Escalator Parts Schematic Diagram

The intricate operation of vertical mobility devices involves numerous elements working in unison to ensure smooth and efficient transportation. These systems are designed to move people effortlessly between floors, with each component playing a crucial role in maintaining safety and performance.

To gain a deeper insight into how these systems function, it is important to explore the various elements that contribute to their overall mechanics. By examining each section individually, one can understand how these mechanisms interact to provide reliable and seamless movement in multi-story buildings.

Key mechanical and electrical elements, along with structural components, ensure not only movement but also security for passengers. Understanding these core elements gives a clearer perspective on how these devices are maintained and how they operate efficiently over time.

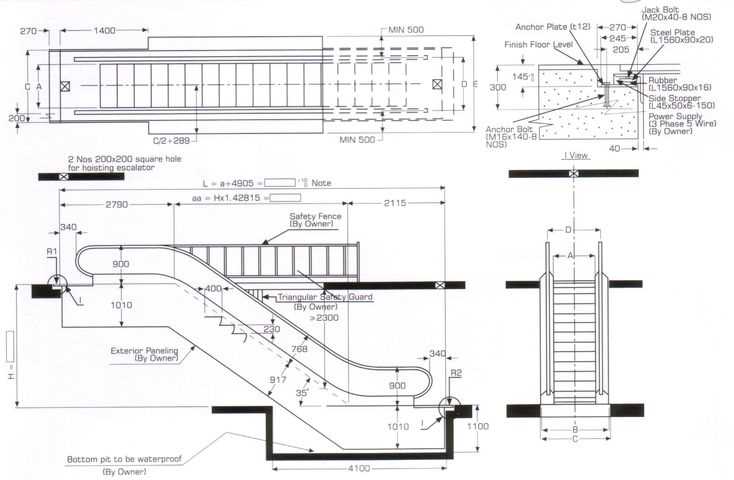

Schematic Diagram of Escalator Mechanisms

The inner workings of a moving staircase are comprised of several key systems working in unison to ensure smooth and safe operation. Each component plays a critical role in the movement and control of the entire structure. Understanding how these mechanisms interact provides a clearer picture of the system’s complexity.

- Step Chain System: This mechanism is responsible for the synchronized movement of the steps, pulling them in a continuous loop.

- Motor and Drive System: The primary force behind the motion, the motor ensures that the structure operates efficiently and maintains a consistent speed.

- Handrail Drive: A separate mechanism ensures that the handrail moves in tandem with the steps, providing users with a stable grip.

- Braking Mechanism: Essential for safety, this system

Main Components of an Escalator

Vertical transport systems rely on a combination of intricate elements that work together to ensure smooth and reliable movement. Understanding the key mechanisms behind these systems helps in maintaining efficiency and safety.

Key Mechanical Elements

Among the most crucial mechanical elements are the drive unit and the chain system. The drive unit powers the movement, while the chain mechanism links the steps, providing synchronized motion. These components are responsible for the seamless upward and downward travel.

Safety Mechanisms

Ensuring user safety is a top priority. Various safety devices are embedded within the system, including emergency brakes and safety sensors that detect any irregularities in operation. These devices halt the mechanism if any issues are detected, preventing accidents.

Component Function Electrical Control Systems Overview

Electrical control systems play a crucial role in the safe and efficient operation of various machinery. These systems are designed to manage the flow of electrical energy, ensuring that all components work together seamlessly. By coordinating functions such as power distribution, safety protocols, and automation, control systems enable complex mechanical devices to operate with precision and reliability.

Key Components of Control Systems

Control systems consist of several critical elements that monitor and regulate the flow of electricity. These include relays, contactors, and circuit breakers, each serving a distinct function in controlling power and safeguarding the equipment. Sensors also play a vital role in detecting changes in operational conditions, allowing the system to adjust performance as needed.

Automation and Safety Features

Modern electrical systems incorporate advanced automation technologies, allowing for smoother and more responsive operations. Programmable logic controllers (PLCs) are commonly used to handle automated tasks, optimizing per

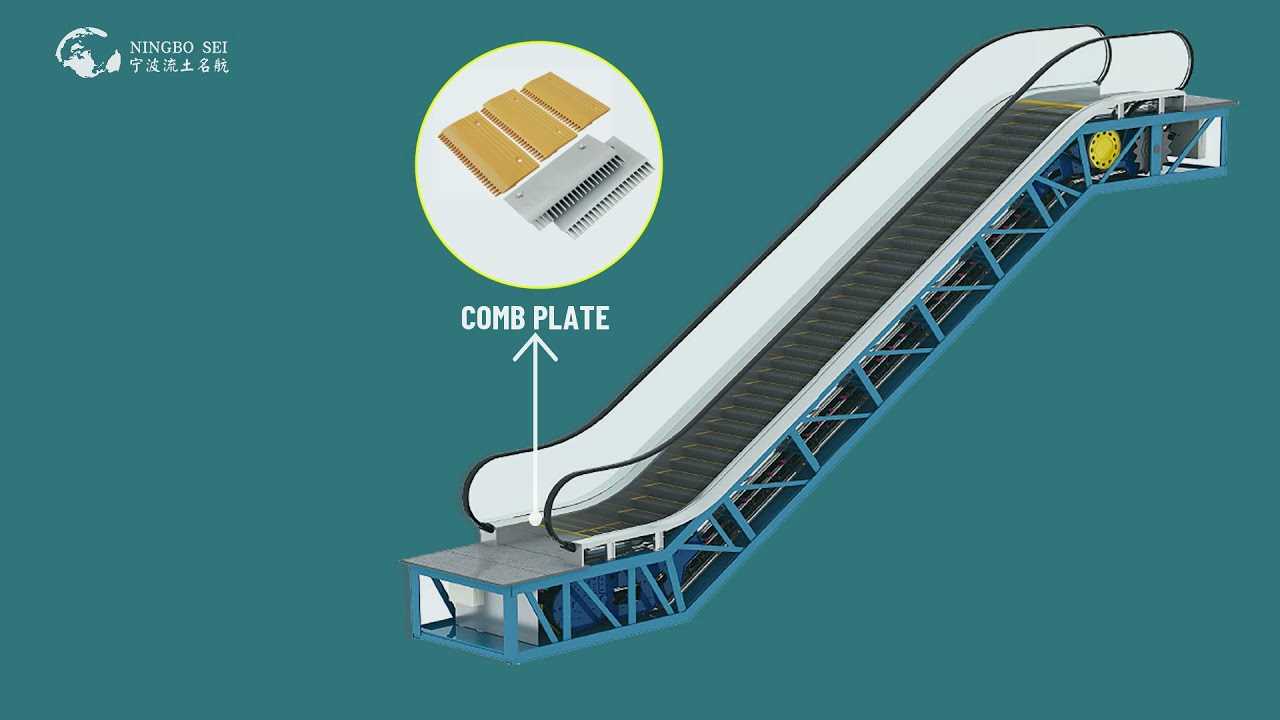

Steps and Treads Structure

The design of the moving platform involves carefully engineered components that ensure smooth and safe operation. These elements are designed to provide durability and stability, accommodating continuous movement while supporting the weight of passengers. The surface pattern and materials used contribute to traction and safety, reducing the risk of slips or falls during usage.

Each individual platform is interconnected, forming a continuous sequence that adjusts in height and position as it moves along the guide tracks. This structural arrangement allows the steps to transition seamlessly, providing a comfortable experience for users. The precision in the assembly and alignment of these elements ensures efficient operation over extended periods of time.

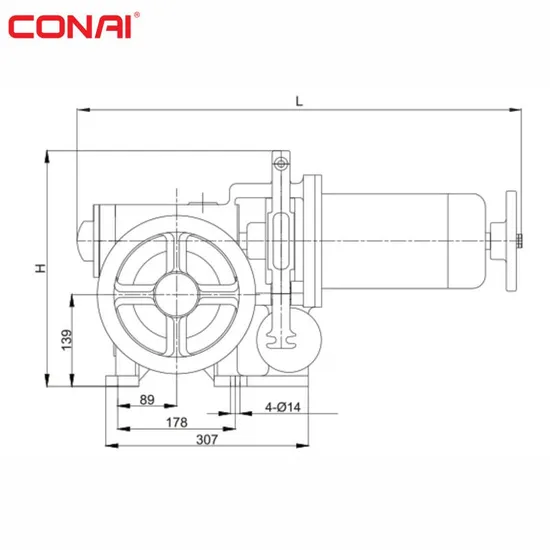

Drive Unit and Motor Function

The drive system and motor serve as the primary components responsible for ensuring smooth and efficient movement. These mechanisms work in harmony, converting energy into motion, thus powering the entire structure. Their precise operation is essential for maintaining reliable and safe functionality.

Power Transmission: The motor is at the heart of the operation, transforming electrical energy into mechanical motion. This power is then transferred through a series of gears and components, providing the necessary force to propel the system forward.

Control Mechanisms: The drive unit is equipped with multiple control features that regulate speed, ensure consistent movement, and adjust to varying loads. These adjustments are crucial for maintaining both performance and user safety.

Energy Efficiency: Modern motor systems are designed with energy efficiency in mind, optimizing power use and minimizing waste. This ensures a balance between operational efficiency and environmental responsibility.

Handrail Design and Movement

The design and functionality of the safety rail are essential for ensuring user comfort and security. This element not only enhances the aesthetic appeal of the system but also plays a crucial role in guiding individuals during their ascent or descent. Understanding the intricacies of this component can significantly impact overall user experience.

Key Features of Handrail Design

- Ergonomics: The handrail should be shaped to fit comfortably in the hand, promoting a natural grip.

- Height: Optimal height is vital to accommodate users of varying heights, ensuring accessibility for everyone.

- Material: Durable materials, such as stainless steel or reinforced plastics, are preferred for longevity and safety.

- Finish: A non-slip surface treatment can enhance grip and prevent accidents in various environmental conditions.

Movement Mechanism

The movement of the safety rail is synchronized with the main system’s operation, ensuring seamless transitions. This mechanism often employs advanced engineering techniques to maintain alignment and stability. Key aspects include:

- Continuous Motion: The rail moves consistently alongside the user, providing a stable support throughout the journey.

- Adjustable Tension: Mechanisms that allow for tension adjustment ensure the rail remains securely in place during operation.

- Sensor Integration: Modern designs may incorporate sensors to detect user presence, enhancing safety by preventing unexpected stops or jerks.

Overall, a well-designed safety rail significantly contributes to user confidence and safety, making it an indispensable feature in vertical transportation systems.

Safety Features in Escalator Systems

In modern transport systems, various mechanisms are designed to ensure user protection and operational reliability. These safety measures are crucial for preventing accidents and maintaining a secure environment for all users.

Key Safety Mechanisms

- Emergency Stop Buttons: Easily accessible controls allow users to halt operation instantly in case of an emergency.

- Automatic Shutdown: Systems are equipped with sensors that trigger a shutdown if a malfunction is detected.

- Handrails: Moving handrails provide support and stability, minimizing the risk of falls.

- Anti-Slip Surfaces: Steps are designed with textured surfaces to enhance grip and prevent slipping.

- Safety Edges: Equipped with sensors to detect obstructions, these edges stop movement to avoid trapping hazards.

Regular Maintenance and Inspections

Consistent upkeep and thorough inspections are vital to ensure all safety features function correctly. Routine checks help identify wear and tear, allowing for timely repairs and adjustments.

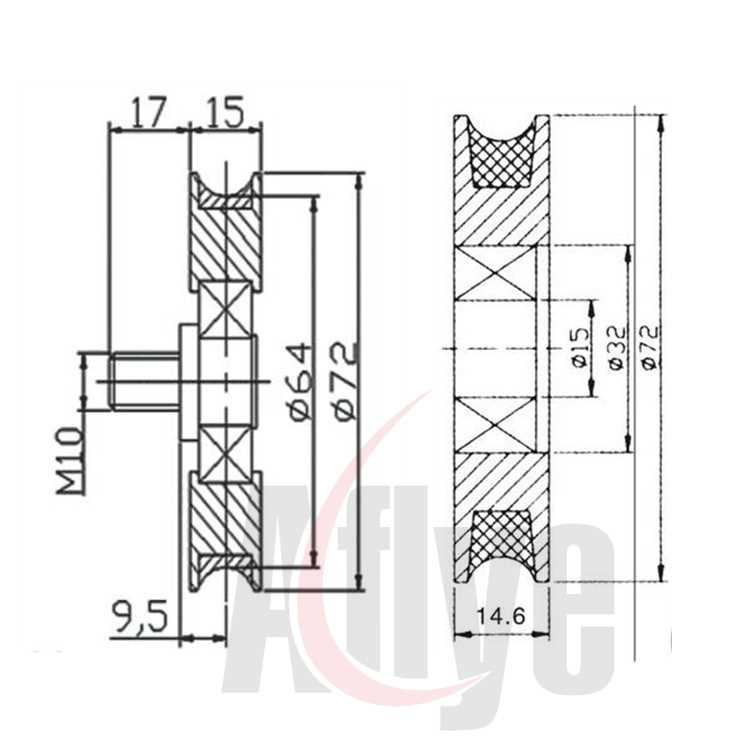

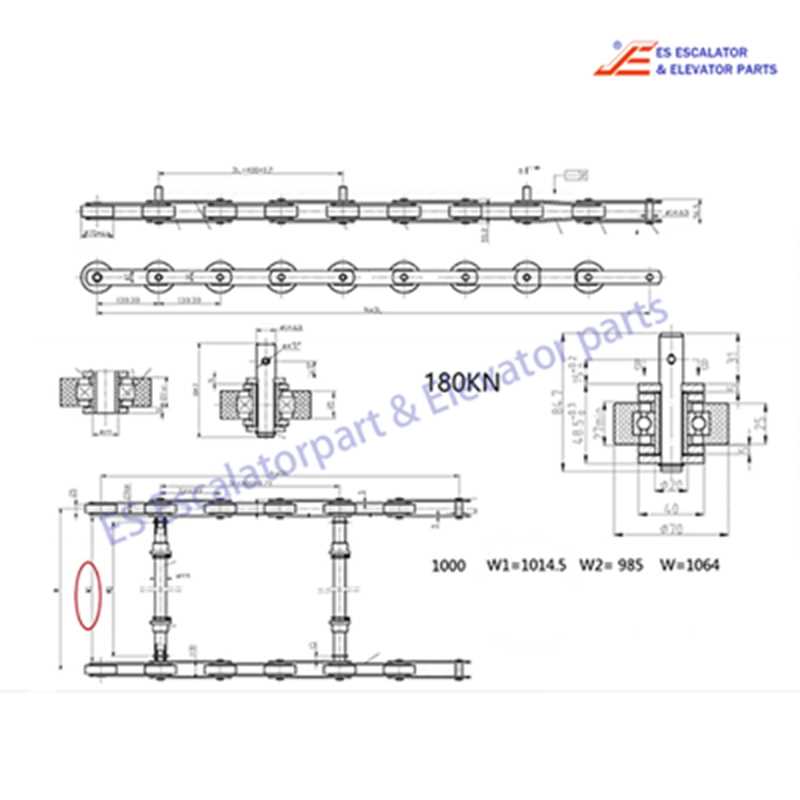

Chain and Track Configuration

This section delves into the essential arrangement of chains and tracks, which plays a pivotal role in the functioning of vertical transportation systems. A well-designed configuration ensures smooth operation and reliability, contributing significantly to the overall efficiency and safety of the mechanism.

Key Components

The primary elements involved in this setup include:

- Chain: A series of interconnected links that transfer motion.

- Track: The guiding path that supports and directs the movement of the chain.

- Drive Mechanism: The component that initiates and controls the movement of the chain along the track.

Configuration Considerations

Several factors must be considered to achieve optimal functionality:

- Alignment: Proper alignment of the chain and track is crucial to prevent wear and ensure smooth movement.

- Material Selection: Choosing durable materials helps enhance longevity and withstand operational stresses.

- Maintenance: Regular checks and adjustments are essential to maintain efficiency and prevent malfunctions.

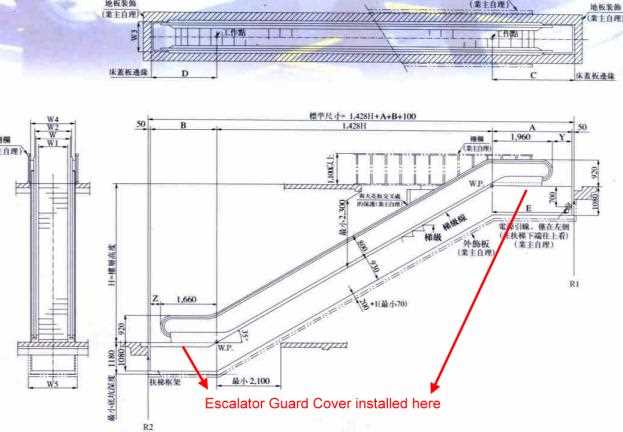

Landing Plates and Structural Supports

Landing plates and structural supports play a crucial role in ensuring the stability and functionality of vertical transportation systems. These components are designed to provide a secure interface for passengers while maintaining the overall structural integrity of the system.

Landing plates serve as the transition points where users embark and disembark. Their design is essential for safety, as they need to accommodate various foot sizes and provide a slip-resistant surface. Additionally, the materials used must withstand regular wear and tear while maintaining their aesthetic appeal.

Structural supports are vital for the framework that holds these landing plates in place. They are engineered to bear the load of both the system and its passengers, ensuring that everything operates smoothly and safely. The configuration of these supports must be carefully considered to prevent any potential failures and to enhance the overall durability of the installation.

In summary, the integration of landing plates and structural supports is fundamental for providing a reliable and safe experience in vertical transportation systems. Their thoughtful design and robust construction contribute to the system’s efficiency and longevity.

Escalator Braking System Explained

The braking mechanism in moving walkways is a critical component designed to ensure safety and reliability during operation. This system plays a vital role in controlling the speed and stopping the equipment effectively, providing users with a secure means of transportation. Understanding the function and design of this system is essential for both operators and maintenance personnel to enhance safety protocols and ensure efficient operation.

Types of Braking Systems

There are primarily two types of braking mechanisms utilized in moving walkways: electromagnetic and mechanical. Electromagnetic brakes rely on electric currents to generate a magnetic field, which effectively halts the movement when required. In contrast, mechanical brakes employ friction to create resistance against the motion, leading to a gradual and controlled stop. Each type has its advantages, making them suitable for different applications and safety standards.

Importance of Maintenance

Regular inspection and maintenance of the braking system are crucial for optimal performance. Over time, components may wear down, leading to reduced efficiency and potential safety hazards. Implementing a routine maintenance schedule helps identify issues before they escalate, ensuring that the mechanism functions correctly and safeguarding users from accidents.

Balustrade and Panel Design

The design of the balustrade and panels plays a crucial role in enhancing the aesthetic appeal and functionality of vertical transportation systems. These elements not only provide safety and support but also contribute to the overall visual identity of the structure. The choice of materials, colors, and shapes can significantly influence the perception of space, making it essential to consider various design aspects.

Material Selection

Choosing appropriate materials is vital for durability and aesthetics. Common options include stainless steel, glass, and wood, each offering unique benefits. Stainless steel is known for its strength and modern appearance, while glass provides a sleek, unobtrusive look that allows light to flow freely. Wood, on the other hand, adds warmth and a natural element, making it suitable for environments where a cozy atmosphere is desired.

Design Elements

The incorporation of various design elements, such as decorative patterns, lighting, and handrail configurations, can elevate the overall experience. Integrating lighting into the balustrade can enhance safety and create an inviting ambiance. Additionally, unique patterns can add character, allowing for personalization that reflects the environment’s theme. Balancing these elements ensures that the design is both functional and visually appealing.

Escalator Gearbox and Power Transfer

The gearbox plays a crucial role in the operation of inclined moving walkways, facilitating the transfer of energy from the motor to the moving platform. This mechanism ensures a smooth and efficient performance, which is vital for the overall functionality and safety of the system.

Functionality of the Gearbox

The primary purpose of the gearbox is to alter the speed and torque generated by the motor. This adjustment allows for optimal operation under varying loads and conditions. Key aspects of the gearbox include:

- Reduction of motor speed to suitable levels

- Increase in torque to handle the weight of users

- Ensuring precise synchronization of the moving steps

Power Transfer Mechanism

Power transfer within this system is achieved through a series of interconnected components. These elements work together to maintain a consistent flow of energy, ensuring that the moving platform operates smoothly. The main components involved in power transfer are:

- Motor: Provides the initial energy required for movement.

- Gearbox: Modifies the motor’s output to meet operational needs.

- Chain or belt system: Transfers power from the gearbox to the moving elements.

- Drive rollers: Assist in the movement of the steps or plates.

Understanding the intricacies of the gearbox and power transfer enhances the ability to maintain and troubleshoot inclined walkways, ensuring they remain a safe and reliable mode of transportation.

Lubrication Systems and Maintenance

Effective maintenance of moving components is crucial for ensuring longevity and smooth operation. A well-designed lubrication approach plays a vital role in minimizing friction, reducing wear, and preventing overheating. This section delves into the various methods and practices employed to keep these mechanisms in optimal condition.

Regular upkeep is essential to maintain the efficiency and functionality of mechanical systems. Here are some key aspects to consider:

- Types of Lubricants: Various lubricants can be utilized, including oils, greases, and solid lubricants. Each type serves specific functions and is suited for different conditions.

- Application Methods: Lubrication can be applied manually or through automated systems. Automated systems enhance consistency and efficiency, reducing human error.

- Frequency of Maintenance: Establishing a regular maintenance schedule is vital. Frequent checks and timely application of lubricants can significantly prolong the lifespan of moving elements.

Moreover, monitoring the condition of lubricants is equally important. Contaminated or degraded lubricants can lead to reduced performance and increased wear. Implementing a system for tracking lubricant quality helps in timely replacements and maintenance actions.

In conclusion, adopting a systematic approach to lubrication and maintenance not only ensures smooth operation but also enhances the durability of mechanical systems. A proactive maintenance strategy is key to achieving optimal performance and reliability.