Comprehensive Guide to the Fs85r Parts Diagram

In the realm of machinery, comprehending the arrangement of individual elements is essential for effective maintenance and troubleshooting. This knowledge not only enhances the efficiency of repairs but also aids in identifying potential issues before they escalate. A clear visualization of how components interact can significantly streamline the process of upkeep.

Exploring the specifics of each section reveals the intricate relationships between various parts, showcasing their roles within the larger system. Whether for assembly or disassembly, having a detailed overview serves as a valuable resource for technicians and enthusiasts alike. Familiarity with this structured layout fosters a deeper appreciation for engineering design.

Furthermore, understanding these configurations allows users to optimize performance and longevity. By recognizing where each piece fits into the whole, one can make informed decisions regarding upgrades and replacements. This not only ensures reliability but also contributes to the overall efficiency of the machinery.

Understanding the Fs85r Parts Diagram

The exploration of mechanical components and their arrangement is crucial for anyone looking to maintain or repair machinery. A visual representation of these elements not only aids in identification but also enhances comprehension of their interrelationships. This section delves into the intricacies of such illustrations, highlighting their significance and utility.

Importance of Visual Representations

Visual aids provide a clear and concise way to understand complex systems. They allow users to quickly locate specific elements and comprehend how each part contributes to overall functionality. Whether for troubleshooting or routine maintenance, these illustrations serve as invaluable tools.

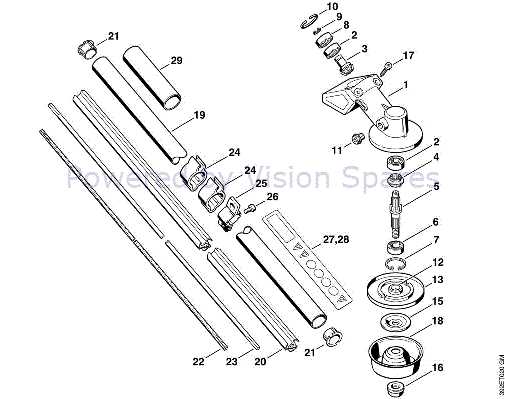

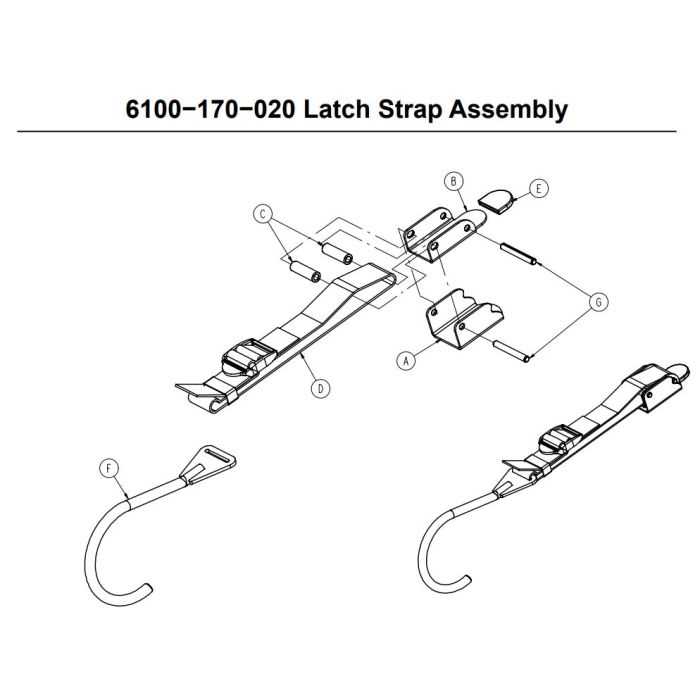

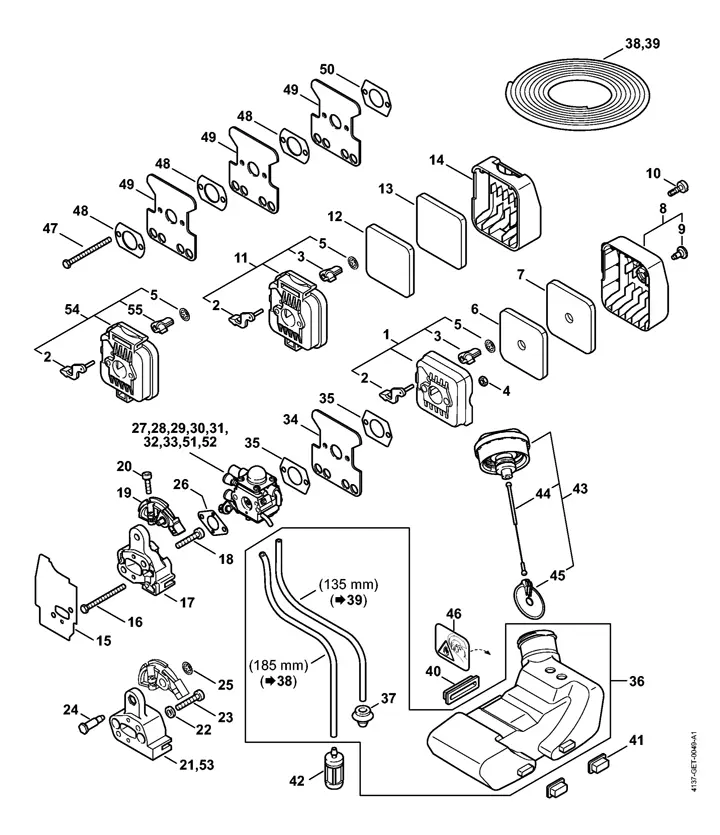

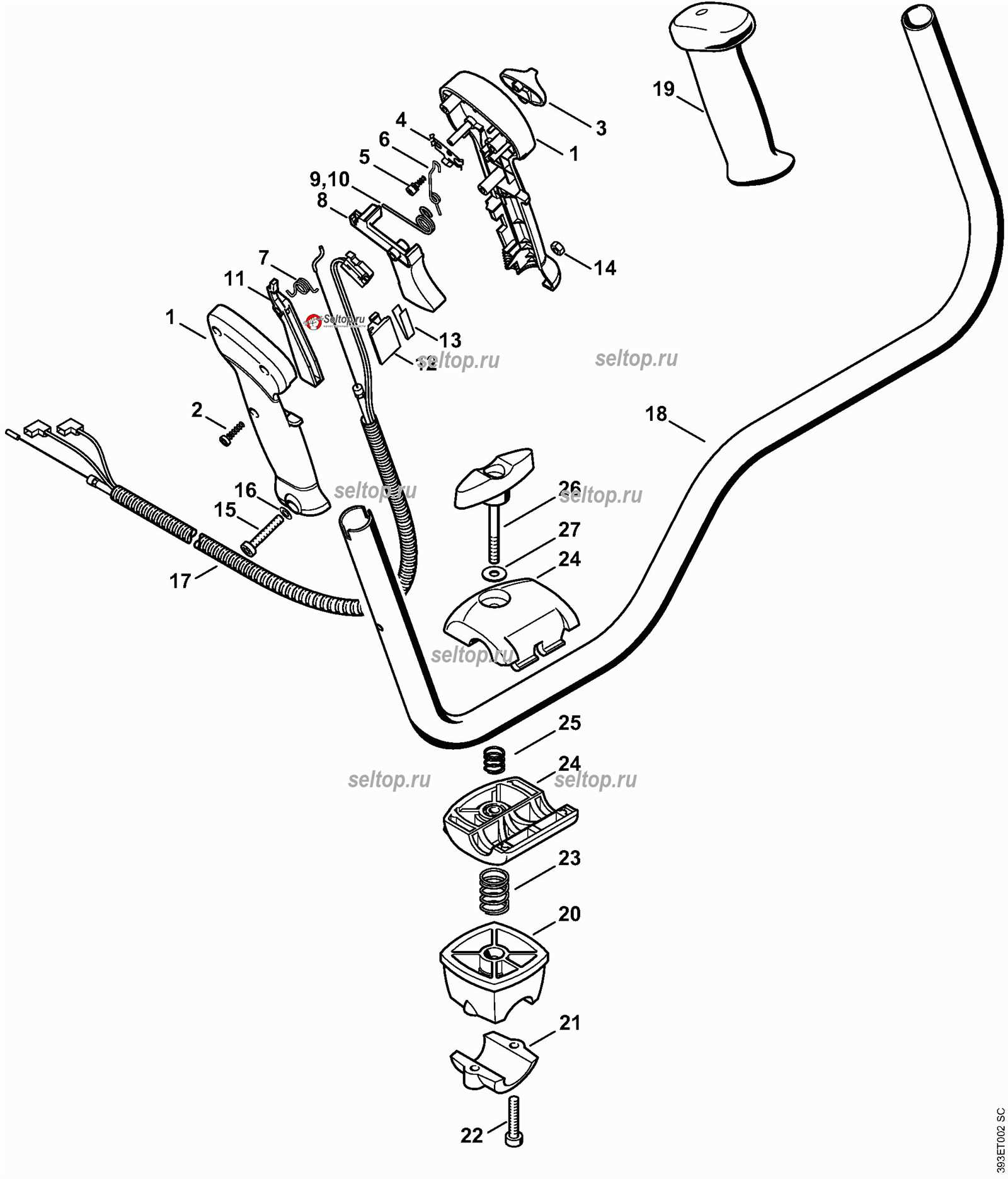

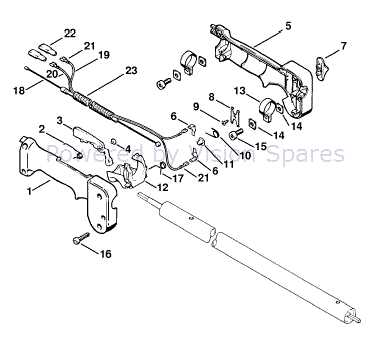

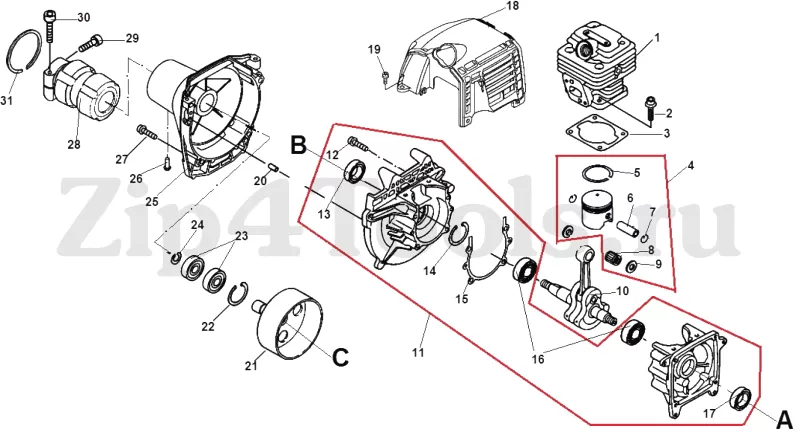

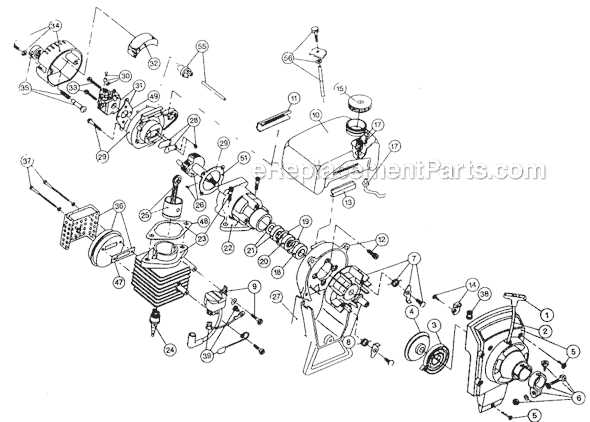

Navigating the Illustration

To effectively utilize these visuals, one should familiarize themselves with common symbols and annotations used. Each segment typically corresponds to a particular function or assembly, which can significantly streamline repair processes. By studying these graphics carefully, technicians can enhance their efficiency and reduce the likelihood of errors during maintenance tasks.

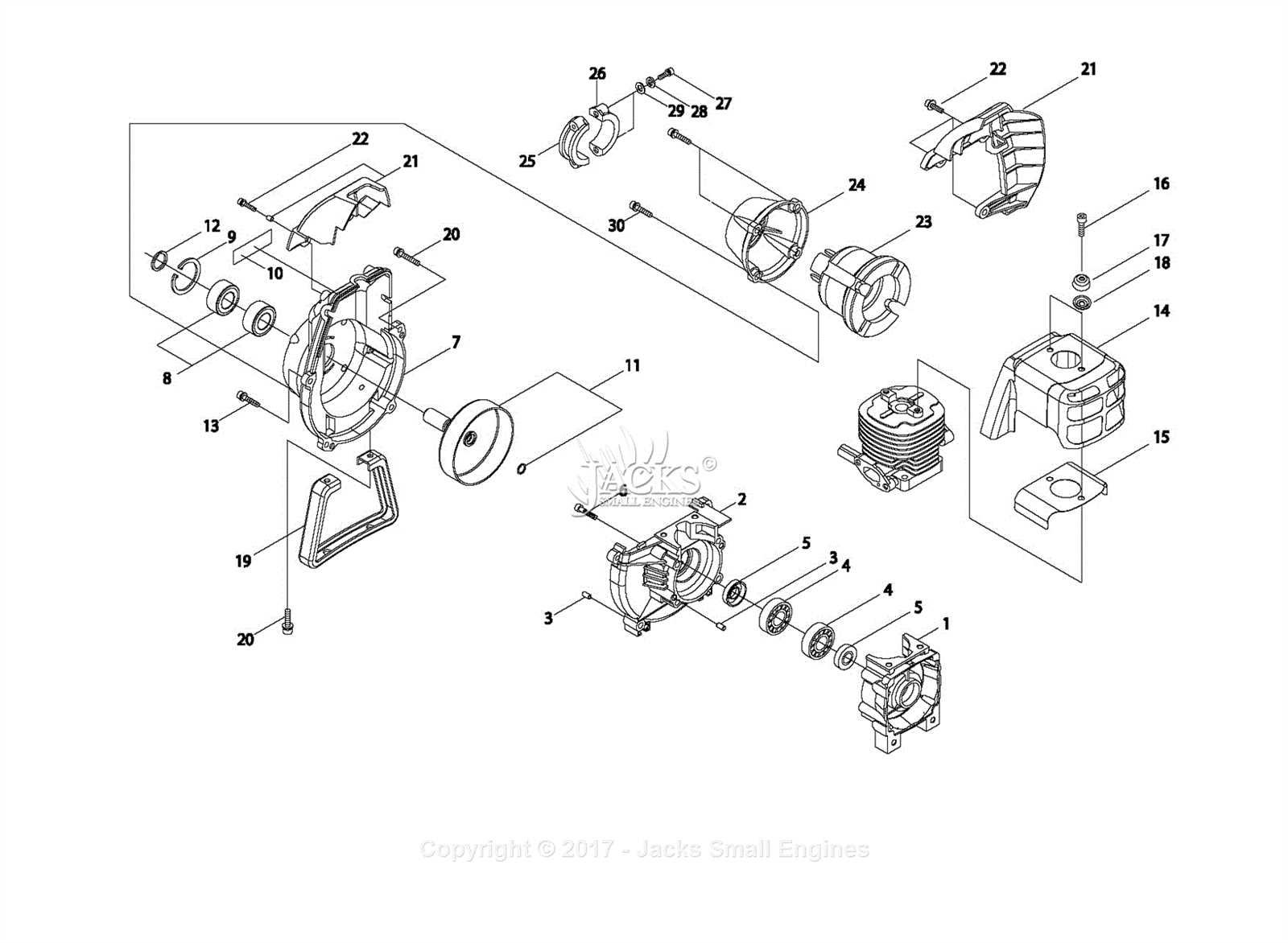

Key Components of the Fs85r

Understanding the essential elements of this equipment is crucial for maintenance and operation. Each component plays a vital role in ensuring efficiency and performance. Below are some of the main features that contribute to its functionality.

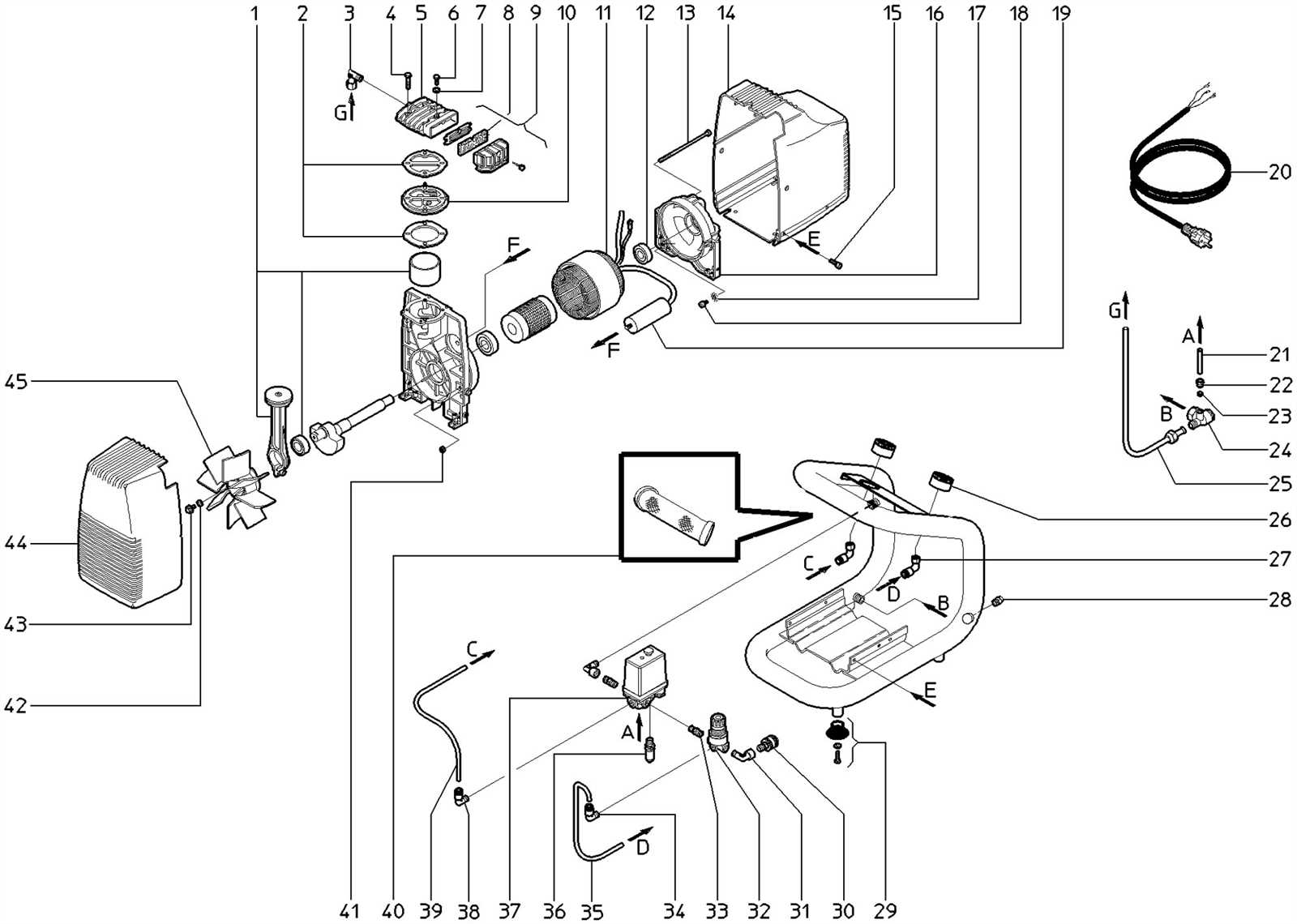

- Engine: The powerhouse that drives the entire mechanism, providing the necessary energy for operation.

- Fuel System: Responsible for delivering the right amount of fuel to the engine, ensuring optimal performance.

- Transmission: This element transfers power from the engine to the wheels, influencing speed and handling.

- Cooling System: Essential for maintaining the right operating temperature, preventing overheating during use.

- Electrical Components: Including the ignition and wiring systems, these parts are vital for starting the engine and powering various functions.

- Chassis: The framework that supports the entire assembly, providing stability and durability.

Each of these components interacts with others, forming a cohesive unit that maximizes efficiency and performance. Regular inspection and maintenance of these features are essential for longevity and reliability.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in various fields, ensuring clarity and understanding when it comes to complex machinery or systems. These visual representations serve as essential tools for technicians, engineers, and users alike, simplifying the identification of components and their interrelations.

Benefits of Clear Visual Representations

- Enhanced Understanding: Clear visuals make it easier to comprehend intricate setups, allowing users to grasp how different elements interact.

- Improved Troubleshooting: Accurate illustrations assist in diagnosing issues quickly by clearly showing potential problem areas.

- Streamlined Maintenance: Well-defined visuals guide technicians through maintenance processes, reducing the likelihood of errors and increasing efficiency.

- Effective Training: New users can learn more effectively when provided with accurate visual aids, fostering quicker adaptation to equipment and systems.

Consequences of Inaccurate Illustrations

- Increased Risk of Errors: Misleading representations can lead to incorrect assembly or repairs, resulting in equipment malfunction.

- Wasted Resources: Time and materials may be wasted due to confusion caused by unclear visuals, affecting overall productivity.

- Safety Hazards: Inaccurate information may pose safety risks, as users may not understand the correct operating procedures.

Ultimately, the significance of precise visuals cannot be overstated, as they are fundamental to the successful operation, maintenance, and safety of machinery and systems.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair tasks. These illustrations provide a systematic way to identify various elements, their arrangement, and how they interact with one another. By familiarizing yourself with these visual tools, you can streamline your approach to assembly and troubleshooting.

Interpreting Symbols and Labels

Each component within the illustration is typically accompanied by specific symbols or labels. These identifiers are essential for recognizing the nature and function of each part. Take time to familiarize yourself with the legend or key that explains these markings, as it will enhance your comprehension and ensure you accurately identify what you need.

Understanding the Layout

The arrangement of components is not random; it usually follows a logical structure that mirrors the actual assembly. Pay attention to how parts are grouped and connected. This layout helps to visualize the overall system, making it easier to pinpoint where an issue may arise or which component needs replacement. By analyzing the configuration, you can gain insights into the operational relationships between different elements.

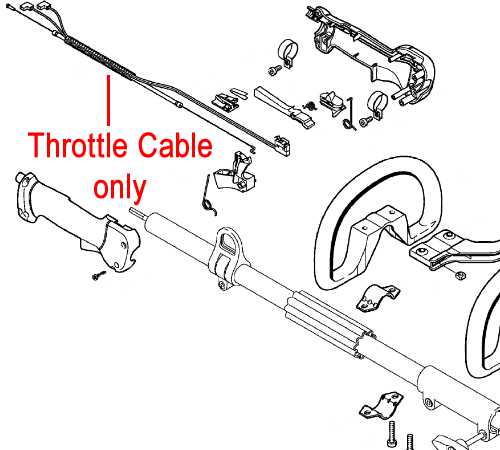

Common Repairs Using the Diagram

Understanding the layout of components is essential for effective maintenance and troubleshooting. By familiarizing yourself with the arrangement of parts, you can identify issues more efficiently and carry out necessary repairs without unnecessary delays. This section highlights frequent repairs and how a visual reference can facilitate the process.

Many users encounter similar problems that can be resolved with a systematic approach. Below are some common repairs and the associated components that may need attention:

| Repair Type | Common Issues | Key Components |

|---|---|---|

| Fuel System Maintenance | Clogged filters, fuel leaks | Fuel line, filter, pump |

| Ignition Troubleshooting | Hard starting, misfires | Spark plug, ignition coil |

| Cooling System Repair | Overheating, coolant leaks | Radiator, hoses, thermostat |

| Electrical System Checks | Dead battery, faulty wiring | Batteries, connectors, fuses |

Utilizing a comprehensive visual guide enables you to pinpoint problems quickly and ensures that you have the right tools and parts at hand. This proactive approach can lead to more efficient repairs and extended longevity for your equipment.

Where to Find Official Diagrams

When seeking precise illustrations for machinery components, it’s essential to know where to locate reliable resources. Accessing official materials can streamline maintenance and repairs, ensuring everything is in order. Below are some valuable sources for obtaining these technical references.

- Manufacturer’s Website: The first place to check is the official site of the manufacturer. They often provide downloadable resources, including schematics and guides.

- User Manuals: Many products come with user manuals that contain detailed drawings and specifications. Look for a PDF version online if the physical copy is unavailable.

- Authorized Dealers: Contacting local authorized dealers can yield additional information. They may have access to proprietary resources that are not available online.

- Technical Forums: Online communities and forums dedicated to specific brands or machinery types can be invaluable. Experienced users often share documents and insights.

- Service Centers: Certified service centers typically have access to comprehensive databases. They can assist with providing necessary diagrams upon request.

By utilizing these resources, you can efficiently obtain the information needed for proper upkeep and repair tasks, ensuring optimal performance of your equipment.

Comparing Diagrams Across Models

When analyzing various models, it’s essential to understand the similarities and differences in their schematics. Each design presents a unique arrangement of components, reflecting the specific engineering choices made during development. By examining these illustrations side by side, one can identify trends, commonalities, and distinctive features that may influence functionality and performance.

Identifying Common Features

One of the key benefits of comparing these representations is the ability to spot shared elements across different models. Often, manufacturers maintain certain design philosophies, which can lead to a degree of standardization. Recognizing these consistent components can simplify maintenance and repair processes, as many parts may be interchangeable or compatible across various units.

Understanding Unique Design Choices

In contrast, it’s equally important to acknowledge the unique design choices that differentiate each model. Variations in layout, materials, and component specifications can significantly affect usability and efficiency. By studying these unique aspects, one can gain insights into the intended application and operational advantages that each model may offer.

Troubleshooting with Parts Diagrams

Effective problem-solving in machinery often hinges on understanding how each component interacts within the system. Visual aids can significantly simplify the identification of issues and the assembly of parts, guiding users through the intricacies of repair and maintenance.

When facing malfunctions, utilizing schematic representations can lead to a more systematic approach. Here are some steps to consider:

- Identify the Issue: Begin by observing the symptoms of the malfunction. Note any unusual sounds, movements, or lack of function.

- Consult the Visual Representation: Locate the schematic that corresponds to your machine. This will help you understand the layout and relationships between various elements.

- Cross-Reference Components: Check the visual aid to pinpoint the specific parts related to the problem. This can include everything from fasteners to larger assemblies.

- Inspect Physical Elements: Once you’ve identified potential culprits, inspect them physically for wear, damage, or misalignment.

- Document Findings: Take notes on what you observe, which will be useful for future reference or when consulting with a technician.

By following this methodical process, users can efficiently diagnose problems and implement effective solutions, minimizing downtime and ensuring optimal performance.

Updating Your Equipment with New Parts

Enhancing the functionality and efficiency of your machinery is essential for optimal performance. By integrating modern components, you can ensure that your tools operate smoothly and effectively. This approach not only boosts productivity but also prolongs the lifespan of your equipment.

Benefits of Upgrading Components

- Improved Efficiency: Newer components often utilize advanced technology that can significantly enhance performance.

- Increased Reliability: Up-to-date parts reduce the likelihood of breakdowns and maintenance issues.

- Cost-Effectiveness: Investing in quality replacements can save money in the long run by reducing repair costs.

Choosing the Right Upgrades

- Assess Your Current Equipment: Identify any weaknesses or areas for improvement.

- Research Compatible Components: Ensure that any new items will work seamlessly with your existing machinery.

- Consult Professionals: Seek advice from experts or forums to get insights on the best options available.

By carefully considering upgrades, you can transform your tools into high-performing assets that meet the demands of your tasks with ease.

Tips for Maintaining Your Fs85r

Proper upkeep of your equipment ensures longevity and optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency during operation. Here are some essential tips to keep your machinery running smoothly.

- Regular Cleaning: After each use, clean the exterior and any accessible areas to remove dirt and debris.

- Check Fuel Quality: Use fresh fuel and inspect for contaminants to prevent engine issues.

- Inspect the Air Filter: Clean or replace the filter regularly to maintain airflow and engine performance.

- Sharpen Blades: Regularly sharpen cutting edges to ensure efficient cutting and reduce strain on the engine.

- Examine Cables and Hoses: Check for wear and tear; replace any damaged components to avoid potential hazards.

By following these guidelines, you can ensure that your machine remains reliable and efficient for years to come. Regular attention to these aspects will help you avoid costly repairs and enhance your overall experience.

Resources for Further Learning

Expanding your knowledge in the field of machinery and equipment maintenance is crucial for both enthusiasts and professionals. Accessing a variety of resources can enhance your understanding of components, their functions, and proper upkeep techniques. Below are some valuable avenues to explore.

Online Platforms

Numerous websites provide detailed guides, tutorials, and forums where individuals can share experiences and seek advice. These platforms often feature video demonstrations and user-generated content that can be particularly useful.

Books and Manuals

Books focused on equipment maintenance and operation can offer in-depth insights. Additionally, manufacturer manuals are essential for understanding specific models and their intricacies.

| Resource Type | Description | Example |

|---|---|---|

| Online Courses | Structured lessons on machinery care and operation. | Coursera, Udemy |

| Forums | Community discussions for troubleshooting and advice. | Reddit, Equipment Forums |

| Technical Manuals | Official documentation from manufacturers. | Service Manuals, User Guides |

| Reference Books | Comprehensive texts on machinery maintenance. | “The Complete Guide to Equipment Maintenance” |