Comprehensive Guide to Stihl 660 Parts Diagram

The intricacies of a chainsaw’s design can often be overwhelming. A thorough exploration of its various elements provides valuable insight into its functionality and maintenance. Grasping how each segment interacts is crucial for both novice users and seasoned professionals.

By examining the layout of these essential components, one can enhance their knowledge and skills in operating and servicing the equipment. This understanding not only facilitates repairs but also boosts overall efficiency and safety during use.

Ultimately, mastering the assembly and organization of a chainsaw’s internal mechanisms empowers users to make informed decisions regarding upkeep and optimization. Let’s delve into the specifics to ensure a comprehensive grasp of these vital features.

Understanding Stihl 660 Parts Diagram

Gaining insight into the intricate layout of components is essential for effective maintenance and repair. A comprehensive understanding can enhance functionality and longevity of equipment.

- Identification of key elements

- Connection between various sections

- Recognizing wear and tear

By analyzing the structure, users can:

- Locate specific items easily

- Facilitate troubleshooting processes

- Ensure proper reassembly after servicing

This knowledge ultimately leads to improved performance and user satisfaction.

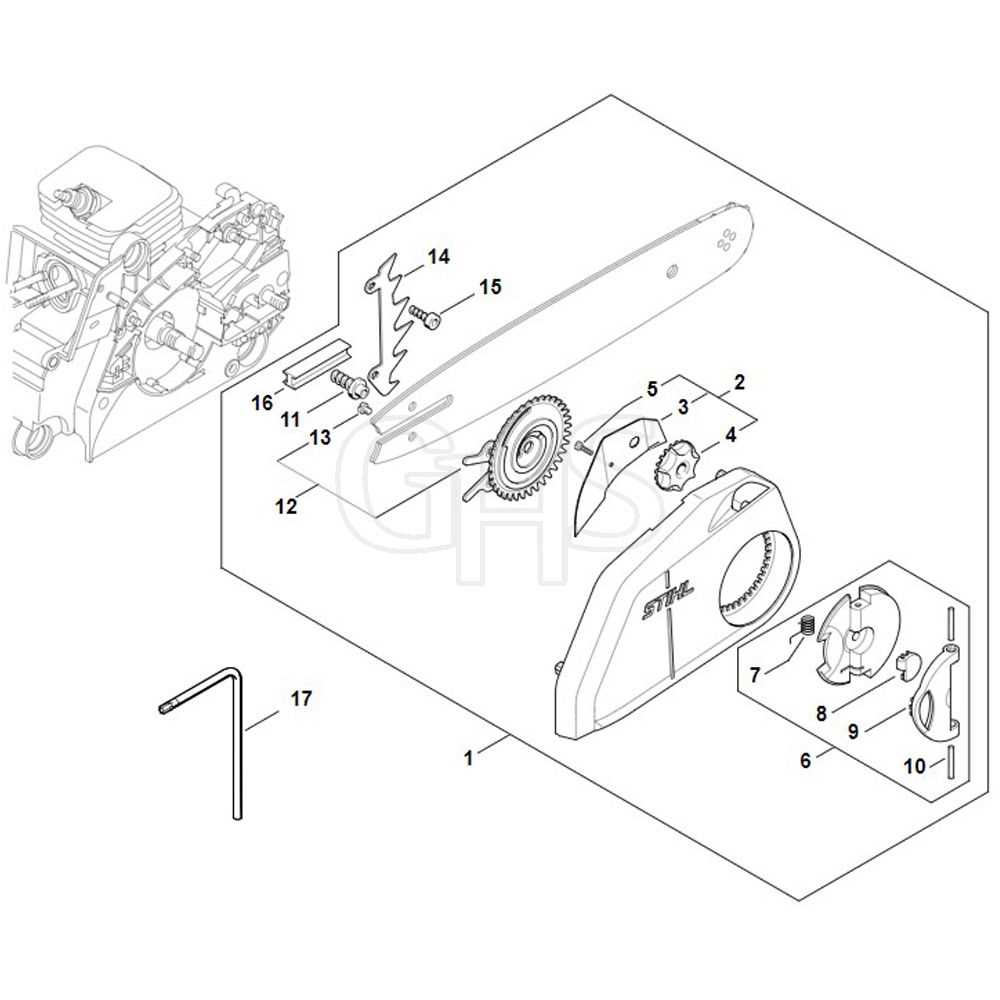

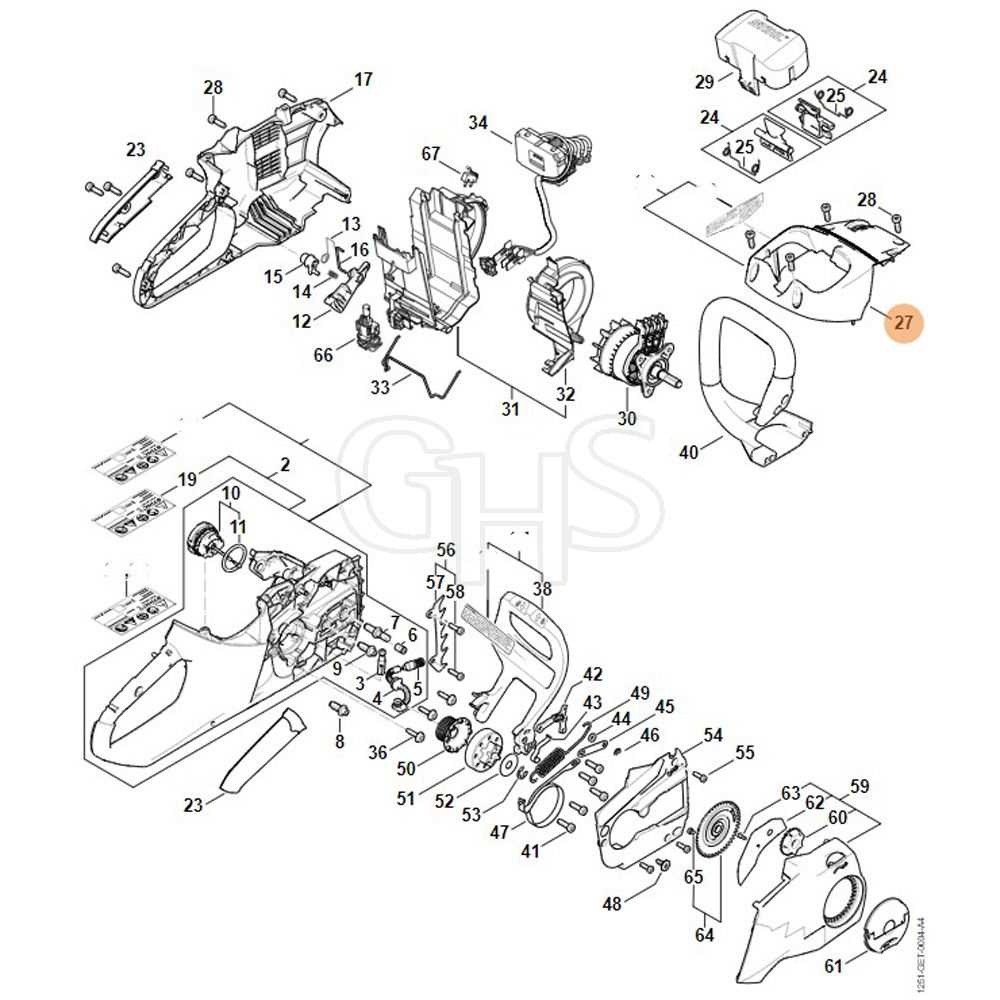

Key Components of Stihl 660

Understanding the essential elements of a powerful cutting tool can enhance both its performance and longevity. This section delves into the critical components that contribute to the efficiency and reliability of the machine, ensuring optimal operation during various tasks.

Major Elements

The core components work together to deliver exceptional power and precision. Each part plays a significant role in the overall functionality, from the engine to the cutting mechanism.

| Component | Description |

|---|---|

| Engine | Provides the necessary power for high-performance cutting. |

| Bar and Chain | Integral for cutting through wood and other materials effectively. |

| Air Filter | Prevents debris from entering the engine, maintaining efficiency. |

| Fuel System | Ensures proper fuel delivery for optimal engine performance. |

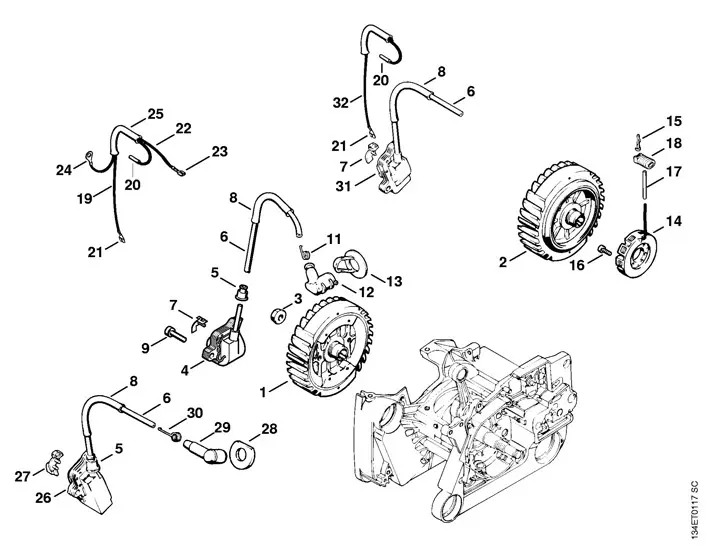

| Ignition System | Responsible for starting the engine and maintaining smooth operation. |

Supporting Features

Additional features enhance user experience and operational efficiency. Understanding these aspects can help in maintenance and troubleshooting.

| Feature | Benefit |

|---|---|

| Vibration Dampening | Reduces operator fatigue during extended use. |

| Safety Switch | Prevents accidental starts, enhancing user safety. |

| Ergonomic Handle | Improves comfort and control during operation. |

Importance of Maintenance for Chainsaws

Regular upkeep is essential for optimal performance and longevity of cutting tools. Neglecting maintenance can lead to diminished efficiency and increased risks during operation. Understanding the significance of proper care can ultimately save time, money, and ensure safety.

Benefits of Routine Maintenance

- Improved Performance: Regular checks and adjustments ensure the tool operates at peak efficiency.

- Increased Safety: Proper maintenance minimizes the risk of accidents and malfunctions.

- Extended Lifespan: Routine care can significantly prolong the lifespan of the equipment.

Key Maintenance Practices

- Regular Cleaning: Remove debris and buildup after each use to prevent damage.

- Chain Tension Adjustment: Ensure the cutting chain is properly tensioned for effective cutting.

- Oil Maintenance: Regularly check and refill lubrication to prevent wear and tear.

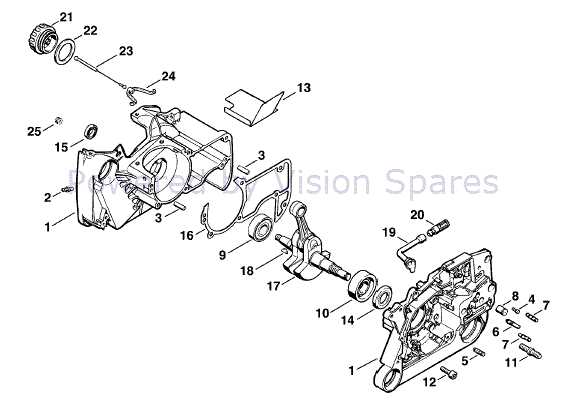

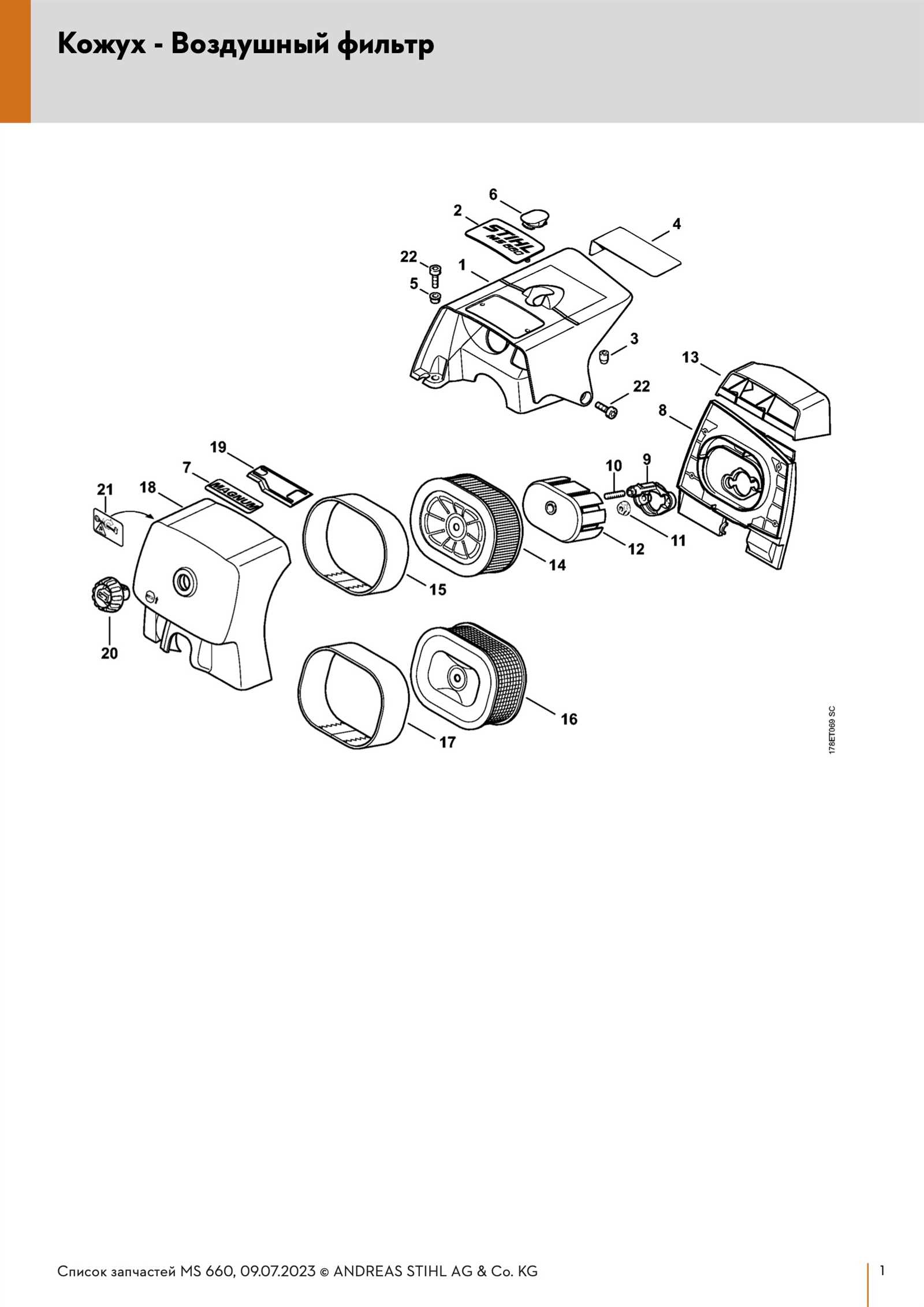

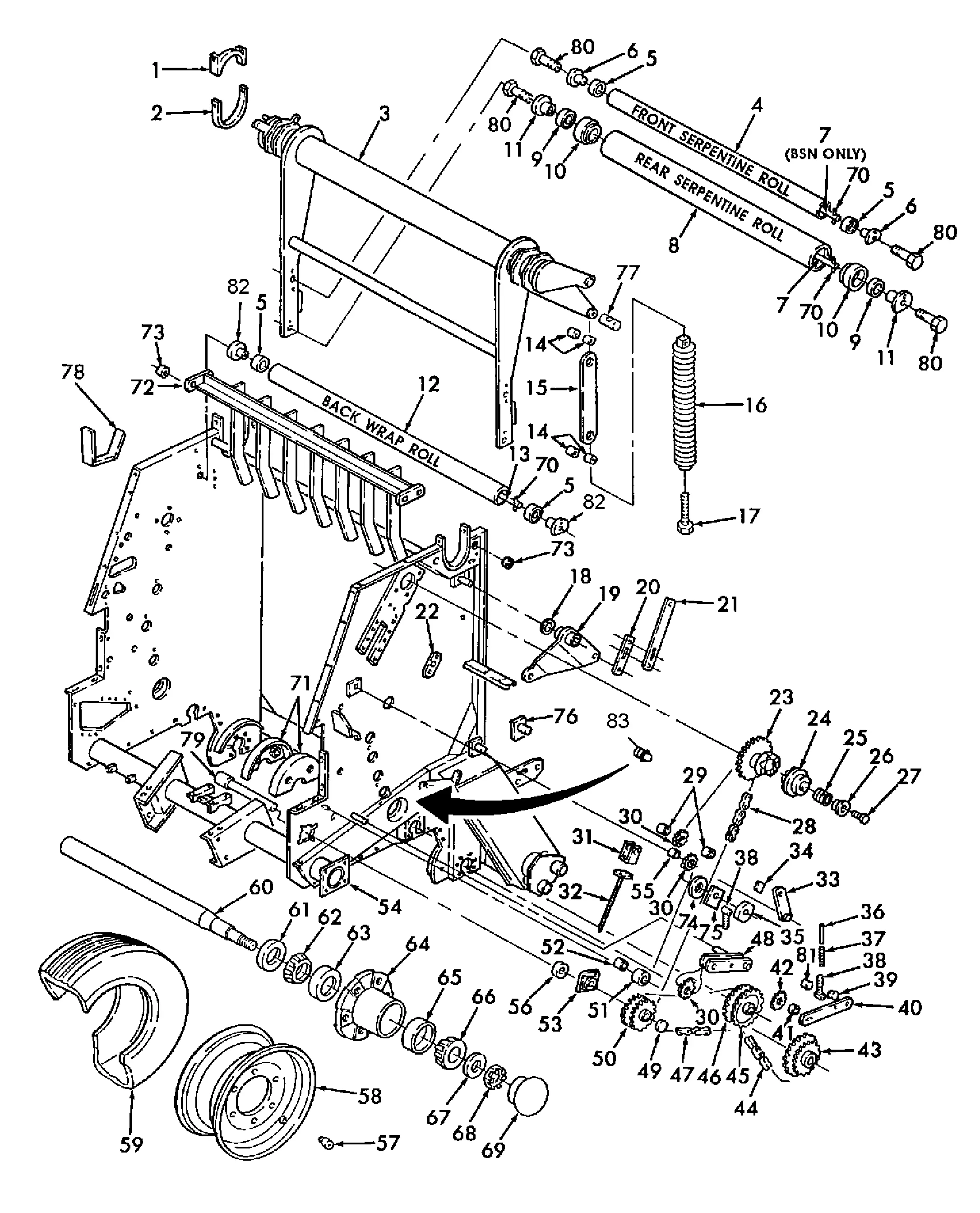

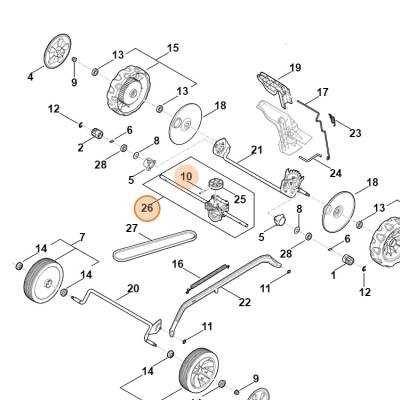

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual representations serve as a roadmap, helping users identify components and their relationships within a system. By familiarizing yourself with these images, you can streamline your repair process and ensure accurate reassembly.

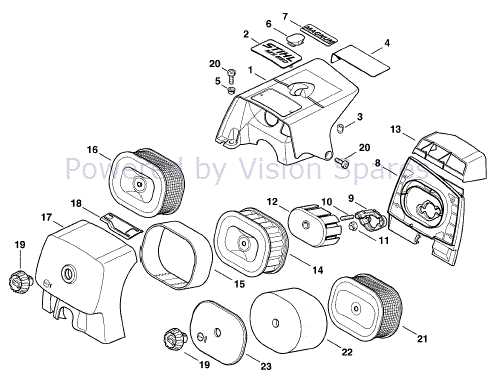

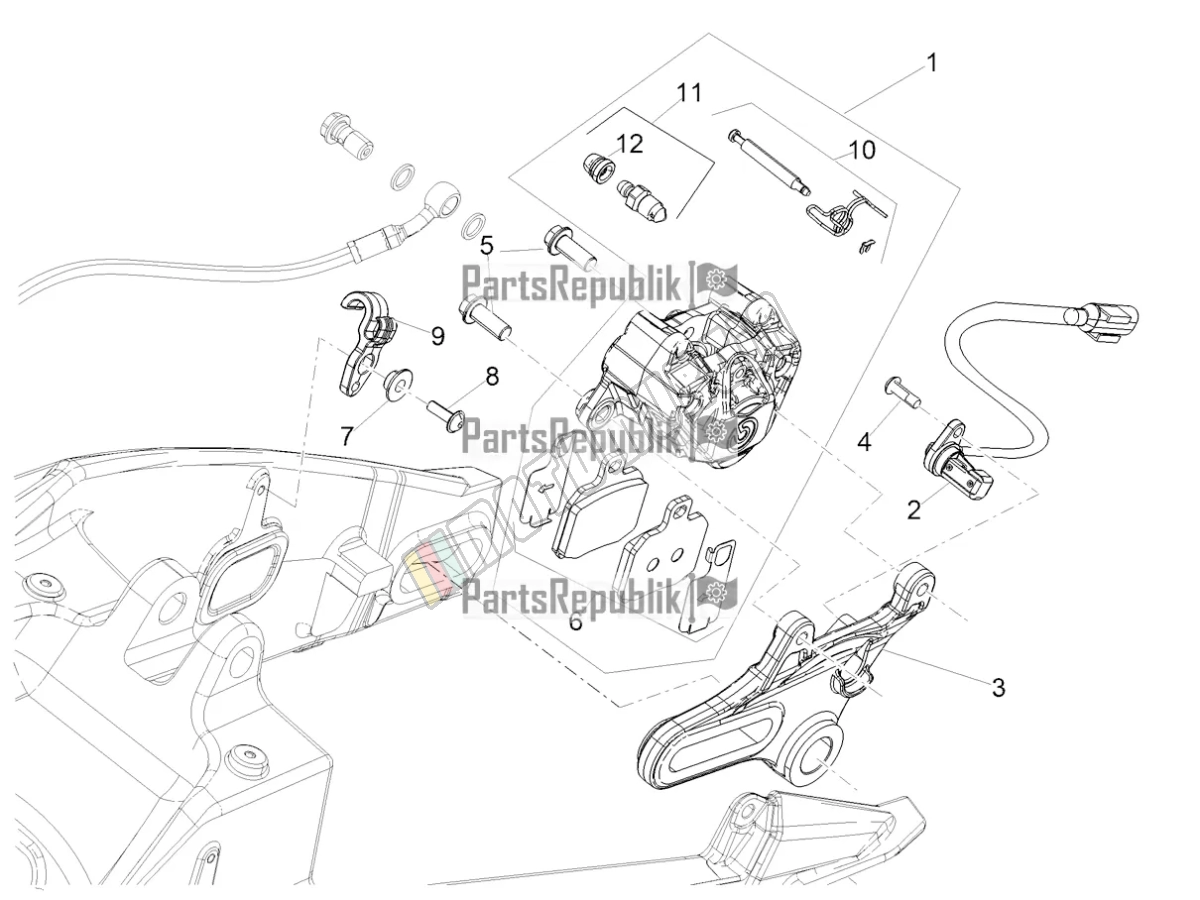

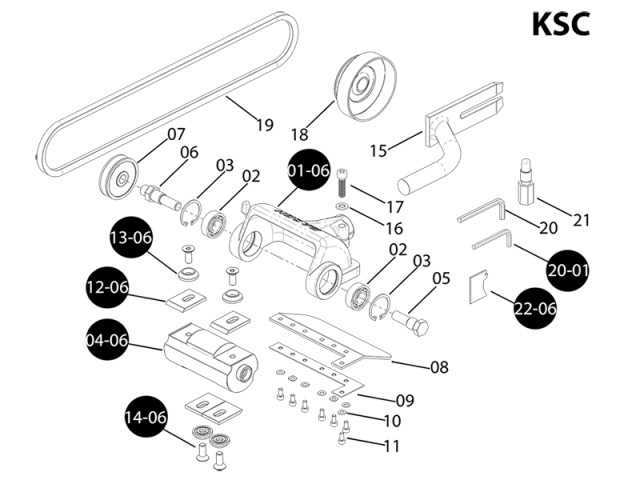

Identifying Components

Each section of the illustration typically features a variety of elements, often labeled with specific numbers or letters. This coding system enables you to pinpoint the exact parts needed for your tasks. To utilize this effectively, follow these steps:

| Step | Description |

|---|---|

| 1 | Locate the key or legend that corresponds with the numbers or letters on the illustration. |

| 2 | Match the identified component from the legend with its corresponding part in the visual. |

| 3 | Note any additional details such as size or type, which are often specified alongside the component numbers. |

Understanding Relationships

In addition to identifying individual elements, it’s crucial to comprehend how these pieces interact. Observing connection points, orientations, and assembly sequences can prevent errors during repairs. Consider these tips:

| Tip | Description |

|---|---|

| 1 | Examine how components fit together by noting the alignment and angles shown in the illustration. |

| 2 | Look for any arrows or lines that indicate movement or flow within the system. |

| 3 | Pay attention to any notes or symbols that may indicate special instructions or warnings. |

Common Issues with Stihl 660

When operating powerful chainsaws, users may encounter various challenges that can hinder performance and efficiency. Understanding these common problems can aid in timely troubleshooting and maintenance, ensuring optimal operation.

- Starting Difficulties:

- Fuel mixture issues.

- Clogged air filters.

- Faulty spark plugs.

- Power Loss:

- Dirty or worn-out filters.

- Fuel line blockages.

- Carburetor malfunctions.

- Chain Problems:

- Improper tension settings.

- Worn sprockets.

- Inadequate lubrication.

- Vibration Issues:

- Loose components.

- Unbalanced cutting chain.

- Excessive wear on dampers.

Addressing these common concerns promptly can enhance the longevity and reliability of the equipment, leading to better results in the field.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining optimal performance. Various sources offer a range of options to ensure you find exactly what you need for repairs or upgrades.

Authorized Dealers: One of the most reliable sources is authorized distributors, who provide genuine items that meet manufacturer specifications.

Online Marketplaces: E-commerce platforms are another convenient option, where you can compare prices and read reviews from other users to make informed choices.

Local Repair Shops: Many local technicians stock commonly used components and can also provide expert advice on compatibility and installation.

Salvage Yards: For those seeking budget-friendly alternatives, salvage yards may offer used parts that are still in good condition.

By exploring these avenues, you can ensure your equipment remains in top shape for years to come.

Identifying Parts by Number

Understanding the components of a machine is essential for efficient maintenance and repair. Identifying each element by its specific number not only simplifies the process of ordering replacements but also ensures compatibility and accuracy in servicing. By familiarizing yourself with the numerical designations of various components, you can streamline your workflow and enhance the longevity of your equipment.

In this section, we will explore how to locate and interpret the numerical identifiers associated with individual components. This knowledge is crucial for anyone looking to perform repairs or upgrades effectively.

| Component | Identifier | Description |

|---|---|---|

| Cylinder | 123-456-789 | Houses the piston and is critical for combustion. |

| Fuel Tank | 987-654-321 | Stores the fuel required for operation. |

| Air Filter | 555-444-333 | Prevents debris from entering the engine. |

| Ignition Module | 222-111-000 | Responsible for spark generation in the engine. |

Using this structured approach allows for quick reference and effective communication with suppliers or service technicians. Properly identifying parts ensures that maintenance can be carried out smoothly and efficiently.

Tools Needed for Disassembly

When embarking on the task of dismantling complex machinery, having the right tools is essential for a smooth and efficient process. A well-prepared toolkit not only simplifies the procedure but also ensures safety and prevents damage to components.

Wrenches are vital for loosening and tightening bolts, while screwdrivers of various types will assist in removing screws from different surfaces. Additionally, pliers can be invaluable for gripping and twisting small parts.

For more intricate tasks, socket sets provide versatility and ease, allowing access to tight spaces. Don’t forget to include torque wrenches to apply the correct force when reassembling components.

Lastly, cleaning brushes and rags are helpful for maintaining cleanliness during the disassembly, ensuring that no debris interferes with the process. Having these tools at hand will ultimately lead to a more successful and organized disassembly experience.

Step-by-Step Repair Guide

This section provides a comprehensive approach to repairing your equipment, ensuring you follow a systematic process for optimal results. By adhering to these steps, you can enhance your skills and achieve effective repairs.

- Assess the Issue: Begin by identifying the problem. Take notes on any unusual sounds or performance issues.

- Gather Tools: Collect all necessary tools, such as screwdrivers, wrenches, and replacement components.

- Disassemble Carefully: Follow a logical sequence to dismantle the unit. Keep track of screws and small parts.

- Inspect Components: Examine each part for wear or damage. Make note of items needing replacement.

- Replace Damaged Parts: Install new components, ensuring they fit correctly and securely.

- Reassemble the Unit: Follow your initial disassembly steps in reverse. Ensure all parts are aligned and secured.

- Test Functionality: Power on the equipment to ensure it operates smoothly. Monitor for any issues.

Following these steps will help you effectively repair your machine and prolong its lifespan.

Safety Tips When Repairing Chainsaws

When engaging in maintenance or repairs on cutting tools, prioritizing safety is crucial. Proper precautions can prevent accidents and ensure a smooth process.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and hearing protection.

- Ensure the tool is completely powered down and disconnected from any power source before starting repairs.

- Work in a well-lit, clutter-free area to maintain focus and reduce hazards.

Following guidelines not only enhances safety but also improves the efficiency of your work.

- Read the manufacturer’s manual for specific safety recommendations.

- Keep all tools organized to avoid misplacing items during repairs.

- Be aware of your surroundings and maintain a safe distance from others while working.

Aftermarket vs. Original Parts

When it comes to maintaining outdoor power equipment, the choice between factory components and third-party alternatives often sparks debate among users. Both options present distinct advantages and challenges that can impact performance, longevity, and overall satisfaction. Understanding these differences is crucial for making informed decisions.

Original components are crafted by the manufacturer to meet specific quality standards and performance criteria. They typically come with warranties, ensuring reliability and consistency. These items are designed to fit perfectly and function seamlessly with the equipment, minimizing the risk of issues arising from compatibility problems.

On the other hand, aftermarket alternatives can offer significant cost savings and a wider range of options. These components are often produced by independent manufacturers and can vary greatly in quality. While some aftermarket offerings match or even exceed the performance of factory parts, others may compromise durability or efficiency. It is essential for users to research and select reputable brands to ensure they receive reliable products.

Ultimately, the decision between these two categories hinges on individual priorities such as budget, performance expectations, and personal experience. Balancing these factors can lead to optimal choices for maintaining equipment effectively.

Upgrades for Improved Performance

Enhancing the functionality of your equipment can significantly impact its efficiency and longevity. Various modifications can be implemented to achieve optimal results and elevate performance standards.

- Air Filter Upgrade: Installing a high-flow air filter can improve airflow, leading to better combustion and increased power output.

- Exhaust System Modification: A performance exhaust can reduce back pressure, enhancing engine efficiency and sound.

- Ignition System Enhancement: Upgrading to a more advanced ignition module can improve spark timing, resulting in better throttle response.

- Fuel Mixture Optimization: Adjusting the fuel mixture for your specific needs can lead to improved engine performance and fuel efficiency.

- Bar and Chain Upgrade: A lighter, more efficient bar and chain combination can reduce drag and improve cutting speed.

Implementing these enhancements can lead to the ultimate improvement in your equipment’s capabilities, ensuring it performs at its best for years to come.

Resources for Stihl Enthusiasts

For those passionate about outdoor power equipment, finding reliable sources of information can enhance the experience significantly. Numerous platforms cater to enthusiasts, offering insights, parts availability, and community support.

- Forums: Online communities allow users to share tips and troubleshoot issues.

- Manufacturer Websites: Official pages provide technical specifications and manuals.

- Instructional Videos: Video tutorials help with maintenance and repairs.

- Local Dealers: Authorized retailers offer expert advice and original components.

By exploring these resources, enthusiasts can delve deeper into their hobby and ensure their equipment runs smoothly.