Toro Titan ZX5400 Parts Breakdown for Efficient Maintenance

Understanding the intricate layout and key elements of equipment is crucial for maintaining its functionality and ensuring long-term efficiency. By closely examining each component, one can uncover the vital role every part plays in the overall operation, making it easier to troubleshoot issues or perform necessary repairs. This knowledge becomes indispensable when dealing with complex systems.

Every mechanical system consists of interconnected elements working in harmony. A clear understanding of how these pieces fit together and function as a whole allows for better performance optimization and upkeep. Knowing the positioning and purpose of specific elements can make all the difference when it comes to efficient maintenance.

Whether you’re looking to enhance performance or simply ensure reliable operation, gaining

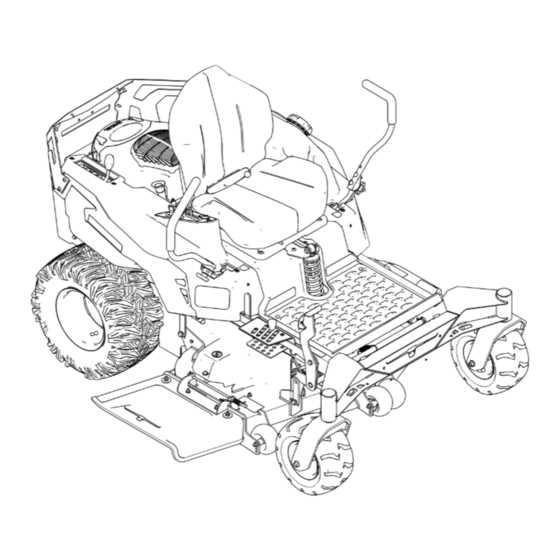

Toro Titan ZX5400: Comprehensive Parts Breakdown

The breakdown of this advanced zero-turn model reveals an intricate assembly of essential components designed to deliver optimal performance and longevity. Each section plays a critical role in ensuring smooth operation, from the power system to the smaller mechanical elements. Understanding these elements is key to maintaining the machine and preventing potential malfunctions.

Key Components Overview

This equipment integrates various systems that work together to provide efficiency and control. Below is a detailed summary of some of the most important segments, illustrating their interrelation and specific functions within the overall design.

| Component | Function | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Assembly | Provides the power needed to drive and maneuver effectively

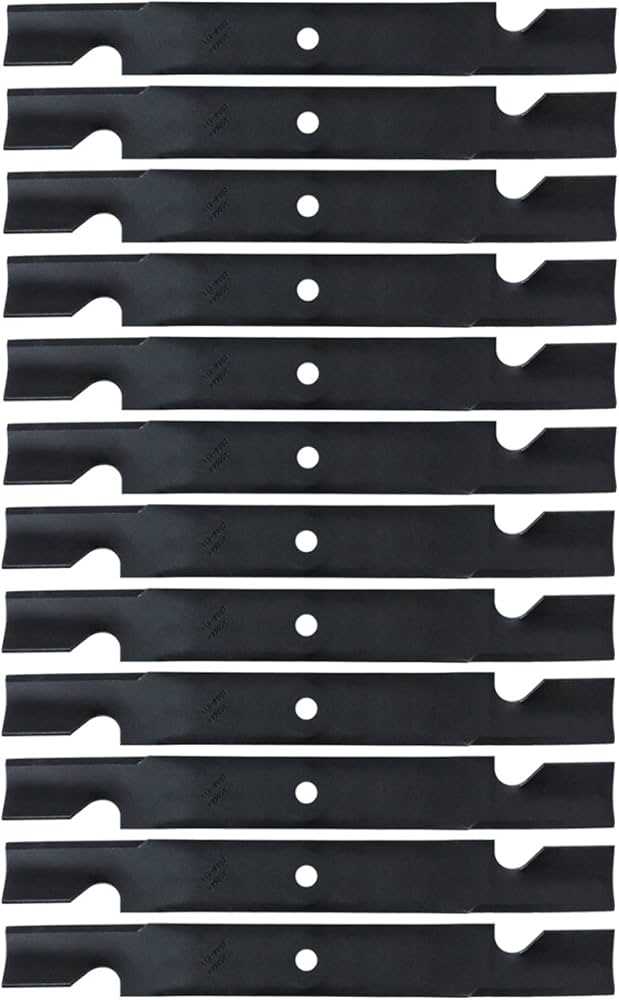

Engine Components Overview and FunctionUnderstanding the various elements that make up a motor and how they work together is essential for maintaining and repairing it. Each part plays a crucial role in the overall performance, contributing to the system’s reliability, power, and efficiency. Proper knowledge of these components can aid in diagnosing issues and optimizing performance for smoother operation. Main Structural ElementsThe primary structural components include several key elements responsible for ensuring the stability and functionality of the motor. These include the block, where most major processes take place, and the cylinder, which houses the combustion process that drives the system. Additionally, the head is mounted on top, closing the chamber and holding the necessary parts for controlling the air-fuel mixture and exhaust. Moving Parts and Their RoleSeveral moving parts work together to transfer energy and power. The Understanding the Mower Deck AssemblyThe mower deck plays a critical role in ensuring efficient and consistent grass cutting. Its design and construction include several key components that work in unison to achieve a smooth and even cut. Understanding how these elements fit together and function helps in maintaining the overall performance and prolonging the lifespan of the equipment. Main Components of the AssemblySeveral essential parts form the foundation of the deck structure, each contributing to its operation. These include the cutting blades, spindles, pulleys, and belt system, which all play vital roles in the mowing process. Proper alignment and maintenance of these parts ensure that the deck operates at peak efficiency. Blade and Spindle ConfigurationThe cutting blades are attached to the spindles, which are responsible for their rotation. The spindle assembly Exploring the Transmission System Structure

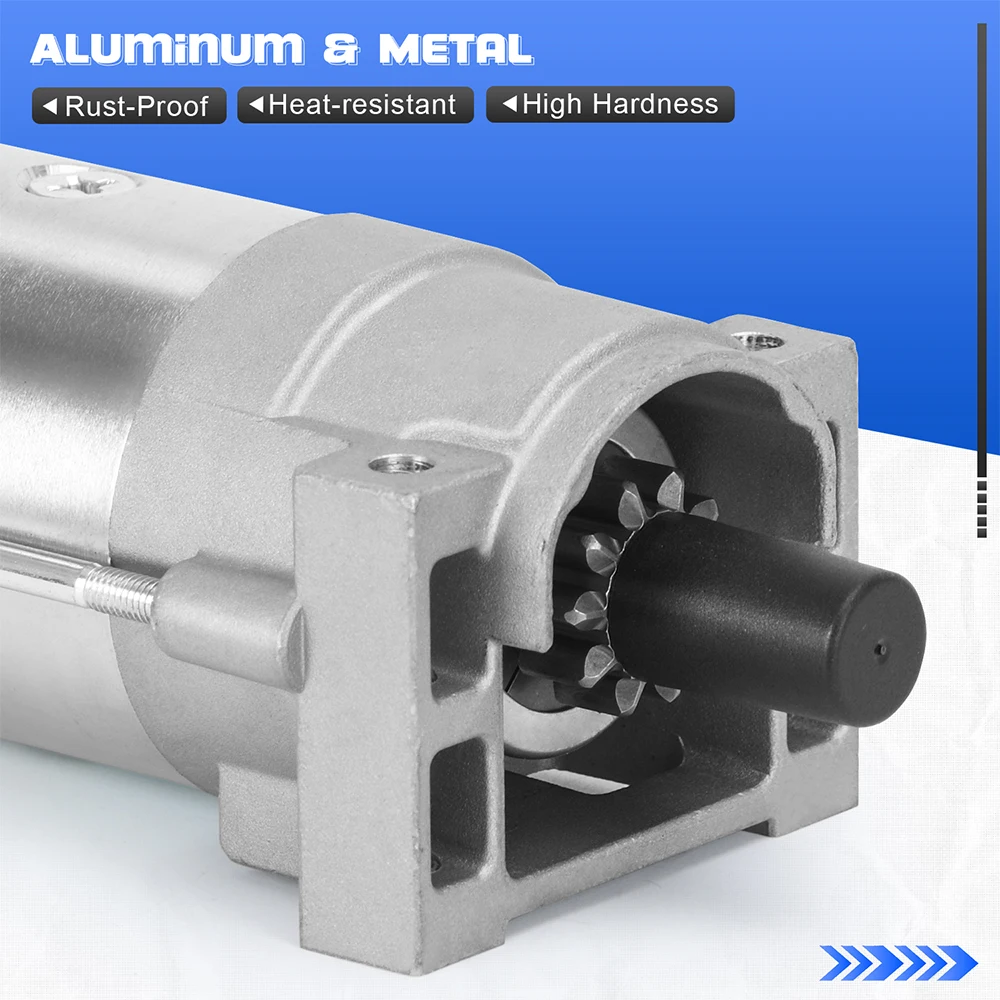

The transmission system is a crucial component that ensures smooth and efficient movement. By distributing power from the engine to the wheels, it enables proper functionality and control of the entire mechanism. Understanding the design and structure of this system is key to maintaining performance and longevity. The system is composed of multiple interconnected elements, each playing a vital role in transferring mechanical power. Key components include drive shafts, gear assemblies, and linkages, all of which contribute to the overall stability and precision of the machinery. Analyzing these elements provides insights into how power is seamlessly managed. Additionally, the layout and alignment of these components are engineered to optimize power flow and reduce wear. Seat Adjustment Mechanism: Key Elements

The seating configuration is an essential aspect of ensuring both comfort and control during operation. A well-designed system allows for seamless modifications to suit different needs, enhancing the overall experience and ergonomics for the user. Primary Components

Guide to the Blade Spindle AssemblyThe blade spindle assembly is a critical component of many mowing machines, designed to facilitate the rotation of the cutting blades. Understanding its construction and function is essential for proper maintenance and effective operation. This assembly is integral in ensuring that the blades perform optimally, providing a clean and precise cut while reducing wear and tear on other machine parts. Components of the Blade Spindle AssemblyThis assembly typically consists of several key elements, each contributing to its overall functionality:

Maintenance Tips for the Blade Spindle AssemblyRegular maintenance of the blade spindle assembly is crucial for ensuring longevity and performance. It is advisable to check the bearings for wear, lubricate the spindle housing, and inspect the blade mounting plate for any signs of damage. Keeping these components in good condition will help maintain cutting efficiency and prevent costly repairs in the future. Analyzing the Steering Control PartsUnderstanding the components that facilitate directional control is crucial for maintaining optimal performance in various machines. The steering mechanism is designed to provide precision and responsiveness, ensuring that operators can navigate their equipment with ease. In this section, we will explore the essential elements involved in steering control, examining their functions and importance in the overall system. Key Elements of Steering MechanismAt the heart of the steering control system lies a combination of interconnected parts that work in unison. Each component plays a significant role in achieving smooth and accurate movements. Below is a breakdown of the primary elements associated with steering control:

Importance of MaintenanceRegular maintenance of these components is essential to ensure longevity and reliability. By monitoring wear and tear, operators can prevent malfunctions that may lead to compromised steering performance. Timely inspections and replacements contribute significantly to the efficiency of the steering control system, enhancing overall functionality. Fuel System Components and MaintenanceThe effective operation of any machine relies heavily on its fuel delivery mechanisms. Understanding the essential elements that comprise this system is crucial for ensuring optimal performance. Proper upkeep of these components not only enhances efficiency but also prolongs the lifespan of the equipment. Key Elements of the Fuel Delivery SystemThe fuel delivery system typically includes several critical components, such as the fuel tank, pump, filter, and injectors. Each part plays a significant role in transporting fuel from the tank to the engine. The fuel tank stores the fuel, while the pump is responsible for moving it through the system. A filter is essential for trapping impurities that could cause damage to the engine, and the injectors precisely dispense the fuel for combustion. Maintenance Tips for Optimal Performance

Regular maintenance of the fuel system is vital for preventing issues that can affect performance. Periodically checking and replacing the fuel filter can prevent blockages that impede flow. Additionally, inspecting the fuel lines for leaks and ensuring that the pump operates efficiently can help maintain a steady supply of fuel. Keeping the fuel tank clean and free from contaminants also contributes to the overall health of the system. Wheel Assembly Breakdown and PartsThe wheel assembly is a crucial component of any outdoor equipment, playing a vital role in mobility and stability. Understanding its structure and the various elements that contribute to its functionality can enhance maintenance and repair efforts. This section delves into the intricate components that make up the wheel assembly, offering insights into their specific functions and importance. At the heart of the assembly lies the wheel hub, which serves as the central unit allowing for rotation. Attached to the hub are the bearings, which reduce friction and facilitate smooth movement. The rim encircles the tire, providing the necessary support and structural integrity. Each of these elements is essential for ensuring optimal performance and longevity of the equipment. Additionally, the spindle connects the wheel to the frame, allowing for pivotal movement during operation. The tire, made from durable materials, ensures traction and grip on various terrains. Understanding how these components work together can aid in troubleshooting issues and performing effective repairs when necessary. Electrical System: Key Components and ConnectionsThe electrical framework of machinery plays a crucial role in ensuring efficient operation and reliable performance. This section delves into the fundamental elements that constitute the electrical setup, highlighting their functions and interconnections. Understanding these components is essential for maintenance and troubleshooting, enabling users to optimize the machinery’s performance. Main ComponentsAt the core of the electrical system are several critical parts, including the battery, starter, and ignition system. The battery serves as the primary energy source, providing the necessary power to initiate operations. The starter is responsible for turning the engine over, while the ignition system ensures proper combustion within the engine cylinders. Together, these elements create a reliable and efficient energy flow. Connections and WiringProper connections and wiring are vital for the seamless operation of the electrical network. High-quality wiring harnesses facilitate the transfer of electrical signals between components, reducing the risk of faults. Additionally, connectors play a significant role in maintaining secure connections, ensuring that power is delivered where needed. Regular inspection and maintenance of these connections can prevent potential issues and enhance overall system reliability. Hydraulic System Parts and Their RolesThe hydraulic system plays a crucial role in enhancing the efficiency and functionality of various machinery by utilizing pressurized fluid to transmit power. Understanding the components involved in this system is essential for maintaining optimal performance and ensuring reliable operation. Each element within the hydraulic framework contributes significantly to the overall effectiveness of the mechanism. Key Components of the Hydraulic SystemFunctions of Hydraulic Components

Maintenance Guide for Toro Titan ZX5400 PartsRegular upkeep of your machinery is essential to ensure optimal performance and longevity. This section provides insights into maintaining the critical components of your equipment, helping to prevent potential issues and extend its operational lifespan. Routine Checks and Procedures

Implementing a consistent maintenance routine can significantly reduce the risk of malfunctions. Start with regular inspections of the engine and its vital systems. Look for signs of wear and tear, such as leaks or unusual noises. Additionally, ensure that filters are clean and replaced as necessary to keep the engine running smoothly. Lubrication and CleaningProper lubrication is crucial for reducing friction between moving parts, enhancing their performance. Use the recommended lubricants and apply them according to the manufacturer’s guidelines. Furthermore, regular cleaning of the equipment will prevent the buildup of dirt and debris, which can lead to overheating and other complications. By following these maintenance practices, you can ensure that your machinery operates efficiently and remains in top condition for years to come. |