Understanding the Husqvarna K760 Parts Diagram for Easy Maintenance

The efficient operation of any cutting equipment hinges on the intricate interplay of its various elements. Each component plays a vital role, contributing to the overall performance and reliability of the device. Grasping the layout and function of these parts is essential for both maintenance and troubleshooting.

In this section, we will delve into a comprehensive overview of the essential elements that make up your machine. By examining the assembly and connections, users can gain insight into how each part works harmoniously to achieve the ultimate cutting results.

Moreover, understanding these components not only enhances your operational skills but also empowers you to make informed decisions regarding repairs and upgrades. This knowledge fosters greater efficiency, prolonging the lifespan of your equipment and optimizing its performance in various tasks.

Understanding Husqvarna K760 Components

Exploring the essential elements of a cutting machine can greatly enhance performance and longevity. Each component plays a crucial role in the overall functionality, making it important to grasp their purpose and interaction.

- Engine: Powers the tool, providing necessary energy for operation.

- Cutter Head: The part that engages with materials, determining cutting efficiency.

- Fuel System: Delivers the necessary mixture for combustion, impacting performance.

- Air Filter: Protects the engine from debris, ensuring clean airflow.

- Handle: Provides grip and control during use, enhancing user comfort.

By understanding these components, users can make informed decisions regarding maintenance and repairs, ultimately improving the machine’s performance.

Key Features of K760 Parts

The components of this powerful cutting tool are designed to enhance performance and reliability. Each element plays a vital role in ensuring the machine operates efficiently, providing users with the best possible results in their tasks. Understanding these features can significantly improve maintenance and operational effectiveness.

One of the standout attributes of these components is their durability. Crafted from high-quality materials, they withstand the rigors of demanding environments, ensuring longevity and consistent performance. Additionally, many elements are engineered for easy replacement, allowing for quick servicing and reduced downtime.

Another significant feature is the precision engineering that goes into each piece. This meticulous design ensures that all components fit seamlessly together, minimizing the risk of malfunction. Enhanced compatibility among parts contributes to smoother operation, making the tool more user-friendly.

Moreover, the lightweight design of several components aids in maneuverability, allowing operators to handle the equipment with ease during various cutting applications. This aspect is particularly beneficial for prolonged use, as it reduces fatigue and increases productivity.

Finally, innovation in design leads to improved efficiency. Advanced features in the cutting elements optimize performance, providing cleaner cuts and greater power output. This not only enhances the user experience but also ensures superior results on the job.

Importance of Proper Maintenance

Regular upkeep is essential for ensuring the longevity and efficiency of any machinery. Proper care not only enhances performance but also prevents costly repairs and extends the lifespan of the equipment.

Here are key reasons why maintenance is vital:

- Performance Optimization: Well-maintained equipment operates at its best, delivering optimal results.

- Safety: Regular checks help identify potential hazards, reducing the risk of accidents.

- Cost Efficiency: Preventative maintenance is often more economical than reactive repairs.

- Resale Value: Keeping machinery in top condition can enhance its market value.

- Reliability: Regular servicing ensures consistent operation, minimizing downtime.

In conclusion, investing time and resources in maintenance ultimately leads to better performance and reduced operational challenges.

Common Issues with K760 Parts

Understanding the frequent challenges that arise with components of cutting equipment is crucial for optimal performance and longevity. Various elements can encounter wear and tear, leading to operational inefficiencies and potential breakdowns.

Wear and Tear

One of the most prevalent concerns is the gradual deterioration of critical components due to extended use. Regular inspection is essential to identify signs of fatigue, which can manifest as cracks or reduced functionality.

Compatibility Problems

Another issue often faced is the mismatch between different components. Ensuring that each element is compatible can prevent premature failure and enhance the overall reliability of the machinery.

How to Replace K760 Components

Replacing various elements of your machine is essential for maintaining its performance and longevity. Understanding the process can greatly enhance efficiency and ensure that every part functions optimally. This guide will help you navigate the replacement of critical components with ease.

| Component | Replacement Steps |

|---|---|

| Blade | 1. Disconnect power. 2. Remove the locking nut. 3. Replace the blade and secure it with the nut. |

| Air Filter | 1. Open the cover. 2. Take out the old filter. 3. Insert the new filter and close the cover. |

| Fuel Filter | 1. Access the fuel tank. 2. Remove the old filter from the hose. 3. Install the new filter and reattach the hose. |

| Spark Plug | 1. Unscrew the spark plug cap. 2. Use a wrench to remove the old plug. 3. Install the new plug and reattach the cap. |

Safety Tips for K760 Operation

Operating powerful machinery requires vigilance and adherence to safety protocols. To ensure a secure working environment, it’s essential to be aware of potential hazards and take proactive measures to mitigate risks associated with tool usage.

Personal Protective Equipment

Always wear appropriate protective gear, including safety goggles, gloves, and ear protection. These items help shield against debris and excessive noise, reducing the risk of injury during operation.

Proper Handling and Maintenance

Before use, inspect the equipment thoroughly for any damage or wear. Regular maintenance not only extends the lifespan of the tool but also enhances safety by ensuring all components function correctly.

Where to Find Genuine Parts

Finding authentic components for your equipment is crucial for maintaining optimal performance and longevity. Sourcing from reliable suppliers ensures you receive high-quality items that meet the original specifications, ultimately enhancing efficiency.

Authorized Dealers: Start your search with authorized retailers who specialize in original equipment. These outlets typically provide a wide selection of genuine items and can offer expert advice.

Online Marketplaces: Numerous online platforms offer the opportunity to purchase authentic replacements. Look for sellers with strong reputations and verify their authenticity guarantees.

Manufacturer’s Website: The official website often lists authorized dealers and provides direct purchasing options. This is a reliable way to ensure you are getting genuine products.

Local Repair Shops: Many repair shops maintain relationships with manufacturers and can source original components for you. They may also have inventory on hand for immediate needs.

Investing time in finding genuine components will ultimately pay off, providing peace of mind and ensuring your equipment operates smoothly for years to come.

Comparing K760 to Other Models

This section explores the distinctions between a specific cutting machine and its counterparts in the market. By examining key features and performance metrics, users can better understand which model suits their needs best.

Key Features

When comparing different machines, several characteristics come into play, including power output, weight, and cutting depth. These elements significantly influence operational efficiency and user experience.

Performance Metrics

| Model | Power Output (HP) | Weight (lbs) | Max Cutting Depth (inches) |

|---|---|---|---|

| Model A | 5.0 | 30 | 5.5 |

| Model B | 4.8 | 28 | 5.0 |

| Model C | 5.5 | 32 | 6.0 |

Evaluating these specifications can help potential buyers make informed decisions based on their specific cutting requirements and job site conditions.

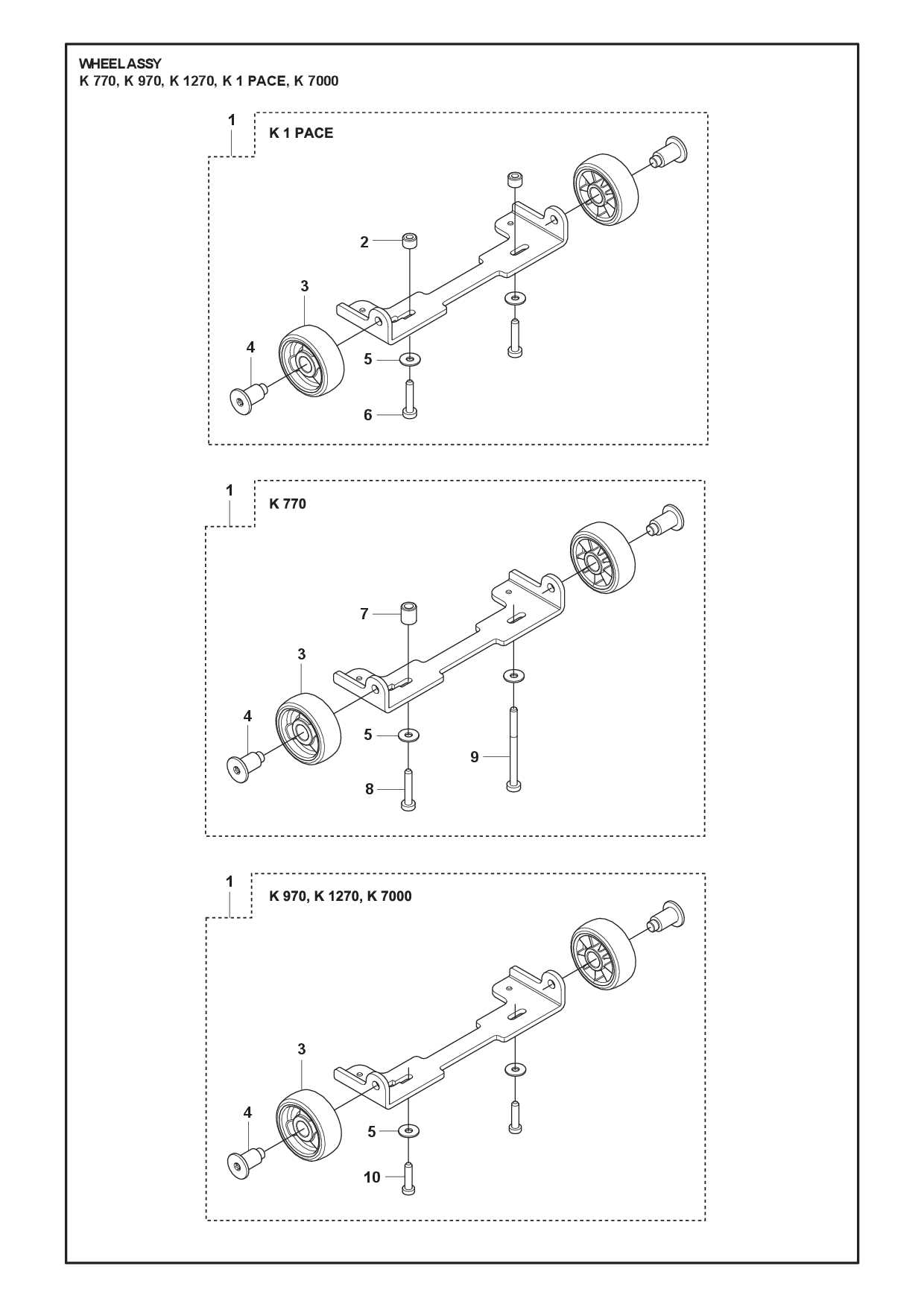

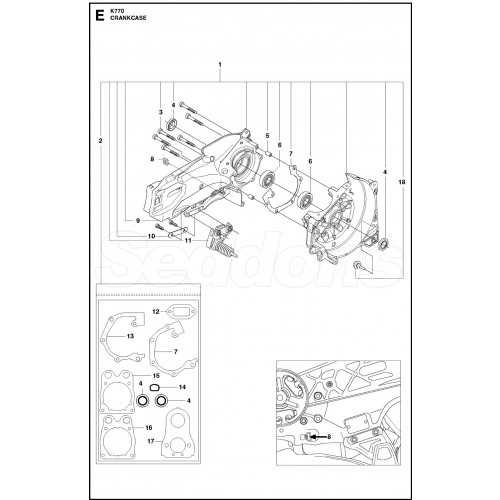

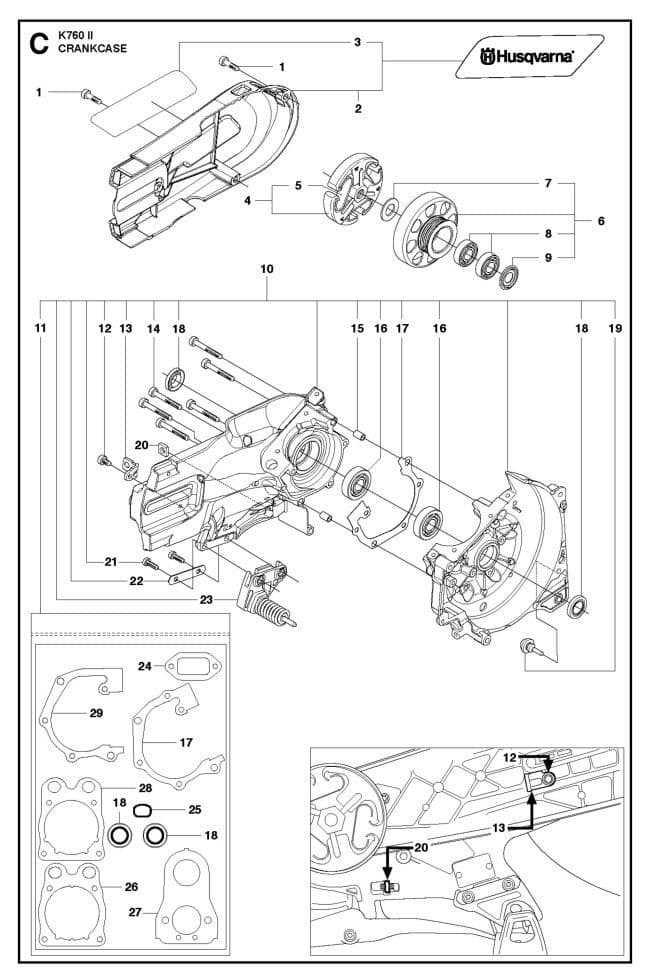

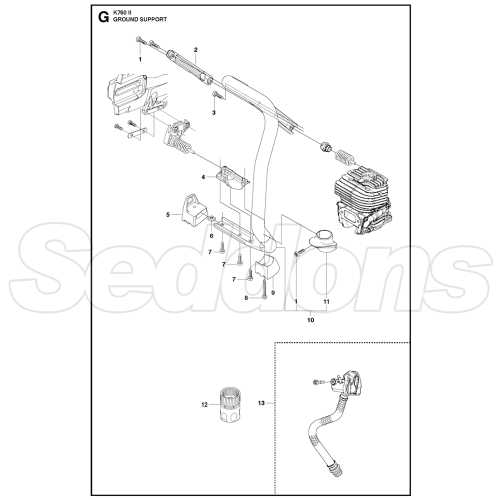

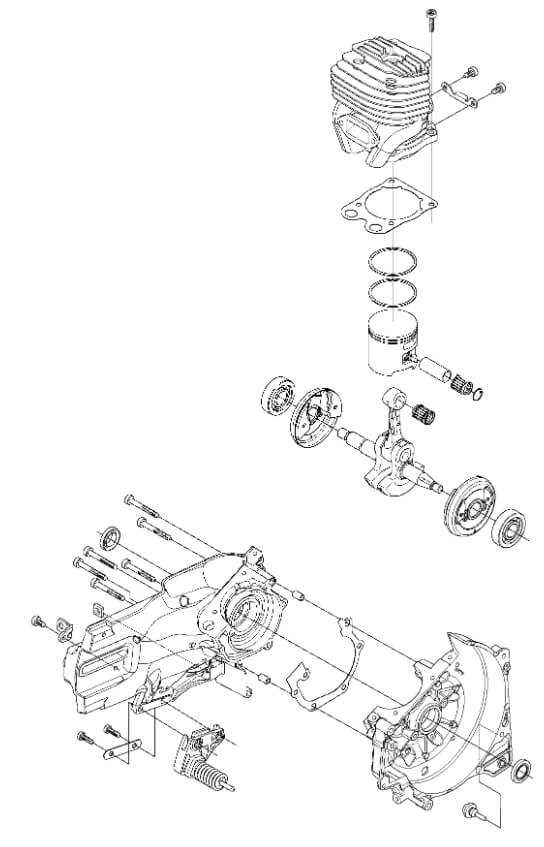

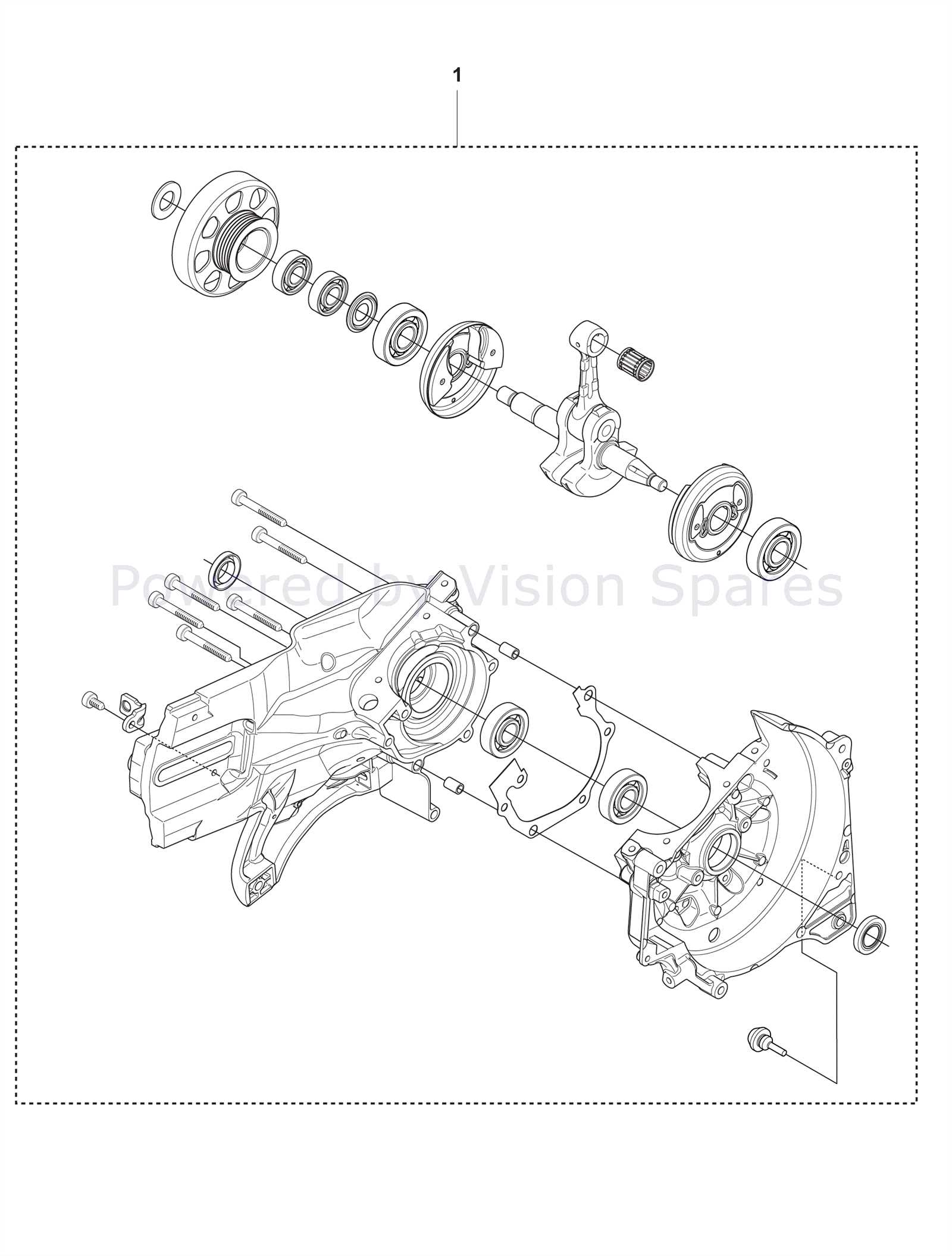

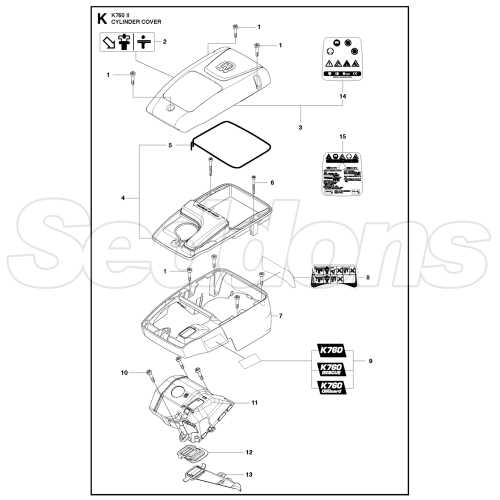

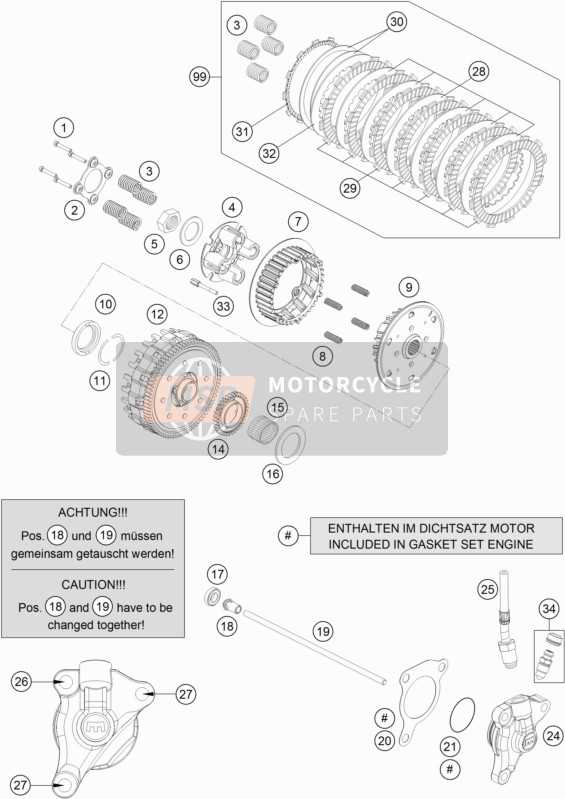

Diagrams: A Visual Guide

Visual representations serve as an essential tool for understanding the intricate components of machinery. These illustrations break down complex systems into easily digestible segments, allowing users to identify each element and its function. By utilizing these resources, individuals can enhance their knowledge and improve maintenance practices.

Exploring these visuals not only clarifies the arrangement of parts but also facilitates troubleshooting and repairs. Each illustration provides a roadmap, guiding users through the assembly and disassembly processes with confidence. Whether for routine checks or extensive overhauls, these visual aids prove invaluable.

Additionally, a comprehensive visual guide can highlight common wear points, enabling proactive measures to extend the lifespan of equipment. With a detailed understanding gained from these diagrams, users can tackle repairs with precision, ensuring optimal performance.

Benefits of Using Original Parts

Utilizing authentic components for your equipment offers a multitude of advantages that contribute to the overall performance and longevity of the machine. These genuine items are designed specifically to meet the exact specifications required for optimal functioning, ensuring a seamless fit and reliable operation.

One of the primary benefits is the assurance of quality. Original components undergo rigorous testing and quality control processes, guaranteeing durability and efficiency. This reliability minimizes the risk of unexpected breakdowns, saving time and money on repairs.

Moreover, using certified parts helps maintain the warranty of your equipment. Many manufacturers stipulate that the use of non-genuine items can void warranties, leaving you unprotected in case of future issues. Sticking to original components not only preserves your warranty but also supports the manufacturer’s commitment to excellence.

Additionally, authentic parts often come with the latest technological advancements and design improvements. This ensures that your machine benefits from the most recent innovations, enhancing its performance and making it more efficient in its operations.

Ultimately, investing in original components is a wise decision for anyone looking to maximize the lifespan and efficiency of their equipment, providing peace of mind and sustained performance over time.

Tips for Troubleshooting K760 Problems

When dealing with issues related to cutting equipment, it’s crucial to adopt a systematic approach to identify and resolve the underlying problems. Understanding common challenges and knowing how to address them can greatly enhance performance and extend the lifespan of your machinery. This section provides essential tips for diagnosing and fixing frequent malfunctions.

Common Issues and Solutions

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Difficulty Starting | Clogged fuel filter, spark plug issues | Check and replace the fuel filter; inspect the spark plug and clean or replace as necessary. |

| Unstable Operation | Improper fuel mixture, air filter blockage | Ensure correct fuel-to-oil ratio; clean or replace the air filter to ensure proper airflow. |

| Poor Cutting Performance | Dull blade, incorrect tension | Sharpen or replace the blade; adjust the tension as per manufacturer guidelines. |

| Excessive Vibration | Worn components, loose fittings | Inspect for wear and replace parts as needed; tighten all connections securely. |

Preventive Measures

To minimize the likelihood of encountering issues, regular maintenance is essential. Keep the equipment clean and well-lubricated, and conduct routine inspections to catch potential problems early. Additionally, always refer to the user manual for guidance on proper operation and care.