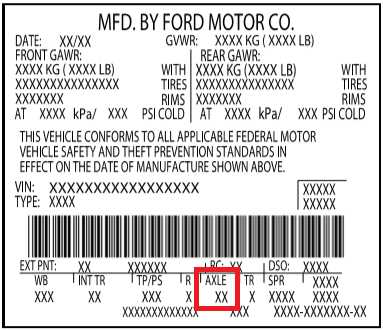

Exploring the Front Axle Parts Diagram of the 2003 Ford F250

In the world of robust transportation, the intricate system that supports the weight and stability of large vehicles plays a critical role. Knowledge of the individual elements that contribute to this framework is essential for both maintenance and repair. Each component has its specific function, ensuring optimal performance under various conditions.

Exploring the layout of these mechanical assemblies can provide valuable insights into their operation. A clear visualization helps in identifying how each segment interacts with others, which is crucial for diagnosing issues or planning upgrades. Grasping the arrangement of these elements can enhance understanding of the overall structure.

Moreover, familiarity with the configuration of these components empowers owners and technicians alike. By recognizing how the system is organized, one can approach troubleshooting with confidence. Whether undertaking routine checks or addressing specific problems, a comprehensive understanding is invaluable.

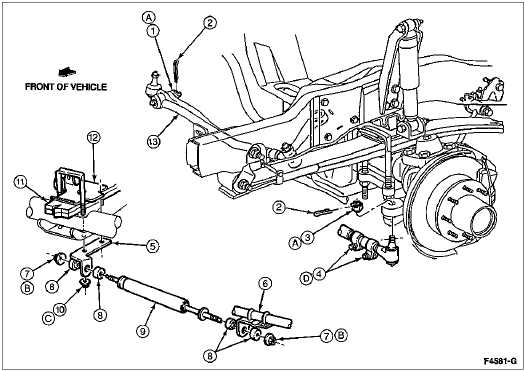

Understanding the 2003 Ford F250 Axle

The foundation of any heavy-duty vehicle’s performance lies in its structural components. One crucial element that ensures stability and maneuverability is the assembly responsible for transferring power from the engine to the wheels. This segment encompasses various components that work in harmony to deliver an optimal driving experience.

Key Components

- Housing: The main structure that encases and protects the internal mechanisms.

- Bearings: Essential for smooth rotation, reducing friction between moving parts.

- Driveshaft: Transfers power from the transmission to the wheels, facilitating movement.

- Differential: Distributes torque to the wheels, allowing them to turn at different speeds during cornering.

- U-Joints: Connect various shafts, accommodating movement and flex while transmitting power.

Maintenance Tips

- Regularly inspect all components for wear and tear.

- Check fluid levels to ensure proper lubrication.

- Listen for unusual noises during operation, as they may indicate issues.

- Consult the vehicle’s manual for specific maintenance schedules.

By understanding the intricacies of this essential assembly, owners can ensure better performance and longevity of their vehicle.

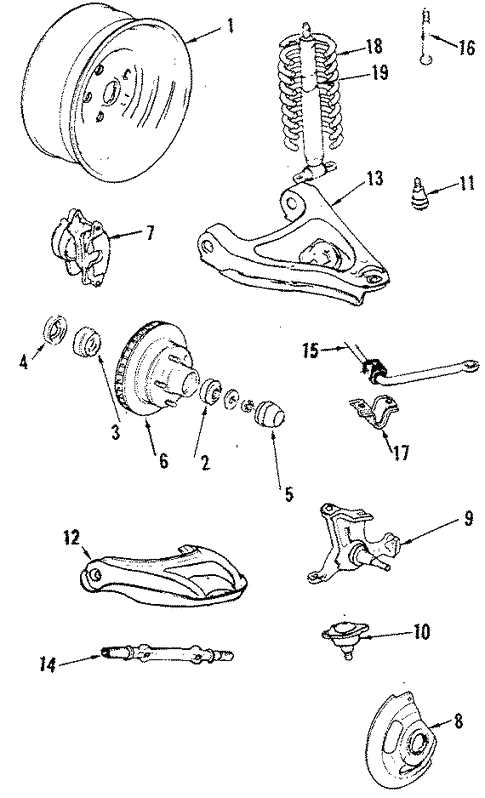

Key Components of the Front Axle

The front suspension system is crucial for vehicle stability and handling. Understanding its main elements can enhance maintenance and performance. Each component plays a vital role in ensuring smooth operation and safety on the road.

Essential Elements

- Hub Assembly: Connects the wheel to the suspension and allows it to rotate freely.

- Spindle: Acts as a pivot point for the wheel, supporting the weight of the vehicle.

- Control Arms: Facilitate vertical movement and help maintain wheel alignment.

- Ball Joints: Serve as flexible joints allowing for movement between the control arms and spindle.

- Steering Knuckle: Connects the wheel assembly to the suspension and allows steering input to be transmitted.

Additional Components

- Anti-roll Bar: Helps reduce body roll during turns, improving stability.

- Shock Absorbers: Dampen the effects of bumps and provide a smoother ride.

- Brake Calipers: Apply pressure to brake pads, enabling effective stopping power.

- Wheel Bearings: Allow for smooth wheel rotation while supporting vehicle weight.

Each of these components is essential for maintaining optimal performance and safety in the suspension system, highlighting the importance of regular inspections and timely replacements.

Common Issues with F250 Axles

When it comes to heavy-duty vehicles, the integrity of the wheel support mechanisms plays a crucial role in performance and safety. Various problems can arise within these systems, affecting the overall functionality and reliability. Understanding these common challenges can help owners address them promptly, ensuring a smoother driving experience.

Frequent Problems

- Worn Bearings: Bearings are essential for smooth rotation. Over time, they can wear out, leading to noise and handling issues.

- Leaking Seals: Seals prevent contaminants from entering and lubricants from escaping. A breach can cause lubrication failure and subsequent damage.

- Misalignment: If the components are not properly aligned, it can lead to uneven tire wear and decreased stability.

- Rust and Corrosion: Exposure to moisture and road salt can cause metal parts to deteriorate, compromising their strength.

- CV Joint Failure: Constant velocity joints are crucial for transferring torque. Damage to these joints can result in vibration and loss of power.

Preventative Measures

- Regular Inspections: Routine checks can help identify issues before they escalate.

- Proper Maintenance: Keeping the system lubricated and replacing worn components timely is vital.

- Environment Awareness: Taking care to wash the undercarriage can minimize rust development.

- Quality Replacement Parts: Investing in high-quality components can enhance durability and performance.

Benefits of Upgrading Axle Parts

Enhancing the critical components of a vehicle’s suspension system can yield significant advantages for performance and safety. By investing in improved components, drivers can experience enhanced handling, increased durability, and greater overall efficiency, which are essential for optimal vehicle operation.

Improved Performance

Upgrading these vital elements can lead to noticeable improvements in vehicle responsiveness and stability. Enhanced components often offer better torque distribution and power transfer, allowing for smoother acceleration and more precise maneuverability. This translates into a more enjoyable driving experience, whether on rugged terrain or smooth highways.

Increased Longevity

Investing in high-quality replacements can extend the lifespan of a vehicle’s suspension system. Premium materials and superior engineering provide enhanced resistance to wear and tear, reducing the frequency of repairs and replacements. This not only saves money in the long run but also contributes to a safer and more reliable vehicle.

Tools Needed for Front Axle Repair

When it comes to maintaining and fixing the crucial components of a vehicle’s steering system, having the right tools is essential. Proper equipment not only facilitates efficient repairs but also ensures safety during the process. Below is a comprehensive list of necessary instruments for effective repairs.

Essential Tools

- Socket set

- Wrenches (metric and standard)

- Screwdrivers (flathead and Phillips)

- Torque wrench

- Pry bar

- Jack and jack stands

- Brake cleaner

- Grease and lubricant

Specialized Equipment

- Ball joint separator

- Spring compressor

- Alignment tools

- Hydraulic press

- Impact wrench

- Measuring tools (caliper and ruler)

Utilizing the right tools not only simplifies the repair process but also contributes to the longevity and performance of the vehicle. Always ensure that tools are in good condition and suitable for the specific tasks at hand.

Step-by-Step Axle Assembly Guide

Assembling a crucial component of your vehicle’s drivetrain requires attention to detail and a systematic approach. This guide will walk you through the essential steps to successfully put together the elements that enable smooth handling and performance. Following these instructions will help ensure that your assembly is both efficient and effective.

Step 1: Gather Your Tools and Components

Before you begin, make sure you have all necessary tools, including wrenches, sockets, and a torque wrench. Collect all the individual pieces that will be part of the assembly to avoid interruptions during the process.

Step 2: Prepare the Workspace

Set up a clean and organized workspace. A well-lit area with sufficient room to maneuver will facilitate the assembly process. Lay out all components neatly, ensuring easy access.

Step 3: Start with the Main Housing

Begin by securing the main housing in place. Ensure that it is stable and free from any debris. This will be the foundation for the subsequent components.

Step 4: Install the Bearings

Carefully position the bearings into their respective seats. Apply the appropriate lubricant to ensure smooth operation. Double-check that they are seated correctly to avoid premature wear.

Step 5: Attach the Spindles

Next, align the spindles with the housing and insert them. Tighten the fasteners to the manufacturer’s specified torque settings, ensuring that all connections are secure.

Step 6: Connect the Drive Shafts

Now, attach the drive shafts to the assembly. Verify that they are aligned properly to prevent any misalignment during operation. Fasten them securely using the correct tools.

Step 7: Final Checks

After assembling all components, perform a thorough inspection. Ensure that all fasteners are tightened to the recommended specifications and that there are no loose parts. A final check will prevent issues down the line.

Step 8: Reinstall and Test

Finally, reinstall the assembled unit back into the vehicle. After everything is secured, conduct a test to verify functionality. Pay attention to any unusual noises or vibrations that may indicate an issue.

Preventive Maintenance Tips for Axles

Regular upkeep of your vehicle’s foundational components is crucial for ensuring optimal performance and longevity. Implementing effective strategies can significantly reduce the risk of breakdowns and costly repairs. Understanding key maintenance practices will help in preserving the integrity of these essential parts.

1. Regular Inspections: Conduct routine checks to identify wear and tear. Look for signs of damage such as cracks, leaks, or unusual noises during operation. Early detection can prevent serious issues.

2. Lubrication: Ensure that all moving components are adequately lubricated. This minimizes friction and helps maintain smooth operation. Use the recommended type of lubricant for your vehicle.

3. Proper Alignment: Regularly check the alignment of your vehicle. Misalignment can lead to uneven wear and affect handling. Correcting alignment issues promptly can enhance safety and performance.

4. Monitor Fluid Levels: Keep an eye on essential fluids, including lubricants and seals. Low levels can lead to increased friction and potential damage. Regularly topping up fluids is a simple yet effective maintenance step.

5. Tire Maintenance: Maintain appropriate tire pressure and tread depth. Tires play a crucial role in the overall performance and can impact the condition of surrounding components. Rotate and balance tires as recommended.

6. Drive with Care: Adopt smooth driving habits to reduce stress on vehicle components. Avoid sudden acceleration and braking, which can lead to premature wear.

By incorporating these proactive measures into your routine, you can enhance the reliability of your vehicle and ensure its performance remains at peak levels.

Identifying Wear and Tear Signs

Recognizing signs of degradation in essential vehicle components is crucial for maintaining optimal performance and safety. Regular inspection can help identify issues before they escalate into more significant problems, ensuring longevity and reliability.

Common indicators of wear may include:

- Unusual Noises: Clunking, grinding, or squeaking sounds when turning or driving can signal impending issues.

- Vibration: Excessive shaking or vibrations during operation may indicate misalignment or imbalance.

- Fluid Leaks: Any signs of leaking fluids underneath the vehicle warrant immediate attention, as they can lead to more severe complications.

- Increased Play: Excessive movement in the steering or suspension can indicate worn components that need replacement.

When examining critical components, look for the following specific signs:

- Cracks or Fractures: Inspect for visible cracks or breaks in metal parts.

- Corrosion: Rust or corrosion can compromise the integrity of components and should be treated promptly.

- Uneven Wear: Check for uneven wear patterns on tires or other related parts, which may suggest alignment issues.

- Reduced Responsiveness: Noticeable delay or lack of responsiveness in steering may indicate deteriorating parts.

Regular maintenance and awareness of these signs can significantly enhance the reliability and safety of your vehicle.

Comparing OEM and Aftermarket Parts

When it comes to vehicle maintenance and repairs, the choice between original equipment manufacturer components and alternative options is crucial. Each type has its own set of advantages and potential drawbacks, influencing performance, cost, and longevity. Understanding these differences can help vehicle owners make informed decisions that best suit their needs.

Advantages of OEM Components

Original equipment manufacturer components are designed to meet the exact specifications of the vehicle. They often provide a perfect fit and reliable performance, ensuring compatibility and adherence to manufacturer standards. This reliability can result in longer lifespan and less frequent replacements, making them an appealing choice for many drivers who prioritize quality and peace of mind.

Benefits of Aftermarket Alternatives

Aftermarket alternatives can offer significant cost savings and a wider variety of options. These components may enhance performance or add features that are not available with original parts. Additionally, some aftermarket manufacturers focus on improving durability or efficiency, appealing to enthusiasts and those seeking to customize their vehicles. However, it’s essential to carefully evaluate the reputation of the manufacturer to ensure reliability.

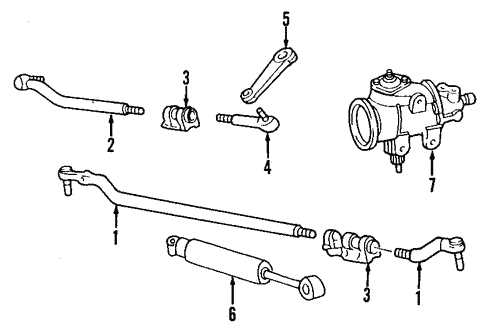

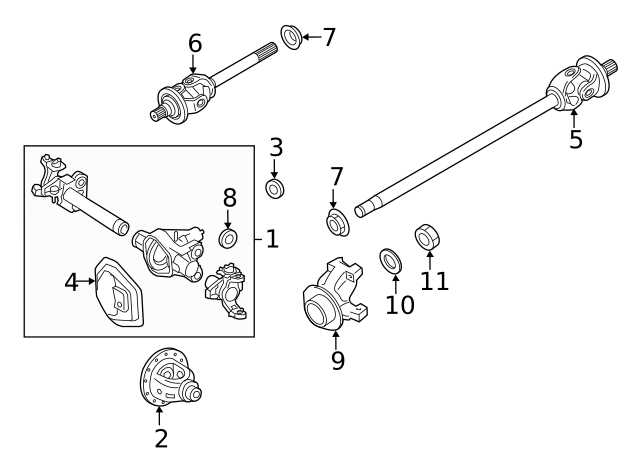

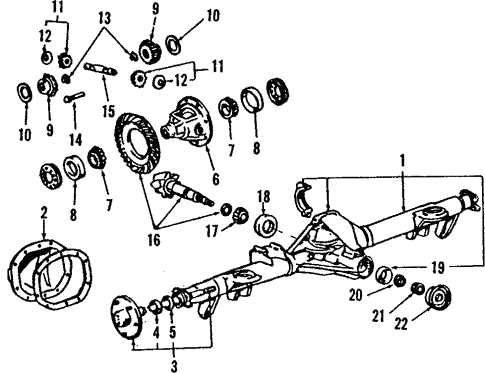

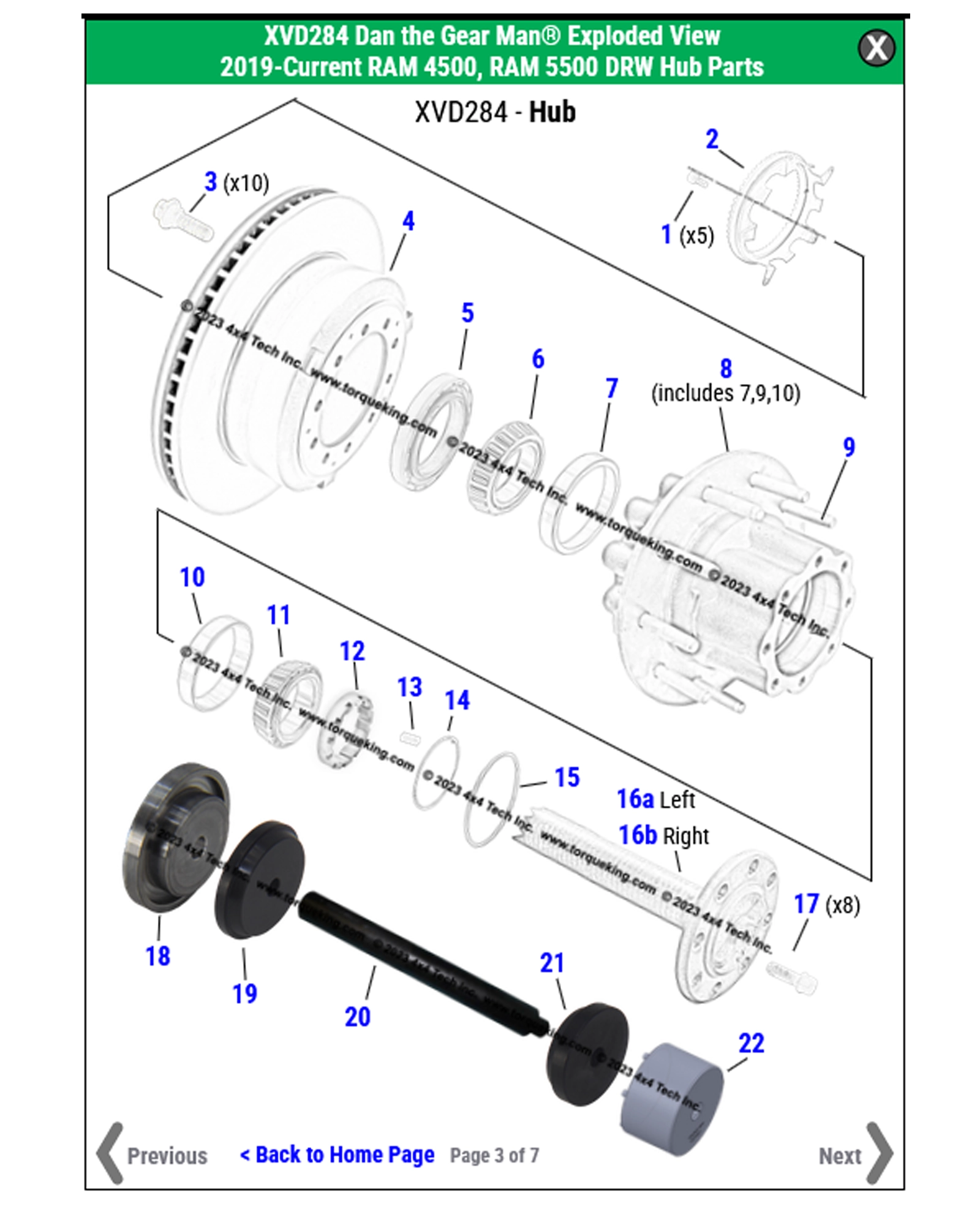

Diagram Analysis: Understanding Layout

Analyzing a technical illustration requires a keen eye for detail and an understanding of the components involved. A well-structured visual representation provides clarity on the arrangement and function of various elements. By breaking down the components and their relationships, one can gain insights into how the entire system operates.

Component Breakdown

Each section of the illustration represents a unique element, often labeled for easy identification. Recognizing these parts allows for a better comprehension of their roles and interactions. By examining the connections between these sections, one can identify critical areas that influence performance and maintenance requirements.

Spatial Relationships

The layout not only depicts individual components but also highlights their spatial relationships. Understanding how elements are positioned relative to one another can reveal potential issues, such as clearance problems or misalignments. This spatial awareness is essential for effective troubleshooting and optimizing performance.

Where to Buy Replacement Parts

Finding high-quality components for your vehicle can be a daunting task, but there are numerous options available to ensure you get the right items for your needs. Whether you prefer shopping online or visiting local stores, knowing where to look can save you time and money.

Online retailers often provide a vast selection, allowing you to compare prices and read reviews from other customers. Websites dedicated to automotive supplies typically feature user-friendly interfaces, making it easy to search for specific components. Additionally, many online platforms offer detailed specifications and compatibility information to help you make informed choices.

If you prefer a more hands-on approach, local auto parts stores can be a great resource. These establishments often have knowledgeable staff who can assist you in identifying the correct components and may even provide installation advice. Furthermore, many of these shops stock a variety of brands, allowing you to choose based on quality and price.

For those looking for specialized or hard-to-find items, salvage yards can be an excellent option. These locations often have a wide range of used components that are still in good condition, offering a cost-effective alternative to new parts. Just be sure to inspect any used items thoroughly before purchasing.

Whichever option you choose, it’s crucial to verify the quality and compatibility of the components with your vehicle to ensure optimal performance and longevity.