Complete Guide to Yamaha 9.9 Parts Diagram

In the world of marine propulsion, the intricate design and assembly of small outboard engines play a crucial role in performance and reliability. Each component serves a specific function, working harmoniously to ensure smooth operation and longevity. A thorough grasp of these elements is essential for both maintenance and enhancement of engine efficiency.

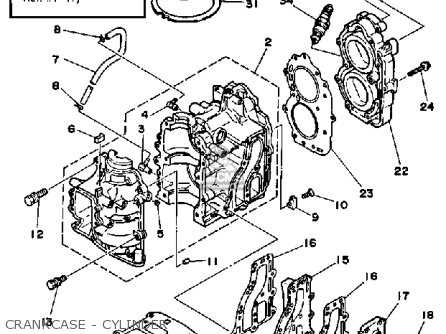

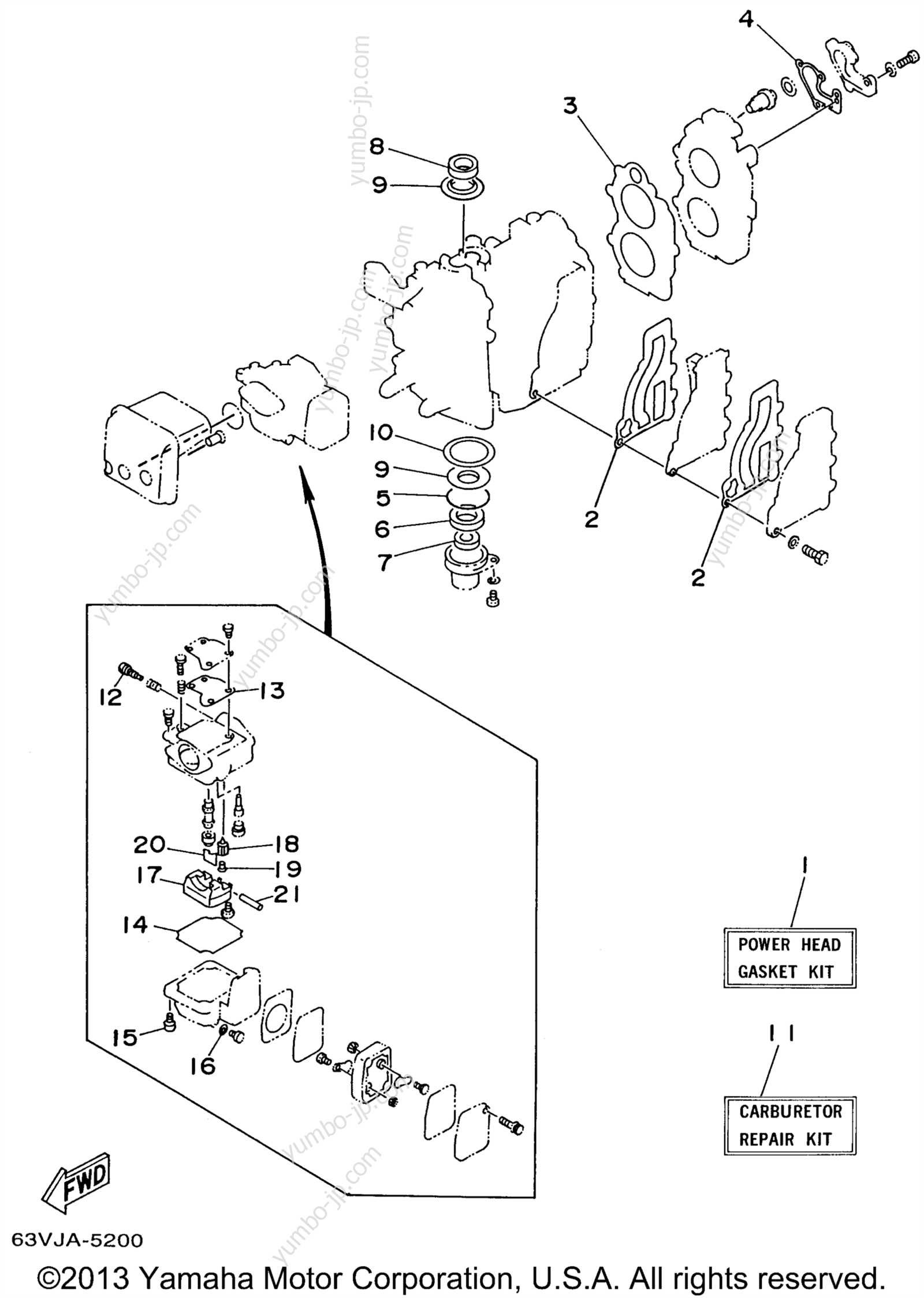

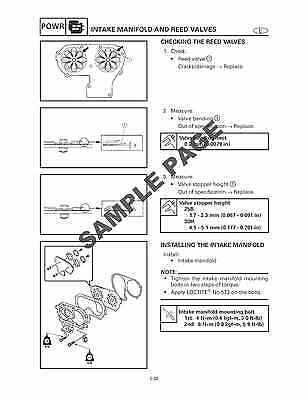

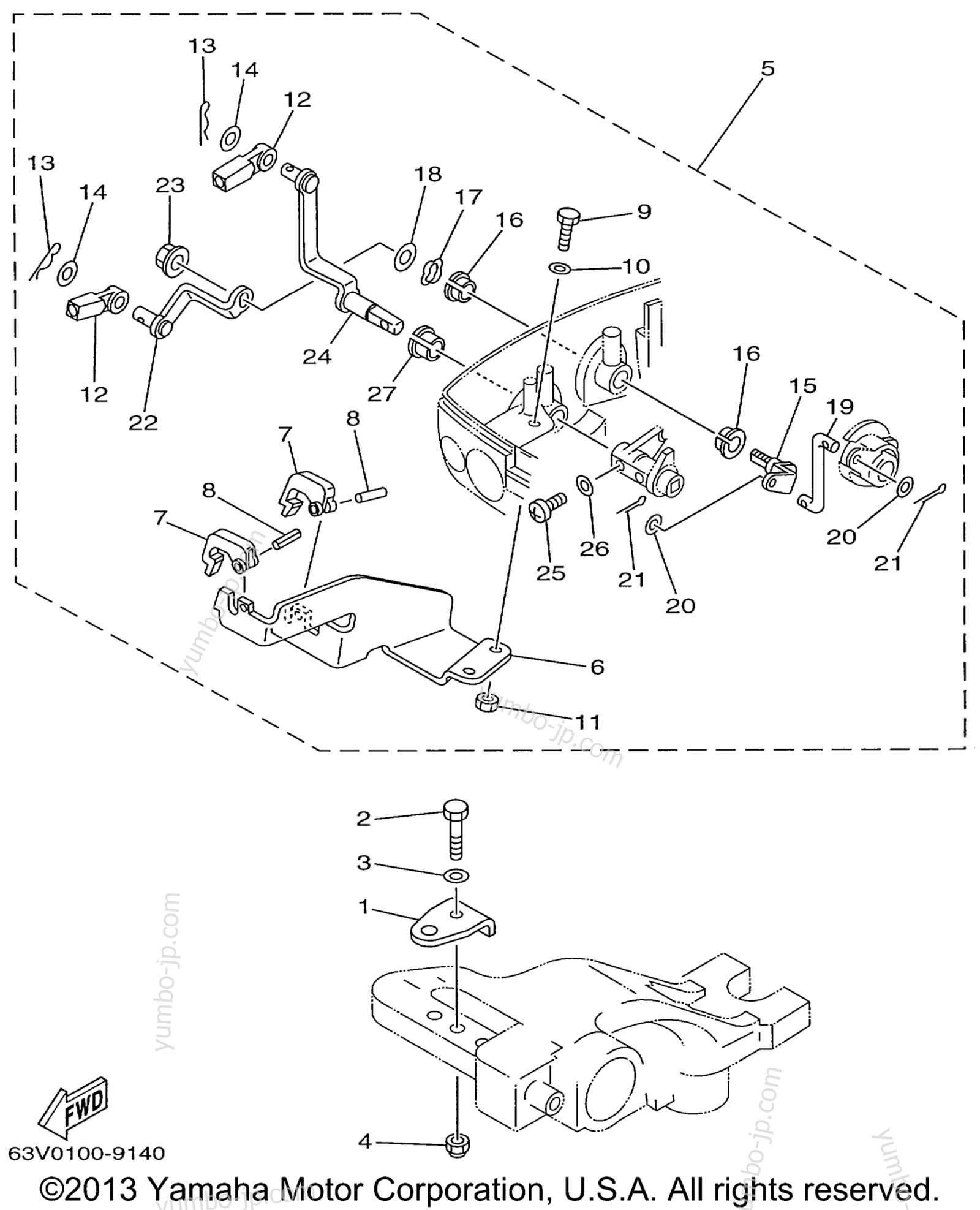

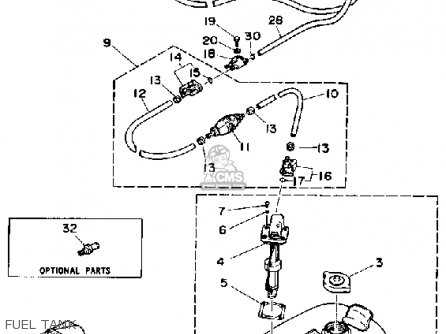

For enthusiasts and technicians alike, visual representations of the engine’s layout can be invaluable. They provide insights into the arrangement and interaction of various mechanisms, making it easier to identify parts and troubleshoot issues. These illustrations serve not only as a reference for repairs but also as educational tools for those seeking to deepen their understanding of engine functionality.

Delving into the specifics of these illustrations reveals a wealth of information. From the core assembly to auxiliary systems, each segment contributes to the overall performance. Recognizing how each piece fits into the larger puzzle allows for more informed decisions regarding repairs and upgrades, ultimately leading to enhanced operational efficiency on the water.

Understanding Yamaha 9.9 Engine Components

Gaining insight into the various elements that comprise an outboard motor is essential for effective maintenance and troubleshooting. Each component plays a critical role in the overall functionality and performance of the engine, contributing to its efficiency and reliability.

Key Elements: The structure includes essential parts such as the powerhead, lower unit, and fuel system, each designed to work in harmony. Understanding how these components interact allows for better decision-making regarding repairs and upgrades.

Maintenance Importance: Regular inspection of these elements is crucial. By familiarizing oneself with the layout and purpose of each part, users can enhance the longevity and performance of their engine, ensuring optimal operation throughout its lifespan.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and maintenance of various machinery. These illustrations not only facilitate repairs but also enhance the learning experience for users by providing clarity and organization.

Benefits of Visual Guides

- Improved comprehension of complex systems.

- Streamlined identification of individual elements.

- Enhanced troubleshooting and repair processes.

- Efficient planning for maintenance tasks.

Effective Communication

Utilizing these visual aids fosters better communication among technicians and users. They serve as a common reference point, reducing misunderstandings and ensuring everyone is aligned on procedures.

Key Features of Yamaha 9.9 Model

This section highlights the essential attributes of a compact and efficient marine engine, emphasizing its performance and design. Users will appreciate the balance of power and portability, making it suitable for various watercraft.

- Lightweight Design: Facilitates easy handling and transport.

- Fuel Efficiency: Maximizes performance while minimizing fuel consumption.

- Durable Construction: Engineered for longevity, resisting corrosion and wear.

- Quiet Operation: Reduces noise levels, enhancing the overall boating experience.

- Easy Maintenance: Simplified access to components for routine checks and repairs.

These characteristics contribute to its ultimate appeal among recreational users and professional operators alike, ensuring reliability in various conditions.

Common Issues with Yamaha Outboards

Outboard motors are essential for many boating enthusiasts, but they can encounter various problems over time. Understanding these issues is crucial for maintenance and longevity. This section outlines some frequent challenges faced by users of these marine engines, along with potential solutions.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Overheating | Loss of power, warning alarms, steam or smoke | Check for obstructions in the cooling system, ensure proper water intake |

| Fuel Problems | Engine stalling, poor performance, difficulty starting | Inspect fuel lines for leaks, replace old fuel, check filters |

| Battery Issues | Engine not starting, dim lights, electrical malfunctions | Test battery voltage, clean terminals, replace battery if needed |

| Propeller Damage | Vibration, loss of speed, difficulty steering | Inspect propeller for bends or cracks, replace if damaged |

| Ignition Failure | Engine won’t start, backfiring, rough idling | Check spark plugs, inspect ignition coils, replace faulty components |

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This illustration provides a systematic way to identify various elements and their relationships, allowing for informed decision-making when tackling mechanical issues.

Key Components

Every illustration consists of several key elements. Typically, each part is labeled with a unique identifier, often a number or letter. This helps in quickly referencing specific items. Additionally, you might find lines or arrows that indicate how components fit together or interact with one another. Familiarizing yourself with these symbols is crucial for proper comprehension.

Utilizing the Legend

Most representations come with a legend or key that explains the symbols used. This may include descriptions of components, material types, or assembly instructions. Taking time to study this section can greatly enhance your understanding, ensuring you grasp the context of each element. Remember that a thorough review of the legend can save time and prevent mistakes during the repair process.

Identifying Replacement Parts Effectively

Finding the right components for your equipment can be a daunting task. Understanding how to navigate resources and references ensures that you select the correct items, enhancing both performance and longevity.

Research and Resources

Utilizing various sources can significantly aid in your search. Manuals, online forums, and manufacturer websites offer valuable insights and specifications that simplify the identification process.

Comparison Table

| Component Type | Common Indicators | Recommended Sources |

|---|---|---|

| Engine Components | Serial numbers, dimensions | Official manuals, online retailers |

| Electrical Parts | Wattage, connectors | Manufacturer websites, community forums |

| Propulsion Elements | Shape, mounting style | User reviews, comparison sites |

Tools Required for Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Having the right instruments on hand can simplify tasks and enhance efficiency during servicing.

- Socket Wrench Set

- Screwdriver Set (Flathead and Phillips)

- Pliers (Standard and Needle Nose)

- Torque Wrench

- Fuel Line Clamps

- Multimeter for Electrical Diagnostics

- Cleaning Supplies (Brushes, Rags)

Each of these tools plays a crucial role in the maintenance process, allowing you to address various components effectively and with precision.

Benefits of Using Genuine Parts

Utilizing authentic components ensures optimal performance and longevity of your equipment. These original items are designed specifically for compatibility, providing a seamless integration that enhances reliability and efficiency.

Durability is a significant advantage of choosing original items. They are crafted from high-quality materials, resulting in better resistance to wear and tear compared to aftermarket alternatives. This leads to fewer replacements and lower overall costs in the long run.

Another essential aspect is warranty protection. Many manufacturers offer guarantees on their products, which often remain valid only if genuine components are used. This can save you from unexpected expenses and ensure peace of mind.

Additionally, using authentic parts can maintain resale value. Equipment equipped with original components is typically more appealing to potential buyers, as it reflects a commitment to quality and proper maintenance.

Lastly, opting for original items provides a higher safety standard. They are subjected to rigorous testing and quality control, reducing the risk of malfunctions that could lead to accidents or further damage.

Where to Find Yamaha 9.9 Parts

Finding the right components for your marine engine can be a challenging task, especially if you want to ensure optimal performance and longevity. It’s essential to know where to look for reliable sources that offer quality replacements, as well as access to detailed schematics for proper assembly and maintenance.

Online Retailers

The internet is a treasure trove of options for sourcing essential components. Many specialized e-commerce sites provide a wide range of options, often featuring user reviews and ratings to help you make informed decisions. Consider searching for dedicated marine equipment suppliers that cater specifically to your needs, ensuring that you find authentic and high-quality items.

Local Dealerships and Repair Shops

Visiting nearby dealerships or repair shops can be advantageous for those who prefer a hands-on approach. These establishments often have knowledgeable staff who can assist you in locating the necessary components. Additionally, they may offer repair services and can provide valuable advice on maintenance practices to extend the life of your engine.

Maintenance Tips for Longevity

Ensuring the durability and performance of your marine engine requires regular care and attention. Adopting a systematic maintenance routine can significantly extend the lifespan of your equipment and enhance its operational efficiency.

- Regular Inspection: Check all components frequently for signs of wear or damage. Early detection can prevent costly repairs.

- Fluid Checks: Monitor oil and coolant levels consistently. Replace fluids as recommended to keep the engine running smoothly.

- Cleaning: Keep the engine and surrounding areas free of debris. Cleanliness helps prevent corrosion and mechanical failures.

- Storage Practices: When not in use, store the engine properly. Ensure it is protected from the elements to avoid deterioration.

By implementing these practices, you can help maintain optimal performance and ensure your marine engine remains in excellent condition for years to come.

- Follow the Manufacturer’s Guidelines: Adhere to the suggested maintenance schedule provided by the manufacturer.

- Use Quality Parts: When replacements are necessary, choose high-quality components to ensure compatibility and reliability.

- Professional Servicing: Consider having a professional service the engine periodically, especially if you are unsure about any maintenance tasks.

Consistent and mindful upkeep will not only safeguard your investment but also enhance your overall experience on the water.

DIY Repairs for Yamaha Outboards

Performing maintenance and repairs on your outboard motor can be a rewarding experience. Understanding the fundamentals of your engine allows you to tackle common issues, saving time and money while enhancing your boating adventures. With the right tools and a bit of patience, many tasks can be accomplished at home.

Common Issues and Solutions

Engines may encounter various challenges, from fuel system problems to electrical failures. One of the most frequent concerns is a lack of power or rough idling. This can often be traced back to fuel quality or clogged filters. Regularly inspecting and replacing fuel lines, along with cleaning or replacing filters, can significantly improve performance.

Essential Tools and Safety Tips

Before diving into repairs, ensure you have the necessary tools on hand, such as wrenches, screwdrivers, and a multimeter for electrical diagnostics. Safety should always be a priority; wearing gloves and goggles will protect you from potential hazards. Additionally, working in a well-ventilated area is crucial, especially when dealing with fuel or chemicals.

Documentation of each step is important, as it helps track changes and maintain a history of your repairs. Embrace the learning process, and don’t hesitate to seek resources or forums for advice from fellow enthusiasts.