Understanding the Yamaha 115 Parts Diagram for Easy Maintenance

When it comes to the maintenance and repair of marine engines, having a clear understanding of the various elements that make up the system is crucial. A visual representation that outlines the arrangement and function of each component can significantly enhance a technician’s ability to diagnose issues effectively. This resource serves as a guide to navigating the intricate web of engine parts, facilitating both routine upkeep and complex repairs.

Detailed illustrations offer invaluable insights into the configuration of components, allowing for easier identification and understanding of their roles within the overall mechanism. Whether you’re a seasoned professional or a novice enthusiast, grasping these layouts can empower you to take on repairs with confidence. By demystifying the relationships between various elements, you can streamline the repair process and ensure optimal performance.

Furthermore, familiarity with these schematics promotes better decision-making when sourcing replacement components. With a comprehensive understanding of how each part interacts with the others, you can avoid unnecessary complications and enhance the longevity of your equipment. Ultimately, mastering these visual aids will transform your approach to engine maintenance, making it more efficient and effective.

Understanding Yamaha 115 Components

Grasping the intricacies of a marine engine is crucial for optimal performance and maintenance. This section delves into the essential elements that constitute a typical outboard motor, highlighting their functions and significance. A clear comprehension of these components can greatly enhance the overall boating experience.

- Powerhead: The powerhouse of the engine, responsible for generating propulsion.

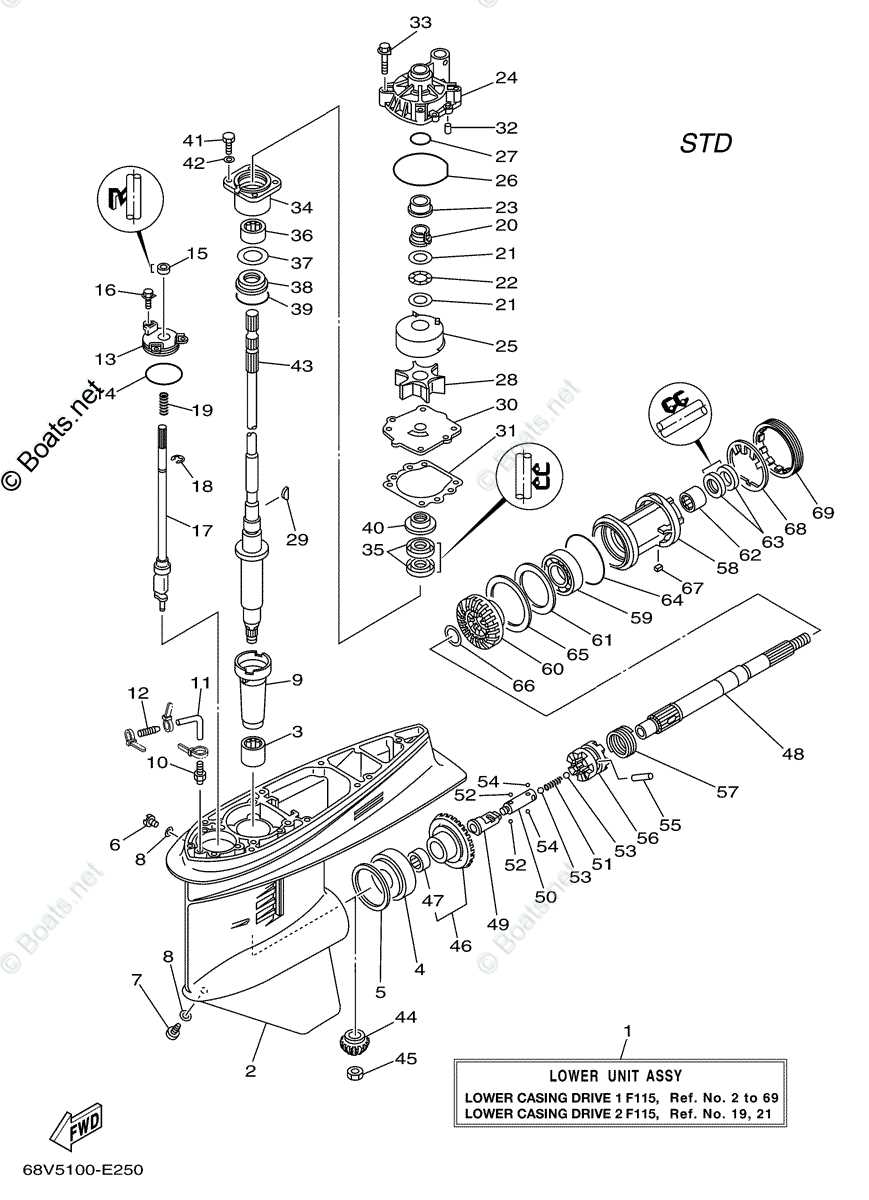

- Lower Unit: Houses the gears and provides thrust, allowing movement through water.

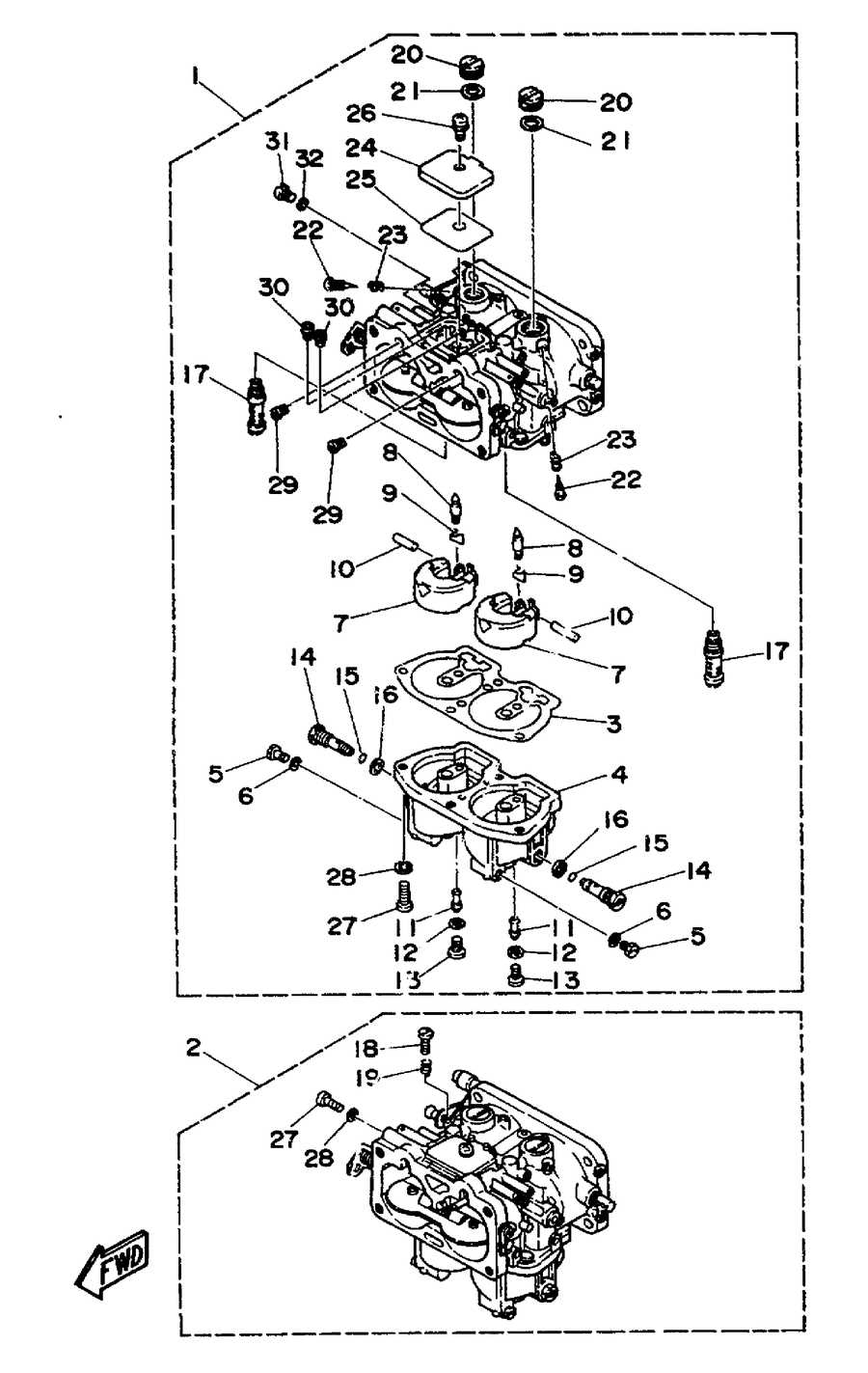

- Fuel System: Critical for delivering the right mixture of fuel and air for combustion.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Electrical System: Powers ignition and other electronic components necessary for operation.

Each of these components plays a vital role in the functionality of the engine, and understanding their interconnections can aid in troubleshooting and maintenance efforts.

- Regular Inspections: Check all components periodically to ensure they are functioning properly.

- Routine Maintenance: Follow recommended service schedules to keep everything in peak condition.

- Replacement Parts: Use high-quality replacements to avoid performance issues.

By familiarizing oneself with these key aspects, boaters can ensure longevity and reliability of their outboard engines.

Importance of Parts Diagrams

Understanding the intricacies of any mechanical system is essential for effective maintenance and repair. Visual representations serve as invaluable tools, allowing users to grasp the layout and functionality of various components. These illustrations enhance comprehension, enabling individuals to identify, locate, and replace specific elements with confidence.

Clear communication is one of the primary benefits of these visual aids. They bridge the gap between technical jargon and practical understanding, making it easier for both novice and experienced technicians to engage with complex machinery. By breaking down the assembly into manageable sections, these representations simplify the troubleshooting process.

Moreover, accurate illustrations can significantly reduce the likelihood of errors during repairs. When technicians can visually confirm the correct parts and their arrangement, they are less prone to mistakes that could lead to costly setbacks. This precision not only improves efficiency but also enhances the longevity of the equipment.

Lastly, having access to such visual guides fosters a sense of confidence and independence among users. Rather than relying solely on external assistance, individuals can tackle repairs and maintenance tasks with greater assurance. This empowerment contributes to a deeper understanding of the machinery, ultimately leading to improved performance and reliability.

Key Features of Yamaha 115 Engine

This section highlights the essential characteristics of a popular marine power unit known for its reliability and performance. Designed to meet the needs of boat enthusiasts, this engine combines advanced technology with user-friendly features, making it a preferred choice for various watercraft applications.

Performance and Efficiency

- Optimized fuel consumption for longer trips

- Robust torque delivery across a wide RPM range

- Advanced cooling system to maintain optimal operating temperatures

Durability and Maintenance

- Corrosion-resistant materials to withstand harsh marine environments

- Easy access to key components for routine servicing

- Proven engineering for extended lifespan and reliability

Overall, this power unit excels in delivering both performance and longevity, making it an excellent choice for those who seek dependable marine propulsion.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations provide a clear overview of how different elements interact and fit together. By familiarizing yourself with the layout and symbols used in these graphics, you can streamline your approach to identifying and obtaining the necessary items for any project.

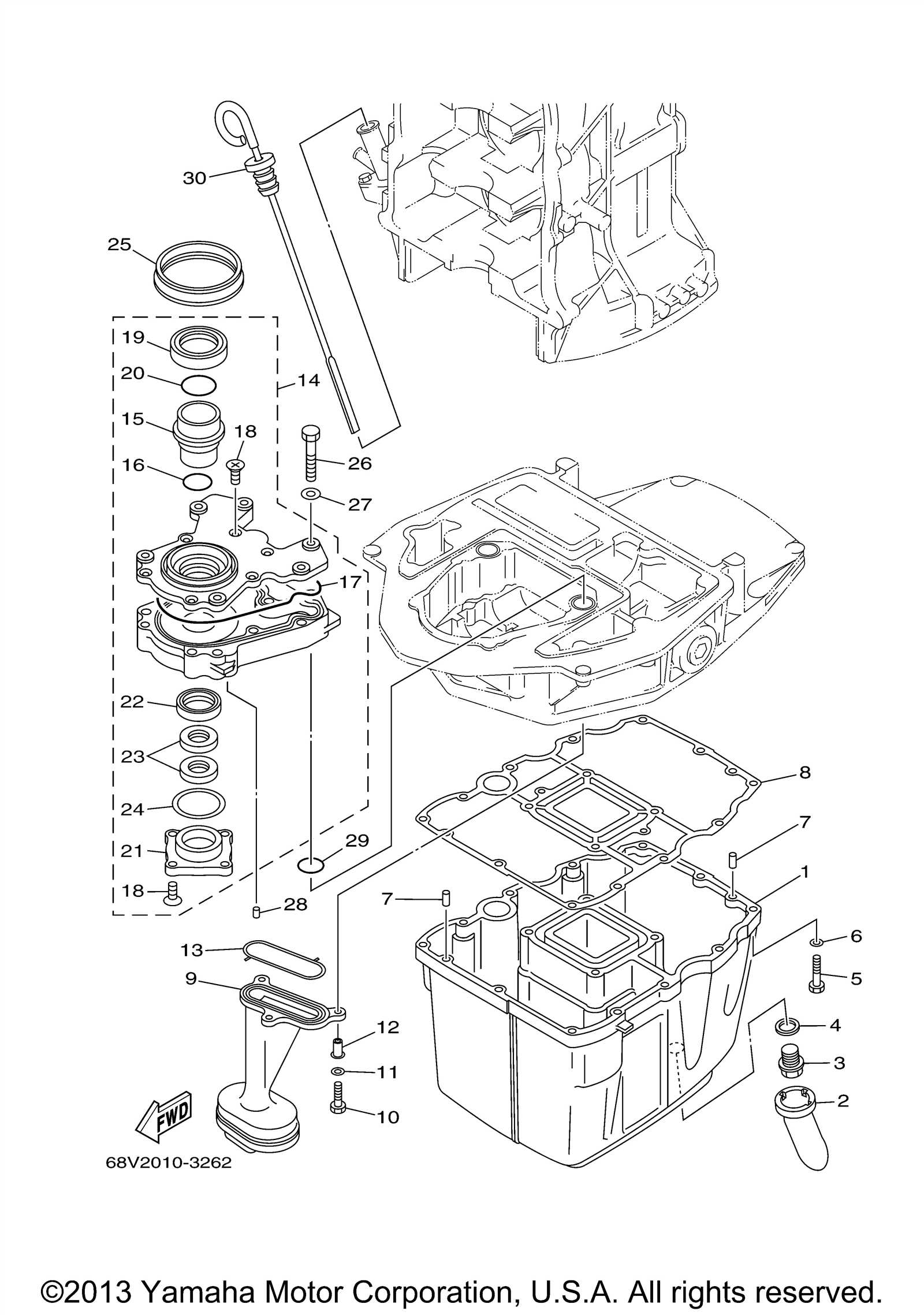

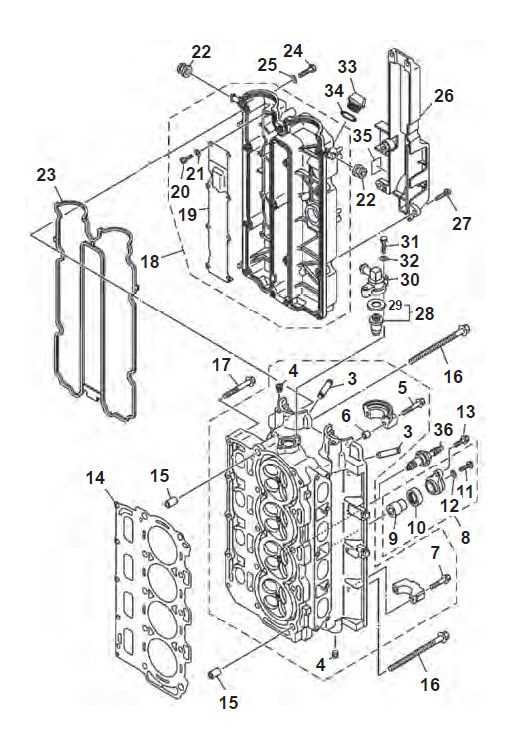

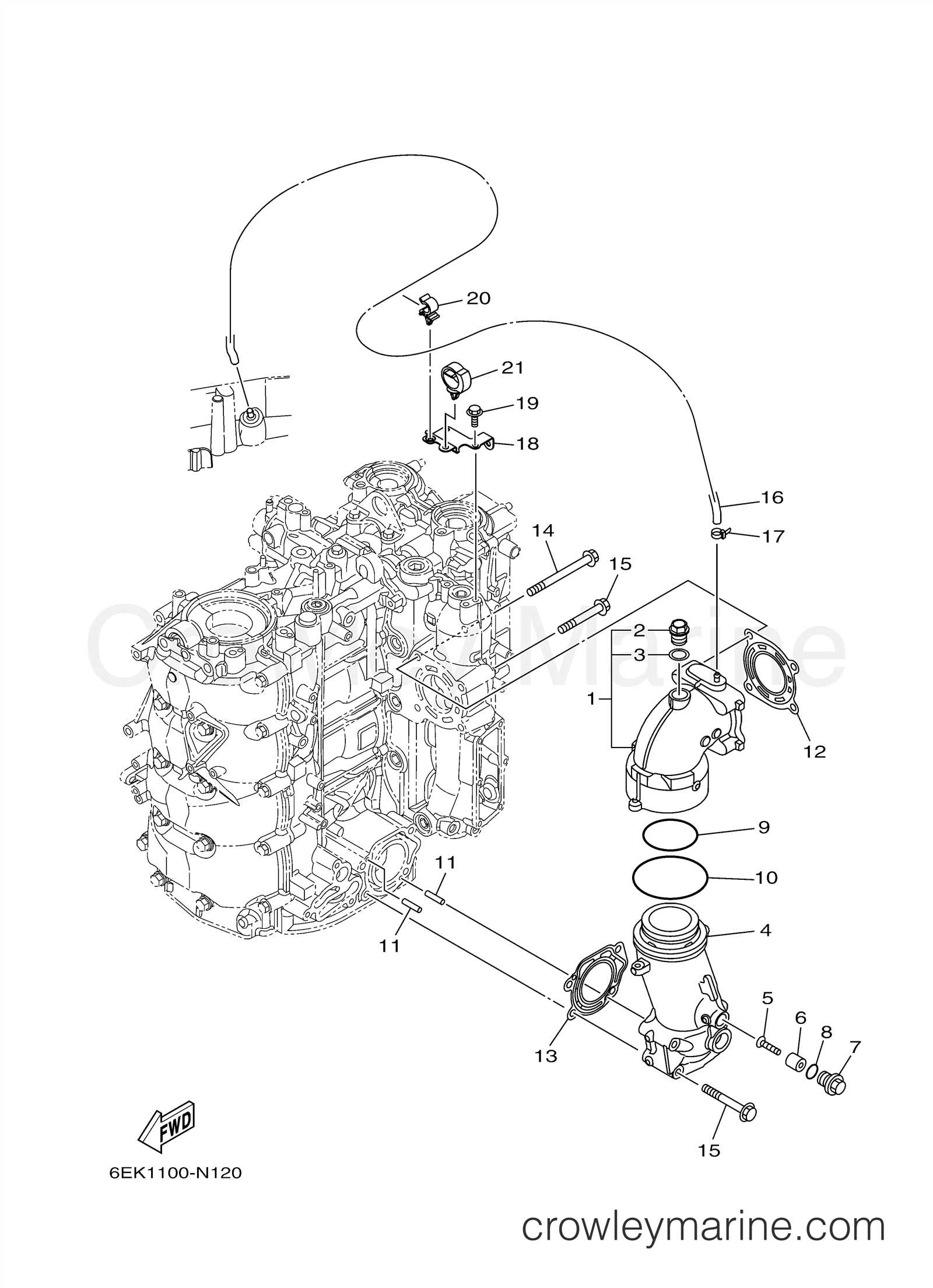

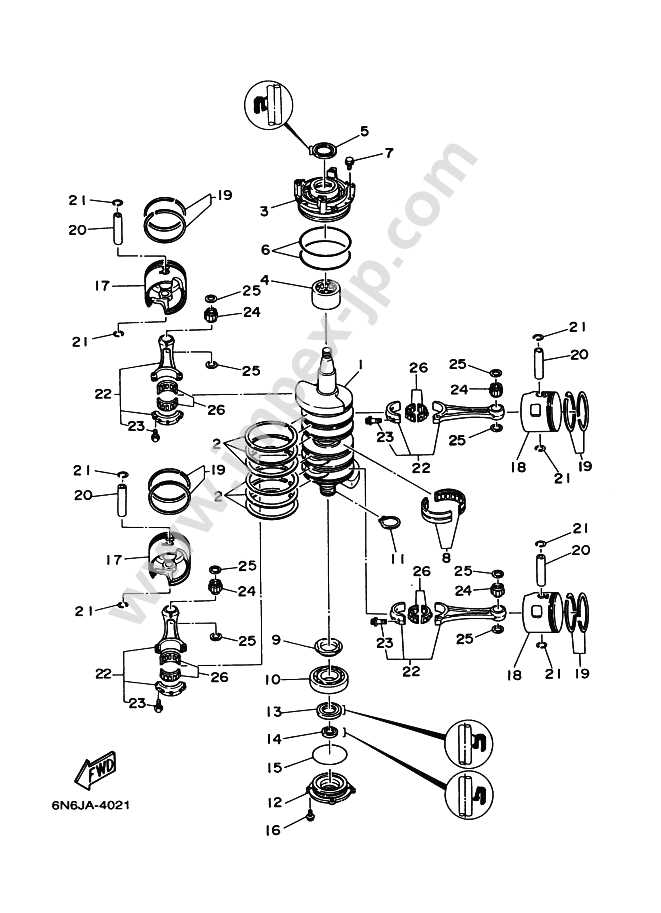

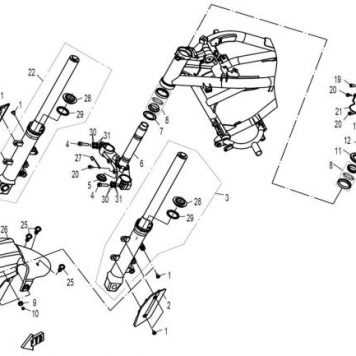

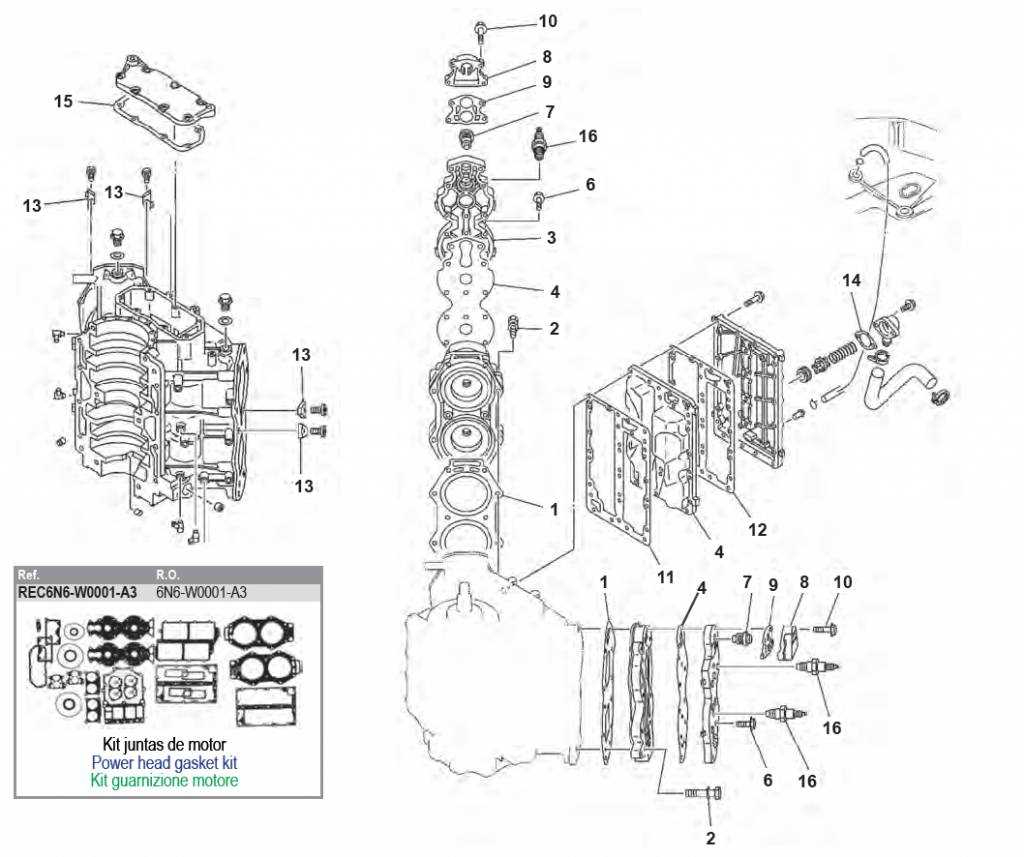

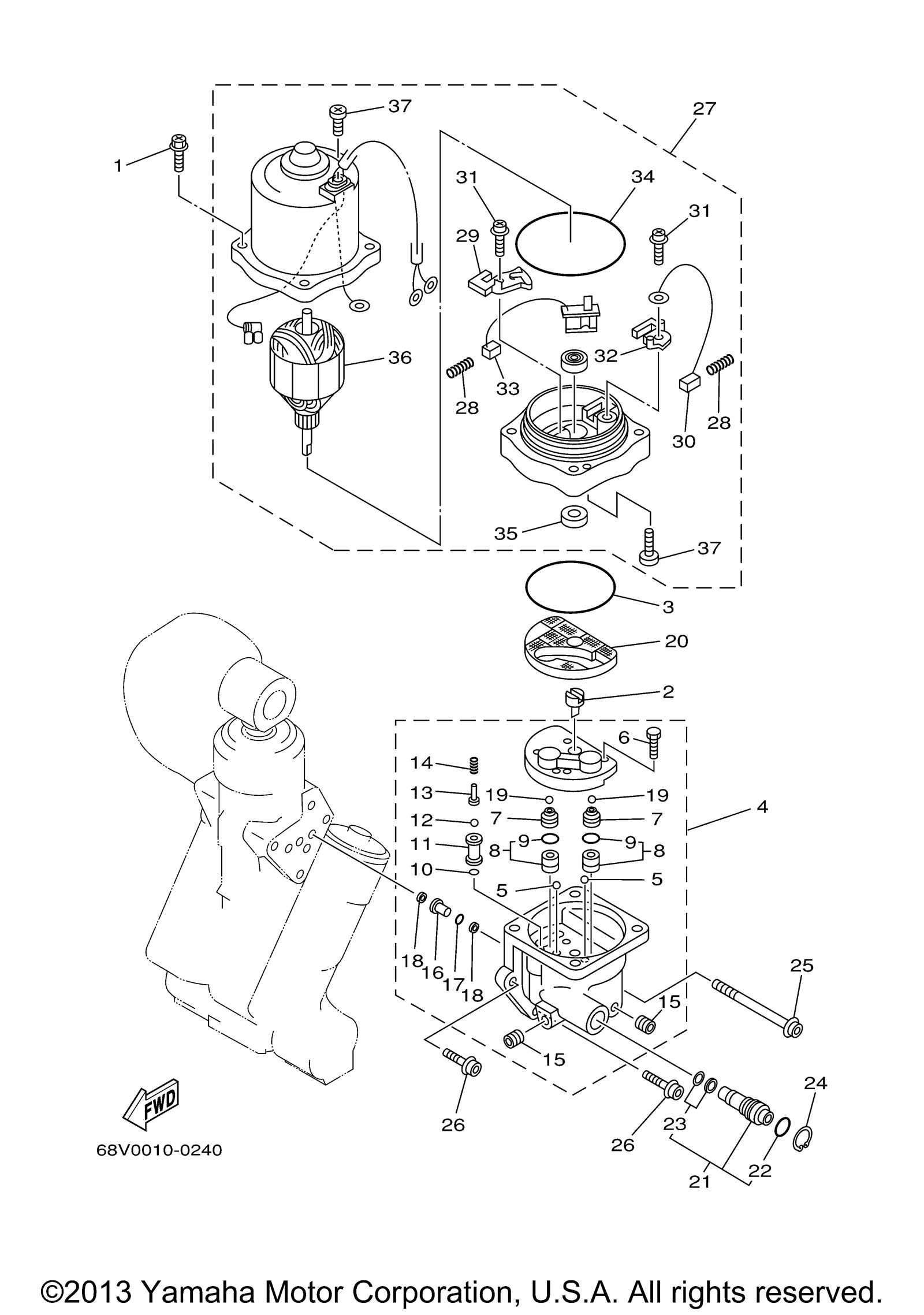

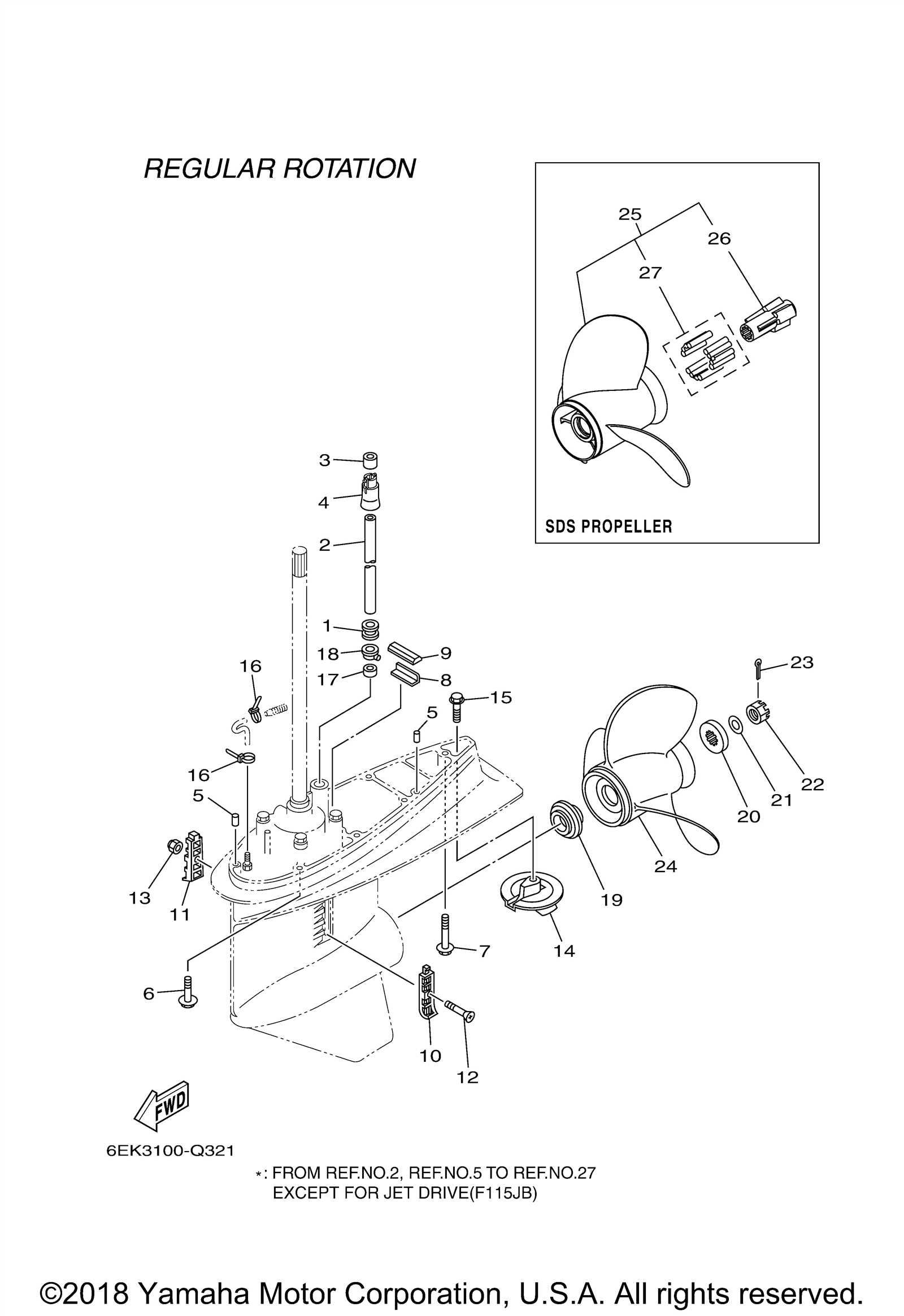

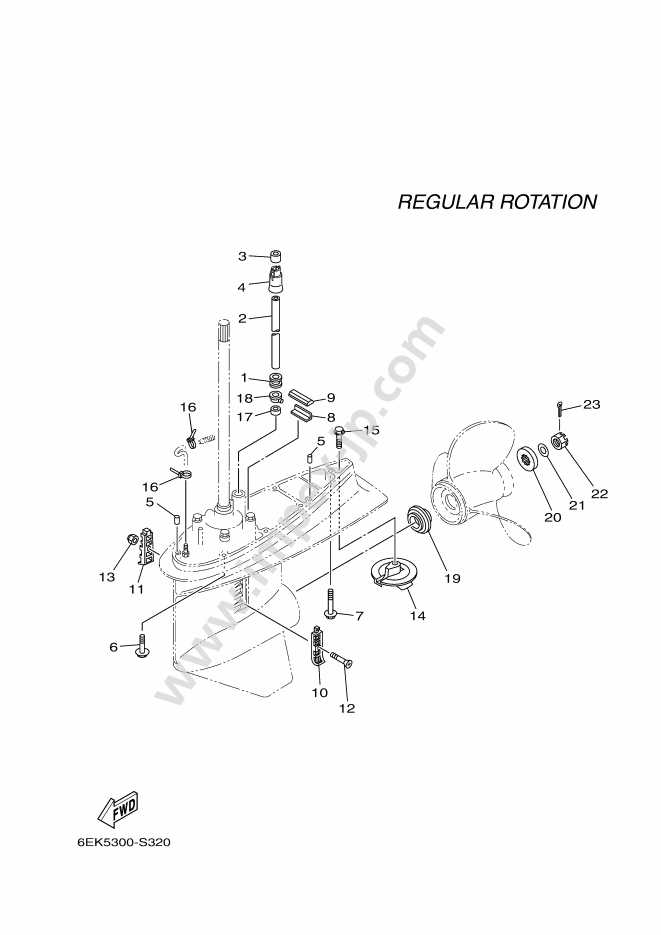

Begin by examining the overall structure of the illustration. Typically, components are arranged logically, often reflecting their physical assembly. Look for labels or numbers that correspond to a list, which usually describes each item in detail. This reference can aid in distinguishing between similar-looking parts and ensure that you select the correct one for your needs.

Pay attention to the connecting lines and arrows within the image. These often indicate relationships between various pieces, showing how they attach or interact. Understanding these connections is crucial for comprehending the functionality of the assembly as a whole.

Additionally, familiarize yourself with any specific symbols or notations that may be used. Each diagram might employ unique markings to represent different materials, sizes, or specifications. Recognizing these can help you make informed decisions about replacements or upgrades.

Finally, practice is key. The more you work with these visual tools, the easier it becomes to interpret them accurately. With time, you’ll develop the skills necessary to navigate these graphics with confidence, ensuring your maintenance and repair efforts are both effective and efficient.

Common Issues with Yamaha 115

When it comes to outboard motors, certain challenges often arise that can affect performance and reliability. Understanding these common problems is essential for maintenance and ensuring a smooth operation on the water. Many users experience similar symptoms, which can typically be traced back to specific components and their wear over time.

Engine Performance Problems

One of the most frequently encountered issues is related to engine performance. Users may notice irregular idling or a lack of power during acceleration. These symptoms can stem from various factors, such as fuel system blockages or issues with ignition components. Regular inspections and timely replacements can help mitigate these performance drops.

Cooling System Failures

Another critical area of concern is the cooling system. Overheating can lead to severe engine damage if not addressed promptly. Common causes include clogged water intakes or faulty thermostats. Keeping the cooling passages clean and ensuring the proper operation of the thermostat is vital for maintaining optimal engine temperatures.

Ordering Replacement Parts Effectively

Acquiring necessary components for maintenance or repairs can often be a daunting task. Understanding the process and knowing where to source reliable items are key factors in ensuring a smooth experience. Efficient ordering not only saves time but also minimizes the risk of purchasing incorrect or substandard materials.

1. Identify the Component: Start by clearly identifying the item you need to replace. Utilize reference materials, such as manuals or online resources, to confirm specifications. Accurate identification prevents mistakes and ensures compatibility with your machinery.

2. Research Suppliers: Take the time to explore various suppliers. Look for reputable vendors with positive reviews and reliable customer service. Compare prices and availability to ensure you are making an informed choice.

3. Check for Authenticity: Whenever possible, opt for original or OEM products. These components are designed specifically for your equipment, ensuring better performance and longevity. Be wary of counterfeit items that may seem appealing due to lower prices but can lead to greater issues down the line.

4. Confirm Return Policies: Before finalizing your order, review the supplier’s return policy. This will provide peace of mind should the item not meet your expectations or if it turns out to be incorrect.

5. Keep Records: Maintain documentation of your orders and any related communications. This practice can be invaluable for future reference or if issues arise with the purchased items.

By following these steps, you can streamline the process of obtaining the components you need, ensuring that your equipment remains in optimal condition without unnecessary delays or complications.

Tools Needed for Maintenance

Regular upkeep of your marine engine requires a variety of essential instruments. Having the right equipment not only simplifies the process but also ensures that tasks are performed efficiently and accurately. Below is a list of common tools that are typically necessary for maintenance procedures.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To remove and secure screws in various components. |

| Wrenches | For adjusting fittings and securing connections. |

| Torque Wrench | To ensure fasteners are tightened to the manufacturer’s specifications. |

| Pliers | For gripping, twisting, and cutting wires or small parts. |

| Multimeter | For checking electrical connections and diagnosing issues. |

| Oil Filter Wrench | To easily remove and replace oil filters during servicing. |

| Cleaning Brushes | For maintaining cleanliness in tight spaces and removing debris. |

Equipping yourself with these tools will enhance your ability to carry out maintenance tasks effectively, ultimately prolonging the life of your engine.

Maintenance Tips for Yamaha 115

Regular upkeep is essential for ensuring the longevity and optimal performance of your outboard engine. Following a consistent maintenance routine can help identify potential issues before they escalate, saving time and money in the long run. Here are some crucial tips to keep your watercraft in top condition.

1. Routine Inspection: Conduct regular visual checks of the engine and its components. Look for any signs of wear, corrosion, or loose connections that may affect performance.

2. Oil Changes: Frequent oil changes are vital for maintaining engine health. Ensure you replace the oil and filter according to the manufacturer’s recommendations to keep the internals lubricated and functioning smoothly.

3. Fuel System Maintenance: Use high-quality fuel and consider adding a fuel stabilizer, especially if the engine will be idle for an extended period. Regularly check fuel lines for leaks and replace any damaged parts.

4. Cooling System Care: Inspect the cooling system to ensure proper function. Clean or replace the water pump impeller as needed to prevent overheating during operation.

5. Battery Maintenance: Keep the battery charged and free of corrosion. Regularly check connections and clean terminals to ensure reliable starting and electrical performance.

6. Propeller Check: Examine the propeller for dings or cracks. A damaged prop can affect efficiency and may require repair or replacement.

7. Seasonal Preparation: Before and after each season, perform a comprehensive checkup. This includes cleaning the engine, checking all fluids, and ensuring all systems are functional.

By adhering to these maintenance practices, you can enhance the reliability and lifespan of your outboard engine, ensuring countless enjoyable hours on the water.

Comparison with Other Outboard Models

When examining various marine propulsion systems, it becomes evident that each model offers distinct features and advantages tailored to specific needs. A comparative analysis allows potential buyers to assess performance, efficiency, and reliability across different brands and specifications.

For instance, some models are renowned for their lightweight construction, enhancing maneuverability and fuel efficiency, while others focus on power output and torque, making them ideal for heavier vessels or challenging waters. The technological advancements in recent designs often include innovative fuel management systems and noise reduction features, setting them apart from older or more basic counterparts.

Furthermore, the availability of aftermarket support and replacement components plays a crucial role in user experience. Some manufacturers provide comprehensive service networks and easy access to upgrades, which can significantly influence long-term ownership satisfaction. By comparing these aspects, potential users can make informed decisions that align with their boating activities and preferences.

Where to Find Authentic Parts

Finding genuine components for your equipment is crucial for maintaining optimal performance and reliability. Many enthusiasts often seek out high-quality replacements that ensure longevity and efficiency, which can be challenging in a market filled with imitations. However, there are several reliable sources to obtain these essential items.

Authorized dealers and service centers are often the best starting points. They typically offer a wide selection of original components and can provide expert guidance on the appropriate choices for your specific model. Additionally, visiting the manufacturer’s official website can lead you to verified sellers and valuable resources.

Online marketplaces dedicated to automotive or marine products frequently feature sections for authentic items. Look for sellers with positive reviews and a solid reputation to ensure you receive quality merchandise. Furthermore, joining community forums or social media groups focused on your type of equipment can connect you with other users who can recommend trustworthy suppliers.

Finally, consider local retailers who specialize in equipment maintenance. They often have access to a range of genuine items and can offer personalized assistance based on your needs. By exploring these options, you can ensure that you are acquiring the right components for your machinery.

Expert Recommendations for Upgrades

Enhancing the performance and longevity of your marine engine can significantly improve your overall boating experience. By focusing on key components, you can achieve better efficiency, reliability, and responsiveness. Here are some expert suggestions to consider for your next upgrade.

Performance Enhancements

Investing in high-quality performance parts can provide noticeable improvements in speed and handling. Upgrading your fuel system and propeller can lead to better acceleration and fuel efficiency.

| Component | Recommended Upgrade | Benefits |

|---|---|---|

| Fuel Injector | High-Performance Injectors | Improved fuel atomization and efficiency |

| Propeller | Stainless Steel Prop | Enhanced durability and better grip in the water |

Maintenance Parts

Regular maintenance is crucial for optimal function. Consider upgrading to superior maintenance components that can prolong the life of your engine and reduce downtime.

| Component | Recommended Upgrade | Benefits |

|---|---|---|

| Oil Filter | High-Performance Filter | Better filtration and longer service intervals |

| Cooling System | Upgraded Water Pump | Improved cooling efficiency and reliability |

Frequently Asked Questions about Yamaha 115

This section addresses common inquiries regarding a specific model of marine engines. Here, we provide insights into maintenance, components, and troubleshooting to assist users in making informed decisions.

What are the essential maintenance practices for this engine?

Regular oil changes, checking fuel lines, and inspecting cooling systems are crucial for optimal performance. It’s advisable to follow the manufacturer’s recommendations for intervals.

Where can I find replacement components for my engine?

Replacement components can be sourced from authorized dealers, marine supply stores, or online retailers specializing in marine equipment. Ensure you verify compatibility before purchasing.

How can I troubleshoot common issues?

Start by checking fuel supply and battery connections. If the engine does not start, inspect the ignition system and look for any warning lights or error codes that may provide further guidance.

Is it necessary to consult a professional for repairs?

While some minor repairs can be handled independently, consulting a professional is recommended for complex issues to avoid potential damage and ensure safety.

What resources are available for learning more about my engine?

Manuals, online forums, and instructional videos are excellent resources for gaining a deeper understanding. Additionally, joining community groups can provide valuable insights from other users.