Comprehensive Guide to John Deere LX188 Parts Diagram

The efficient functioning of any lawn maintenance machinery relies heavily on its intricate assembly. Understanding how these elements fit together is crucial for both repair and maintenance. This exploration will provide insights into the structural layout and interrelation of various components, enhancing your ability to troubleshoot and optimize performance.

Each segment plays a vital role in ensuring the overall efficiency of the equipment. From the engine to the cutting mechanism, a comprehensive grasp of these units will empower users to perform necessary upkeep and replacements when required. Familiarity with the configuration allows for a smoother operation and prolonged lifespan of the machine.

In this guide, we will delve into the specifics of the component arrangement, providing clarity and aiding in the identification of potential issues. By familiarizing yourself with this intricate design, you can elevate your understanding and confidence in managing your lawn care tools effectively.

Understanding John Deere LX188 Parts

This section delves into the essential components of a popular riding mower model, highlighting the significance of each element in ensuring optimal performance. Knowing these elements not only aids in maintenance but also enhances the overall experience for operators.

Key Components and Their Functions

Each section of the mower plays a crucial role in its operation. The engine, for instance, is the powerhouse that drives the entire machine, while the transmission ensures smooth movement across various terrains. Other critical elements include the cutting deck, which determines the quality of the lawn finish, and the steering system, providing maneuverability and control.

Maintenance and Replacement

Regular upkeep of these essential elements is vital for longevity. Identifying wear and tear early can prevent more significant issues down the line. Operators should familiarize themselves with common signs of deterioration, such as unusual noises or reduced efficiency, allowing for timely replacements and repairs to keep the mower functioning at its best.

Overview of LX188 Lawn Tractor

The LX188 model represents a versatile and efficient solution for homeowners seeking to maintain their lawns and gardens. This machine combines power and maneuverability, making it ideal for a variety of tasks, from mowing to light towing. With user-friendly features, it caters to both novice and experienced users, ensuring a seamless experience in lawn care.

Key Features

Designed with attention to detail, this tractor offers a range of attributes that enhance its performance and reliability. From its robust engine to the comfortable seating arrangement, each element contributes to a superior mowing experience.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a powerful engine for efficient cutting and hauling. |

| Mowing Deck | Durable mowing deck designed for precision cutting and easy maintenance. |

| Comfort | Ergonomically designed seat for prolonged comfort during use. |

| Maneuverability | Compact design allows for easy navigation around obstacles in the yard. |

Maintenance and Care

Proper maintenance is essential to ensure longevity and optimal performance. Regular checks on the engine, blades, and other components will help keep the machine in excellent condition. Users are encouraged to refer to the maintenance guidelines provided by the manufacturer for detailed instructions.

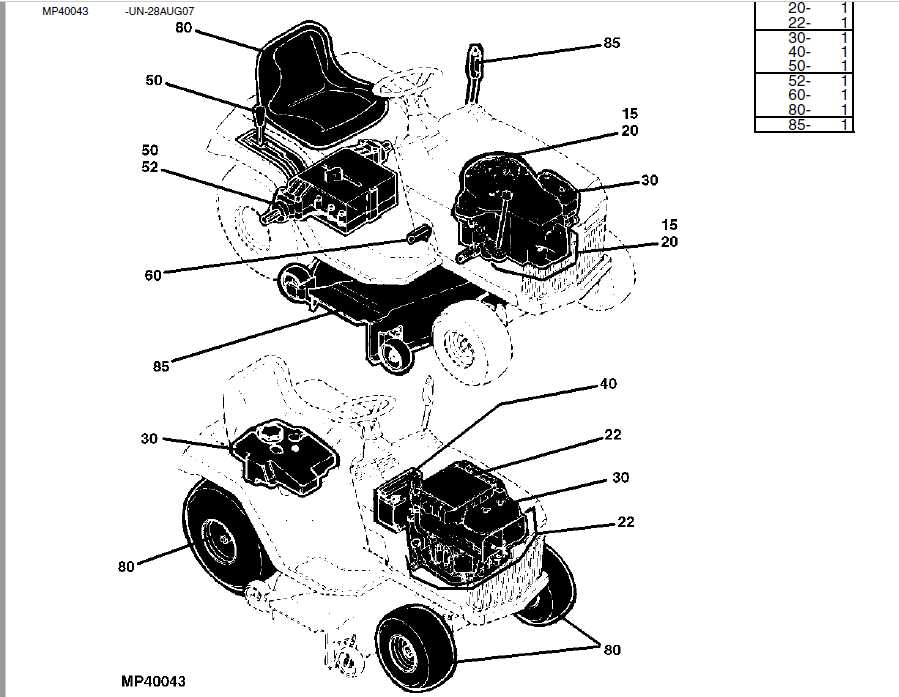

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations of individual elements not only facilitate a clearer grasp of the equipment’s structure but also streamline the troubleshooting process. This clarity ensures that users can easily identify specific components when issues arise or when replacements are needed.

Enhancing Efficiency

- Quick identification of components

- Reduced time in locating specific parts

- Improved accuracy in repairs and maintenance

Facilitating Learning

- Visual aids enhance understanding of machinery functions

- Support training for new operators and technicians

- Encourage better problem-solving skills

Utilizing these visual resources ultimately leads to improved performance and longevity of the equipment, making them invaluable tools in any maintenance toolkit.

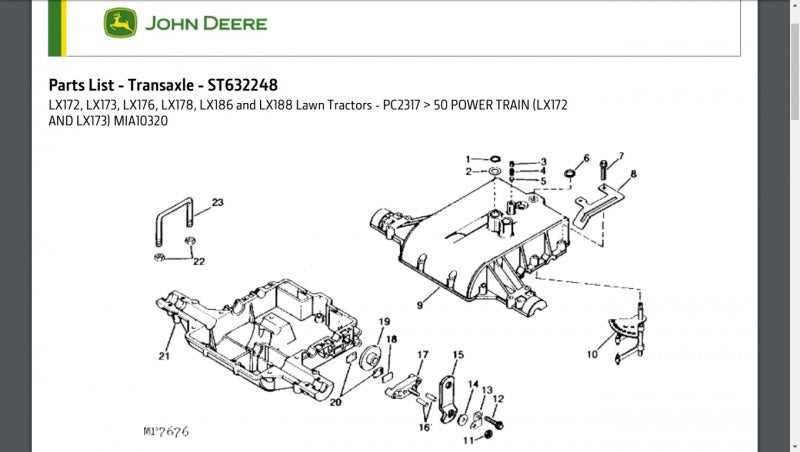

Key Components of LX188

The success of any lawn maintenance equipment relies heavily on its essential elements. Understanding these critical parts can enhance performance, longevity, and overall user satisfaction. Each component plays a unique role, contributing to the efficient functioning of the machine.

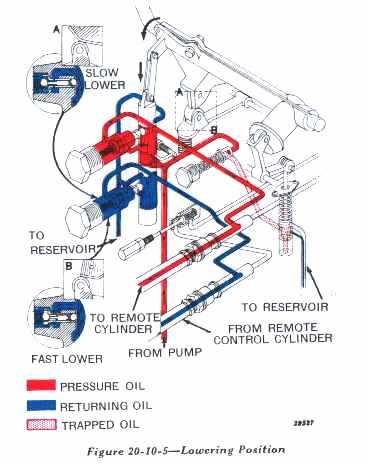

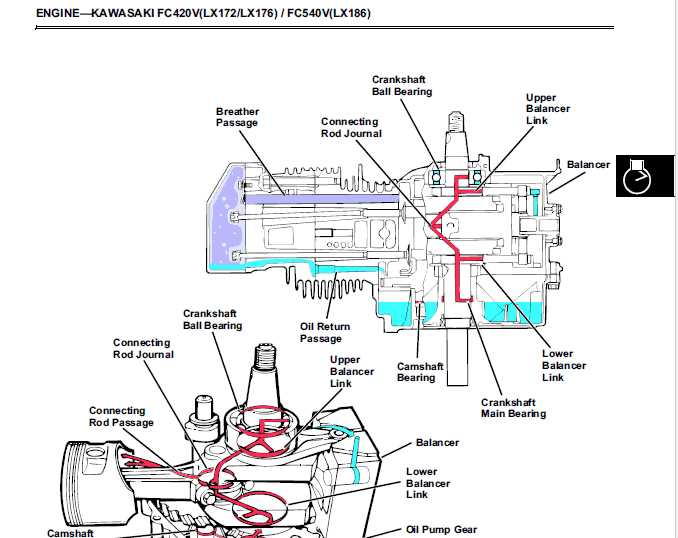

The engine serves as the powerhouse, providing the necessary energy for operation. Coupled with the transmission system, it ensures smooth power delivery to the wheels, allowing for effortless navigation across various terrains. Additionally, the cutting deck is vital for achieving a precise and clean cut, with adjustable heights for different grass types and conditions.

The steering mechanism offers ease of control, allowing operators to maneuver with precision. Moreover, the battery and electrical system are crucial for starting and powering various features, ensuring reliable operation at all times. Maintenance parts, such as filters and belts, are essential for keeping the machine in optimal working condition, ultimately extending its lifespan.

By familiarizing oneself with these integral components, users can make informed decisions regarding repairs and upgrades, enhancing the overall performance and durability of their equipment.

Locating Replacement Parts Online

Finding the right components for machinery can be a daunting task, especially when seeking reliable sources. The internet offers a vast array of options, making it easier to locate what you need without leaving your home. Understanding how to navigate these resources efficiently is key to a successful search.

Here are some effective strategies to help you in your quest:

- Search Engines: Utilize major search engines by entering specific queries that include the type of item you need.

- Manufacturer Websites: Visit the official websites of the manufacturers, as they often have dedicated sections for replacements.

- Online Marketplaces: Explore platforms that specialize in selling a variety of components, often at competitive prices.

- Forums and Communities: Join online forums or social media groups where enthusiasts share their insights and recommendations.

When searching, ensure you have details about the specifications and model numbers. This information will aid in pinpointing the exact items needed for your equipment.

Additionally, consider comparing prices and checking reviews to ensure you choose a reputable seller. With these tips, you can simplify the process of sourcing quality replacements online.

Common Issues with LX188 Parts

When dealing with outdoor machinery, certain components may encounter frequent challenges that can affect overall performance. Understanding these issues is crucial for maintaining efficiency and prolonging the lifespan of your equipment. Identifying common problems can lead to timely interventions and reduce the likelihood of extensive repairs.

Frequent Mechanical Failures

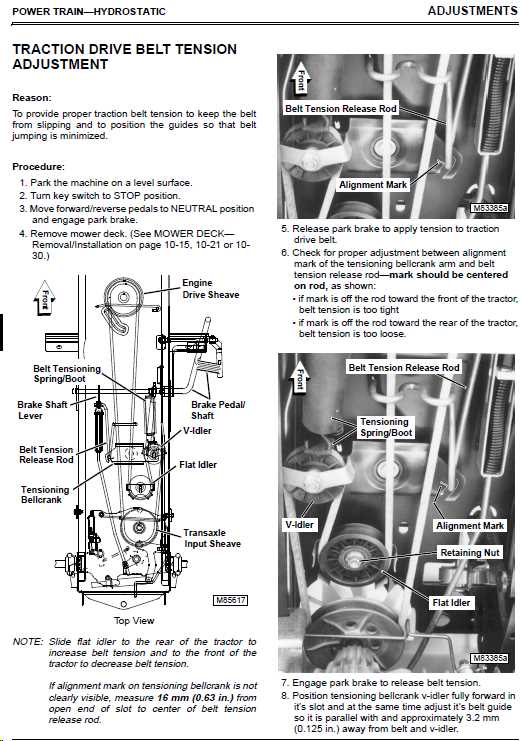

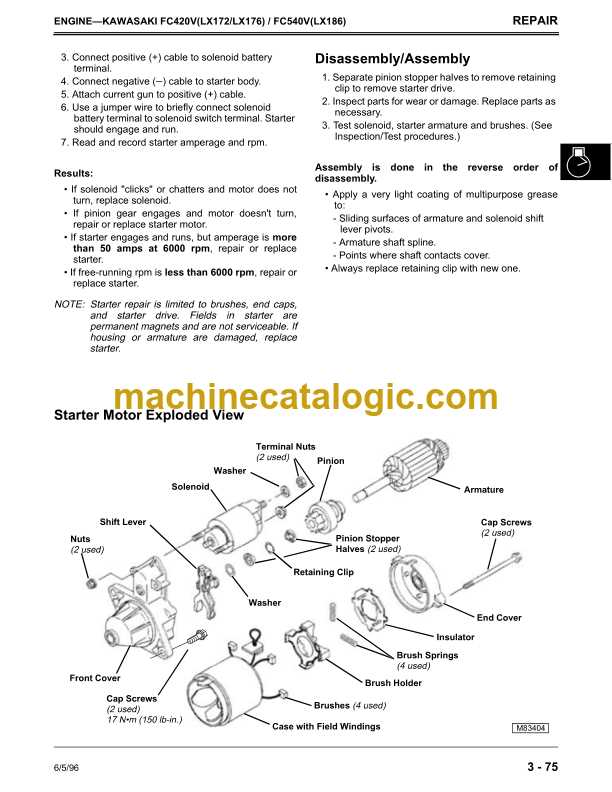

One prevalent concern is mechanical failure, which can stem from wear and tear over time. Components such as belts and gears may degrade, leading to decreased functionality. Regular inspection and maintenance can help in identifying these issues early, ensuring smooth operation.

Electrical System Troubles

Electrical malfunctions are another common problem area. Wiring issues, faulty connections, or battery failures can disrupt the performance of machinery. It is advisable to routinely check the electrical components to prevent unexpected breakdowns and ensure reliable operation.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your outdoor machinery. By following a systematic approach, you can keep your equipment running smoothly and efficiently. This guide outlines essential maintenance tasks to help you stay on top of your machinery care.

-

Inspect the Engine:

- Check for leaks and any signs of wear.

- Ensure the air filter is clean and free of debris.

- Replace the spark plug if it appears worn or dirty.

-

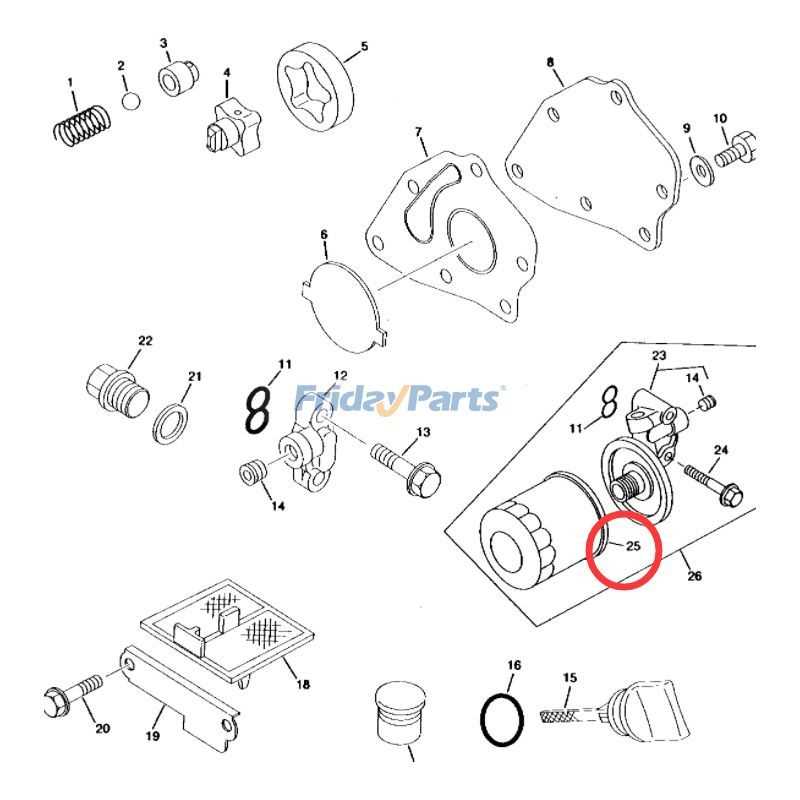

Change the Oil:

- Locate the oil drain plug and allow the old oil to fully drain.

- Replace the oil filter if applicable.

- Refill with fresh oil according to the manufacturer’s specifications.

-

Examine the Fuel System:

- Check the fuel lines for cracks or leaks.

- Replace old fuel with fresh gasoline if necessary.

- Inspect the fuel filter and replace it if it’s clogged.

-

Maintain the Blades:

- Remove the blades and inspect for damage.

- Sharpen or replace the blades as needed.

- Ensure the blades are properly balanced when reinstalled.

-

Check the Tires:

- Inspect the tires for wear and proper inflation.

- Rotate the tires if uneven wear is noted.

- Replace any damaged or punctured tires immediately.

-

Clean the Exterior:

- Remove any grass clippings and debris from the chassis.

- Use a brush or hose to clean the engine compartment.

- Inspect for any corrosion or rust and treat as necessary.

Following these steps regularly will help maintain your equipment’s efficiency and performance. Always refer to the specific manual for your model for any unique requirements or recommendations.

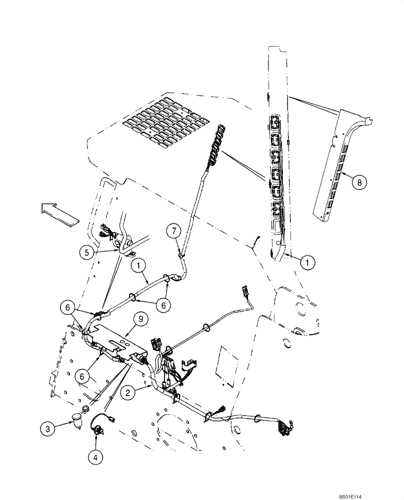

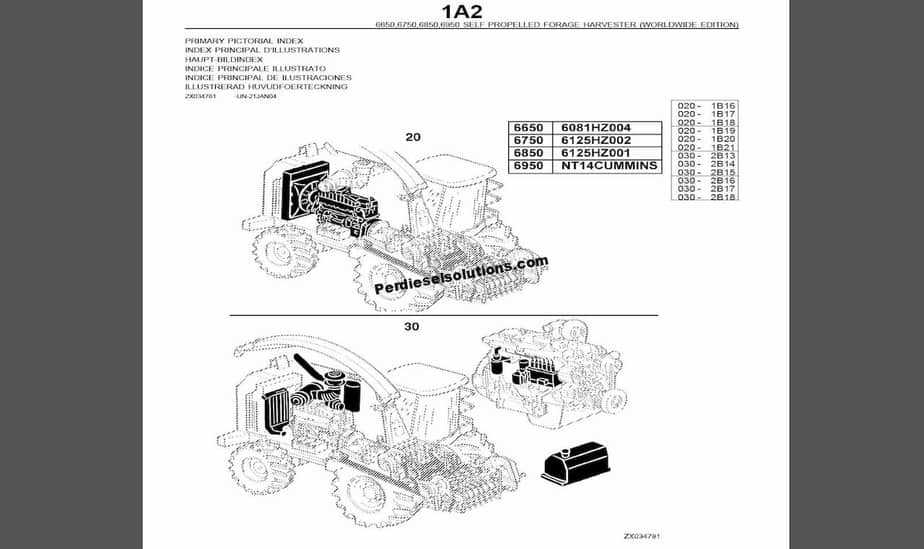

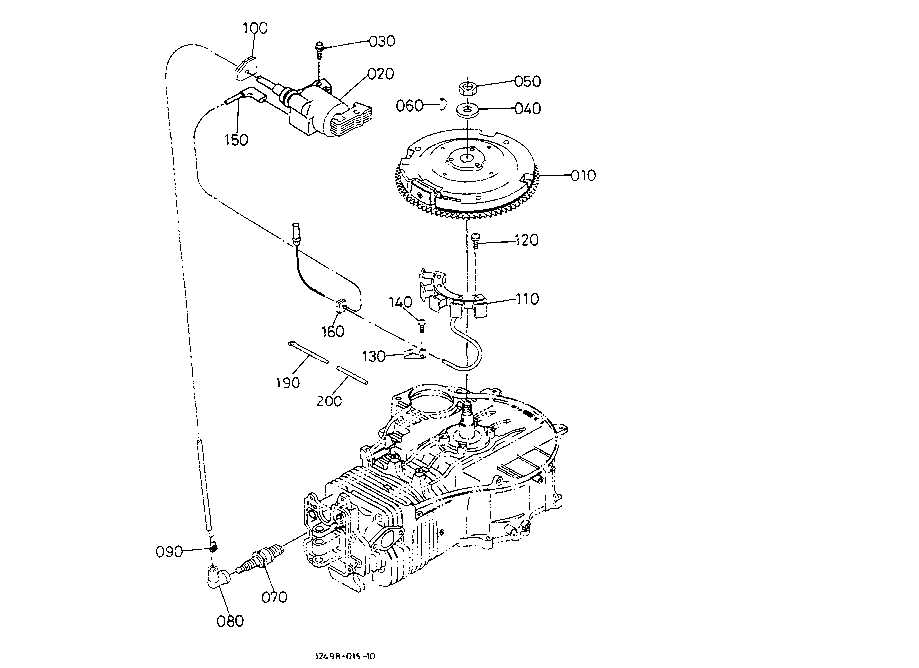

How to Read Parts Diagrams

Understanding schematics is essential for anyone looking to maintain or repair machinery effectively. These visual representations provide a clear overview of the components involved, allowing users to identify each part’s location and function within the overall system. Familiarity with these illustrations can save time and reduce frustration during maintenance tasks.

To interpret these visual guides, start by examining the legend or key, which explains symbols and notations used throughout the illustration. Next, look for a breakdown of each component, often numbered or labeled, to understand its specific role. Pay attention to the arrangement and connections between elements, as these details reveal how the system operates as a whole.

Additionally, note the orientation and scale of the illustration, as this can impact your understanding of the layout. Cross-referencing with written descriptions can enhance comprehension, providing context that might not be immediately apparent from the visual alone. By mastering these skills, you can efficiently navigate the complexities of machinery and ensure proper maintenance.

Ordering Parts from Authorized Dealers

When it comes to acquiring components for your equipment, sourcing them from certified vendors ensures quality and compatibility. These dealers provide a range of original items, guaranteeing that your machinery operates at its best. Additionally, they often have access to specific manuals and resources that aid in the selection process.

It is essential to follow a few steps when placing an order with these authorized distributors:

| Step | Description |

|---|---|

| 1 | Identify the exact component you need, referencing your equipment’s manual for specifications. |

| 2 | Contact the dealer either through their website or by phone to check the availability of the item. |

| 3 | Provide any necessary details such as model number and year of manufacture to ensure accuracy. |

| 4 | Review pricing and shipping options before finalizing your order. |

| 5 | Complete the purchase and keep a record of your transaction for future reference. |

By following these steps, you can be confident that the components you receive will meet your expectations and enhance the performance of your machinery.

DIY Repairs for LX188 Owners

For owners of this popular lawn care machine, performing your own maintenance and repairs can be a rewarding experience. Not only does it save money, but it also allows you to gain a deeper understanding of your equipment. With the right tools and knowledge, many issues can be resolved without the need for professional assistance.

Identifying Common Issues

Common problems include issues with the engine, electrical system, and cutting deck. Understanding the typical signs of wear and tear can help you address these concerns promptly. Regularly checking for leaks, strange noises, or irregular performance can prevent more significant problems down the line.

Essential Tools for Repair

Equipping yourself with basic tools is crucial for tackling repairs. A quality socket set, wrenches, and screwdrivers are fundamental. Additionally, having a multimeter on hand can help diagnose electrical issues effectively.

Maintenance Tips

Regular upkeep is key to prolonging the life of your machine. Cleaning the air filter, changing the oil, and sharpening the blades are simple tasks that can enhance performance. Consulting the owner’s manual for specific maintenance schedules will ensure you keep everything in top shape.

Resources for Assistance

If you encounter challenges, numerous online forums and video tutorials provide guidance. Engaging with fellow owners can also lead to valuable tips and tricks. Sharing experiences fosters a sense of community and supports collective learning.

By taking initiative with repairs and maintenance, you can keep your equipment running smoothly for years to come, ensuring your outdoor spaces remain pristine.

Tools Needed for Maintenance

Proper upkeep of equipment requires specific instruments to ensure efficiency and longevity. Having the right tools on hand not only facilitates repairs but also enhances the overall performance of the machinery. Regular maintenance can prevent costly breakdowns, making it essential to be equipped with appropriate devices.

Essential Hand Tools

Basic hand tools are vital for routine inspections and minor repairs. Wrenches, screwdrivers, and pliers are fundamental for adjusting components and tightening connections. Additionally, having a quality set of sockets allows for easier access to bolts in tight spaces, promoting effective maintenance practices.

Specialized Equipment

In some cases, specialized tools may be necessary for more intricate tasks. Diagnostic equipment can help identify issues that are not immediately visible. Lubrication devices ensure all moving parts are adequately maintained, preventing wear and tear. Investing in these specialized instruments can save time and enhance the reliability of the machinery.

Frequently Asked Questions About LX188

This section addresses common inquiries related to a popular model in the lawn care equipment sector. Users often seek clarity on maintenance, performance, and compatibility aspects to ensure optimal functionality and longevity.

What are the common maintenance tasks for this model?

How can I improve the performance of my lawn mower?

What should I do if my machine won’t start?

Are there recommended upgrades or modifications?

Where can I find replacement components?