Understanding the Parts Diagram of Stihl HT 133 Pole Saw

When it comes to maintaining your outdoor equipment, a thorough comprehension of its structure is essential. A telescopic cutting tool can offer versatility and efficiency in managing overgrown branches and shrubs. Familiarity with the various components not only enhances operational effectiveness but also aids in troubleshooting and repairs.

In this section, we will delve into the intricate assembly of this essential device. By exploring the layout and functions of each element, users can gain insights into how to optimize performance and prolong the lifespan of their equipment. This knowledge empowers you to take control of maintenance tasks and ensures that your tool remains reliable for years to come.

Moreover, understanding the assembly of your cutting apparatus can lead to safer handling and usage. Each piece plays a crucial role in the overall functionality, and recognizing their relationships can help prevent misuse and accidents. Equip yourself with this knowledge to enhance your experience and achieve professional results in your gardening and landscaping endeavors.

Understanding Stihl HT 133 Pole Saw

This section explores a versatile gardening tool designed for efficient tree maintenance and pruning. With its robust engineering and user-friendly features, it stands out as an essential device for both professionals and enthusiasts alike.

Key Characteristics: The model boasts a powerful engine that ensures optimal performance even in challenging conditions. Its lightweight design allows for prolonged use without excessive fatigue, making it ideal for extended tasks.

Maintenance and Care: Proper upkeep is crucial for longevity. Regular inspections and timely replacements of worn components can significantly enhance efficiency and reliability.

Conclusion: Understanding the intricacies of this tool enables users to harness its full potential, ensuring a productive and satisfying experience in outdoor maintenance.

Key Components of the Pole Saw

Understanding the essential elements of this cutting tool is crucial for effective operation and maintenance. Each part plays a significant role in ensuring optimal performance and longevity. By familiarizing yourself with these components, you can enhance your efficiency and achieve better results in your tasks.

Power System

The power system serves as the heart of the equipment, providing the necessary energy to drive the cutting mechanism. This can be a gasoline engine or an electric motor, each with its own advantages. A well-functioning power source ensures consistent performance and enables the tool to tackle various cutting challenges.

Cutting Mechanism

The cutting mechanism is designed to deliver precision and efficiency. It typically consists of a blade or chain that rotates at high speeds, allowing for clean cuts through branches and foliage. The design and sharpness of this component directly impact the tool’s effectiveness, making regular maintenance essential for optimal results.

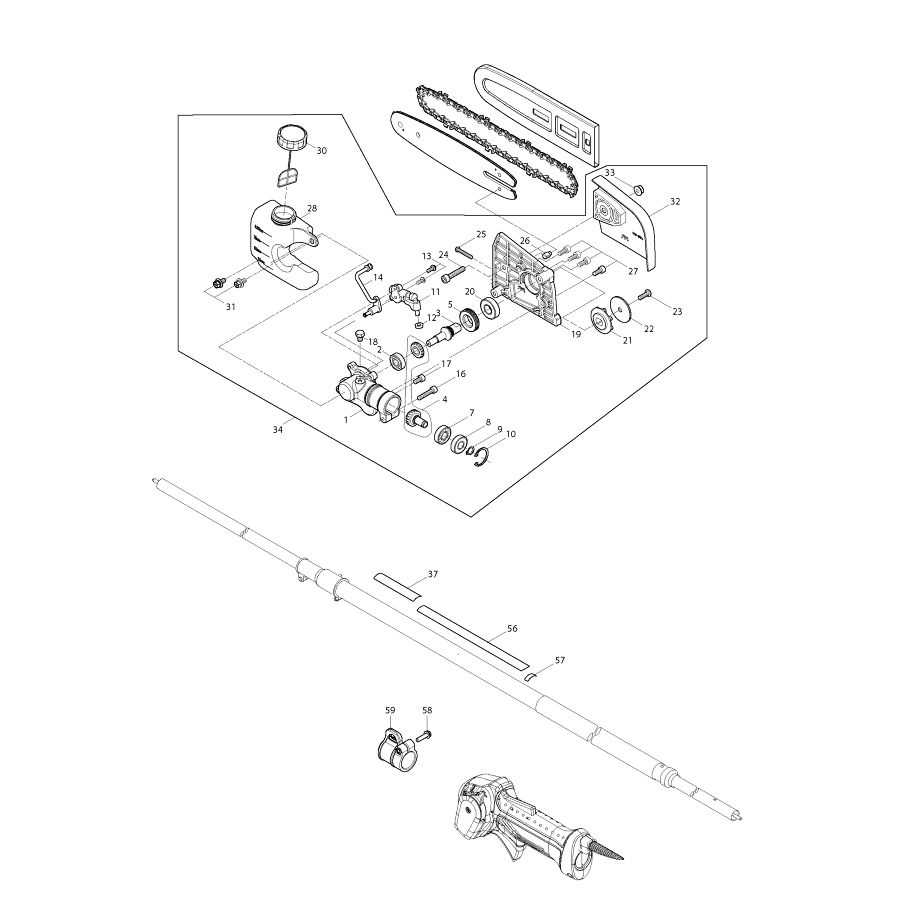

Importance of Parts Diagram

Understanding the configuration of components within machinery is crucial for effective maintenance and repair. A visual representation aids users in recognizing each element’s function, ensuring efficient troubleshooting and assembly.

Benefits of a Visual Guide

- Enhances clarity in identifying components.

- Facilitates accurate reassembly after repairs.

- Minimizes the risk of errors during maintenance.

Key Considerations

- Ensure the diagram is up-to-date with the latest model specifications.

- Utilize alongside a user manual for comprehensive guidance.

- Keep it accessible during repair sessions for quick reference.

How to Read the Diagram

Understanding the visual representation of components is crucial for effective maintenance and repairs. This guide will help you navigate the intricate details presented in the illustration, enabling you to identify each element with ease.

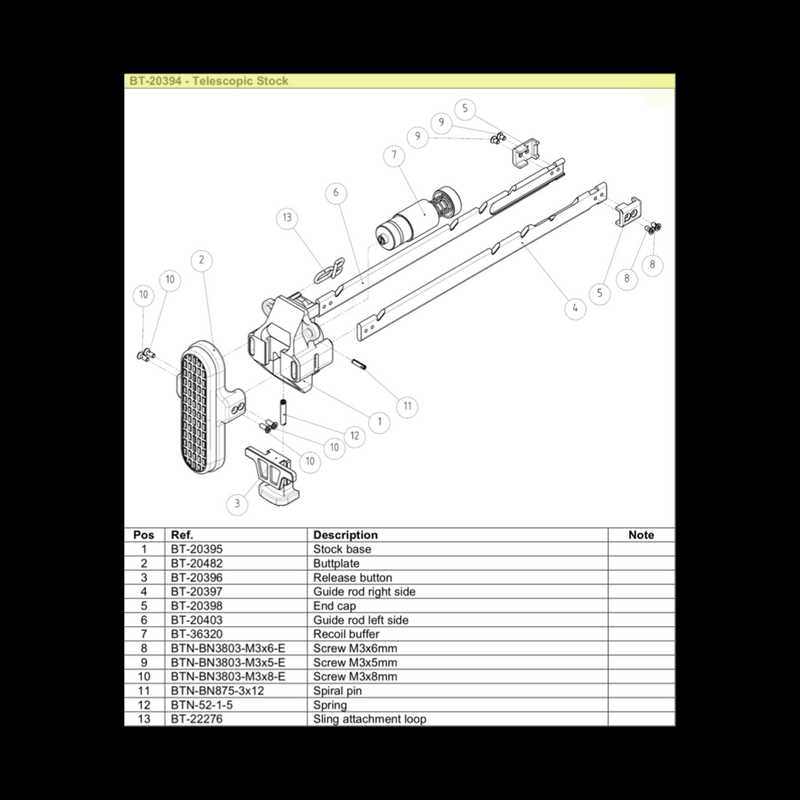

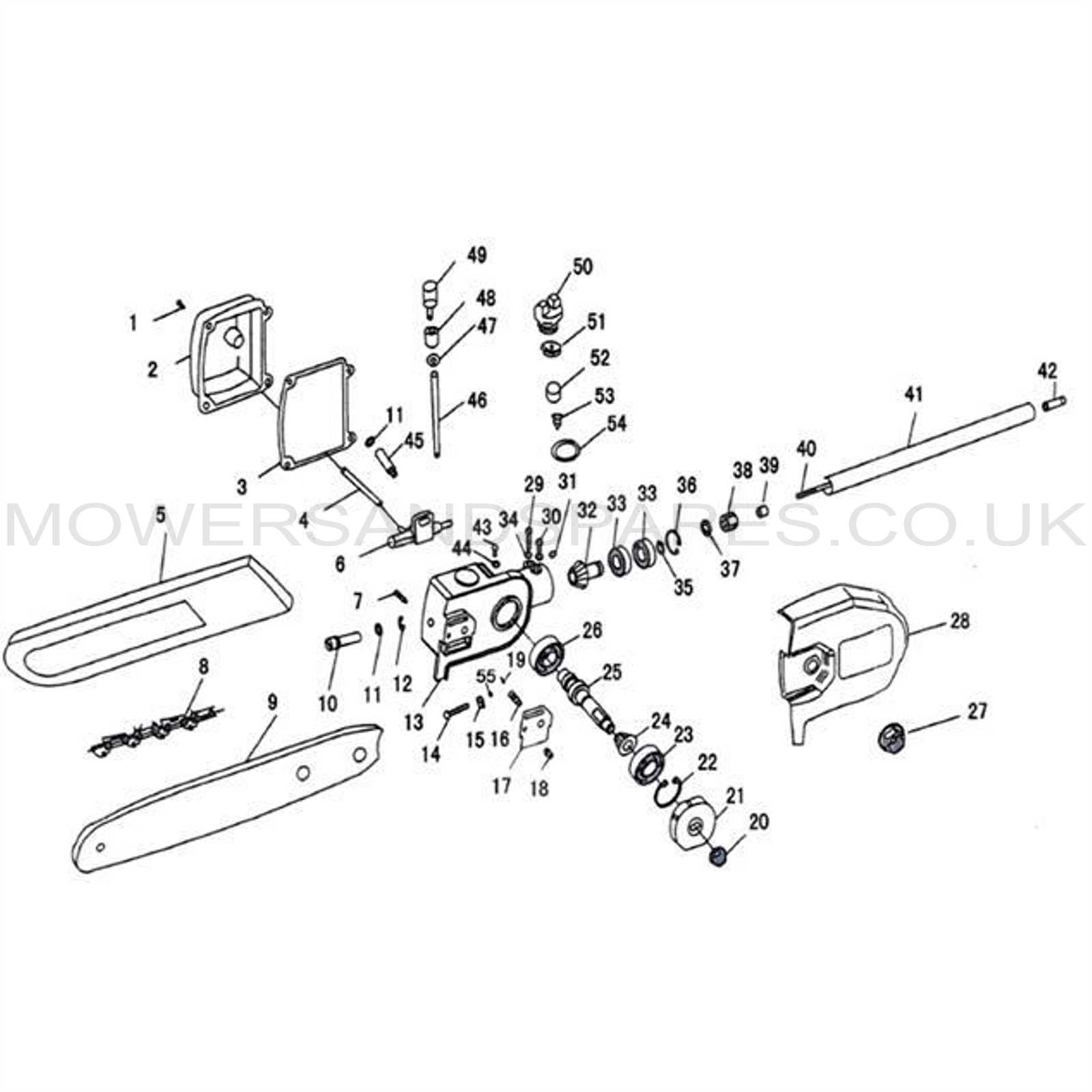

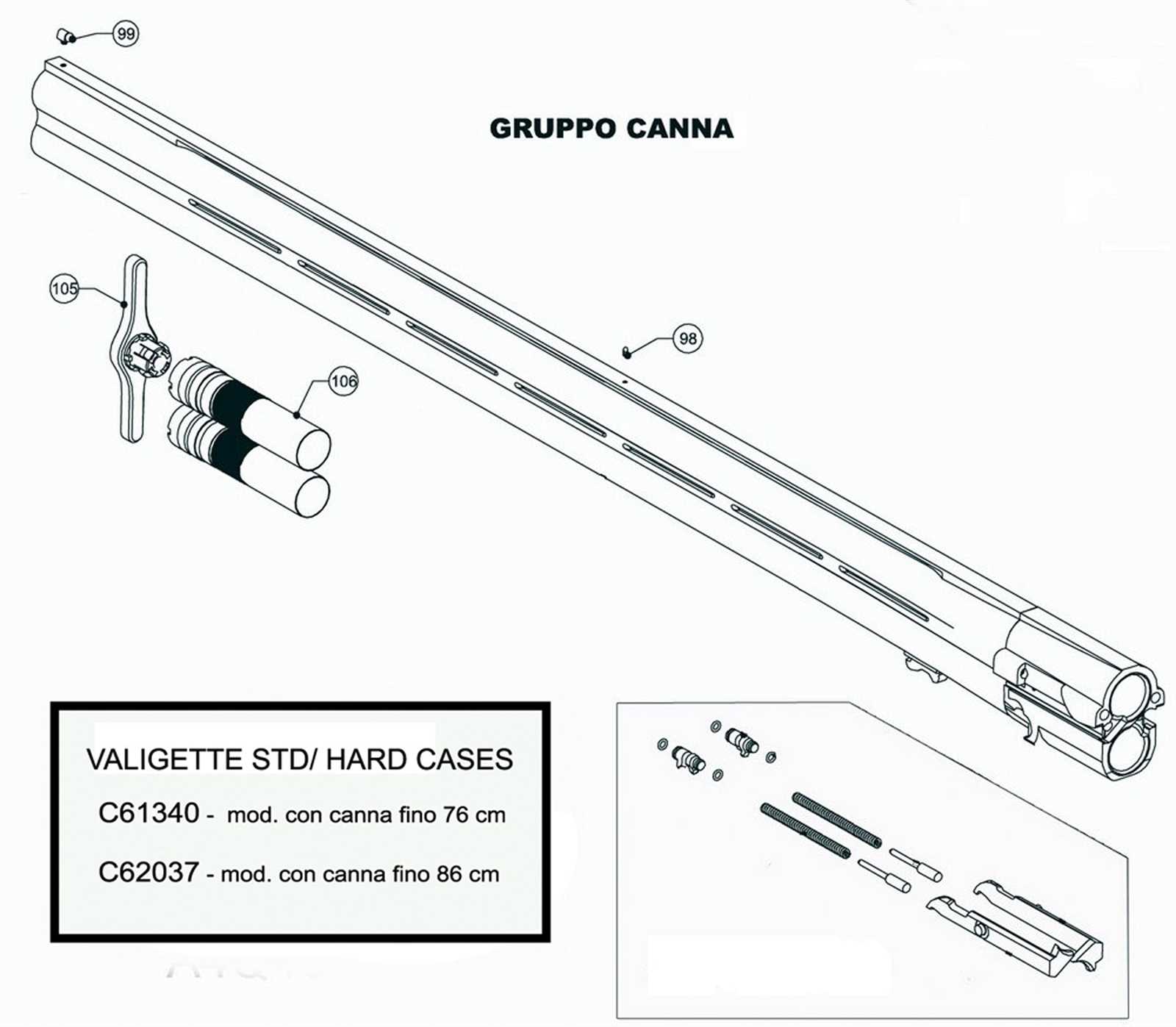

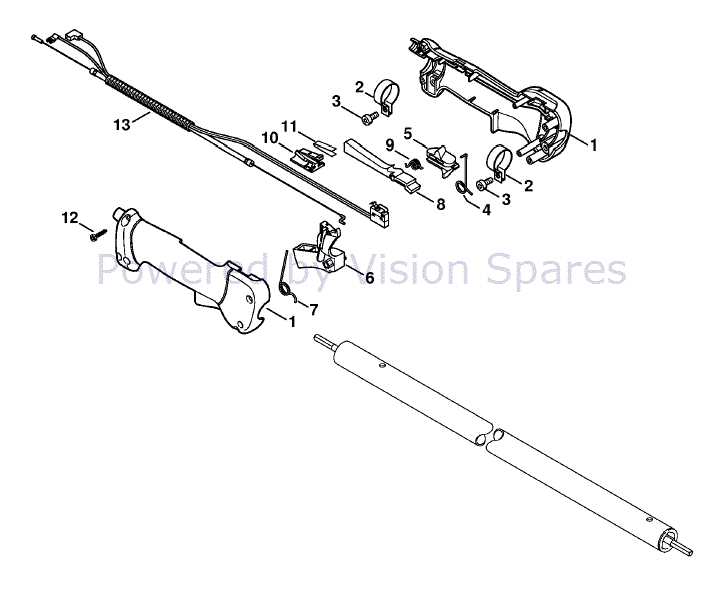

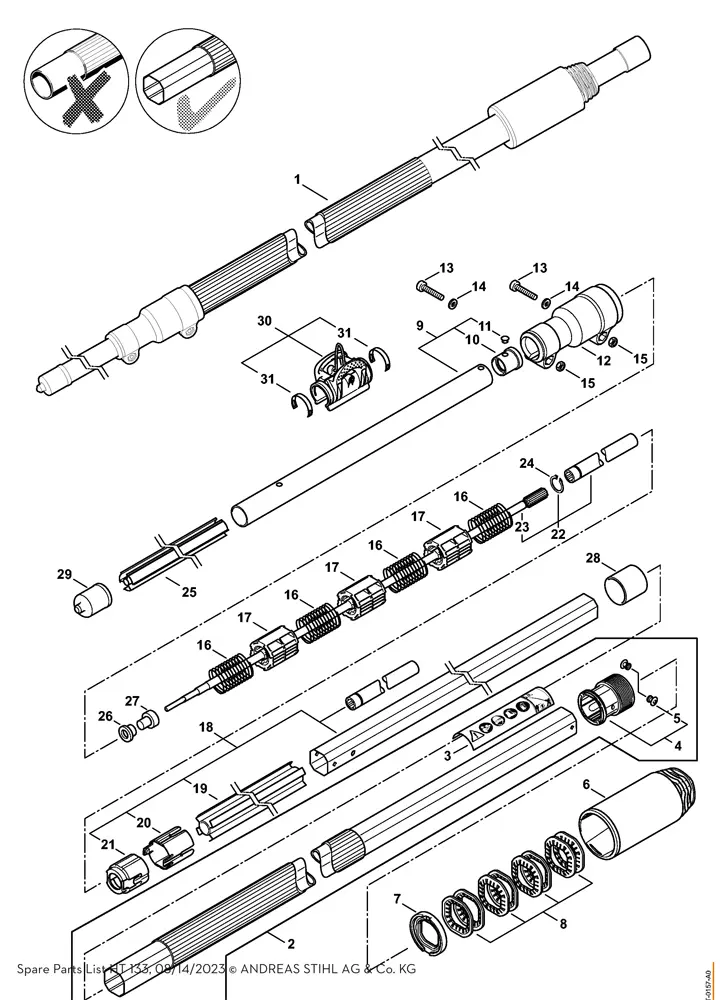

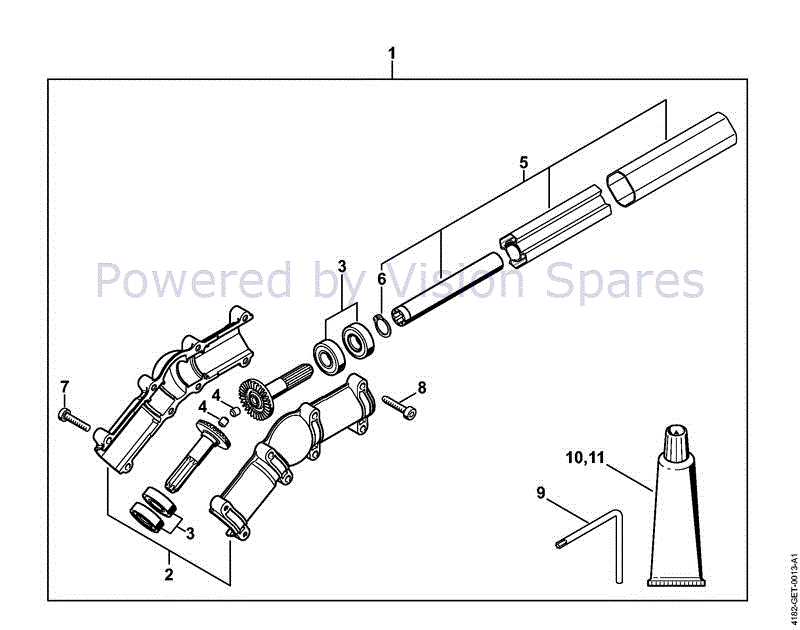

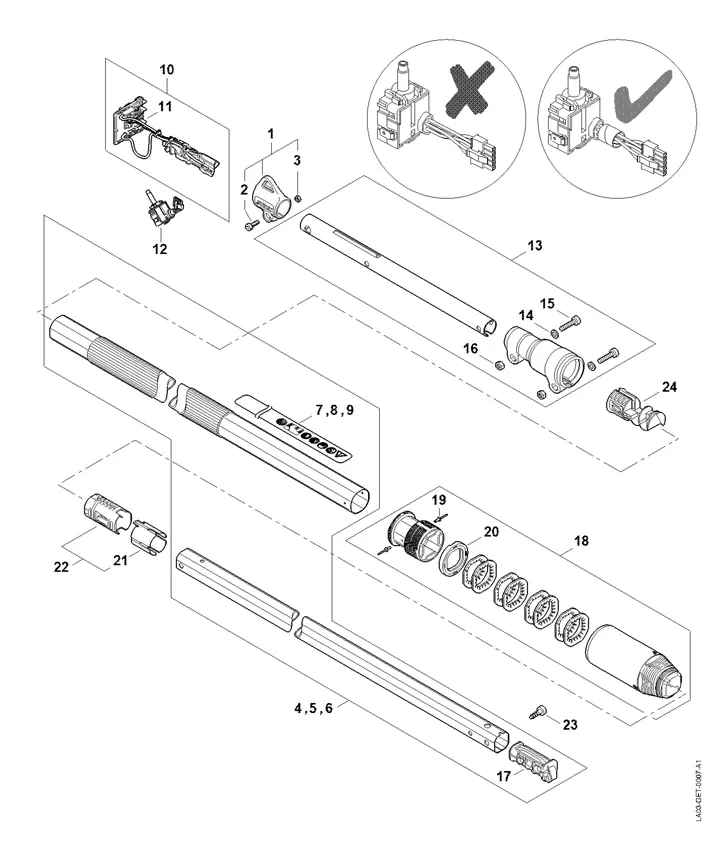

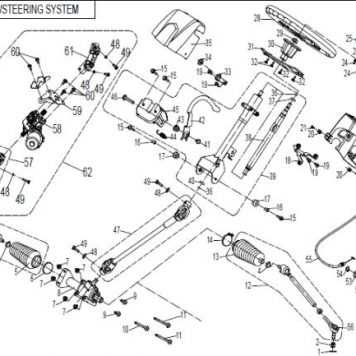

Identifying Components

Start by familiarizing yourself with the labels and symbols used throughout the illustration. Each part is usually marked with a unique identifier, which corresponds to a list of items. Pay attention to the various shapes and lines that connect different sections, as they indicate the relationships and assembly order.

Understanding Assembly

Next, focus on how each piece interacts within the overall structure. The arrangement can provide insights into the assembly process, helping you determine how to effectively disassemble or reassemble the unit. Consider taking notes or highlighting key areas for future reference.

Common Replacement Parts Explained

When it comes to maintaining outdoor power equipment, understanding the key components that may require replacement is essential. These elements play a vital role in ensuring optimal performance and longevity of the machine. Below, we outline some frequently needed components, detailing their functions and importance.

| Component | Function | Importance |

|---|---|---|

| Chain | Facilitates cutting by rotating around the guide bar. | Essential for efficient cutting and overall performance. |

| Guide Bar | Provides support and guides the chain during operation. | Critical for accurate and safe cutting. |

| Drive Sprocket | Engages with the chain to transfer power from the motor. | Vital for smooth operation and energy transfer. |

| Fuel Filter | Prevents debris from entering the fuel system. | Important for maintaining engine performance and longevity. |

| Air Filter | Traps dirt and debris before it enters the engine. | Crucial for ensuring clean airflow and efficient combustion. |

Regularly inspecting and replacing these essential components can greatly enhance the reliability and functionality of your equipment, allowing you to tackle outdoor tasks with confidence.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. Adopting a few best practices can significantly extend its lifespan and enhance performance, allowing for smoother operation and reducing the likelihood of unexpected failures.

Regular Cleaning

After each use, take the time to clean the machinery thoroughly. Remove debris, dust, and any residue that may accumulate during operation. This practice not only prevents corrosion but also ensures optimal functioning. Pay special attention to air filters and cooling vents, as these components are crucial for preventing overheating.

Routine Inspections

Conduct periodic checks on all vital components to identify wear and tear early. Look for cracks, loose fittings, or any signs of damage. Addressing these issues promptly can prevent more significant problems in the future and keep your device running smoothly. Regular lubrication of moving parts is also essential, as it minimizes friction and helps maintain efficiency.

Identifying Issues Through the Diagram

Understanding the intricacies of a machine’s structure is essential for effective troubleshooting. By analyzing a visual representation of its components, users can quickly pinpoint potential malfunctions and assess which elements may require attention.

- Familiarize yourself with each component’s function.

- Look for common wear indicators, such as discoloration or corrosion.

- Compare the layout with operational performance to identify discrepancies.

Utilizing this visual guide enhances the ability to recognize issues before they escalate, leading to more efficient maintenance and repairs.

- Inspect connections for looseness or damage.

- Examine moving parts for obstructions or irregularities.

- Assess the overall assembly for alignment problems.

By regularly referring to this schematic, users can ultimately ensure their equipment remains in optimal condition, ready for any task.

Where to Find OEM Parts

Locating original equipment manufacturer components is essential for maintaining the optimal performance of your equipment. These authentic pieces ensure compatibility and longevity, providing peace of mind that aftermarket alternatives may not offer.

Authorized Dealers

One of the most reliable sources for genuine components is through authorized dealers. These retailers are certified and provide a selection of original items, often backed by warranties and expert advice.

Online Marketplaces

Another convenient option is to explore online marketplaces that specialize in OEM items. Websites dedicated to specific brands often feature a comprehensive inventory, making it easy to find what you need. Always check for customer reviews and seller ratings to ensure quality.

Tools Needed for Assembly

Assembling outdoor equipment requires a selection of essential implements to ensure a smooth and efficient process. Having the right tools not only enhances accuracy but also minimizes the risk of damage to components.

Essential Tools

To begin, you will need a screwdriver set for securing fasteners, along with a wrench for tightening bolts. A pair of pliers can also be invaluable for gripping and manipulating smaller parts.

Additional Supplies

Consider including a measuring tape to ensure precision during assembly. Lastly, having lubricant on hand will aid in maintaining smooth operation once the assembly is complete.

Safety Precautions When Repairing

When undertaking maintenance or repairs on any equipment, it is crucial to prioritize safety to prevent injuries and ensure effective functioning. Adhering to specific guidelines can significantly reduce risks during the process.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure the equipment is turned off and disconnected from power sources before beginning any work.

- Keep your workspace clean and organized to avoid accidents.

- Be aware of your surroundings and avoid distractions while performing repairs.

Proper Handling Techniques

- Use tools designed for the specific task to ensure efficiency and safety.

- Handle all components carefully to avoid damaging them or causing injury.

- Follow manufacturer instructions and recommendations for disassembly and reassembly.

Upgrading Parts for Better Performance

Enhancing the efficiency of your equipment can significantly elevate its overall functionality. By focusing on specific components, you can achieve smoother operation, increased durability, and improved results in your tasks. Investing in high-quality alternatives or modern upgrades often yields the ultimate performance boost, making your work more enjoyable and effective.

Key Components to Consider

Several elements can be upgraded to enhance the performance of your device. Below are critical components that can make a noticeable difference:

| Component | Benefits |

|---|---|

| Engine | Increased power and efficiency |

| Bar | Improved cutting capacity and speed |

| Chain | Better grip and reduced friction |

| Handle | Enhanced comfort and control |

Choosing the Right Upgrades

When selecting upgrades, ensure compatibility with your equipment. Research reputable brands and consider user reviews to make informed choices. Delve into the specific features that meet your performance needs, ultimately leading to a superior experience in your work.