Kubota Zero Turn Mower Parts Diagram Explained

The efficient operation of landscaping machinery is crucial for maintaining beautiful outdoor spaces. A comprehensive grasp of the essential elements that make up these machines allows users to perform effective maintenance and repairs. This knowledge not only enhances the longevity of the equipment but also optimizes its performance.

In this section, we will explore the intricate layout of a specific type of lawn care apparatus, breaking down its components into easily digestible segments. By visualizing the arrangement of each element, users can pinpoint potential issues and understand the functionality of their tools more thoroughly.

Whether you’re a professional landscaper or a dedicated homeowner, familiarizing yourself with these mechanical features is the ultimate key to successful upkeep. Dive into the details and empower yourself with the insights necessary for effective care and operation.

Kubota Zero Turn Mower Overview

This section provides a comprehensive look at a specific type of landscaping equipment designed for exceptional maneuverability and efficiency. The model is engineered to simplify the process of maintaining lawns and gardens, combining powerful performance with ease of use. Users can expect enhanced control and precision, making it an ideal choice for both residential and commercial applications.

The design emphasizes user comfort and accessibility, featuring ergonomic controls and a robust frame. The equipment is equipped with advanced technology to ensure reliable operation and longevity, catering to the needs of professional landscapers and homeowners alike.

| Feature | Description |

|---|---|

| Engine | High-performance engine providing ample power for various tasks. |

| Deck | Durable cutting deck for efficient grass management. |

| Control System | User-friendly controls for effortless navigation. |

| Comfort | Ergonomic seating and controls for reduced fatigue. |

| Durability | Designed to withstand heavy use and harsh conditions. |

In summary, this equipment stands out for its reliability and functionality, making it a valuable tool for anyone seeking to maintain lush and well-kept outdoor spaces. With a focus on performance and user experience, it meets the demands of modern landscaping needs.

Understanding the Mower’s Design

The structure of a lawn care machine plays a vital role in its efficiency and functionality. By exploring its components and layout, users can gain insight into how each element contributes to optimal performance. This understanding allows for better maintenance and troubleshooting, ultimately enhancing the longevity of the equipment.

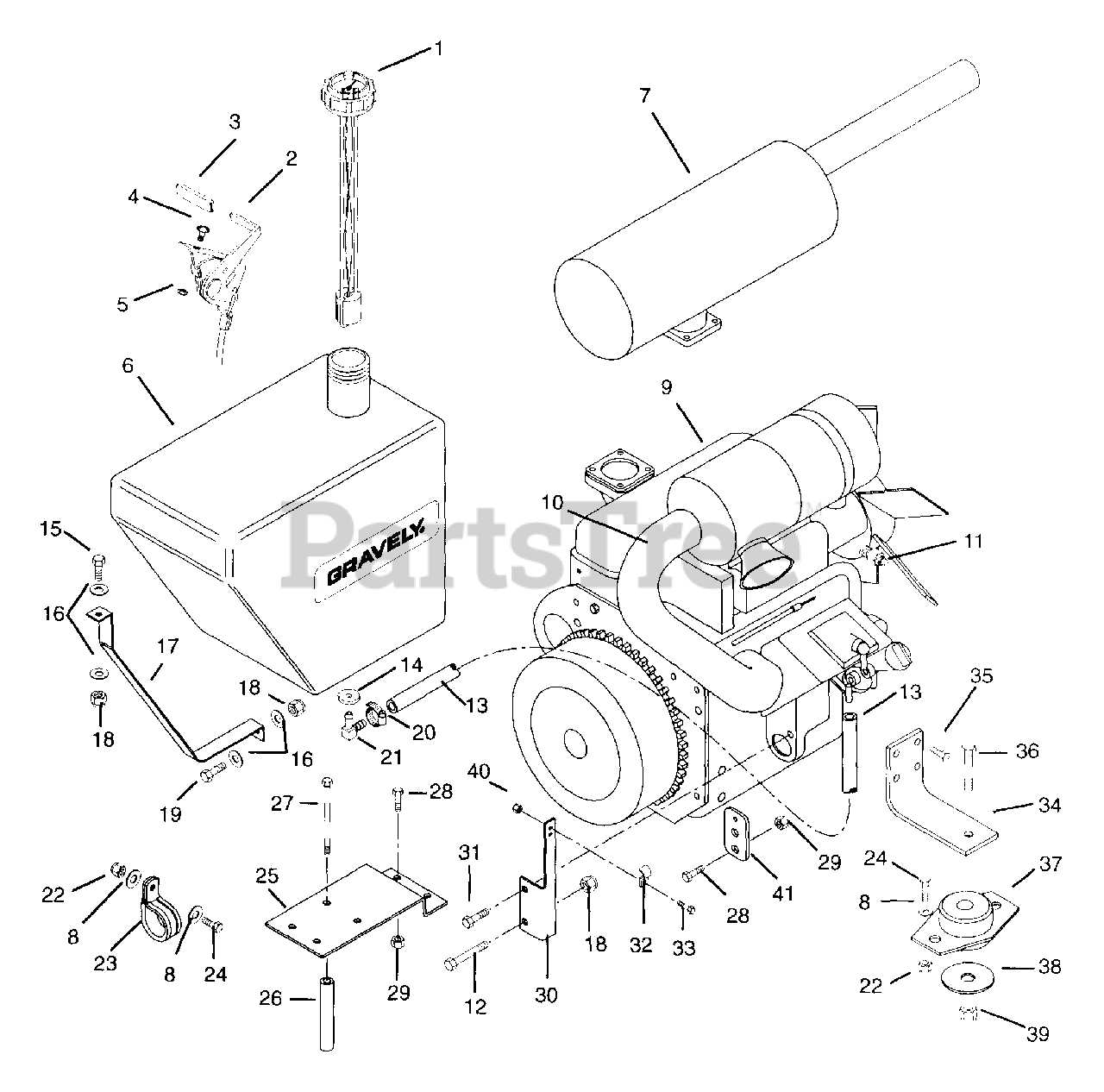

Key Components

Every cutting device is composed of several critical parts that work in harmony. The engine serves as the powerhouse, providing the necessary energy to operate various functions. The deck is another essential element, housing the blades that facilitate grass trimming. Additionally, the transmission system is crucial for maneuverability, enabling smooth navigation across different terrains.

Design Considerations

When assessing the design, one must consider factors such as ergonomics and durability. Ergonomic designs ensure that users can operate the machine comfortably for extended periods, reducing fatigue. Meanwhile, the materials used in construction affect the machine’s resistance to wear and tear, making it imperative to choose robust options for long-term use. Understanding these aspects can significantly improve the user experience and operational efficiency.

Key Components of the Machine

Understanding the essential elements of this landscaping equipment is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring efficiency and longevity, contributing to the overall functionality of the unit.

Engine: The powerhouse of the device, responsible for generating the necessary energy to operate. A well-maintained engine ensures smooth operation and effective cutting.

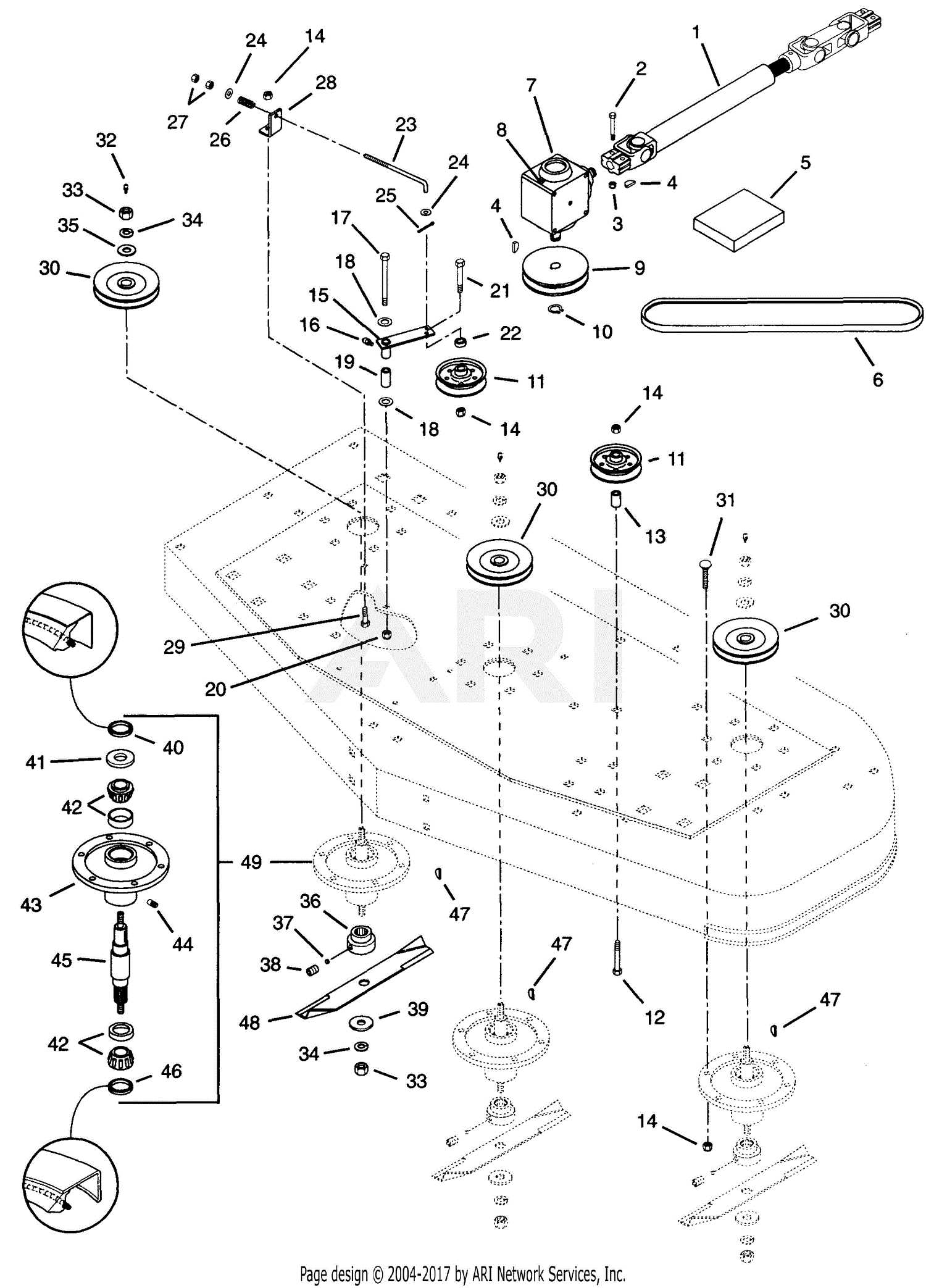

Deck: This component houses the blades and is vital for achieving a clean cut. Its design influences maneuverability and cutting height, making it an integral part of the equipment’s performance.

Blades: Sharp and durable, these are the primary tools for trimming grass. Regular inspection and replacement are essential for maintaining cutting efficiency and preventing damage to the lawn.

Transmission: This system controls the speed and direction of the machine. A reliable transmission allows for precise handling and movement, which is especially important in navigating tight spaces.

Chassis: The framework supports all other components, providing stability and strength. A sturdy chassis enhances durability, ensuring that the equipment can withstand various terrains.

Control System: This interface allows the operator to manage the machine’s functions easily. An intuitive control system improves user experience and enhances operational safety.

Importance of Maintenance Parts

Regular upkeep is crucial for the longevity and efficiency of any machinery. Ensuring that each component is functioning optimally can prevent larger issues and enhance performance. This proactive approach not only saves money but also extends the lifespan of the equipment.

Benefits of Routine Maintenance

- Prevents Unexpected Breakdowns

- Improves Overall Performance

- Enhances Safety for Users

- Maintains Equipment Value

Key Components to Focus On

- Filtration Systems

- Blades and Cutting Mechanisms

- Drive Belts

- Lubricants and Fluids

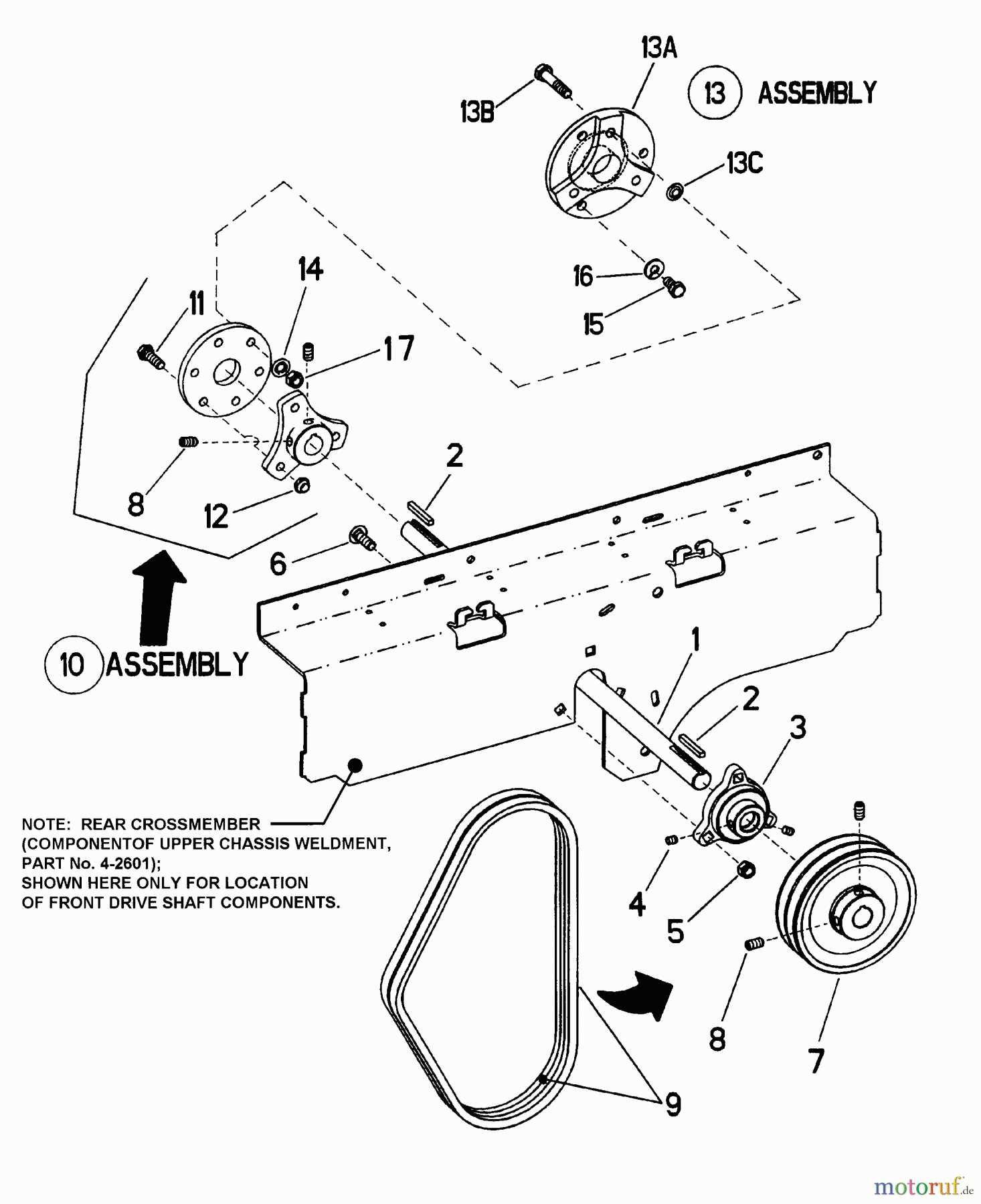

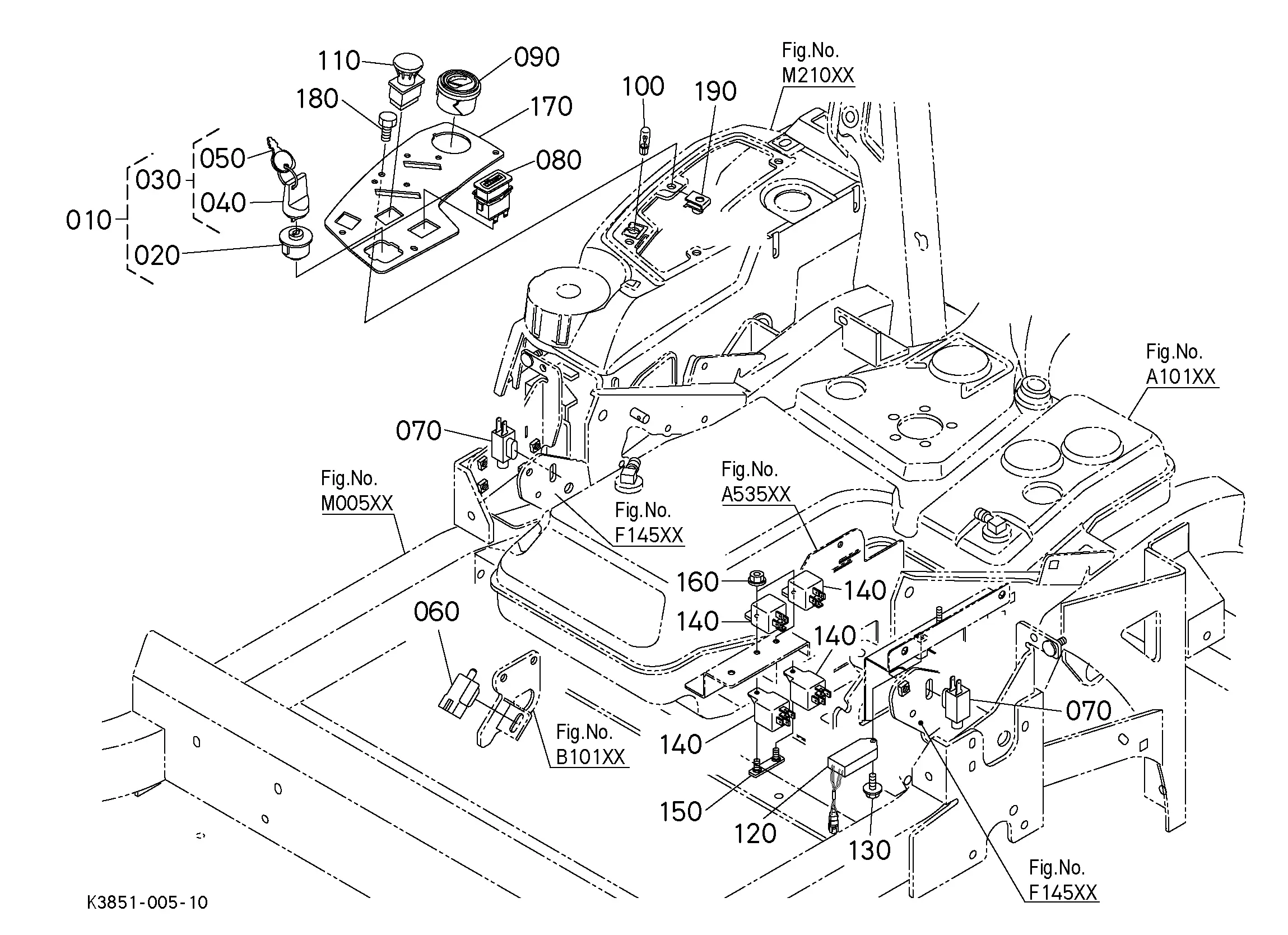

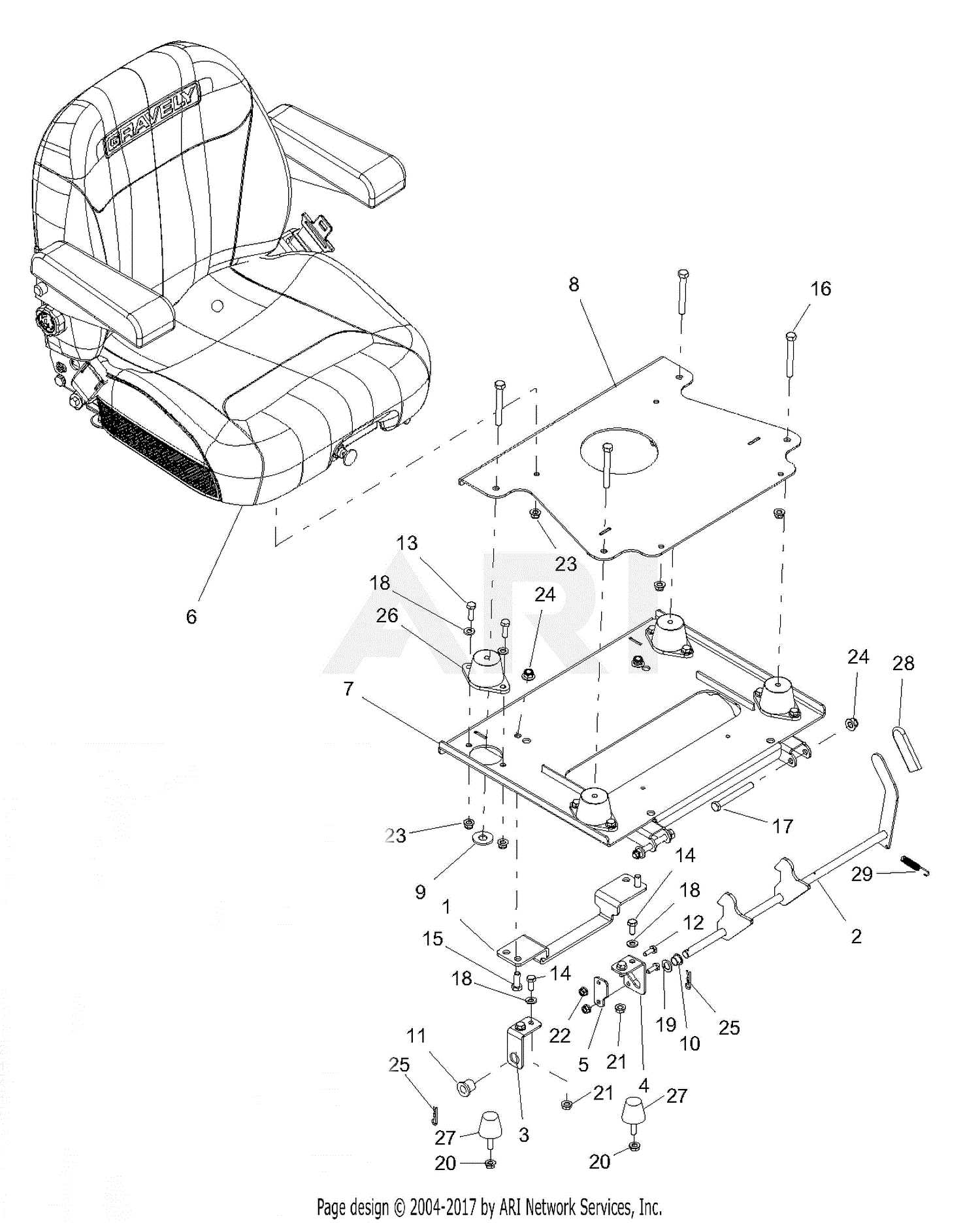

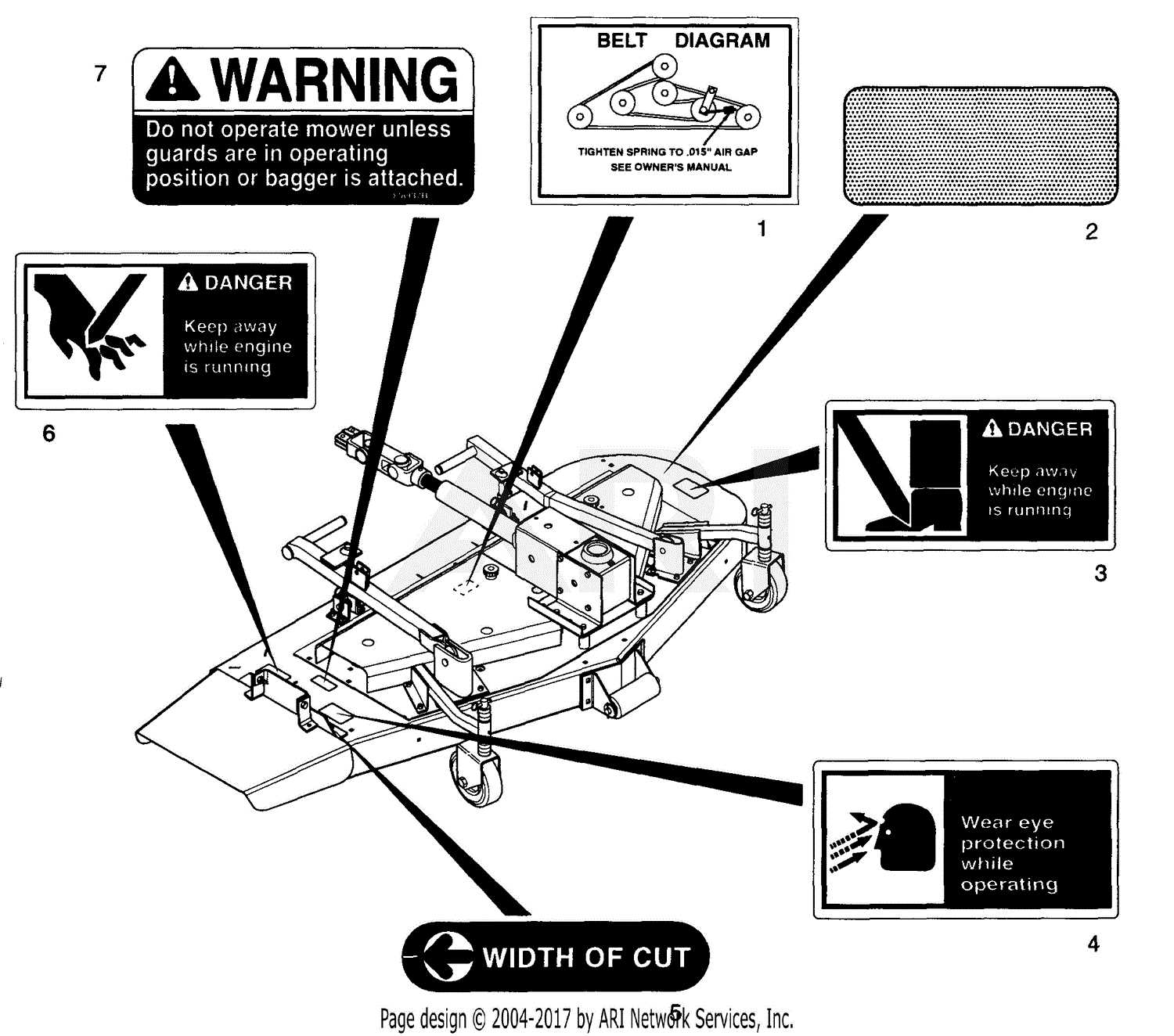

How to Read Parts Diagrams

Understanding assembly visuals is essential for effective maintenance and repair of equipment. These illustrations provide a clear representation of components and their arrangement, allowing users to identify necessary replacements and assembly procedures easily.

Key Elements of Assembly Illustrations

- Labels: Components are usually marked with numbers or letters for easy identification.

- References: Diagrams often include a reference list that matches labels to part names.

- Connections: Lines may indicate how parts connect or interact with each other.

Tips for Effective Use

- Start by familiarizing yourself with the layout and labeling system.

- Cross-reference the visual with the parts list to ensure accuracy.

- Take notes on any components that need replacement for quick reference.

Common Replacement Parts Explained

Maintaining your equipment’s efficiency often requires understanding the components that may need replacement over time. Familiarizing yourself with these essential elements can enhance performance and longevity.

| Component | Function | Signs of Wear |

|---|---|---|

| Blades | Cutting grass and ensuring a clean finish. | Dull edges or uneven cutting. |

| Filters | Prevent dirt and debris from entering the engine. | Reduced power or visible dirt accumulation. |

| Batteries | Powering the ignition and electrical systems. | Slow starting or dim lights. |

| Belts | Transfer power from the engine to the cutting mechanism. | Cracking or slippage during operation. |

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right tools is essential for a smooth and efficient process. Proper equipment not only simplifies the task at hand but also ensures safety and accuracy during repairs.

Essential Hand Tools: A basic set of hand tools should include wrenches, sockets, screwdrivers, and pliers. These tools allow for easy access to various components, making it simpler to disassemble and reassemble parts.

Specialized Equipment: Depending on the complexity of the repairs, certain specialized tools may be required. For instance, a torque wrench ensures that fasteners are tightened to the correct specifications, while a multimeter can help diagnose electrical issues.

Protective Gear: Safety should never be overlooked. Wearing gloves, safety goggles, and sturdy footwear can protect against injuries while working on machinery.

Organizational Supplies: Having bins or trays to organize screws, bolts, and other small components can greatly reduce the time spent searching for parts during the repair process.

By equipping yourself with the right tools and safety gear, you can enhance your repair experience and ensure your machinery runs smoothly for years to come.

Identifying Wear and Tear

Recognizing signs of deterioration is essential for maintaining optimal performance of your equipment. Regular inspections can help prevent more significant issues, ensuring longevity and efficiency in operation.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Blades | Chips, cracks, or dull edges | Sharpen or replace |

| Belt | Fraying or cracking | Inspect and replace |

| Tires | Uneven wear or low pressure | Inflate or replace |

| Deck | Rust or corrosion | Clean and treat |

Where to Find Quality Parts

Finding reliable components for your landscaping equipment is essential for maintaining optimal performance. The market offers a variety of sources, but selecting the right one can make all the difference in durability and efficiency.

Authorized Dealers

Authorized retailers often provide original components that ensure compatibility and quality. They typically offer warranties, adding extra assurance for buyers.

Online Marketplaces

Numerous online platforms cater to equipment enthusiasts, featuring a wide array of components. Always check reviews and seller ratings to ensure you are purchasing from reputable sources.

| Source | Advantages |

|---|---|

| Authorized Dealers | Original quality, warranties |

| Online Marketplaces | Variety, convenience |

| Local Repair Shops | Expert advice, community support |

Upgrading Your Mower’s Performance

Enhancing the efficiency of your landscaping equipment can significantly elevate its functionality and longevity. By implementing strategic modifications, you can unlock the true potential of your machine, ensuring it operates at peak performance while also increasing its versatility in various tasks.

One effective way to achieve this is by investing in high-quality components. Upgrading elements like the engine, transmission, or cutting deck can lead to a smoother operation and better results. Moreover, maintaining optimal tire pressure and selecting the right blades can enhance maneuverability and cutting precision.

Additionally, regular maintenance plays a crucial role in performance improvement. Routine checks on oil levels, air filters, and spark plugs can prevent issues that may hinder functionality. By staying proactive with maintenance, you ensure your equipment remains reliable and efficient throughout its lifespan.