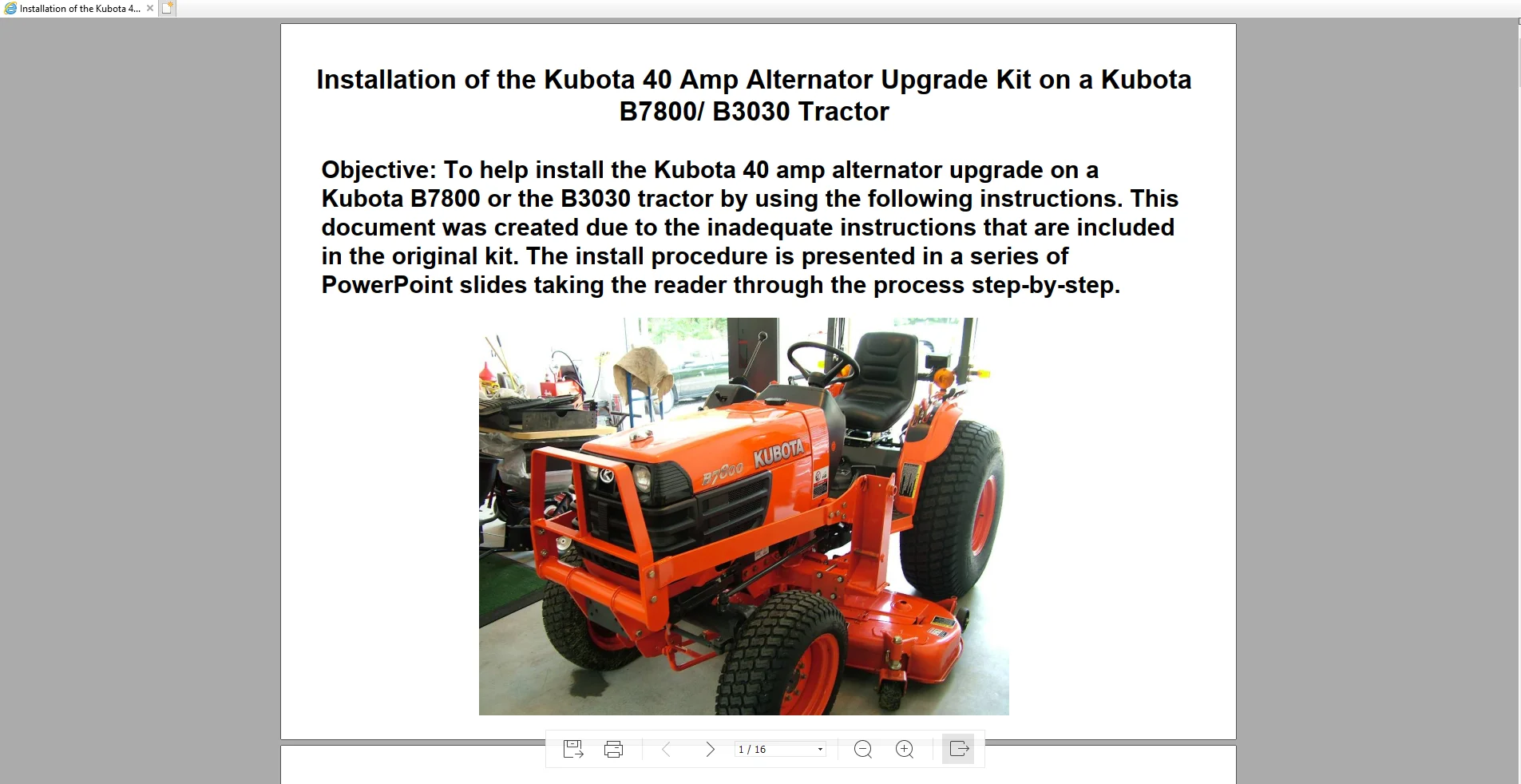

Kubota B20 Parts Diagram Overview

In the realm of mechanical engineering, visual representations of intricate systems serve as invaluable tools for both novices and experts alike. These illustrations not only simplify complex assemblies but also enhance comprehension of individual elements and their interactions within the whole structure.

When seeking to master the functionality and maintenance of a specific machine, having access to detailed schematics is essential. These guides illuminate the layout and relationships of various components, enabling users to identify essential features and troubleshoot effectively.

Ultimately, a thorough grasp of these representations empowers operators to optimize performance and ensure longevity. By delving into the specifics of each segment, one can appreciate the craftsmanship behind every piece, leading to more informed decisions and enhanced operational efficiency.

Kubota B20 Parts Overview

This section provides a comprehensive look at the components that make up a specific model of compact machinery. Understanding these elements is essential for effective maintenance and operation. Each part plays a crucial role in ensuring the equipment functions optimally and efficiently.

Among the various elements, the engine serves as the powerhouse, delivering the necessary energy for performance. Complementing this are the transmission and hydraulic systems, which facilitate movement and operation of attachments. The chassis and frame provide structural integrity, ensuring stability during use.

Additionally, the electrical system is vital for starting and running the machinery, while the control panel allows the operator to manage functions seamlessly. Each of these components is designed for durability and reliability, contributing to the overall effectiveness of the machine.

For those looking to service or upgrade their equipment, familiarizing oneself with the layout and function of these elements can lead to improved performance and longevity. Proper care and attention to each component can result in enhanced productivity and reduced downtime.

Understanding the Importance of Diagrams

Visual representations are essential tools that facilitate comprehension and communication. They help to clarify complex information and make it accessible to a broader audience.

Here are some key benefits of using these visual aids:

- Enhance understanding of intricate systems.

- Provide a quick reference for assembly and maintenance.

- Help identify components and their functions effectively.

- Reduce the likelihood of errors during repairs or installations.

- Facilitate training for new users or technicians.

In summary, these illustrations play a crucial role in ensuring efficiency and accuracy in various tasks, making them indispensable in technical fields.

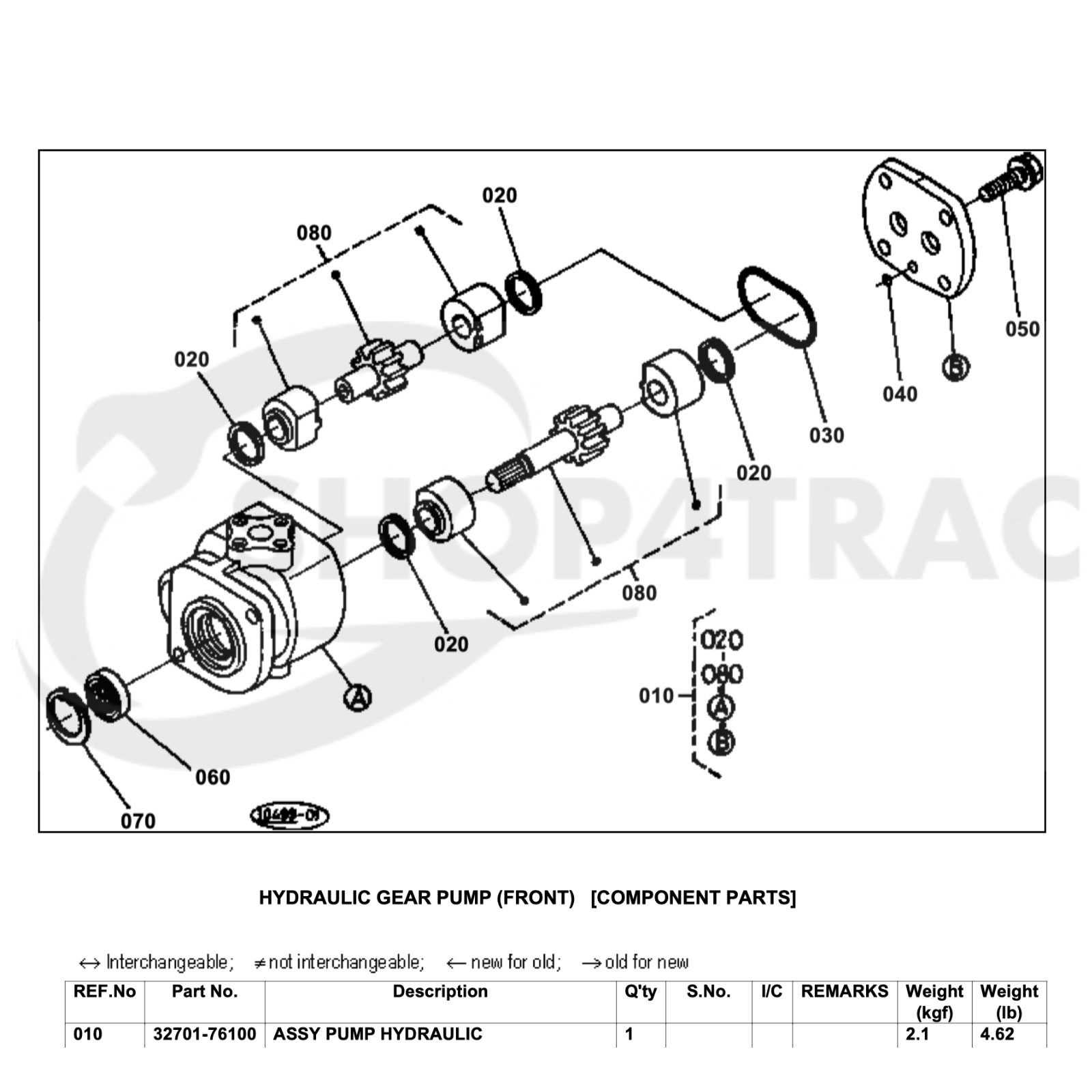

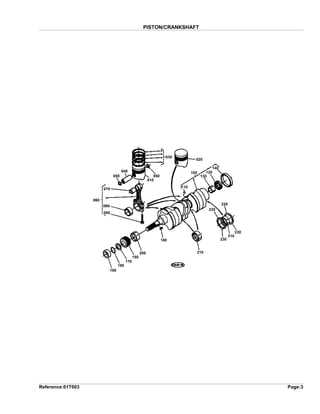

Key Components of the B20 Model

This section explores the essential elements of the machinery, highlighting their roles and significance in overall performance. Understanding these components is crucial for optimal maintenance and functionality.

| Component | Description |

|---|---|

| Engine | Powers the machine, ensuring reliable performance and efficiency. |

| Hydraulic System | Facilitates the movement of attachments and implements, providing versatility. |

| Transmission | Transfers power from the engine to the wheels, enabling smooth operation. |

| Chassis | Serves as the frame, supporting various components and ensuring stability. |

| Controls | Allows the operator to manage the machine effectively, enhancing usability. |

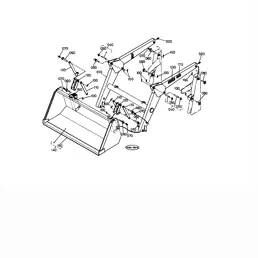

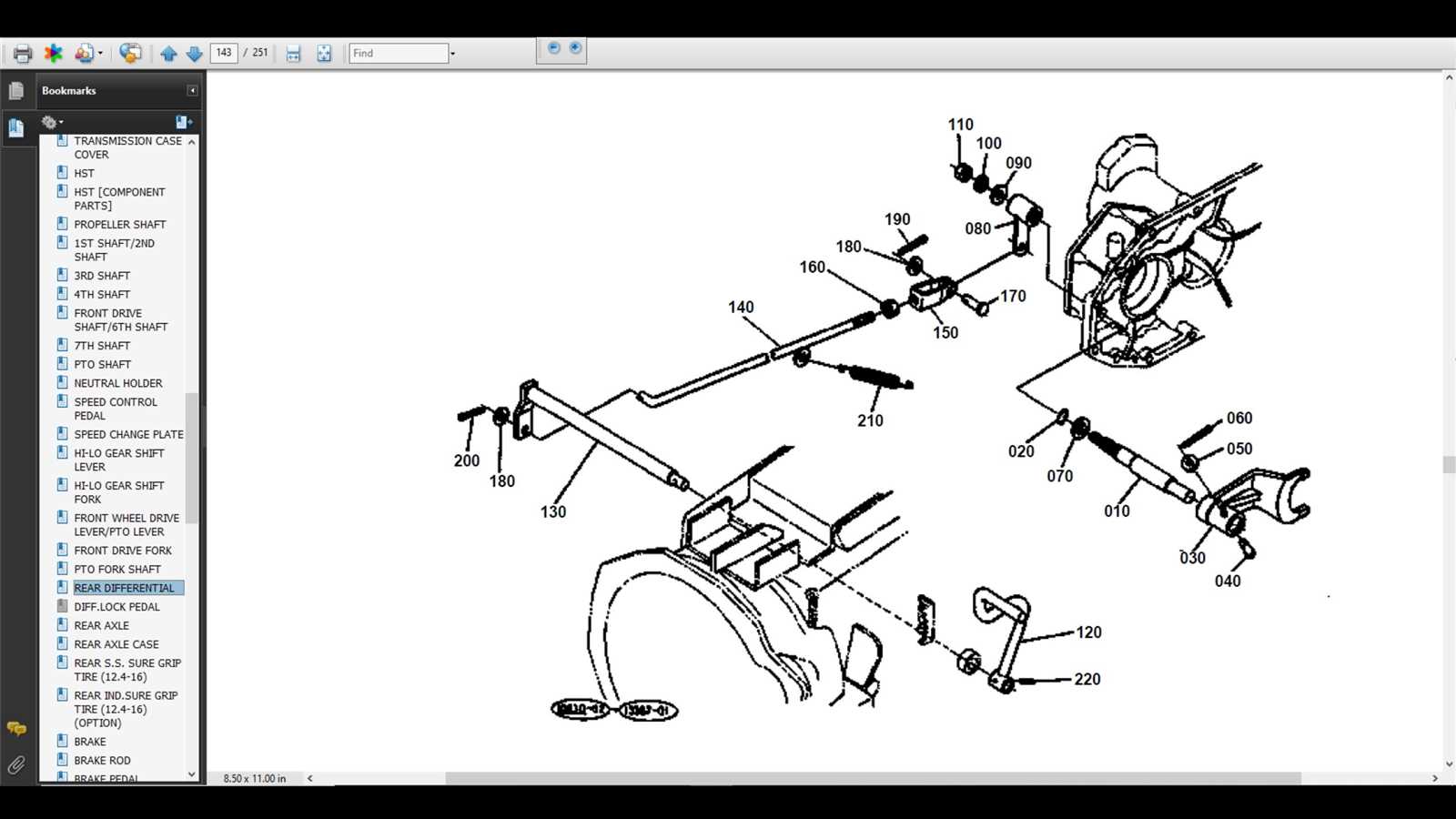

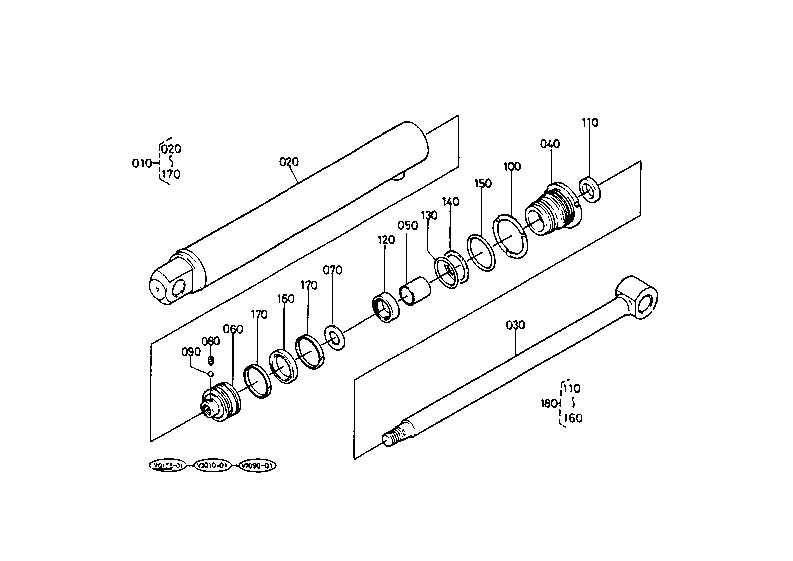

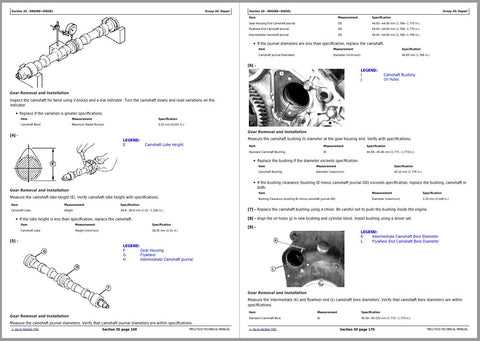

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone working with machinery. These visual representations provide crucial information about components, their arrangement, and functionality. Familiarizing yourself with the structure of these images can significantly enhance your maintenance and repair skills.

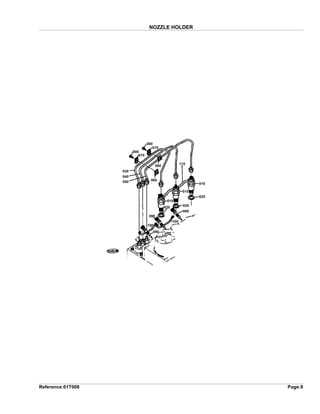

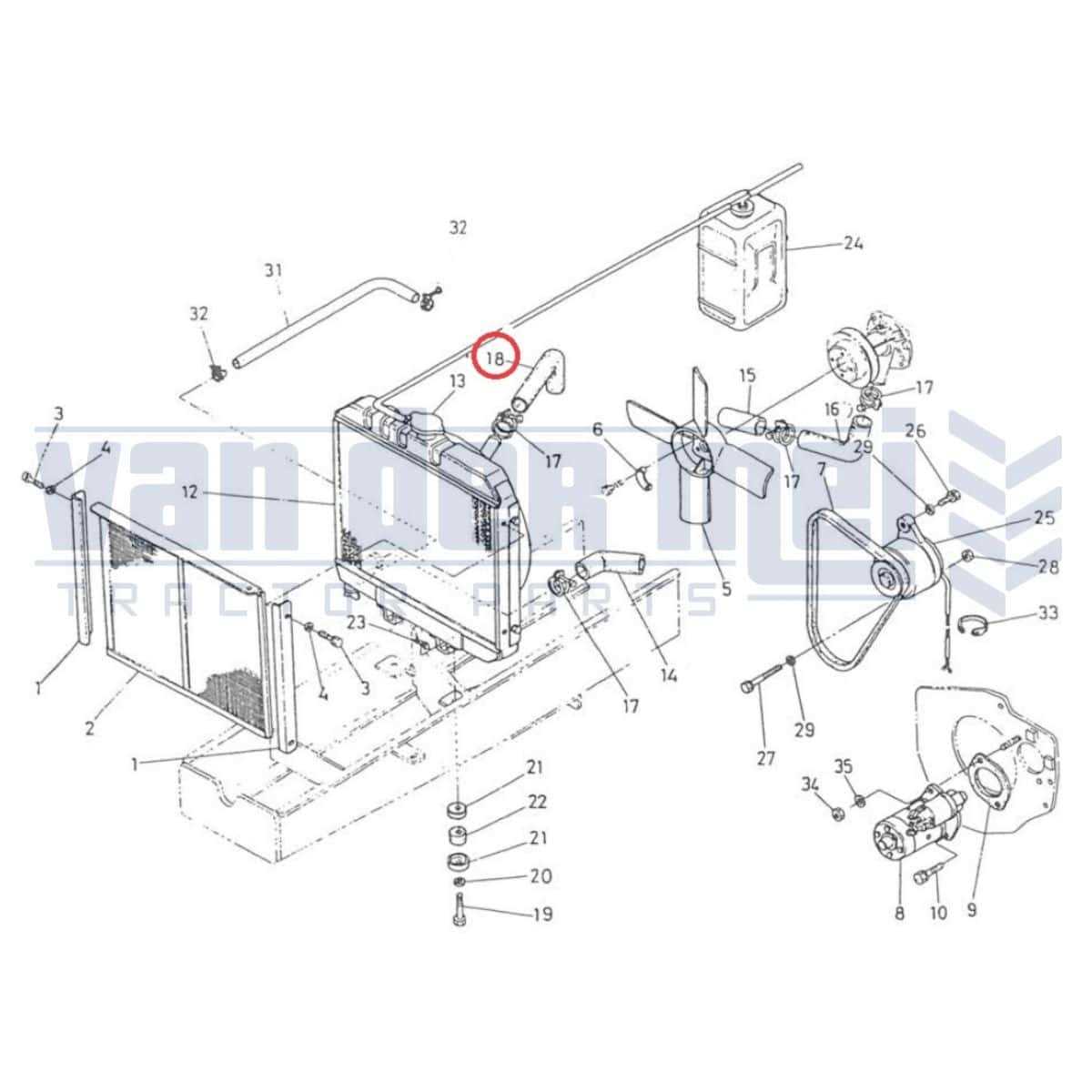

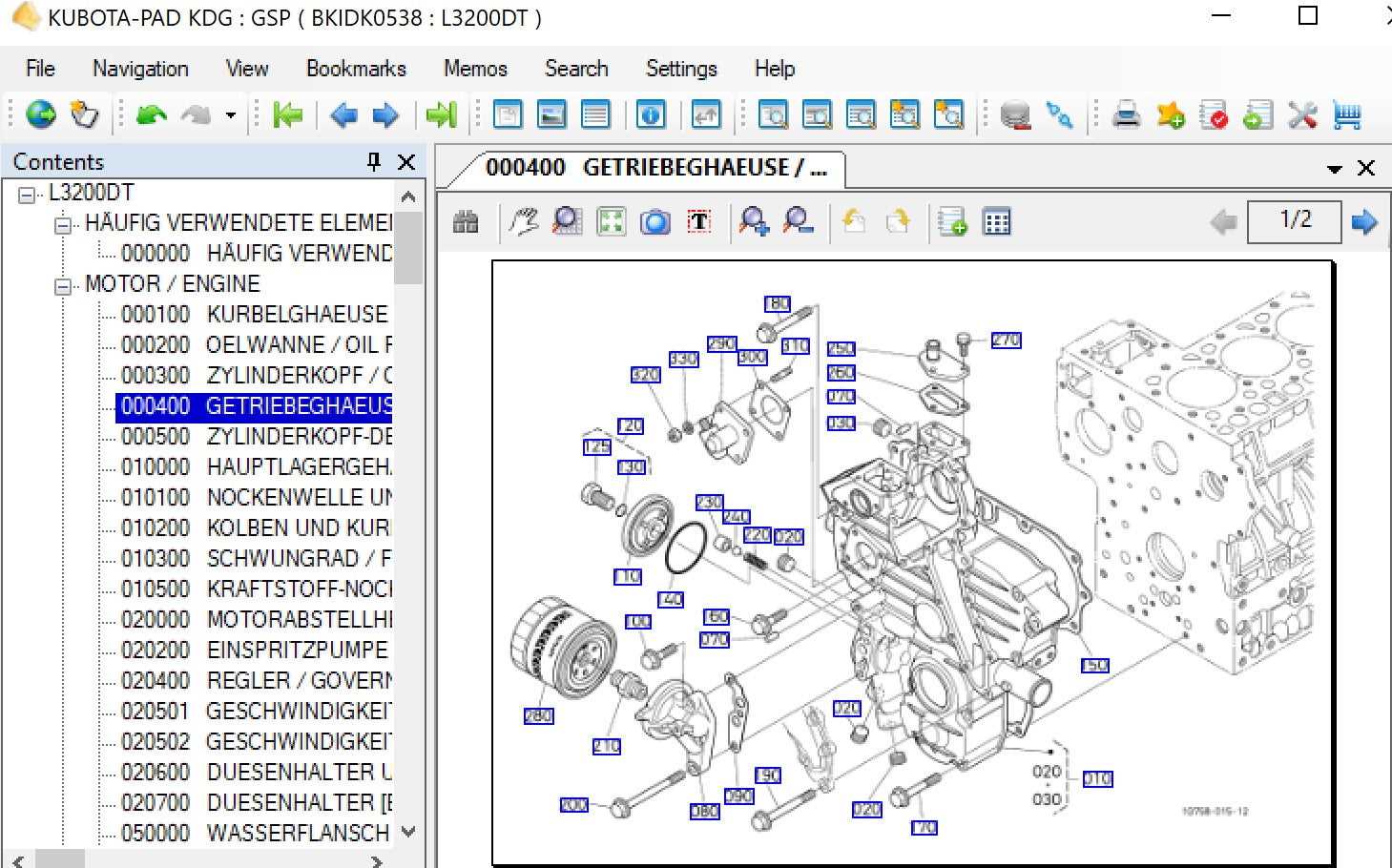

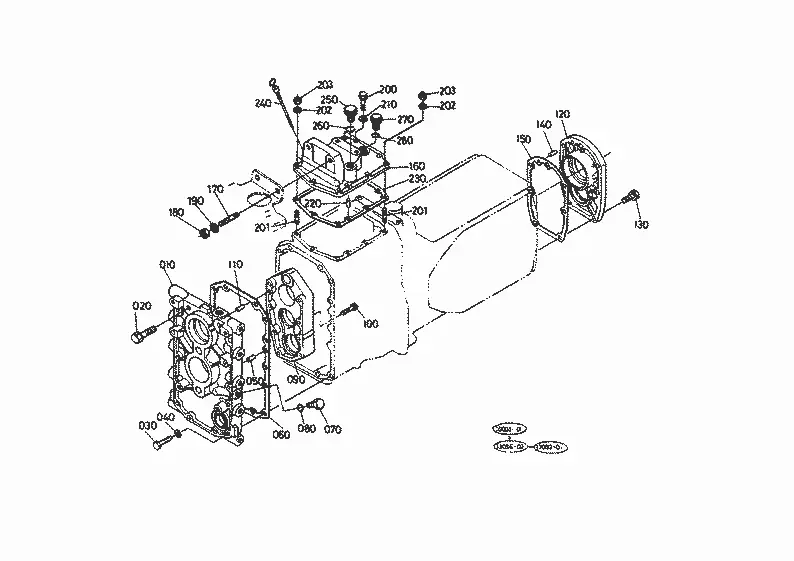

Identifying Components

Begin by locating the labels associated with each item in the illustration. These identifiers often correspond to a list or legend, helping you match parts with their descriptions. Pay attention to numbers and symbols, as they denote specific elements and relationships within the system.

Understanding Relationships

Observe how components interact with one another. Arrows or lines often indicate connections, movements, or dependencies. Recognizing these relationships is vital for troubleshooting and effective repairs, as it provides insight into the overall functionality of the machinery.

Common Replacement Parts for B20

When it comes to maintaining machinery, certain components often require attention and replacement over time. Understanding which elements tend to wear out can help ensure smooth operation and longevity of the equipment. Below are some frequently replaced items that users should keep in mind.

Essential Components

- Filters: Regularly changing oil and air filters is crucial for optimal performance.

- Belts: Drive and fan belts may degrade and should be inspected regularly.

- Hoses: Rubber hoses can crack and leak, necessitating timely replacement.

- Battery: A reliable power source is vital; batteries typically have a limited lifespan.

Mechanical Elements

- Seals and Gaskets: Over time, seals may wear out, leading to leaks and performance issues.

- Blades: Sharp cutting edges are essential for efficient operation; replacing dull blades can enhance performance.

- Spark Plugs: Ensuring good ignition is important; these should be replaced according to manufacturer recommendations.

Where to Find Kubota B20 Parts

Locating the necessary components for your machinery can be essential for ensuring optimal performance and longevity. Several avenues exist for sourcing these vital elements, ranging from authorized dealers to online marketplaces. Understanding where to look can save time and ensure you receive quality items.

Authorized Dealers

Visiting an authorized retailer remains one of the most reliable methods for acquiring the needed equipment. These outlets typically provide a wide range of options and can guarantee that the components meet the required standards. Additionally, they often offer expert advice, which can be invaluable for maintenance and repair projects.

Online Marketplaces

The internet offers numerous platforms where you can find what you need. Websites specializing in agricultural machinery frequently have extensive listings of various components. When purchasing online, ensure you check the seller’s reputation and reviews to avoid potential pitfalls. Moreover, many forums and community groups dedicated to equipment enthusiasts can provide leads on where to find specific items.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. By following a few essential practices, you can significantly extend its operational life and enhance performance.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Checks | Weekly | Inspect oil and coolant levels to prevent overheating and ensure smooth operation. |

| Filter Replacement | Every 100 hours | Change air, oil, and fuel filters to maintain efficiency and engine health. |

| Visual Inspections | Daily | Look for signs of wear or damage, including hoses, belts, and tires. |

| Battery Maintenance | Monthly | Clean terminals and check for corrosion to ensure reliable starts. |

Implementing these practices will ultimately contribute to optimal performance and reduce the likelihood of unexpected breakdowns.

Differences Between B20 and Other Models

Understanding the variations among different models is essential for users seeking optimal performance and suitability for specific tasks. Each machine comes with its unique features, functionalities, and design elements that cater to different needs and preferences.

One of the primary distinctions lies in the engine specifications and power output. While some models may offer higher horsepower, others focus on efficiency and torque, which can significantly impact their usability in various applications. Additionally, the hydraulic systems can differ, with certain versions providing enhanced lifting capacity or improved responsiveness for attachments.

Another notable difference can be found in the size and maneuverability of the equipment. Compact models may be designed for tighter spaces and easier transport, while larger variants might prioritize stability and durability on rugged terrain. This factor is crucial for users who need to navigate specific work environments.

Moreover, the ergonomics and controls can vary, affecting operator comfort and ease of use. Some machines may feature advanced technology, making operation smoother and more intuitive, while others might stick to traditional designs that appeal to a different user base. These variations ultimately determine which model is the best fit for individual requirements.

Identifying OEM vs. Aftermarket Parts

When maintaining machinery, understanding the difference between original components and alternatives is crucial for performance and longevity. Each option has its own set of advantages and disadvantages, impacting reliability, cost, and compatibility. Knowledge in this area can lead to better purchasing decisions, ensuring that equipment operates efficiently.

Understanding Original Components

Original components are made by the manufacturer and designed specifically for their machinery. These items typically guarantee a precise fit and performance that meets the original specifications. Quality assurance is a significant benefit, as these components often undergo rigorous testing and adhere to strict manufacturing standards. Investing in original components can provide peace of mind and enhance the overall lifespan of the equipment.

Exploring Alternative Options

Alternative options are produced by third-party manufacturers and can vary widely in quality and price. While they may offer cost savings, it is essential to assess their reliability and compatibility with the original machinery. Some alternatives might perform adequately, while others could lead to premature wear or operational issues. Careful consideration and research are necessary when selecting these components to avoid potential pitfalls.

Tools Needed for B20 Repairs

Proper maintenance and repair of heavy machinery require a well-equipped toolkit. Having the right instruments on hand not only simplifies the process but also ensures that tasks are completed efficiently and safely. Below is a comprehensive list of essential tools that are typically required for effective servicing.

Basic Hand Tools

- Wrenches (various sizes)

- Socket set

- Adjustable pliers

- Torque wrench

- Flat and Phillips screwdrivers

- Hex key set

Specialized Equipment

- Oil filter wrench

- Fuel line disconnect tool

- Grease gun

- Diagnostic scanner

- Safety goggles and gloves

Having these tools readily available will facilitate smooth repairs and maintenance, allowing you to keep your machinery in optimal working condition.

Typical Issues and Their Solutions

Every mechanical system faces challenges over time, leading to performance declines or operational failures. Identifying common problems and implementing effective solutions can enhance longevity and efficiency.

Common Challenges

- Overheating due to inadequate cooling

- Starting issues stemming from battery failures

- Hydraulic fluid leaks from worn seals

- Electrical malfunctions causing erratic behavior

Solutions

- Ensure the cooling system is clean and regularly maintained.

- Test and replace batteries as needed to maintain reliable starts.

- Inspect seals and replace any that show signs of wear or damage.

- Check wiring and connections to address any electrical issues.

Resources for Technical Support and Guides

Accessing reliable support and informative resources is essential for maintaining and repairing machinery effectively. Whether you are looking for troubleshooting tips, maintenance schedules, or detailed instructions, a variety of platforms offer valuable assistance. These resources help users navigate challenges and enhance their understanding of equipment operation.

Online forums and communities can be excellent sources for real-world advice, where experienced users share their insights and solutions. Additionally, many manufacturers provide downloadable manuals and technical bulletins that serve as comprehensive guides for servicing and operating equipment. Video tutorials on popular platforms also offer step-by-step instructions, making complex tasks more approachable.

For those seeking professional help, local dealerships and certified service centers can provide expert assistance. They often have access to specialized tools and knowledge, ensuring that any issues are resolved efficiently. Utilizing these diverse resources can significantly improve your experience and extend the lifespan of your machinery.