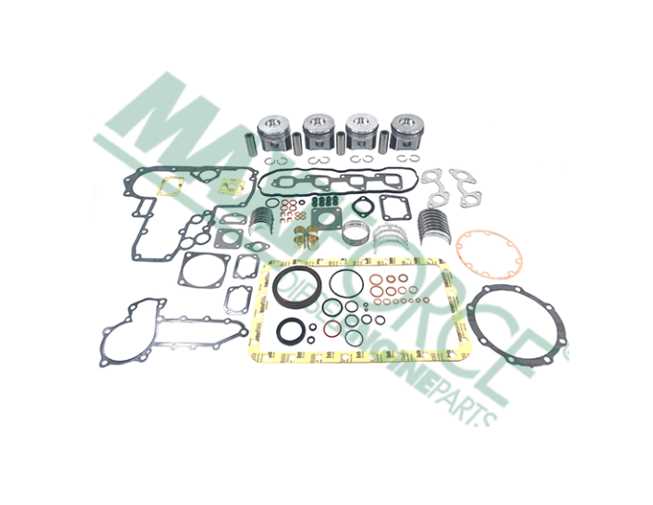

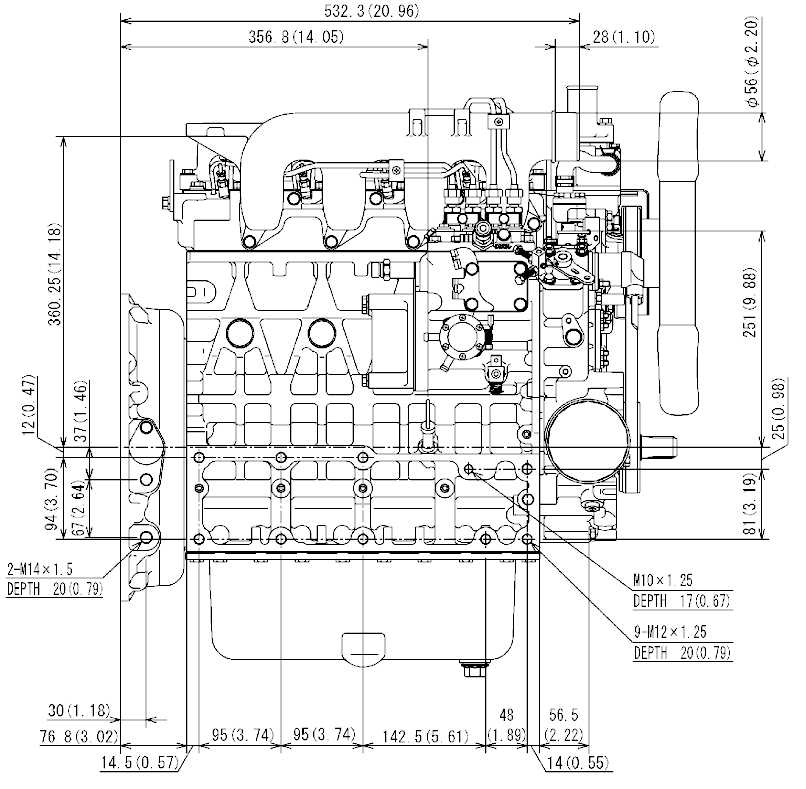

Kubota V2403 Parts Diagram Overview

In the realm of machinery maintenance, grasping the intricate layout of engine components is essential for effective troubleshooting and repair. An organized visual representation aids technicians in identifying individual elements, streamlining the diagnostic process, and ensuring the longevity of the equipment.

These detailed illustrations serve as invaluable tools, providing clarity on the relationships and functions of various parts within the engine assembly. By familiarizing oneself with these layouts, operators can enhance their understanding of how each component interacts, leading to more informed decisions during servicing.

Moreover, such schematics not only facilitate the identification of necessary replacements but also empower users to carry out maintenance tasks with confidence. Whether for educational purposes or practical application, having access to comprehensive component representations is crucial for anyone involved in engine care.

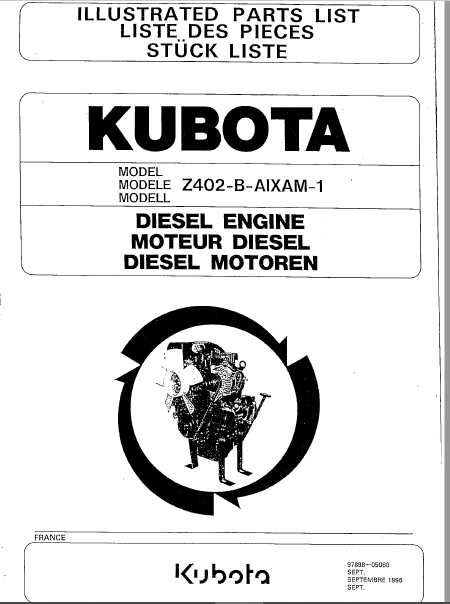

Kubota V2403 Overview

This section provides a comprehensive look at a particular engine model renowned for its efficiency and durability. Designed for various applications, it stands out in the market due to its robust performance and reliability. Users can expect exceptional power output while maintaining fuel efficiency, making it an ideal choice for a range of machinery.

| Feature | Description |

|---|---|

| Engine Type | Four-cylinder diesel engine |

| Power Output | Approx. 50-60 HP |

| Displacement | 2.4 liters |

| Cooling System | Water-cooled |

| Applications | Agricultural, construction, and industrial |

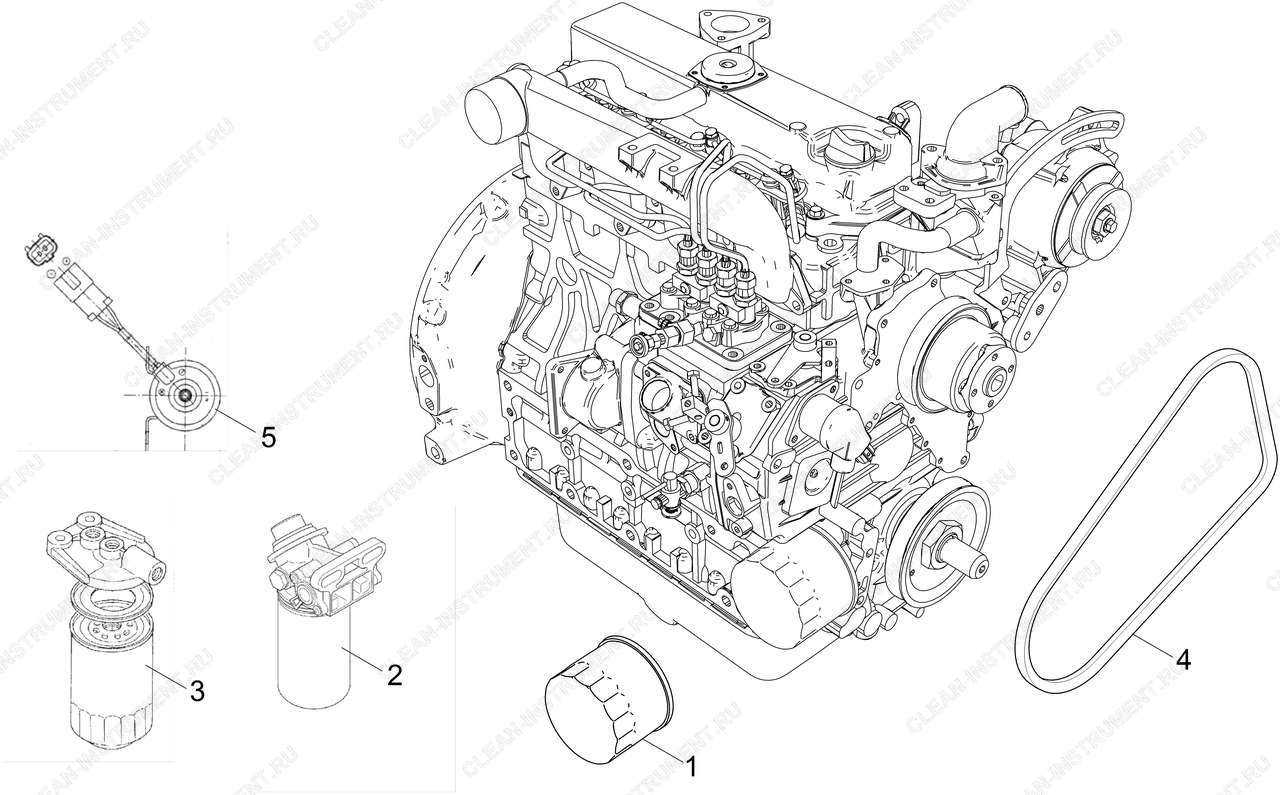

Understanding Engine Components

Engines are complex machines composed of various parts that work in unison to generate power. Each component plays a crucial role, contributing to the overall efficiency and functionality of the unit. Understanding these elements is essential for maintenance, troubleshooting, and performance enhancement.

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and supports other components. |

| Pistons | Convert fuel energy into mechanical motion. |

| Cylinder Head | Seals the top of the cylinders and contains valves. |

| Valves | Control the intake of air and fuel and the exhaust of gases. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion. |

| Camshaft | Operates the valves at the correct timing. |

| Fuel Injector | Delivers the precise amount of fuel into the combustion chamber. |

| Cooling System | Regulates engine temperature to prevent overheating. |

A thorough grasp of these components and their functions allows for better diagnostics and improvements in performance, ultimately enhancing the longevity and reliability of the engine.

Importance of Parts Diagrams

Understanding the assembly and functionality of complex machinery is crucial for maintenance and repair. Visual representations play a significant role in conveying how different components interact and fit together. They serve as essential tools for technicians and engineers, enabling them to identify issues quickly and ensure proper reassembly after servicing.

Enhancing Troubleshooting Efficiency

When a machine malfunctions, having a visual guide can streamline the diagnostic process. Technicians can easily locate problematic areas and understand the relationship between various elements. This clarity reduces downtime, allowing for faster repairs and less disruption to operations.

Facilitating Accurate Repairs

Clear illustrations aid in ensuring that replacements are executed correctly. Without visual aids, the risk of misalignment or incorrect installation increases, potentially leading to further complications. Such resources help maintain the integrity of the equipment and extend its lifespan.

In summary, visual aids are indispensable for effective maintenance. They not only enhance troubleshooting capabilities but also promote accuracy in repairs, ultimately contributing to the reliability of machinery.

Common Issues with V2403 Parts

Various components in diesel engines can encounter specific challenges that affect performance and longevity. Understanding these issues is crucial for effective maintenance and repair.

- Wear and Tear: Regular usage can lead to deterioration of critical components, impacting efficiency.

- Fluid Leaks: Seals and gaskets may degrade over time, causing leaks that can compromise engine function.

- Overheating: Inefficient cooling systems can result in excessive temperatures, potentially damaging internal mechanisms.

- Electrical Failures: Faulty wiring or connections can disrupt the electrical system, leading to operational failures.

To address these concerns, regular inspections and timely replacements are essential for optimal engine performance.

Finding Replacement Parts

Locating suitable components for your machinery can be a crucial task for maintenance and repairs. Ensuring that you have the correct items enhances performance and longevity. With the right approach, you can streamline this process and avoid common pitfalls.

Researching Online is often the most effective way to find necessary components. Numerous websites offer extensive catalogs, allowing you to compare specifications and prices. Be sure to read customer reviews to gauge reliability.

Consulting Manuals can provide vital information about compatible items. These documents typically include identification numbers and detailed descriptions, helping you make informed choices.

Visiting Local Dealers is another option. Engaging with professionals can lead to personalized advice and insights about availability and quality.

Networking with Fellow Users can also yield useful recommendations. Online forums and community groups often share experiences and suggestions that can guide you to trustworthy sources.

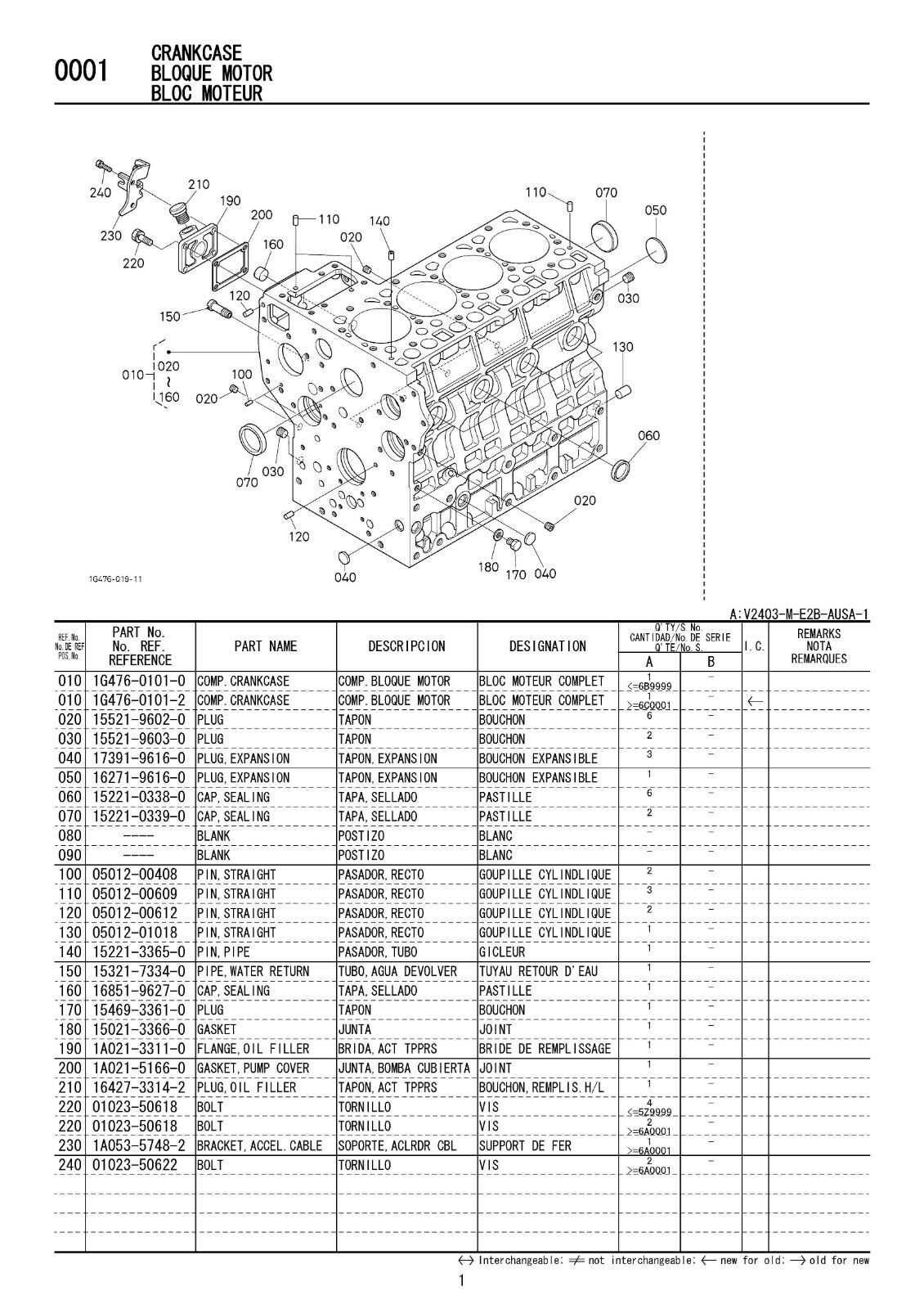

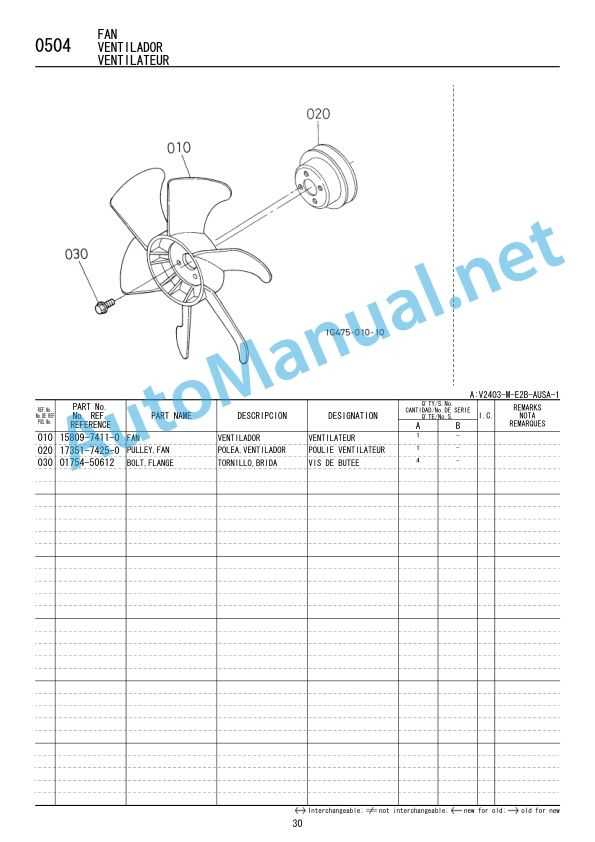

How to Read Parts Diagrams

Understanding schematic representations of components is essential for effective maintenance and repair. These visual aids provide a clear view of how various elements interact and fit together within a complex system. By mastering the interpretation of these illustrations, you can enhance your troubleshooting skills and streamline your repair processes.

Identifying Components

The first step in decoding these illustrations is recognizing the individual elements. Each part is typically labeled with a unique identifier that corresponds to a specific item in the accompanying list. Familiarize yourself with these labels to easily locate the necessary components during repairs.

Understanding Relationships

Beyond identifying each element, it’s crucial to grasp how they connect and interact. Lines and arrows often indicate relationships, showing how parts are linked or how they function together. Pay attention to these connections, as they provide insight into assembly and disassembly processes, ensuring you maintain the integrity of the system.

Key Specifications of V2403

This section outlines the essential features and characteristics of a well-regarded engine model, highlighting its performance, efficiency, and design. Understanding these specifications is crucial for anyone looking to maximize its capabilities and ensure optimal operation.

| Specification | Details |

|---|---|

| Displacement | 2.4 liters |

| Cylinder Configuration | Inline 4-cylinder |

| Power Output | 49.6 HP at 2800 RPM |

| Torque | 130 Nm at 1600 RPM |

| Fuel Type | Diesel |

| Cooling System | Water-cooled |

| Weight | 290 kg |

Maintenance Tips for Longevity

Ensuring the extended lifespan of machinery requires consistent care and attention. Regular maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns, saving time and resources.

Regular Inspection

- Check fluid levels frequently to avoid overheating and wear.

- Inspect belts and hoses for signs of wear and tear.

- Clean air filters regularly to maintain optimal airflow.

Scheduled Servicing

- Follow a maintenance schedule based on hours of operation.

- Replace worn parts promptly to prevent further damage.

- Lubricate moving components to reduce friction and wear.

Manufacturer’s Recommendations

Ensuring the longevity and optimal performance of machinery relies heavily on adhering to the guidelines set forth by the manufacturer. These recommendations encompass a variety of aspects, from regular maintenance schedules to specific operational practices. Following these guidelines not only enhances efficiency but also minimizes the risk of unexpected breakdowns.

Key Maintenance Practices

- Regular oil changes to maintain engine health.

- Frequent inspections of cooling systems to prevent overheating.

- Consistent monitoring of filters to ensure clean fuel and air intake.

Operational Guidelines

- Always operate within recommended load limits to avoid excessive strain.

- Warm up the engine adequately before use to ensure smooth operation.

- Utilize the appropriate fuel type as specified to prevent damage.

By adhering to these essential practices, operators can significantly extend the lifespan of their equipment and enhance overall productivity.

Cost Considerations for Repairs

When assessing the financial implications of maintenance and restoration tasks, several factors come into play. Understanding these elements is crucial for budgeting effectively and avoiding unexpected expenses. Each component’s pricing, labor costs, and the complexity of the repair can significantly influence the overall expenditure.

One of the primary aspects to consider is the availability and pricing of replacement components. Genuine parts often come at a premium, while aftermarket alternatives may offer cost savings, albeit with potential trade-offs in quality and longevity. Evaluating the long-term benefits versus initial costs can help in making informed decisions.

Additionally, labor charges can vary widely depending on the technician’s expertise and the regional market. Some repairs may require specialized skills, which can further elevate costs. It’s essential to seek multiple quotes and consider the reputation of service providers to ensure a balance between quality and affordability.

Another consideration involves the frequency of maintenance. Regular servicing can prevent major breakdowns and costly repairs down the line. Investing in proactive care often pays off by extending the lifespan of equipment and minimizing the likelihood of significant financial outlays.

Lastly, it’s wise to account for potential downtime during repairs. The impact on productivity can translate to lost revenue, making it essential to weigh repair costs against operational efficiency. Careful planning and timely maintenance can mitigate these risks, ensuring a smoother workflow and more predictable budgeting.

Best Sources for OEM Parts

When seeking high-quality components for machinery, it’s essential to identify reliable vendors. These sources provide authentic replacements that ensure optimal performance and longevity.

Authorized Dealers are often the first choice, as they offer genuine items backed by warranties. Additionally, their staff can provide expert guidance on compatibility and installation.

Online Marketplaces also present a vast selection, but it’s crucial to verify the seller’s credibility. Look for those with positive reviews and a solid return policy.

Specialty Suppliers often focus on specific brands or types of equipment, making them valuable for hard-to-find components. They typically have extensive knowledge and can assist in locating the right part.

In summary, investing time in finding trustworthy sources will ultimately lead to better performance and durability of your machinery.

Upgrades and Modifications Options

Enhancing the performance and efficiency of machinery can significantly improve its longevity and effectiveness. Various upgrades and modifications can be implemented to tailor equipment to specific needs, ensuring optimal functionality and reliability. This section explores some of the most beneficial options available.

Performance Enhancements

Investing in performance upgrades, such as advanced fuel injection systems or improved exhaust components, can lead to enhanced power output and fuel efficiency. These modifications allow for smoother operation and reduced emissions, aligning with environmental standards while maximizing productivity.

Durability Improvements

Strengthening the structural integrity of key components is essential for prolonged usage. Upgrading to high-quality materials or incorporating protective coatings can mitigate wear and tear, extending the lifespan of critical parts. Such improvements ensure that the machinery can withstand demanding conditions while maintaining its operational capabilities.