Ultimate Guide to Grizzly 660 Parts Diagram

The world of off-road machines is both fascinating and intricate, filled with a variety of elements that contribute to their performance and reliability. For enthusiasts and mechanics alike, gaining insight into the intricate structure of these vehicles is essential for effective maintenance and upgrades. Each segment plays a critical role in the overall functionality, and comprehending these aspects can lead to a more enjoyable riding experience.

To effectively service or enhance an all-terrain vehicle, it’s vital to familiarize oneself with the specific features and configurations that define its makeup. Analyzing the relationships between different sections allows for a deeper understanding of how each component interacts with others. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions regarding modifications and repairs.

In this exploration, we will delve into the various sections of off-road machines, providing a comprehensive overview that highlights the importance of each part. Whether you are a seasoned rider or a newcomer, grasping the essentials of these vehicles will enhance your ability to maintain their peak performance and longevity.

Understanding the Grizzly 660 Parts Diagram

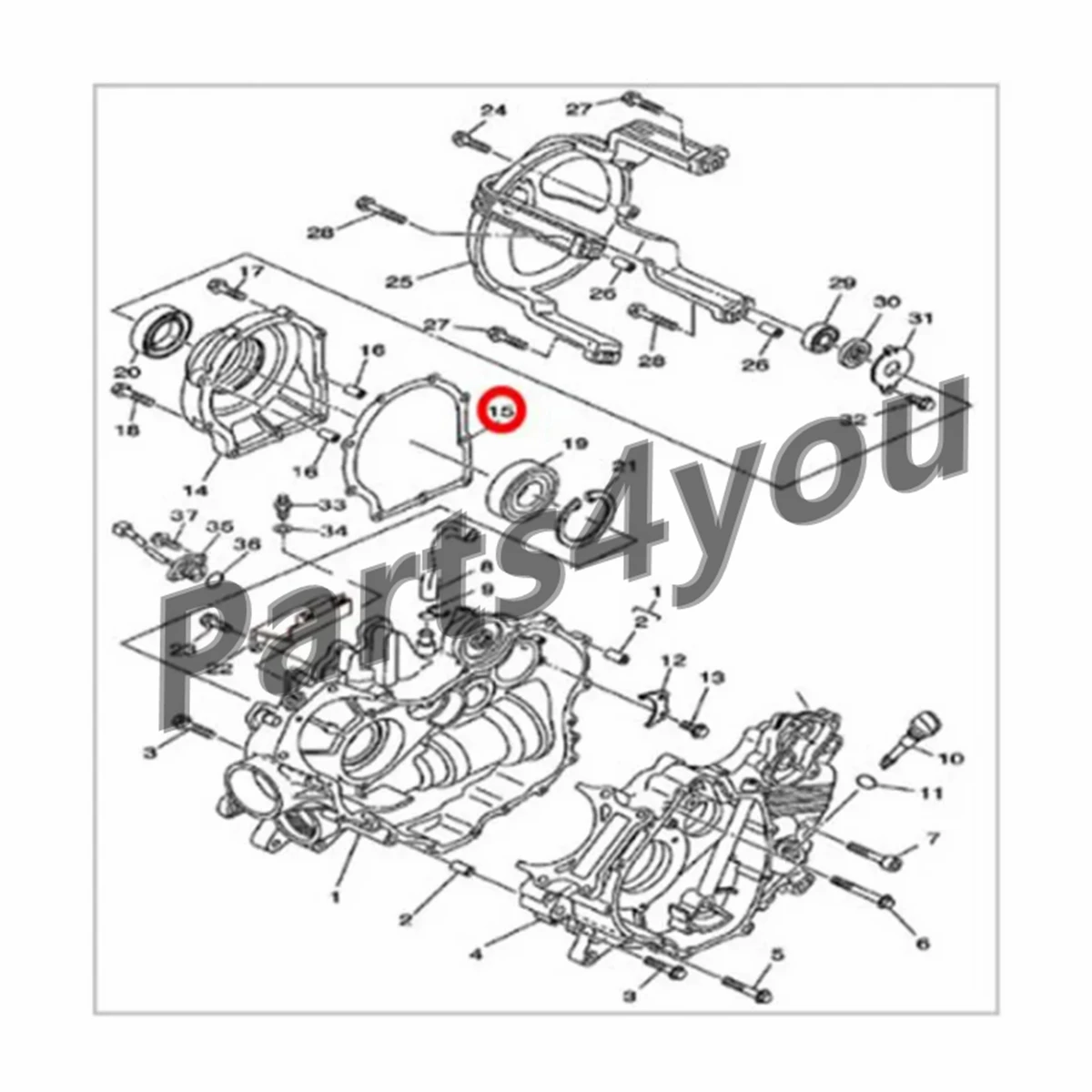

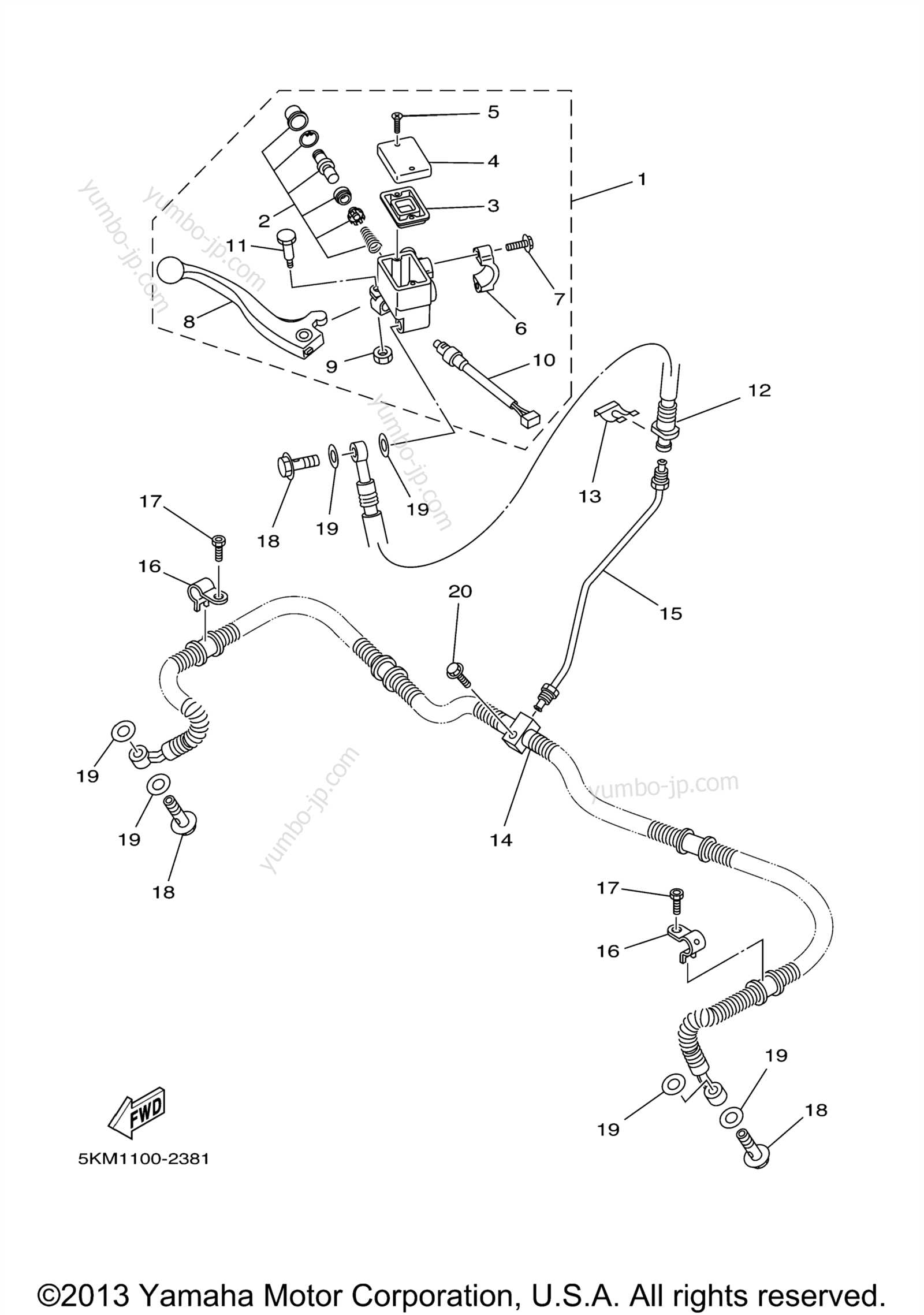

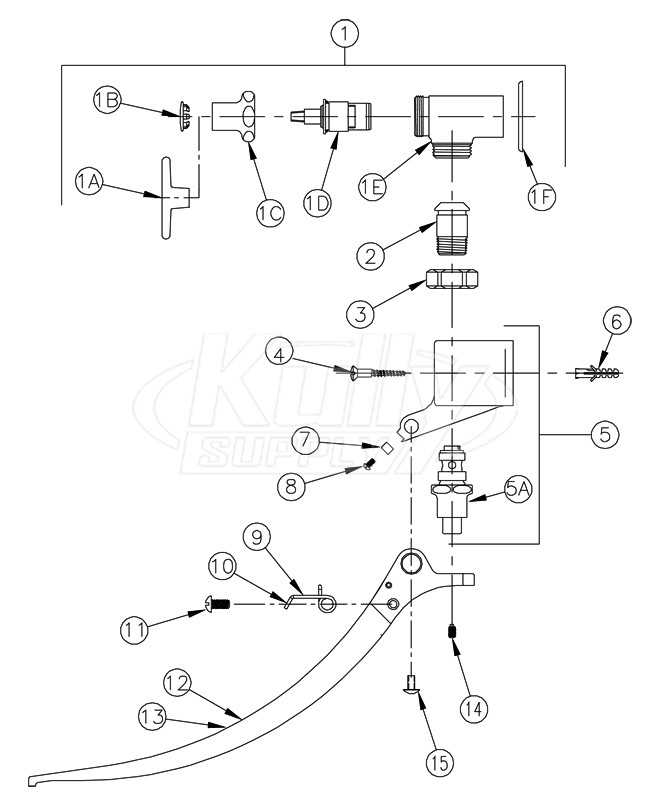

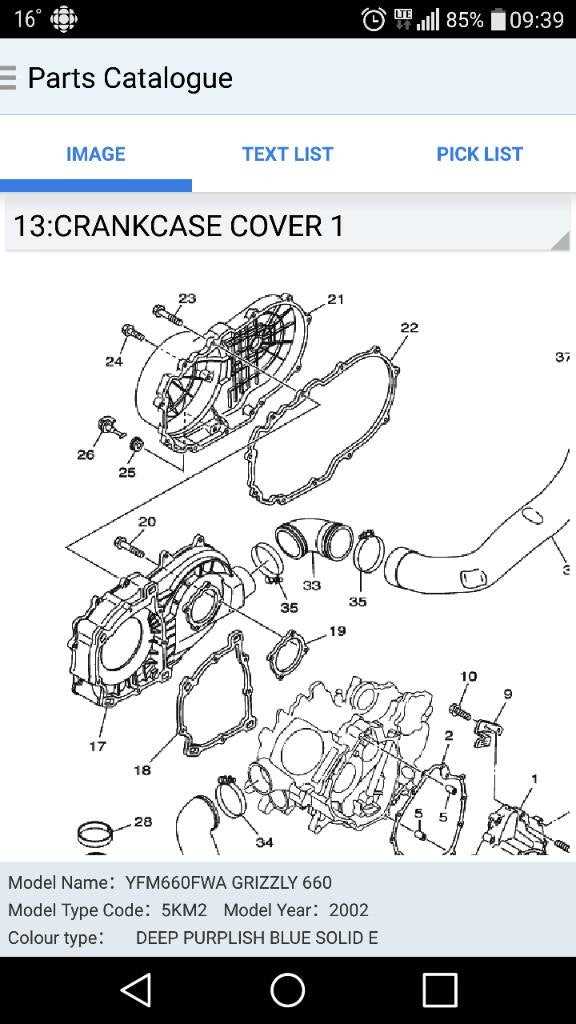

Gaining insight into the schematic representation of vehicle components is essential for effective maintenance and repair. This visual tool serves as a guide, showcasing the relationship between various elements, enabling enthusiasts and technicians to comprehend assembly and disassembly processes. Familiarity with this resource can enhance the efficiency of troubleshooting and part replacement.

Within the illustration, each segment is labeled clearly, indicating the specific roles and functions of individual components. By analyzing this representation, users can identify potential issues and understand how different elements interact within the system. This knowledge is crucial for anyone looking to optimize performance or undertake restoration projects.

| Component | Description | Function |

|---|---|---|

| Engine | Power unit | Generates propulsion |

| Transmission | Power transfer mechanism | Transmits power to wheels |

| Suspension | Shock absorption system | Ensures ride stability |

| Brakes | Stopping mechanism | Provides vehicle control |

| Wheels | Circular components | Facilitates movement |

By utilizing the schematic effectively, users can ensure that their vehicle operates smoothly and efficiently. Understanding each part’s role fosters better decision-making when it comes to repairs and upgrades, ultimately enhancing the overall experience for any operator.

Overview of Grizzly 660 Components

This section provides a comprehensive examination of the key elements that contribute to the functionality and performance of the all-terrain vehicle. Understanding these components is crucial for maintenance, repair, and enhancement of the machine’s capabilities.

Key Elements

- Engine: The heart of the vehicle, responsible for power generation.

- Transmission: Facilitates gear shifting for optimal speed and torque.

- Suspension: Enhances stability and comfort over uneven terrain.

- Braking System: Ensures safety through effective stopping power.

- Electrical System: Powers lights, ignition, and electronic components.

Maintenance Considerations

- Regularly check fluid levels for the engine and transmission.

- Inspect suspension components for wear and tear.

- Test the braking system for responsiveness and effectiveness.

- Ensure the electrical system is free from corrosion and damage.

Importance of Parts Diagrams

Understanding the various components of a machine is crucial for effective maintenance and repair. Visual representations serve as essential tools, allowing users to quickly identify each element’s location and function. This clarity can significantly enhance the efficiency of troubleshooting and restoration processes.

Benefits of Visual Representations

- Facilitates easy identification of components.

- Streamlines the repair process by providing clear guidance.

- Minimizes the risk of errors during assembly or disassembly.

Enhancing Maintenance Practices

- Promotes a deeper understanding of machine structure.

- Encourages systematic approaches to repairs.

- Improves communication among technicians and users.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for anyone involved in maintenance or repair tasks. This guide will help you navigate the visual layout, making it easier to identify each element and its role within the overall system.

Here are some key steps to effectively interpret the visual representation:

- Familiarize Yourself with the Legend:

Most schematics include a legend or key that defines symbols used throughout the illustration. Reviewing this section first can save time when trying to identify various components.

- Identify Sections:

Typically, the illustration is divided into sections, each representing a specific part of the system. Take note of these divisions to better understand the organization of elements.

- Follow the Flow:

Observe the flow of the layout. Components may be connected in a particular order, indicating how they interact. Tracing these connections can clarify their functions.

- Check Reference Numbers:

Each item usually has a reference number corresponding to a list. This list often provides additional details, such as specifications or compatibility, that are crucial for procurement or installation.

- Use Visual Cues:

Pay attention to visual indicators such as arrows or lines that may suggest movement or direction. These cues can enhance your understanding of how parts work together.

By following these steps, you can effectively decode the schematic and gain valuable insights into the components and their interactions, facilitating smoother repairs and maintenance.

Common Parts in the Grizzly 660

This section explores the essential components that contribute to the overall performance and functionality of this robust utility vehicle. Understanding these elements is crucial for maintenance and enhancing the riding experience.

Engine and Transmission Components

The heart of any off-road machine lies in its power unit and transmission system. Key components such as the cylinder head, piston, and clutch assembly play vital roles in ensuring efficient power delivery and smooth operation. Regular checks on these elements can prevent breakdowns and extend the life of the vehicle.

Suspension and Chassis Elements

Another critical aspect involves the suspension and frame. Parts like the shocks, arms, and frame supports provide stability and comfort, especially on rough terrains. Proper maintenance of these elements not only enhances ride quality but also ensures safety during adventures.

Maintenance Tips for Grizzly 660

Regular upkeep is essential for ensuring optimal performance and longevity of your off-road vehicle. Proper maintenance practices not only enhance functionality but also help prevent costly repairs down the line. Here are some key suggestions to keep your machine in excellent condition.

Routine Checks

Conducting periodic inspections can significantly extend the life of your vehicle. Pay attention to the following components:

| Component | Recommended Frequency |

|---|---|

| Oil Level | Every 100 miles |

| Tire Pressure | Before each ride |

| Brake Fluid | Monthly |

| Air Filter | Every 500 miles |

Cleaning and Lubrication

Keeping your vehicle clean and well-lubricated is vital. Regularly wash away dirt and debris, particularly from the undercarriage. Use appropriate lubricants for moving parts to prevent wear and ensure smooth operation. A clean and well-lubricated machine not only performs better but also has a reduced risk of breakdowns.

Where to Find Replacement Parts

Finding components for your vehicle can be essential for maintaining performance and longevity. Fortunately, numerous resources are available for sourcing high-quality replacements.

- Authorized Dealers: Start by visiting official dealerships that specialize in your brand. They often stock genuine replacements.

- Online Retailers: E-commerce platforms provide a wide selection of aftermarket options, often at competitive prices.

- Local Repair Shops: These establishments may offer recommendations or stock essential components.

- Forums and Communities: Engaging with online forums dedicated to enthusiasts can lead to valuable insights and direct sources.

Consider comparing prices and quality before making a purchase to ensure you receive the best possible options for your needs.

Identifying Faulty Components

Recognizing malfunctioning elements in your machinery is crucial for maintaining optimal performance. Various indicators can signal the need for inspection, and understanding these signs can save time and resources. Proper diagnosis ensures that replacements are timely and effective, prolonging the lifespan of your equipment.

Common Symptoms of Malfunction

Many issues manifest through unusual noises, decreased efficiency, or irregular functioning. Strange sounds during operation often point to wear and tear on mechanical parts. Similarly, a noticeable drop in performance can indicate that certain components are no longer operating at their full capacity. Observing these symptoms closely will assist in pinpointing the source of the problem.

Steps for Diagnosis

To accurately identify defective components, follow a systematic approach. Start with a visual inspection to check for obvious signs of damage or wear. Next, perform a series of tests to assess functionality. Utilizing a multimeter can help determine electrical issues, while checking fluid levels can reveal leaks or contamination. Documenting your findings can aid in tracking recurring problems and determining the best course of action.

Comparing Models: Grizzly 660 vs Others

This section explores the distinctions between various all-terrain vehicles, focusing on their specifications, features, and performance. By comparing one popular model with others in the same category, we can better understand their unique advantages and disadvantages, helping potential buyers make informed choices.

Key Features to Consider

- Engine Power

- Suspension System

- Load Capacity

- Fuel Efficiency

- Durability and Build Quality

Comparative Analysis

- Engine Power: Some models offer higher horsepower, while others focus on torque for better off-road performance.

- Suspension System: Advanced suspension setups can enhance ride quality and handling on rough terrains.

- Load Capacity: Different designs cater to various hauling needs, from recreational use to heavy-duty tasks.

- Fuel Efficiency: Evaluating fuel consumption is crucial for long trips and overall cost-effectiveness.

- Durability and Build Quality: Materials used in construction impact longevity and performance in challenging environments.

Ultimately, selecting the right model requires careful consideration of personal preferences and intended use, ensuring the best fit for individual needs.

Assembly Instructions for Key Parts

This section provides essential guidelines for the assembly of crucial components within your vehicle. Following these instructions will ensure optimal functionality and longevity of the parts.

Step-by-Step Assembly

Begin by gathering all necessary tools and components. Carefully review each piece to identify any potential wear or damage before starting. Align each part according to the provided specifications, ensuring a secure fit. Tighten fasteners progressively to avoid misalignment, and always follow torque specifications.

Final Checks

Once assembly is complete, conduct a thorough inspection. Verify that all connections are secure and there are no loose components. It’s also advisable to perform a test run to confirm that everything operates smoothly before putting the vehicle back into service.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components and their maintenance. Understanding these elements can enhance your overall experience and ensure optimal performance.

- What should I consider when replacing a component?

- Compatibility with your model

- Quality and durability of the material

- Warranty and return policies

- How do I identify a faulty component?

- Unusual noises during operation

- Visible wear and tear

- Performance issues

- Where can I find quality components?

- Authorized dealers

- Reputable online retailers

- Local repair shops

- How often should I check my components?

- Regularly during routine maintenance

- Before long trips or heavy use

- After any significant impact or damage

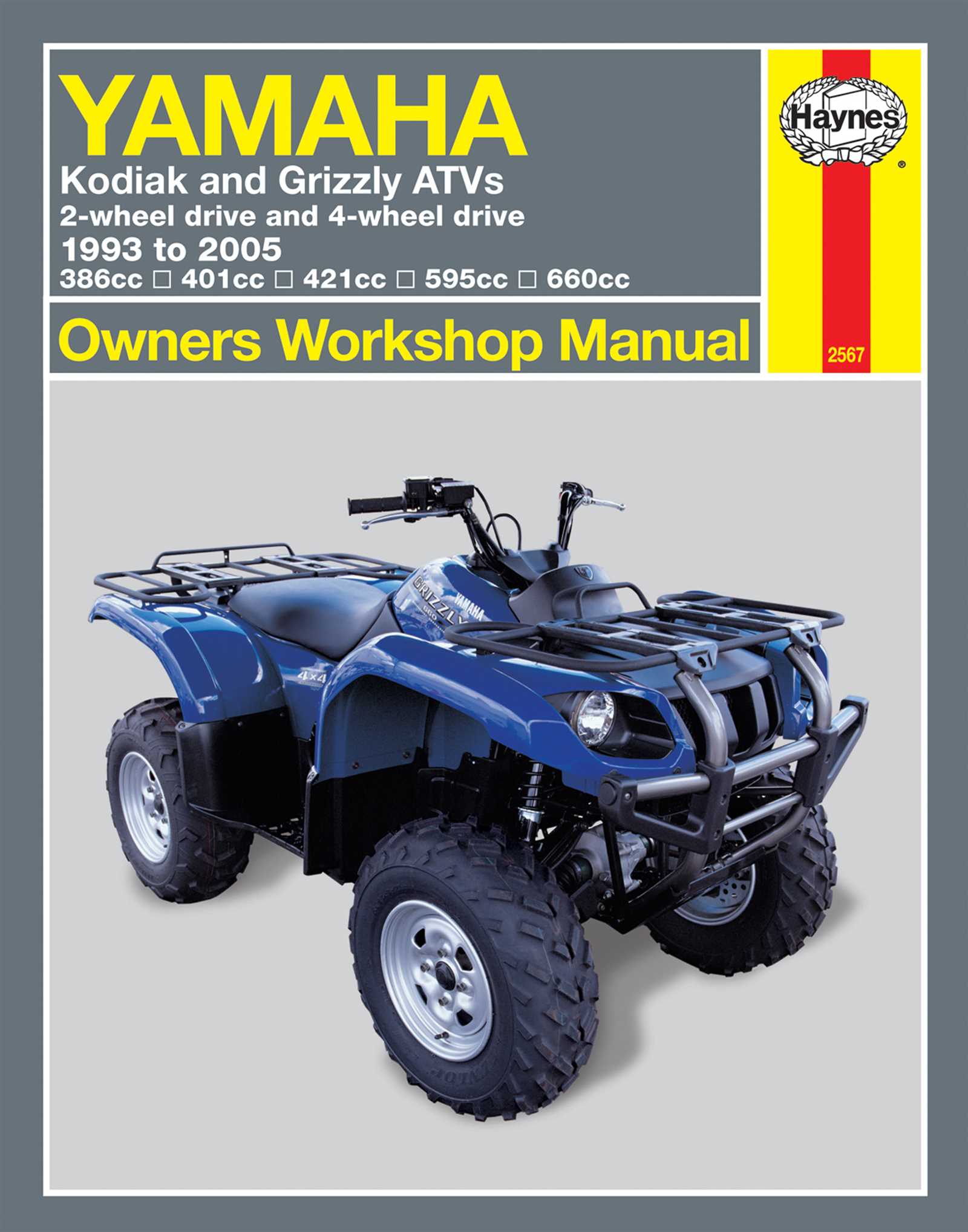

Resources for Further Learning

Expanding your knowledge about maintenance and components is essential for enthusiasts and professionals alike. This section provides various resources to help you delve deeper into the subject, enhancing your understanding and skills.

Books and Manuals

Consider investing in specialized literature that offers comprehensive insights into the machinery. These texts often include detailed instructions and troubleshooting tips.

Online Forums and Communities

Joining online platforms allows you to connect with others who share your interests. These communities often feature discussions, advice, and shared experiences.

| Resource Type | Recommended Sources |

|---|---|

| Books | Repair Manuals, Technical Guides |

| Websites | Manufacturer Sites, Educational Blogs |

| Forums | Community Boards, Social Media Groups |