Essential Guide to John Deere 125 Parts Diagram

Exploring the intricate layouts of essential machinery can greatly enhance the efficiency of maintenance and repairs. A comprehensive overview of these structures not only aids in understanding how various elements interact but also streamlines the process of identifying necessary components.

In this section, we will delve into the specifics of a popular model, examining its arrangement and the relationships between different elements. Grasping these details empowers users to address issues proactively, ensuring optimal performance in the field.

Whether you’re a seasoned technician or a DIY enthusiast, familiarity with the configuration of machinery components is invaluable. It enables effective troubleshooting and minimizes downtime, ultimately contributing to a more productive agricultural operation.

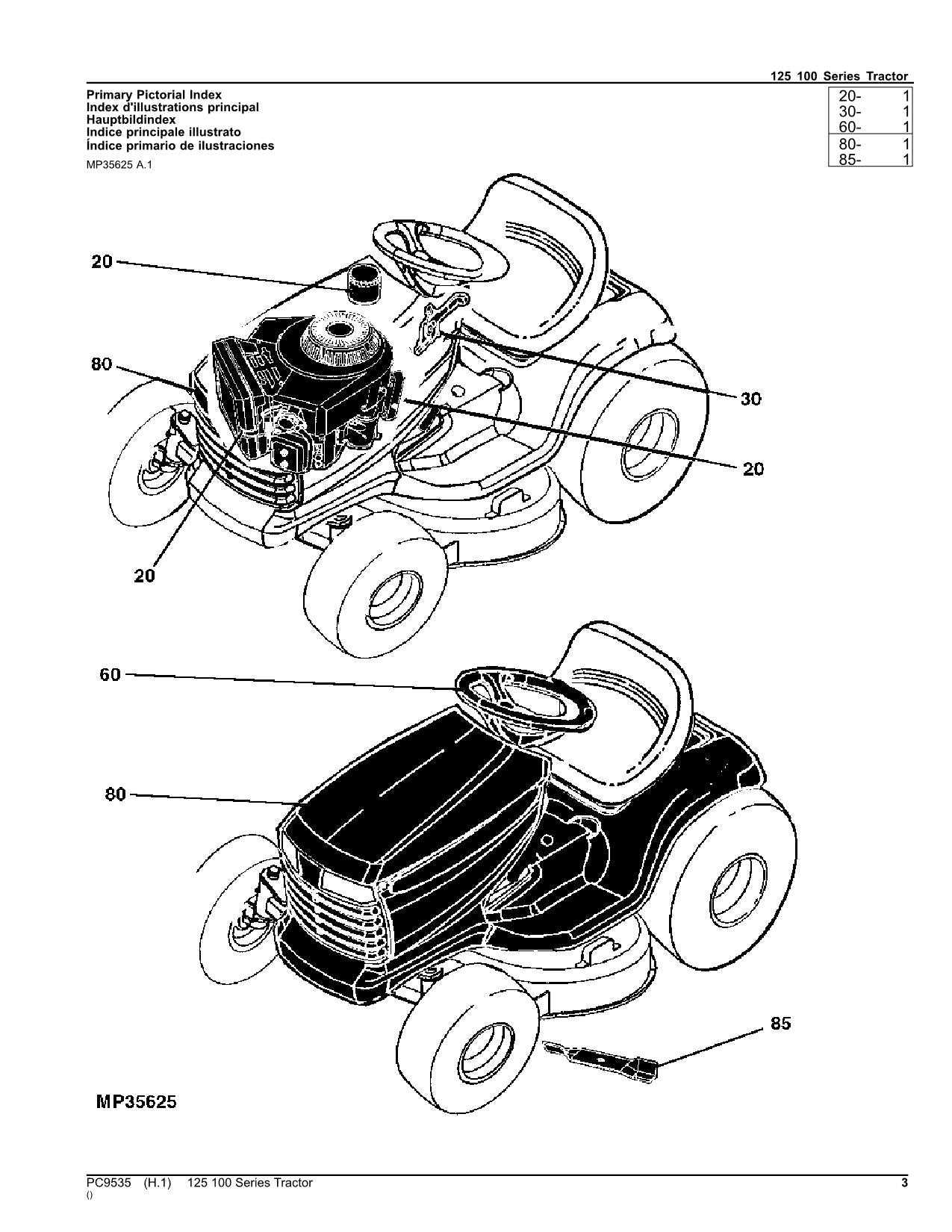

Understanding John Deere 125 Components

Grasping the various elements that comprise a specific machine is essential for optimal performance and maintenance. Each component plays a crucial role, contributing to the overall functionality and efficiency. By familiarizing oneself with these parts, operators can ensure longevity and reliability.

| Component | Function |

|---|---|

| Engine | Drives the machinery and powers all functions. |

| Transmission | Transfers power from the engine to the wheels. |

| Chassis | Serves as the framework, supporting all components. |

| Deck | Houses the cutting mechanism, essential for operation. |

| Wheels | Facilitates mobility and stability on various terrains. |

Key Features of the John Deere 125

This section explores the essential attributes that define a certain model from a renowned manufacturer, emphasizing its design and functionality. The vehicle is crafted to meet diverse needs, providing reliability and efficiency for various tasks.

One of the standout aspects is its powerful engine, which delivers robust performance while maintaining fuel efficiency. This makes it ideal for both residential and commercial applications. Additionally, the ergonomic design ensures comfort during extended use, allowing operators to perform tasks with ease.

Furthermore, the user-friendly controls enhance the overall experience, making it accessible for individuals with varying levels of expertise. Durability is another key feature, with high-quality materials that withstand wear and tear, ensuring longevity.

Lastly, the versatile attachments available expand its functionality, enabling users to tackle a range of chores effectively. Overall, this model embodies a blend of strength, convenience, and adaptability, making it a valuable asset for many users.

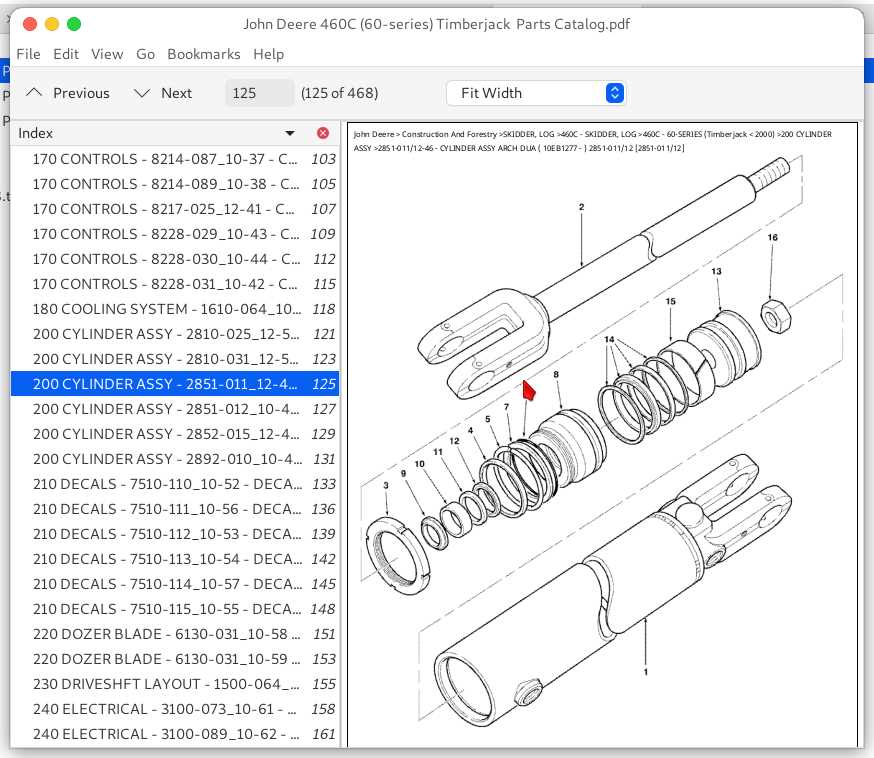

Importance of Parts Diagrams

Understanding the layout of components within machinery is crucial for efficient maintenance and repair. Visual representations serve as invaluable tools, allowing users to identify individual elements and comprehend their relationships. This clarity aids in troubleshooting and ensures that repairs are conducted correctly, minimizing downtime.

Enhanced Troubleshooting

When a machine malfunctions, having a clear visual guide can significantly expedite the diagnostic process. By referencing an illustration, technicians can quickly pinpoint faulty components, streamlining the identification of issues. This reduces the time spent on repairs, leading to improved operational efficiency.

Effective Maintenance Planning

Visual aids also facilitate better planning for regular upkeep. Knowing the precise arrangement of elements allows for more organized and proactive maintenance schedules. Regular checks and timely replacements become easier to implement, ultimately extending the lifespan of the equipment.

In summary, clear visual representations of machinery components play a vital role in both troubleshooting and maintenance, ensuring that equipment operates smoothly and efficiently.

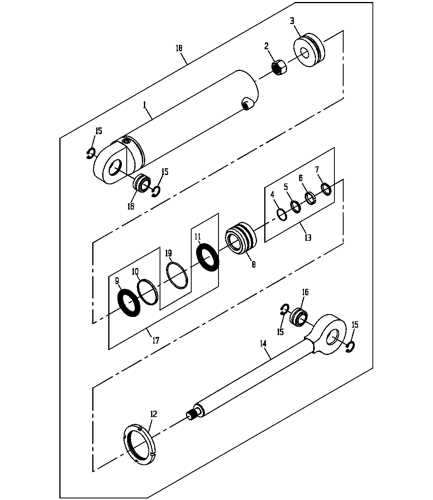

How to Read Parts Diagrams

Understanding illustrations that showcase components is essential for effective maintenance and repair. These visuals serve as a roadmap, helping users identify each piece’s location and function within the larger system. Mastering this skill can save time and enhance the overall efficiency of the process.

Breaking Down the Illustration

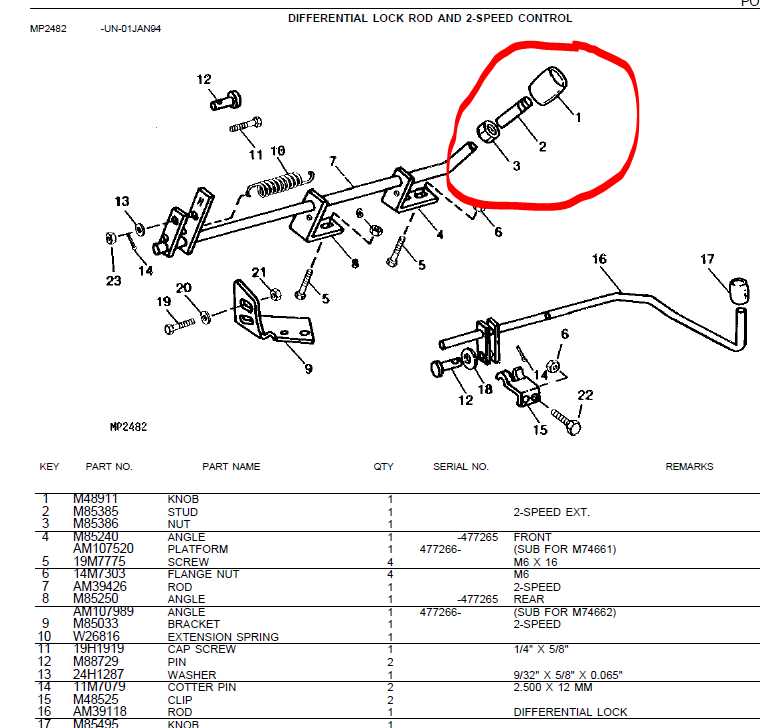

Each section of the illustration is typically labeled, making it easier to locate specific items. Pay attention to the numbering system, as it often correlates with a list of descriptions or specifications. This connection allows for quick identification and procurement of necessary items.

Utilizing Reference Tables

Reference tables accompanying the illustration can provide detailed information about each component. These tables usually include part numbers, descriptions, and compatibility notes, which are invaluable for ensuring the right items are obtained.

| Item Number | Description | Compatibility |

|---|---|---|

| 1 | Spring | Model A, B |

| 2 | Gear | Model A |

| 3 | Bracket | Model B, C |

Common Repairs for John Deere 125

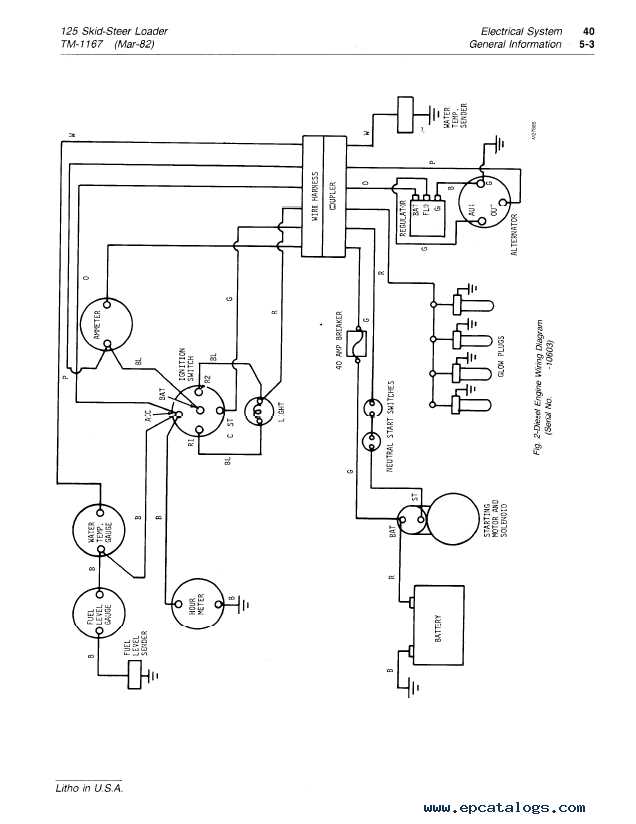

Maintenance and troubleshooting are essential for ensuring optimal performance and longevity of outdoor machinery. Understanding common issues can help owners address problems efficiently and minimize downtime. Various repairs may be necessary, ranging from mechanical adjustments to electrical component replacements.

One frequent concern involves the cutting mechanism, where dull blades can lead to poor performance. Regular sharpening or replacement of the blades is crucial for maintaining effective operation. Additionally, ensuring that the deck is free from debris can prevent further complications.

Another common area of focus is the engine. Over time, issues such as starting difficulties or unusual noises may arise. Regular oil changes, air filter replacements, and spark plug inspections are vital steps in keeping the engine running smoothly.

The transmission system can also present challenges. If the machinery struggles to move or shifts roughly, checking the fluid levels and replacing worn components may be necessary to restore functionality.

Electrical problems, such as a malfunctioning battery or faulty wiring, are also typical concerns. Regular checks of the battery condition and connections can prevent unexpected failures, ensuring reliable operation.

Where to Find Replacement Parts

Locating suitable components for machinery can enhance its longevity and performance. Various sources offer a range of options to acquire the necessary items, ensuring efficient repairs and maintenance. Whether you’re seeking genuine or aftermarket solutions, knowing where to look is essential for keeping equipment in optimal condition.

Online retailers often provide a vast selection, allowing users to compare prices and find specific components easily. Authorized dealers also offer original items, ensuring compatibility and quality. Local shops may have what you need as well, providing the benefit of immediate access and personalized service.

Forums and communities dedicated to machinery enthusiasts can be invaluable resources. Members often share experiences and recommendations for sourcing parts, as well as tips for installation. Lastly, salvage yards can be a treasure trove for hard-to-find components, offering a sustainable option for repairs.

Identifying Worn Components

Understanding how to recognize deteriorated elements in machinery is crucial for maintaining optimal performance. Regular inspection of various components can help prevent unexpected failures and extend the lifespan of the equipment. By focusing on specific signs of wear and tear, operators can ensure that their machinery operates efficiently and safely.

Key indicators of wear include unusual noises, decreased efficiency, and visible damage. Components may exhibit cracks, discoloration, or excessive play, signaling the need for closer examination. Monitoring performance metrics can also provide valuable insights, as any deviations from standard operation often point to underlying issues.

Maintaining a detailed log of inspections and repairs is essential. Documenting changes in performance or appearance over time can help in identifying patterns and predicting when parts may require replacement. Ultimately, being proactive in identifying worn components can save time and resources in the long run.

Benefits of Using Original Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. These items are specifically designed to fit perfectly and function seamlessly, enhancing the overall efficiency of your equipment.

Quality Assurance: Genuine components undergo rigorous testing to meet strict industry standards, providing peace of mind regarding reliability and durability.

Enhanced Performance: Original items are crafted to work harmoniously with existing systems, resulting in improved operation and reduced wear over time.

Warranty Protection: Many manufacturers offer warranties on their authentic components, safeguarding your investment and providing support in case of issues.

Resale Value: Using genuine components can maintain or even increase the resale value of your machinery, appealing to potential buyers who prioritize quality.

In summary, investing in original items not only optimizes machinery performance but also supports long-term maintenance and value retention.

DIY Maintenance Tips for Owners

Regular upkeep of your machinery is essential for longevity and performance. Engaging in simple maintenance tasks can prevent costly repairs and enhance efficiency. Here are some practical suggestions for keeping your equipment in top shape.

Routine Inspections

Conducting frequent checks can help identify potential issues before they escalate. Look for wear and tear on components, inspect fluid levels, and ensure all systems are functioning properly.

Cleaning and Lubrication

Keeping machinery clean is vital. Remove debris and dirt, which can hinder performance. Additionally, applying lubricant to moving parts reduces friction and prolongs the life of your equipment.

| Maintenance Task | Frequency |

|---|---|

| Check oil levels | Every 10 hours |

| Inspect air filter | Every 25 hours |

| Clean exterior | As needed |

| Lubricate moving parts | Every 50 hours |

Upgrading John Deere 125 Parts

Enhancing the performance and durability of your machinery can lead to improved efficiency and longevity. By selecting quality components and considering advanced alternatives, you can significantly elevate the overall functionality of your equipment.

| Component | Upgrade Option | Benefits |

|---|---|---|

| Engine | Performance Enhancer Kit | Increased horsepower and torque |

| Blades | High-Performance Blades | Sharper cuts and reduced wear |

| Transmission | Heavy-Duty Gearbox | Enhanced durability and smoother operation |

| Battery | High-Capacity Battery | Longer run times and better reliability |

Resources for John Deere Enthusiasts

For those passionate about agricultural machinery, a wealth of information is available to enhance knowledge and skills. Engaging with various materials can lead to a deeper appreciation of equipment and its maintenance. Here are some valuable resources tailored for enthusiasts.

| Resource Type | Description | Link |

|---|---|---|

| Forums | Online communities for sharing tips and experiences. | Visit Forum |

| Manuals | Comprehensive guides for operation and repair. | Download Manuals |

| Videos | Tutorials showcasing maintenance and usage techniques. | Watch Videos |

| Blogs | Articles covering topics from restoration to upgrades. | Read Blogs |

Comparing Models: John Deere 125 vs Others

This section explores the distinctions between a specific model and its competitors in the market. Understanding these differences can help potential buyers make informed decisions based on their needs, preferences, and the features offered by each machine.

Design and Features

When evaluating various models, it is essential to consider the overall design and available features. The machine in focus boasts a user-friendly interface, allowing for seamless operation. In contrast, several alternatives may offer unique functionalities, such as enhanced fuel efficiency or advanced technological integrations. Each option presents its advantages, making it crucial to assess which attributes align best with individual requirements.

Performance and Reliability

Performance is a key factor when comparing these machines. The highlighted model is known for its robust power and reliability under various conditions. However, other contenders might excel in specific tasks or provide a more versatile experience. By examining performance metrics, users can determine which machine will best meet their expectations in real-world applications.