise during movement, check the hydraulic fluid levels and inspect for leaks. Ensuring that the wheels and axles are in good condition is crucial for maintaining maneuverability.

Benefits of OEM Parts

Using original equipment manufacturer components offers numerous advantages that enhance performance and reliability. These specialized elements are designed to meet the exact specifications of your machinery, ensuring optimal functionality.

- Quality Assurance: OEM components are produced to the highest standards, guaranteeing durability and efficiency.

- Perfect Fit: These components are engineered to match perfectly, reducing the risk of malfunctions.

- Warranty Protection: Many manufacturers offer warranties on their original products, providing peace of mind.

- Performance Enhancement: Using these components can significantly improve the overall efficiency of your equipment.

- Long-term Savings: Investing in high-quality parts can minimize repair costs and extend the lifespan of your machinery.

Ultimately, choosing original components is a wise decision for maintaining your equipment’s performance and reliability.

Aftermarket vs. Original Parts

The choice between alternative components and genuine manufacturer offerings often sparks debate among users. Each option presents distinct advantages and drawbacks that can influence performance and longevity.

Original components are crafted by the same manufacturer that produced the machinery. This ensures compatibility and often comes with warranties, providing peace of mind for users seeking reliability.

On the other hand, alternative components can offer cost savings and availability. While they may not always match the exact specifications of the original, many users find them sufficient for their needs. However, quality can vary significantly among different brands.

Ultimately, the decision hinges on individual priorities, whether it’s budget, performance, or assurance of quality. Users should delve into research to determine which option best suits their requirements.

Using Diagrams for Repairs

Visual representations serve as invaluable tools in the maintenance and repair of machinery. They provide a clear layout of components, enabling users to identify parts and their relationships effectively. By utilizing these illustrations, technicians can streamline their repair processes, ensuring accuracy and efficiency in their work.

Benefits of Visual Aids

Employing graphical guides significantly enhances understanding. These visuals allow individuals to grasp complex systems at a glance. Familiarity with the arrangement and function of various elements reduces the likelihood of errors during disassembly and reassembly. Moreover, they assist in locating specific components quickly, saving time and effort.

Enhancing Repair Efficiency

Incorporating these resources into repair tasks leads to more efficient workflows. Technicians can follow step-by-step instructions depicted in the illustrations, which often highlight critical points and necessary tools. Ultimately, this structured approach minimizes downtime and improves overall productivity.

Customer Reviews on F510 Parts

This section explores feedback from users regarding components for a specific lawn care equipment model. Insights shared here provide valuable information for potential buyers and highlight overall satisfaction levels.

Positive Feedback

- Quality of materials received high praise.

- Easy installation process noted by many users.

- Durability exceeds expectations in various conditions.

Areas for Improvement

- Some users reported delays in shipping.

- Occasional mismatches in compatibility with older models.

- Higher price point compared to alternatives was a concern for some.