Understanding the John Deere 310B Backhoe Parts Diagram

In the realm of heavy machinery, a thorough understanding of the various elements that make up the equipment is essential for efficient operation and maintenance. Each machine comprises numerous intricate components, each serving a specific purpose. Grasping the arrangement and function of these parts can significantly enhance the effectiveness of repairs and servicing.

For operators and technicians alike, familiarizing oneself with the structural layout of machinery is crucial. It allows for quicker diagnostics and a more streamlined approach to troubleshooting. Visual representations of component arrangements can serve as invaluable resources, aiding in the identification and management of each piece.

In this discussion, we will delve into the intricate specifics of a well-known loader model, focusing on the essential assemblies that contribute to its functionality. Whether you are a seasoned professional or a novice, understanding these configurations will empower you to optimize performance and extend the lifespan of your machinery.

Understanding the John Deere 310B

This section aims to provide insights into a specific construction equipment model known for its versatility and reliability. By exploring its features and components, users can better appreciate its design and functionality.

The machinery is engineered to tackle various tasks in construction and landscaping. Key elements include:

- Powerful engine capabilities

- Robust digging and lifting functionalities

- User-friendly controls for efficient operation

Understanding these components allows operators to maximize efficiency and ensure proper maintenance. Regular check-ups and familiarity with the equipment contribute to its longevity and optimal performance.

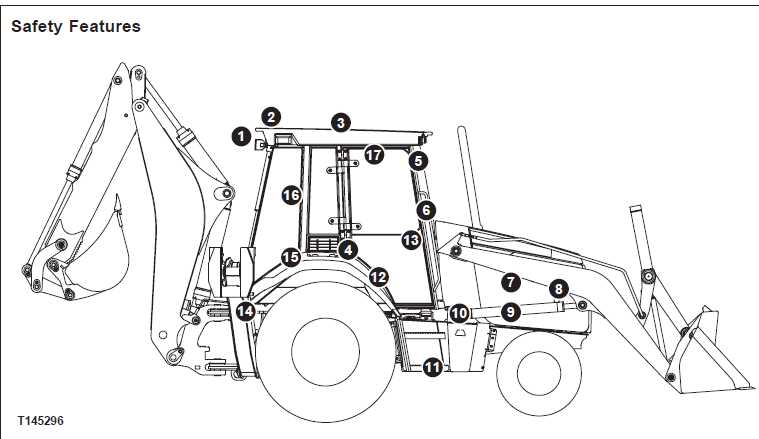

Key Components of the Backhoe

Understanding the essential elements of an excavating machine is crucial for optimal performance and maintenance. Each component plays a vital role in the overall functionality, contributing to the effectiveness and versatility of the equipment in various applications.

| Component | Description |

|---|---|

| Loader Arm | The structure responsible for lifting and moving materials. It provides the necessary leverage for excavation tasks. |

| Bucket | Attached to the loader arm, this element is designed for digging, scooping, and transporting soil or debris. |

| Hydraulic System | This system powers the movement of various components, allowing for precise control and effective operation. |

| Stabilizers | These supports are crucial for maintaining balance during operation, preventing tipping while digging or lifting. |

| Cab | The operator’s space, equipped with controls and instruments for monitoring performance and ensuring safety. |

| Chassis | The main frame that supports the entire machine and houses critical systems, providing stability and durability. |

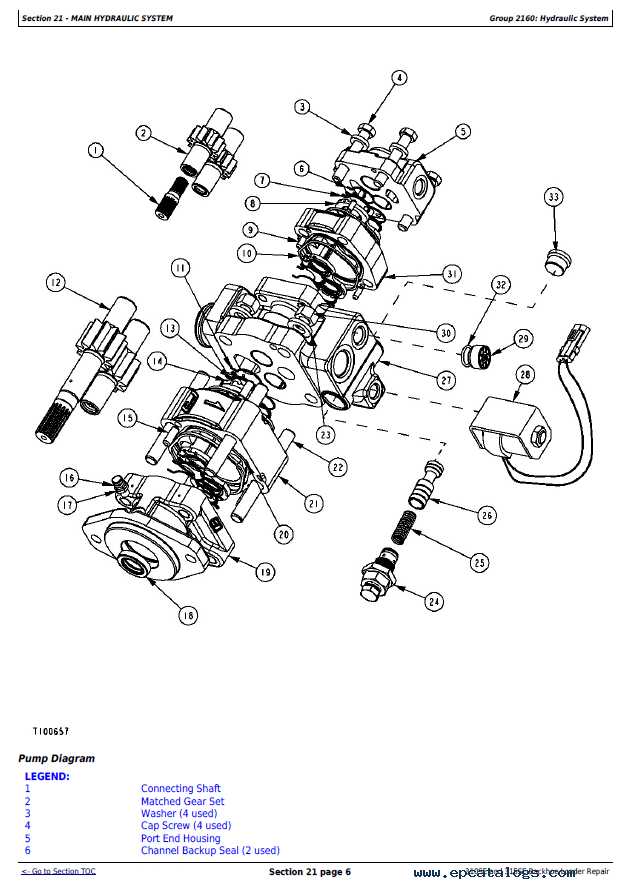

Importance of Accurate Parts Diagrams

Having precise schematics is crucial for maintaining and repairing heavy machinery. These visual guides provide essential information that ensures proper assembly, disassembly, and replacement of components. Without accurate representations, the risk of errors increases significantly, which can lead to costly downtime and safety hazards.

Key benefits of detailed schematics include:

- Efficiency: Clear visuals streamline the repair process, reducing the time spent searching for components or instructions.

- Accuracy: Detailed illustrations help technicians identify the correct pieces needed for specific tasks, minimizing the chance of mistakes.

- Training: New employees can learn faster with comprehensive guides, gaining confidence in their ability to perform repairs.

- Cost-effectiveness: Accurate diagrams reduce the likelihood of ordering incorrect items, saving both time and money.

In summary, precise schematics are vital for the effective operation and maintenance of machinery. They not only enhance the repair process but also contribute to a safer work environment.

Common Issues with 310B Backhoe

Heavy machinery often faces various challenges during operation, which can affect performance and efficiency. Understanding these issues is crucial for maintenance and repair.

- Hydraulic Problems: Leaks and pressure loss are frequent, leading to reduced lifting capability.

- Electrical Failures: Faulty wiring or dead batteries can cause starting issues.

- Engine Overheating: Insufficient coolant or blocked radiators can lead to overheating.

- Transmission Issues: Slipping gears or unresponsive shifting are common complaints.

- Wear and Tear: Regular use can lead to excessive wear on critical components, requiring replacements.

Identifying and addressing these issues promptly can enhance longevity and reliability.

Finding Reliable Parts Suppliers

When seeking components for heavy machinery, identifying trustworthy vendors is crucial for maintaining operational efficiency and safety. Reliable suppliers ensure high-quality items that enhance performance and longevity.

Here are some key factors to consider:

- Reputation: Look for suppliers with positive reviews and a solid track record in the industry.

- Quality Assurance: Ensure the products meet relevant standards and regulations.

- Customer Service: Good support can make a significant difference in your purchasing experience.

- Availability: Check if they have a wide range of components readily accessible.

Incorporating these criteria into your search can ultimately lead you to the best sources for your machinery needs.

Maintenance Tips for Longevity

Ensuring the prolonged life of your machinery involves regular upkeep and attention to detail. Adopting a systematic approach to maintenance not only enhances performance but also prevents costly repairs down the line. Here are some essential practices to follow for optimal functionality.

Regular Inspection

Conducting routine checks is crucial. This helps identify potential issues before they escalate. Focus on the following:

- Inspect hydraulic systems for leaks and pressure inconsistencies.

- Check for wear and tear on key components such as tires and joints.

- Monitor fluid levels, including oil and coolant, to ensure proper operation.

Scheduled Servicing

Implementing a schedule for professional servicing can significantly extend your equipment’s lifespan. Key aspects include:

- Change the oil and filters as recommended by the manufacturer.

- Grease all moving parts to reduce friction and wear.

- Calibrate systems to maintain precision in operation.

By prioritizing these maintenance practices, you can enhance the durability and reliability of your machinery, ultimately leading to improved efficiency and reduced downtime.

Installation Procedures for Major Parts

This section outlines the essential steps for the proper installation of significant components within the machinery, ensuring optimal functionality and longevity. Following these procedures meticulously is crucial for maintaining performance and safety standards.

Preparation Steps

- Gather necessary tools and materials.

- Refer to the maintenance manual for specific guidelines.

- Ensure the work area is clean and organized.

Installation Process

- Disconnect any power sources to prevent accidents.

- Remove the old component carefully, noting any connections.

- Align the new component according to manufacturer specifications.

- Secure all fasteners tightly, ensuring no loose connections.

- Reconnect power sources and perform a functionality test.

Upgrading vs. Replacing Components

When it comes to maintaining machinery, deciding between enhancement and outright substitution of elements can be pivotal. Each option carries distinct advantages and considerations that can affect performance, longevity, and overall functionality.

Benefits of Upgrading

- Cost-effective solution

- Improved efficiency without full replacement

- Extended lifespan of existing framework

- Opportunity to integrate advanced technology

When to Consider Replacement

- Severe wear or damage beyond repair

- Compatibility issues with upgraded technology

- Increased operational costs due to inefficiencies

- Desire for a complete overhaul for enhanced capabilities

Comparing 310B with Other Models

This section aims to highlight the distinctions and similarities between a specific model and its counterparts in the same category. By examining various features, performance metrics, and user feedback, we can better understand the unique advantages offered by this particular machine.

Key Features Comparison

- Engine Power: The model in question provides robust horsepower, enhancing productivity.

- Hydraulic System: A superior hydraulic capacity allows for improved lifting and digging capabilities.

- Operator Comfort: Ergonomic design and intuitive controls set a high standard for user experience.

Performance Metrics

- Efficiency: Compared to others, it demonstrates remarkable fuel efficiency.

- Durability: The construction is built to withstand heavy-duty tasks over time.

- Maintenance: Simplified maintenance procedures reduce downtime and costs.

In summary, while each model has its strengths, the specific features and performance metrics of this machine often lead to a more favorable evaluation among users. Ultimately, understanding these differences aids in making informed choices for prospective buyers.

Resources for Technical Support

When operating heavy machinery, having access to reliable assistance is crucial for efficient maintenance and repairs. Various resources are available to provide users with the necessary guidance and support, ensuring that equipment remains in optimal working condition.

Consider exploring the following avenues for technical support:

- Manufacturer’s Official Website: This is often the first place to check for detailed manuals, FAQs, and troubleshooting guides.

- User Forums: Online communities can be a valuable source of shared experiences and solutions from other operators.

- Local Dealers: Authorized dealers typically offer expert advice, parts availability, and service options tailored to specific models.

- Online Retailers: Websites specializing in machinery components often provide diagrams and descriptions that can assist in identifying needed items.

For in-depth assistance, consider the following resources:

- Service Manuals: These documents provide comprehensive instructions for repairs and maintenance, helping to understand complex systems.

- Tutorial Videos: Platforms like YouTube feature visual guides that can be especially helpful for hands-on learners.

- Technical Support Hotlines: Many manufacturers offer direct access to knowledgeable representatives for immediate concerns.

Utilizing these resources can enhance your ability to manage and maintain your equipment effectively, ensuring reliability and performance in the field.

Customer Reviews on 310B Performance

Feedback from users provides invaluable insights into the effectiveness and reliability of heavy machinery. Many operators share their experiences, highlighting the strengths and weaknesses of their equipment. These reviews often reflect real-world usage, allowing potential buyers to make informed decisions.

Efficiency: Numerous reviews commend the model for its robust performance in various tasks, noting its ability to handle demanding projects with ease. Users appreciate its fuel efficiency, which contributes to overall cost savings during operation.

Durability: Many customers express satisfaction with the longevity of their machines, emphasizing how well they withstand heavy use. Several operators mention that proper maintenance significantly enhances the lifespan and functionality of their equipment.

Ease of Use: Operators frequently praise the user-friendly design, making it accessible for both seasoned professionals and newcomers. The intuitive controls and comfortable seating enhance the overall operating experience.

Challenges: While many reviews are positive, some users point out specific challenges, such as limited visibility from the operator’s seat in certain positions. Addressing these concerns can help improve the design in future models.

Overall, customer feedback serves as a crucial resource for understanding the performance characteristics of this machinery, guiding potential buyers in their decision-making process.