Understanding the 4.3 Mercruiser Engine Parts Diagram

In the realm of marine propulsion, grasping the intricate arrangement of vital components is essential for optimal performance and maintenance. Each unit plays a crucial role in ensuring smooth operation and longevity of the vessel. By familiarizing oneself with these elements, boat owners can better appreciate the engineering marvels that allow for seamless adventures on the water.

Delving into the specifics, one can uncover a wealth of information that reveals how each component interacts within the broader framework. This knowledge not only enhances troubleshooting capabilities but also empowers enthusiasts to engage in informed discussions about their aquatic machinery. Understanding the layout and function of these critical units transforms the daunting task of repairs into a manageable challenge.

Moreover, this exploration opens doors to enhancing efficiency and performance. A comprehensive comprehension of the configuration aids in recognizing potential areas for improvement, paving the way for upgrades and modifications. Whether you are a seasoned mariner or a newcomer, this insight serves as a foundation for deeper engagement with your watercraft’s mechanics.

Understanding the 4.3 MerCruiser Engine

This section explores the key components and functionalities of a popular marine power source, focusing on its design, operation, and maintenance requirements. With a blend of reliability and efficiency, this power unit has garnered significant attention among boating enthusiasts.

The structure of this marine unit consists of several essential elements that contribute to its overall performance:

- Block: The core structure that houses various mechanisms.

- Fuel System: Responsible for delivering the right mixture of fuel and air.

- Ignition System: Ensures efficient combustion for optimal power output.

- Cooling System: Maintains appropriate operating temperatures to prevent overheating.

- Lubrication System: Reduces friction and wear among moving components.

Understanding each of these components can enhance your ability to troubleshoot and maintain the unit effectively.

Maintenance practices play a crucial role in the longevity of this power source:

- Regular oil changes to keep the lubrication system functioning optimally.

- Routine inspections of the cooling system to prevent overheating.

- Monitoring the fuel system for any blockages or leaks.

- Checking the ignition system for wear to ensure reliable starting.

By prioritizing these maintenance tasks, users can ensure a smoother and more efficient operation, leading to an enjoyable boating experience.

Key Components of MerCruiser Engines

Understanding the essential elements of marine propulsion systems is crucial for anyone involved in boating or maintenance. Each component plays a vital role in ensuring optimal performance and reliability. Familiarity with these elements can greatly enhance the experience of boat ownership and operation.

Power Generation and Distribution

The heart of any propulsion system is the power generation unit, which transforms fuel into mechanical energy. Coupled with a robust distribution mechanism, this system ensures that power flows efficiently to drive the vessel. Regular inspection and maintenance of these units are necessary to avoid performance issues.

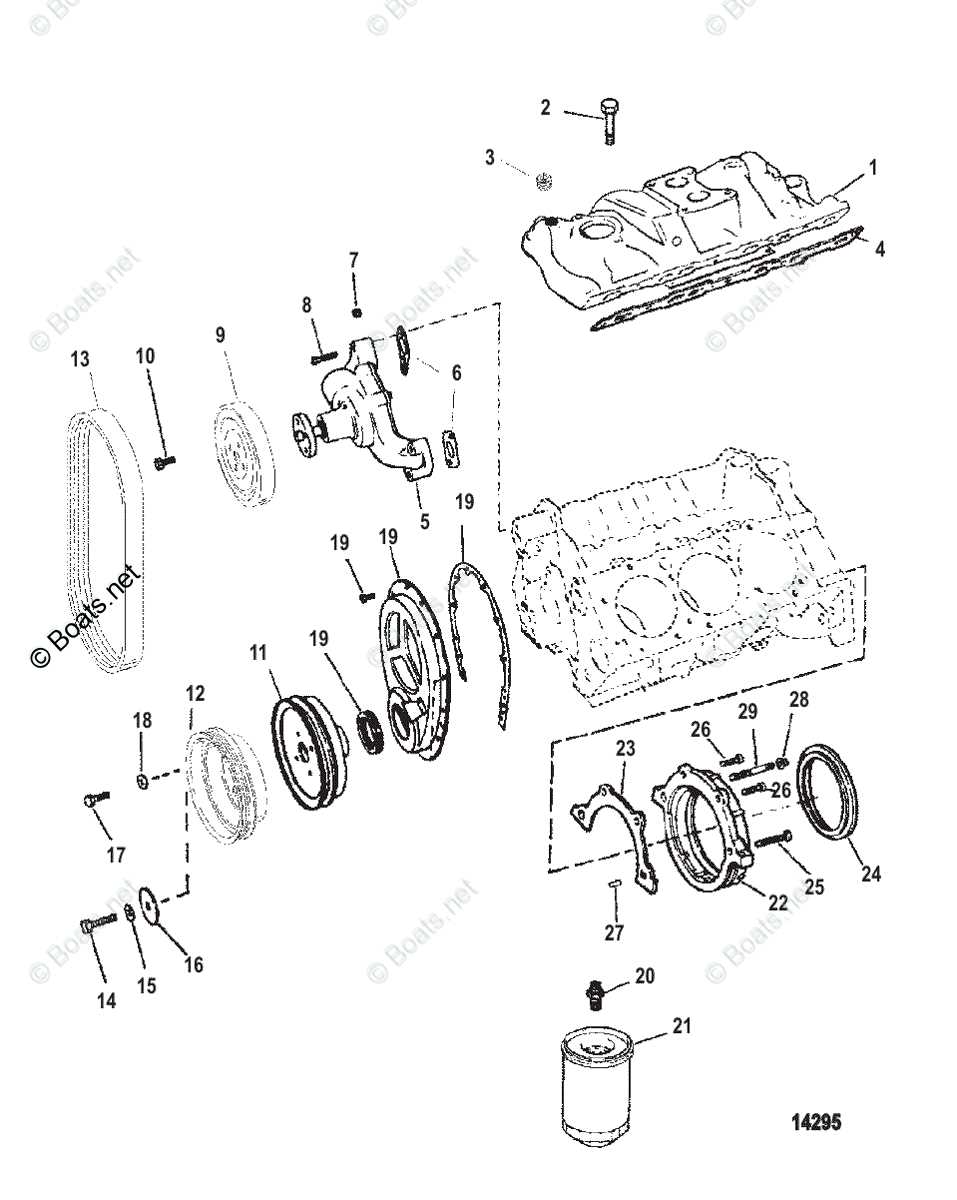

Cooling and Lubrication Systems

Effective cooling and lubrication are paramount for maintaining optimal operating temperatures and reducing friction. A well-functioning cooling mechanism prevents overheating, while the lubrication system ensures that all moving parts operate smoothly. Neglecting these systems can lead to severe damage and costly repairs.

In summary, recognizing and understanding the key elements of marine propulsion systems not only aids in maintenance but also enhances the overall performance and longevity of your vessel.

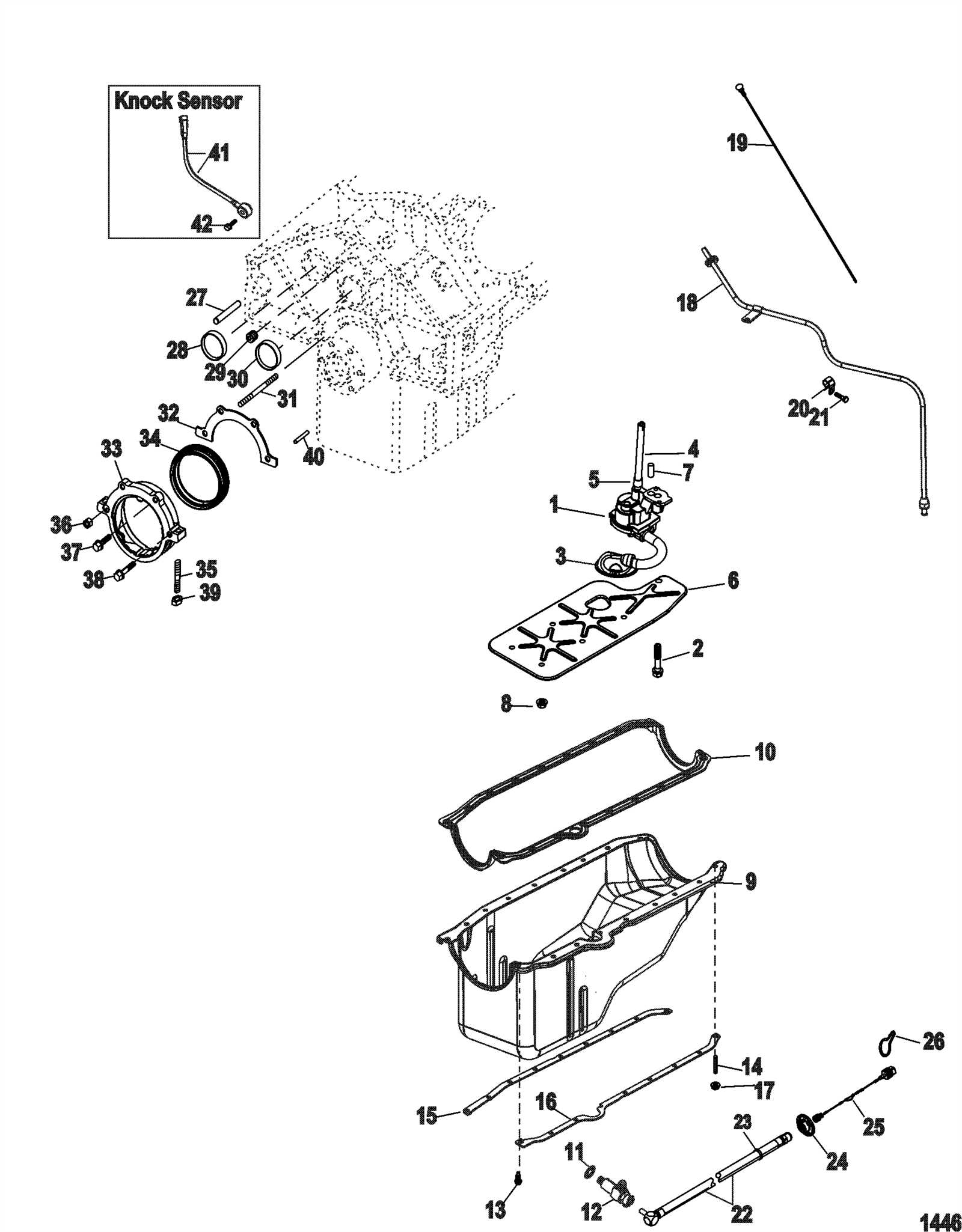

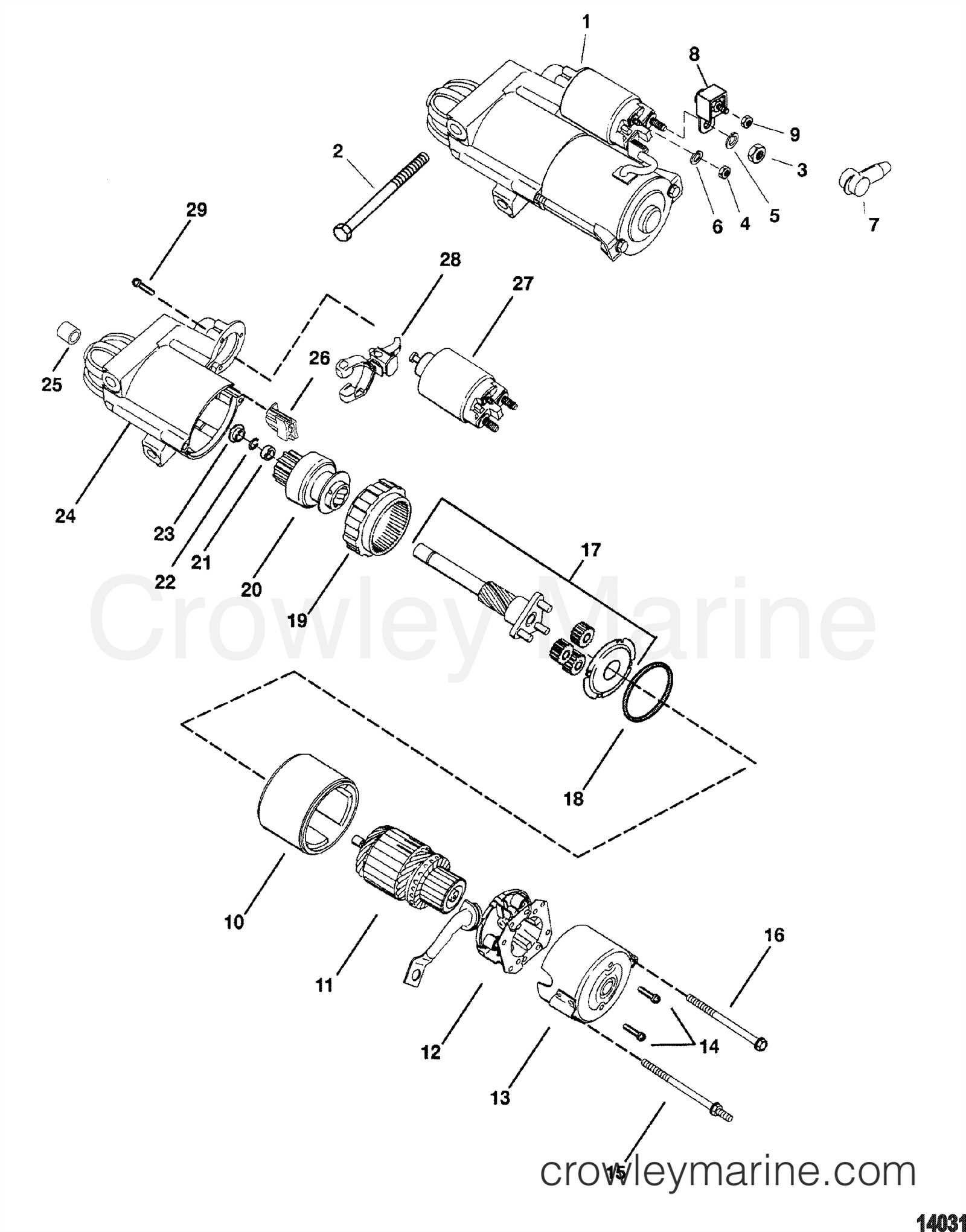

How to Read Engine Diagrams

Understanding technical illustrations is essential for anyone working with mechanical systems. These visual representations provide a roadmap to the components and their relationships, making it easier to diagnose issues or perform maintenance. By mastering how to interpret these visuals, you can enhance your troubleshooting skills and gain deeper insights into the mechanics involved.

First, familiarize yourself with the symbols and notations commonly used in these illustrations. Each symbol typically represents a specific component or function, so understanding their meanings is crucial. Look for a legend or key that explains these symbols to help you decode the visual information.

Next, pay attention to the layout. Diagrams often arrange elements in a logical sequence, reflecting the flow of operation. Identify how parts connect and interact with each other, noting any directional arrows that indicate movement or flow. This will help you understand the overall function of the system.

Lastly, don’t overlook any accompanying annotations. These notes can provide additional context, specifications, or troubleshooting tips that enhance your understanding. Taking the time to study these details can significantly improve your ability to work effectively with mechanical systems.

Common Issues with 4.3 MerCruiser Parts

Maintaining optimal performance in marine propulsion systems often comes with its own set of challenges. Various components may encounter problems over time, affecting reliability and efficiency. Understanding these common issues can help in proactive maintenance and timely repairs.

- Corrosion: Saltwater exposure can lead to significant degradation of metal components. Regular inspection and protective coatings are essential.

- Overheating: Cooling system failures, often caused by clogged passages or malfunctioning pumps, can lead to severe damage.

- Fuel Delivery Problems: Issues with filters, lines, or injectors can hinder performance and cause starting difficulties.

- Electrical Failures: Wiring and connectors may corrode, leading to starting issues or erratic operation.

- Wear and Tear: Regular use can cause deterioration of seals and gaskets, resulting in leaks that impact performance.

Addressing these concerns early can prevent costly repairs and extend the lifespan of your marine system. Routine maintenance checks and using high-quality replacements are key strategies for avoiding these issues.

Importance of Regular Maintenance

Regular servicing offers numerous benefits, including:

- Prolonged Lifespan: Consistent care can significantly extend the operational life of components.

- Enhanced Performance: Well-maintained systems operate more smoothly and efficiently.

- Cost Savings: Preventative measures can reduce the likelihood of costly repairs and replacements.

- Safety Assurance: Routine checks help identify potential hazards before they escalate.

Moreover, staying proactive with maintenance can lead to:

- Improved Fuel Efficiency: Properly maintained systems consume fuel more efficiently.

- Reduced Emissions: Keeping machinery in top condition helps minimize environmental impact.

- Increased Resale Value: A well-documented maintenance history can enhance the market value of your equipment.

In conclusion, prioritizing regular maintenance is crucial for achieving peak performance, ensuring safety, and maximizing the value of your investment. A diligent approach to upkeep will pay dividends in the long run, providing peace of mind and reliability.

Replacement Parts for Optimal Performance

Maintaining peak functionality requires attention to detail and the timely replacement of worn components. Ensuring that each element operates at its best enhances overall efficiency and extends the lifespan of your machinery.

Key Components to Monitor

Regular checks on vital elements can prevent unexpected failures. Focus on these critical areas:

- Fuel delivery systems

- Cooling mechanisms

- Ignition assemblies

- Lubrication systems

- Exhaust structures

Choosing Quality Alternatives

Selecting reliable substitutes is essential for maintaining performance standards. Consider the following when sourcing replacements:

- Compatibility with existing systems

- Manufacturer reputation

- Warranty offerings

- Material durability

- Customer reviews

Investing in high-quality replacements not only ensures optimal function but also provides peace of mind during operation.

Tools Needed for Engine Repair

When undertaking mechanical repairs, having the right instruments is crucial for achieving optimal results. The proper tools not only enhance efficiency but also ensure safety during the maintenance process. Understanding the essential implements can make a significant difference in the overall experience of working on machinery.

Essential Hand Tools

- Wrenches: A variety of sizes for different fasteners.

- Screwdrivers: Both flathead and Phillips for various applications.

- Pliers: Needle-nose and standard for gripping and bending.

- Socket set: Provides flexibility in loosening and tightening bolts.

- Torque wrench: Ensures fasteners are tightened to the correct specifications.

Specialized Equipment

- Diagnostic tools: Essential for troubleshooting and identifying issues.

- Oil filter wrench: Simplifies the removal of stubborn oil filters.

- Compression tester: Measures the pressure within cylinders.

- Feeler gauges: Useful for checking clearances and gaps.

- Lift or jack: Necessary for accessing components underneath.

By equipping yourself with these vital tools, you can approach repairs with confidence and precision, ultimately leading to a more successful and satisfying experience in maintenance tasks.

Upgrades to Enhance Engine Efficiency

Improving performance and fuel economy can significantly transform the operation of any vessel. By implementing strategic modifications, boat owners can achieve smoother navigation and reduced consumption. These enhancements not only boost overall power but also contribute to a more enjoyable experience on the water.

High-Performance Air Intake Systems are a popular choice among enthusiasts looking to increase airflow to the combustion chamber. By replacing factory-installed components with upgraded versions, it’s possible to enhance the engine’s responsiveness and overall power output.

Exhaust Systems play a crucial role as well. Upgrading to a more efficient setup can reduce back pressure, leading to better exhaust flow. This change often results in improved horsepower and torque, while also creating a more aggressive sound that many boaters appreciate.

Fuel Management Systems can also be optimized. By fine-tuning the fuel delivery process, you can achieve a more balanced air-fuel mixture, which enhances combustion efficiency. This improvement can lead to noticeable gains in both performance and fuel savings.

Lastly, regular maintenance and the use of high-quality lubricants are essential. Keeping components in optimal condition ensures that every upgrade functions effectively, prolonging the lifespan of the entire system.

Differences Between MerCruiser Models

Understanding the variations among different models of inboard propulsion systems is essential for enthusiasts and professionals alike. Each version brings unique features and specifications, catering to diverse boating needs and preferences. This section will explore key distinctions that set these models apart.

Performance Characteristics

One of the primary factors that differentiates these systems is their performance capabilities. Key aspects include:

- Horsepower Output: Varying power levels influence acceleration and top speed.

- Torque Delivery: Some models excel in low-end torque, ideal for towing, while others provide better high-speed performance.

- Fuel Efficiency: Different designs offer varying levels of fuel consumption, impacting operational costs.

Design and Technology

Innovations and design choices significantly contribute to the uniqueness of each system. Notable elements include:

- Cooling Systems: Different configurations affect temperature management and longevity.

- Fuel Injection Types: Varieties in fuel delivery systems influence performance and maintenance.

- Material Composition: The use of different materials affects weight, durability, and overall efficiency.

By recognizing these differences, users can make informed choices that align with their specific boating experiences and requirements.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is essential to prevent accidents and injuries. Proper precautions help create a secure working environment and minimize risks associated with mechanical work. Adopting the right practices not only protects the technician but also extends the lifespan of the equipment.

Before starting any work, it is crucial to wear appropriate personal protective equipment (PPE). This may include gloves, safety goggles, and steel-toed boots. Additionally, the workspace should be organized and free from clutter to avoid potential hazards.

| Precaution | Description |

|---|---|

| Use Protective Gear | Always wear gloves, goggles, and suitable footwear to safeguard against injuries. |

| Secure the Workspace | Ensure that the area is clean and well-lit, with tools and materials neatly arranged. |

| Disconnect Power Sources | Before starting repairs, disconnect all electrical sources to prevent accidental starts. |

| Follow Manufacturer Guidelines | Always refer to the specific guidelines provided by the manufacturer for safety protocols. |

| Be Aware of Hazards | Identify potential risks in the environment, such as flammable materials or sharp objects. |

By implementing these safety measures, individuals can ensure a safer working experience, allowing for efficient and effective maintenance tasks without compromising well-being.

Where to Find Reliable Diagrams

Locating accurate illustrations for mechanical components can greatly enhance your understanding and maintenance efforts. Whether you’re working on repairs or upgrades, having access to dependable visual references is essential for success. Below are several avenues to explore when searching for these valuable resources.

Online Resources

- Manufacturer Websites: Many brands offer downloadable manuals and visual aids directly on their official platforms.

- Forums and Communities: Enthusiast forums often contain user-shared diagrams and insights from experienced individuals.

- Educational Websites: Sites dedicated to mechanical education frequently provide detailed charts and schematics.

Printed Manuals

- Service Manuals: These often include comprehensive illustrations and can be purchased through various retailers.

- Repair Guides: Books focusing on specific models or types of equipment usually contain detailed images and descriptions.

- Library Resources: Local libraries may have manuals available for loan, providing access to a range of useful diagrams.

By exploring these options, you can find the illustrations you need to facilitate your maintenance tasks efficiently and effectively.