Comprehensive Guide to John Deere Z530R Parts Diagram

When maintaining your lawn care equipment, having a clear understanding of its various elements is essential. This knowledge not only aids in effective repairs but also enhances the overall performance of your machinery. By familiarizing yourself with the layout and functionality of each part, you can ensure your device runs smoothly and efficiently.

The intricacies of mower construction can seem daunting at first glance. However, breaking down the machinery into manageable sections reveals how each component contributes to the overall operation. Whether you are a seasoned technician or a novice user, grasping the arrangement of these elements empowers you to tackle maintenance tasks with confidence.

In this article, we will explore a comprehensive visual representation of the different sections of your mower, highlighting the significance of each component. This exploration will serve as a valuable resource for anyone looking to optimize their equipment’s performance and longevity.

Understanding John Deere Z530R Parts

When it comes to maintaining your outdoor equipment, grasping the components involved is essential. Each element plays a pivotal role in ensuring smooth operation and longevity. This section will explore the various sections and how they contribute to overall performance.

Identifying Components is crucial for effective maintenance. Familiarity with the key elements allows for timely replacements and repairs, reducing downtime and enhancing functionality.

Additionally, knowing the relationship between different sections helps in diagnosing issues quickly. Understanding how parts interact can lead to more informed decisions about upgrades or modifications.

In summary, a comprehensive understanding of the various elements not only aids in effective upkeep but also empowers you to optimize your machinery for the best results.

Overview of Z530R Specifications

This section presents a comprehensive examination of the features and technical attributes that define this exceptional mowing machine. Understanding these specifications is crucial for users looking to optimize performance and maintenance.

Key Features

- Powerful engine with efficient fuel consumption

- Advanced cutting deck design for superior grass handling

- Ergonomic controls for enhanced user comfort

Technical Attributes

- Engine Type: Air-cooled, V-twin

- Cutting Width: Adjustable options available

- Transmission: Hydrostatic for smooth operation

Common Parts and Their Functions

Understanding the essential components of a mowing machine is crucial for effective maintenance and operation. Each element plays a specific role that contributes to the overall performance, ensuring the equipment runs smoothly and efficiently.

Cutting Deck

The cutting deck is fundamental for achieving a clean and even lawn. It houses the blades, allowing for precise trimming of grass to the desired height. Regular inspection and maintenance of this component are vital to prevent uneven cuts and ensure longevity.

Transmission System

The transmission system is responsible for transferring power from the engine to the wheels. This component enables smooth movement and maneuverability, allowing the user to navigate various terrains with ease. Keeping the transmission well-maintained enhances performance and efficiency.

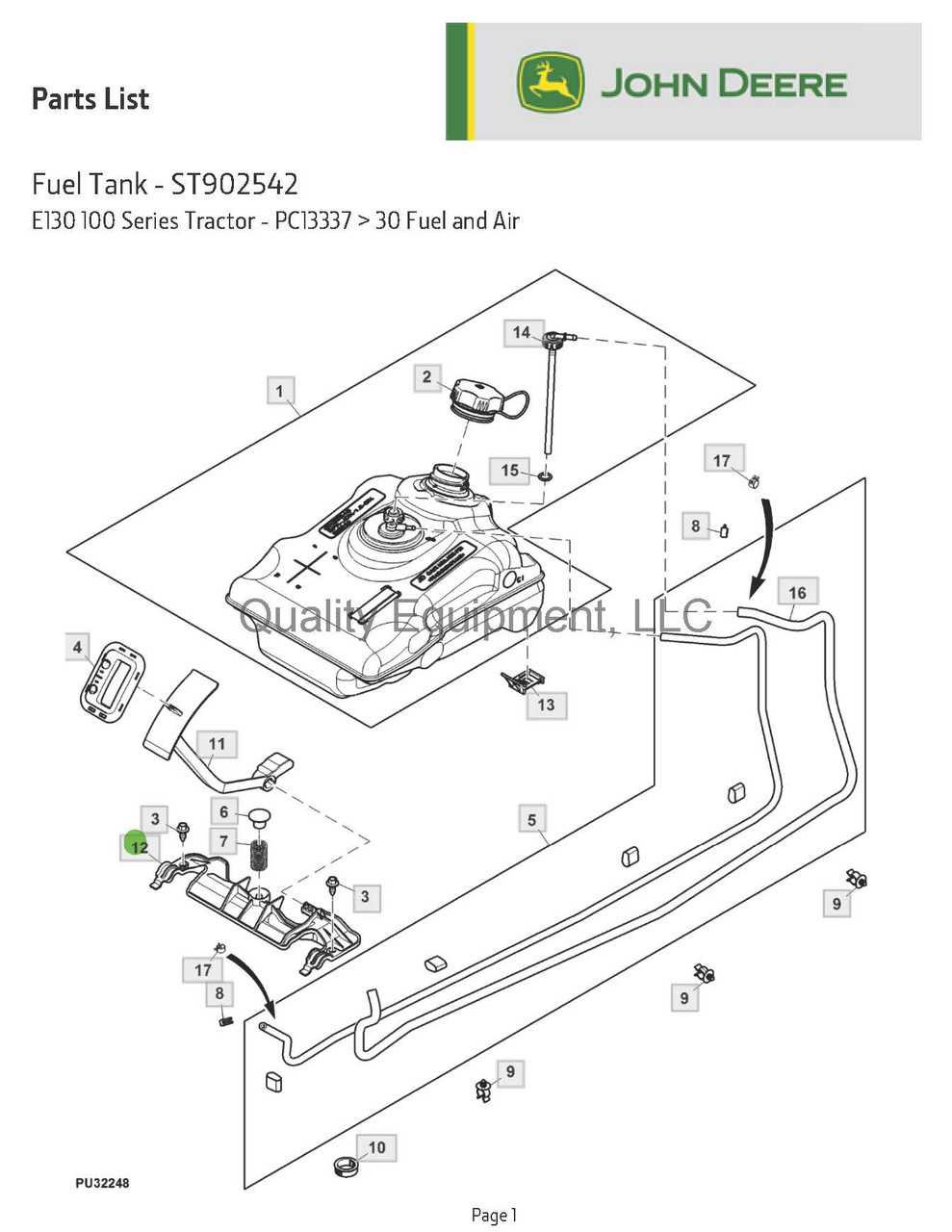

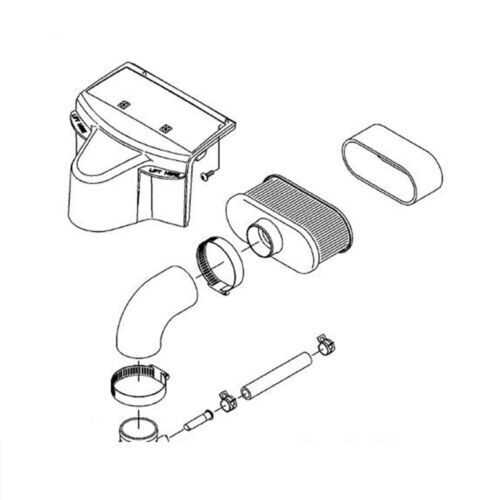

Visualizing the Parts Diagram

Understanding the assembly of complex machinery can be greatly enhanced through the use of visual representations. Such illustrations provide clarity on how various components interact and fit together, aiding in both maintenance and repair tasks. A well-structured visual guide can streamline the identification process, ensuring that users can efficiently locate each segment.

When examining a visual representation of components, it’s helpful to consider several key aspects:

- Organization: Elements are typically arranged in a logical sequence, making it easier to follow the assembly process.

- Labeling: Clear annotations help identify each piece, ensuring that users know precisely what they are looking at.

- Color Coding: Different colors can be employed to categorize parts, which simplifies understanding their respective functions.

Additionally, there are various approaches to enhancing comprehension of these visuals:

- Utilizing interactive tools that allow users to zoom in and explore details.

- Providing exploded views that separate components for better visibility.

- Incorporating 3D models to facilitate a more immersive experience.

Overall, a clear and informative visual guide is an essential resource for anyone looking to gain deeper insights into machinery configurations and repair strategies.

Maintenance Tips for Z530R Components

Ensuring the longevity and efficiency of machinery requires a proactive approach to upkeep. Regular inspections and servicing can significantly enhance performance and prevent costly repairs. This section offers essential advice on maintaining various elements to keep your equipment running smoothly.

First, always refer to the manufacturer’s guidelines for recommended maintenance intervals. These instructions provide crucial information on when to perform checks and replacements. For example, oil changes should be scheduled based on usage hours or seasonal shifts to guarantee optimal lubrication.

Next, pay close attention to air filters. Regular cleaning or replacement of these filters helps prevent debris from entering the engine, thereby enhancing airflow and efficiency. A clean filter can contribute to better fuel economy and reduced emissions.

Additionally, inspecting the cutting blades regularly is vital. Dull or damaged blades not only hinder performance but also place unnecessary strain on the engine. Sharpen or replace blades as needed to maintain cutting efficiency and overall machine health.

Lastly, don’t overlook the importance of tire maintenance. Check for proper inflation and tread wear to ensure stability and control. Properly maintained tires can improve traction and reduce wear on other components, ultimately extending the lifespan of the equipment.

How to Order Replacement Parts

When the time comes to replace components of your machinery, knowing the right approach can save you both time and money. Understanding the process of acquiring the necessary items is crucial for maintaining optimal performance and longevity of your equipment.

Identify the Needed Components

Start by assessing the specific elements that require replacement. Refer to your user manual or consult a reliable resource to ensure you are selecting the correct components. Detailed identification will prevent errors and streamline the ordering process.

Choose a Reputable Supplier

Select a trusted vendor that specializes in machinery components. Online platforms, local dealers, and authorized service centers are excellent options. Compare prices, availability, and delivery times to make an informed choice.

Tools Needed for Parts Replacement

When undertaking the task of component substitution, having the right equipment is essential for a seamless experience. Proper tools not only ensure efficiency but also enhance safety during the procedure.

Essential tools include wrenches, screwdrivers, and pliers, which are vital for loosening and securing fasteners. Additionally, a socket set can provide the versatility needed for various sizes and types of nuts and bolts.

For more intricate operations, specialty tools such as torque wrenches and diagnostic equipment may be necessary to achieve the ultimate precision. Furthermore, protective gear, including gloves and goggles, is highly recommended to safeguard against potential injuries.

By ensuring that you have these tools readily available, you can streamline the replacement process and minimize the likelihood of complications.

Identifying Worn or Damaged Parts

Recognizing components that show signs of wear or damage is crucial for maintaining optimal performance and longevity of machinery. This process involves careful observation and assessment to ensure safe and efficient operation.

Signs of Wear and Damage

- Visible cracks or fractures on surfaces

- Unusual noises during operation

- Excessive vibration

- Decreased efficiency or performance

Assessment Techniques

- Conduct regular visual inspections.

- Listen for any abnormal sounds while in operation.

- Check for play or looseness in moving parts.

- Review performance metrics and compare them to standard benchmarks.

Compatibility with Other Models

This section explores how components from a specific model align with various other machines in the same lineup, highlighting their interchangeability and shared features. Understanding compatibility can enhance maintenance and repair efforts, ultimately improving efficiency.

Key Compatible Models

- Model A

- Model B

- Model C

These models share similar designs, making it easier to source parts and conduct repairs without extensive modifications.

Benefits of Compatibility

- Simplified Maintenance

- Cost Efficiency

- Reduced Downtime

Utilizing interchangeable components can significantly streamline operational processes, providing the ultimate advantage for users.

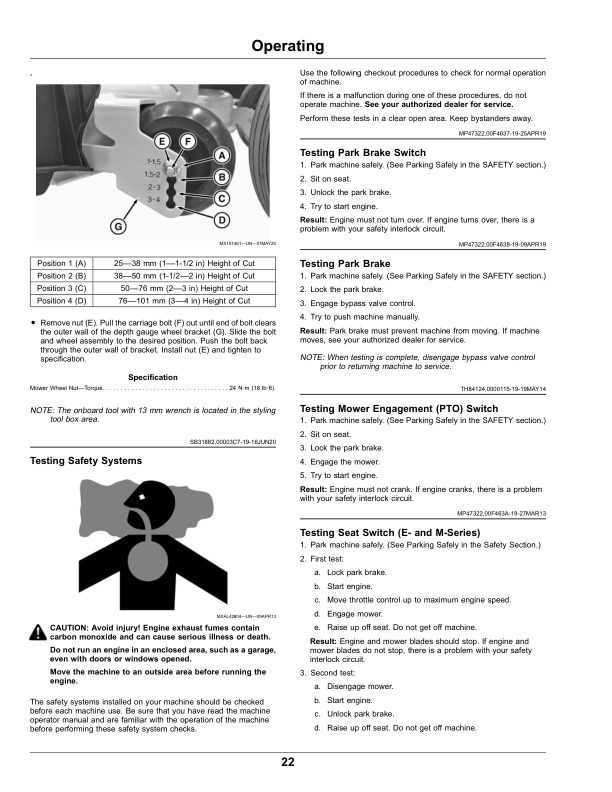

Installation Process for Key Components

Proper installation of essential elements is crucial for ensuring optimal performance and longevity of any machinery. This section outlines the fundamental steps and considerations involved in the installation of various critical components, emphasizing precision and attention to detail throughout the process.

Before beginning the installation, it’s important to gather all necessary tools and components. Reviewing the manufacturer’s guidelines can provide valuable insights into specific requirements for each part. Additionally, creating a clean and organized workspace will help streamline the procedure and minimize the risk of misplacing items.

When installing components, always start by ensuring that the machinery is powered off and secured. This step is vital for safety. Following this, carefully position the new parts according to the specifications. Utilizing appropriate fasteners and ensuring that they are tightened to the correct torque levels will prevent future issues.

After installation, it’s advisable to conduct a thorough inspection to confirm that everything is aligned and secured properly. Testing the machinery to verify its functionality is also essential. Addressing any irregularities immediately can save time and resources in the long run.

Cost Considerations for Z530R Parts

When maintaining and upgrading machinery, understanding the financial implications is essential. Factors such as quality, brand reputation, and availability significantly influence pricing. It’s crucial to evaluate these elements to make informed decisions that align with your budgetary constraints.

OEM components typically come with a higher price tag due to their guaranteed compatibility and durability. However, aftermarket alternatives can provide significant savings, though they may vary in quality. Weighing the long-term benefits against immediate costs is vital for optimal investment.

Additionally, sourcing from reputable dealers can affect expenses. Shipping and handling charges may also play a role, especially for larger items. Always consider total expenditure rather than just upfront prices to ensure a sound financial approach.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is essential for ensuring optimal performance and longevity. Using genuine replacements guarantees compatibility and reliability, helping you avoid potential issues that may arise from using substandard alternatives. Understanding where to find these components can save you time and money in the long run.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealerships. These establishments are equipped with a comprehensive inventory and knowledgeable staff who can assist you in identifying the correct items for your needs. Additionally, purchasing from authorized dealers often comes with the assurance of quality and warranty support.

Online Retailers

The internet offers a wide range of options for acquiring genuine components. Reputable online retailers specialize in quality products and often provide detailed specifications to help you make informed choices. Look for customer reviews and ratings to ensure you’re purchasing from a trustworthy source. Additionally, manufacturer websites frequently have a list of recommended online vendors.

Frequently Asked Questions About Z530R

This section addresses common inquiries regarding the model in question, offering insights that assist users in understanding its features and maintenance requirements. Whether you’re a new owner or looking to enhance your knowledge, these answers aim to clarify important aspects.

What should I know about maintenance?

Regular upkeep is essential for optimal performance. It’s advisable to follow the manufacturer’s recommendations for oil changes, filter replacements, and blade sharpening. Additionally, checking tire pressure and cleaning the undercarriage can prolong the life of your equipment.

How can I enhance performance?

To boost efficiency, consider investing in high-quality fuel and ensuring that all components are in good condition. Keeping the machine clean and properly calibrated will help maintain its performance over time. Consulting the user manual for specific tips tailored to your model can also be beneficial.