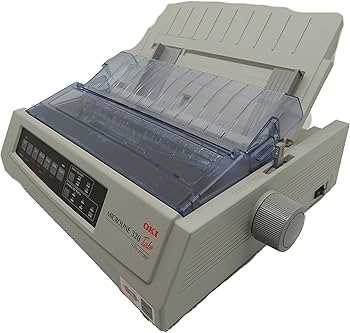

Okidata Microline 320 Turbo Parts Diagram Overview

The functionality of any printing device relies heavily on its internal architecture. To optimize performance and ensure longevity, it is essential to comprehend how each element interacts within the system. This knowledge not only aids in effective maintenance but also empowers users to troubleshoot issues independently.

By examining the layout of various components, one can gain insights into the operational mechanics that drive printing efficiency. Whether you are a technician or an enthusiastic user, familiarity with these intricacies can significantly enhance your ability to address challenges as they arise.

Furthermore, understanding the specific arrangements and functions of each segment can streamline the repair process. Armed with this information, individuals can make informed decisions when sourcing replacements or undertaking modifications, ultimately leading to a more reliable and efficient device.

Understanding the Okidata Microline 320 Turbo

This section explores a well-known printing device renowned for its efficiency and durability. Aimed at delivering high-quality output, this printer is often utilized in various professional environments. Understanding its functionality and components can enhance maintenance practices and extend its lifespan.

The device operates using a series of mechanisms that work in harmony to produce printed material. Familiarity with these elements is essential for effective troubleshooting and repairs. Below is a table summarizing key features and specifications that contribute to its reliable performance:

| Feature | Description |

|---|---|

| Print Technology | Dot matrix printing |

| Print Speed | Up to 550 characters per second |

| Input Capacity | Multiple paper types and sizes |

| Connectivity | Parallel and serial interfaces |

| Dimensions | Compact design for easy integration |

By recognizing the various components and specifications, users can better appreciate the advantages of this reliable printing solution and ensure optimal performance in their operations.

Key Features of the Microline 320 Turbo

This model is recognized for its robust performance and reliability, making it an essential tool in various environments. Users appreciate its efficiency and the quality of output, which together enhance productivity in demanding tasks.

Durability is one of the standout characteristics, allowing it to handle high-volume printing with ease. The construction ensures longevity, even in challenging conditions, reducing the need for frequent replacements.

Another important aspect is its speed. This device operates at impressive rates, enabling users to complete their printing tasks swiftly without compromising on quality. The fast processing time makes it ideal for busy offices or industrial settings.

The versatility of this machine cannot be overlooked. It is compatible with various media types and sizes, providing flexibility for different printing requirements. This feature is especially beneficial for users who work with diverse projects.

Furthermore, the user-friendly interface simplifies operation, ensuring that even those with minimal technical knowledge can navigate the functions with ease. This accessibility contributes to a smoother workflow and minimizes downtime.

Lastly, the cost-effectiveness of this printer is noteworthy. It delivers high-quality prints while maintaining reasonable operational costs, making it a smart choice for businesses looking to optimize their resources.

Common Issues with the Printer

Printers often encounter a variety of challenges that can disrupt their performance and efficiency. Understanding these common problems can help users troubleshoot and maintain their devices effectively. From print quality issues to operational errors, being aware of potential malfunctions is crucial for a seamless printing experience.

Poor Print Quality

One of the most frequent complaints involves subpar print quality, which may manifest as faded text, streaks, or smudges on the output. This issue can stem from several factors, including low ink levels, clogged nozzles, or incorrect settings. Regular maintenance, such as cleaning print heads and ensuring the right media is used, can significantly enhance print results.

Frequent Paper Jams

Another common predicament is paper jams, which can be frustrating and time-consuming to resolve. These jams may occur due to improper paper loading, using incompatible paper types, or debris in the paper path. Users should ensure that the paper is correctly aligned and regularly check for any obstacles that could hinder smooth feeding.

Importance of Accurate Parts Diagrams

Detailed illustrations that represent components of machinery are essential for effective maintenance and repair. These visual aids serve as a guide for technicians, ensuring that each element is correctly identified and handled. Accurate representations help streamline the troubleshooting process, minimizing the risk of errors and enhancing overall efficiency.

Enhancing Understanding

Clear and precise visuals contribute to a better understanding of complex systems. When technicians can easily locate and comprehend each part’s role, they are more likely to diagnose issues correctly. This leads to quicker resolutions and less downtime, benefiting both service providers and users.

Facilitating Repairs

Having reliable visuals at hand allows for smoother repair processes. When each component is clearly labeled, it reduces the chances of using incorrect replacements, ultimately preserving the integrity of the machinery. Moreover, accurate depictions aid in training new technicians, equipping them with the necessary knowledge to handle repairs confidently.

| Benefits | Description |

|---|---|

| Efficiency | Reduces time spent on identifying parts and resolving issues. |

| Accuracy | Minimizes the risk of errors during repairs and maintenance. |

| Training | Provides essential knowledge for new technicians, enhancing their skills. |

| Cost-Effectiveness | Prevents unnecessary expenses related to incorrect replacements and repairs. |

How to Read Parts Diagrams Effectively

Understanding technical illustrations is essential for anyone looking to maintain or repair equipment. These visuals provide a detailed representation of components, helping users identify parts and their functions. Here are some tips to enhance your ability to interpret these illustrations.

- Familiarize Yourself with Symbols: Before diving into the illustration, take time to learn the common symbols used. This knowledge will help you decode the representation more easily.

- Start with the Legend: Most illustrations include a legend or key. This section explains what each symbol and label means, serving as a guide to the entire visual.

- Identify Main Components: Look for the primary parts first. These are often highlighted or marked in a different color. Understanding the main elements will give context to the surrounding details.

- Pay Attention to Numbers: Many visuals include reference numbers next to components. These correspond to a list or catalog that provides detailed descriptions, making it easier to find replacements.

- Follow the Flow: Observe how components connect and interact. This understanding is crucial for troubleshooting or when assembling parts correctly.

By applying these strategies, you can improve your ability to interpret technical illustrations, leading to more efficient repairs and maintenance. Remember, practice makes perfect, so spend time studying different visuals to become more proficient.

Essential Replacement Parts for Maintenance

Maintaining the longevity and performance of your printing device is crucial for efficient operation. Regularly replacing key components can prevent unexpected downtime and enhance print quality. Understanding which items are essential for upkeep will help ensure smooth functionality and minimize wear and tear.

Key Components to Consider

- Drum Unit: This is a vital element that transfers toner onto paper. Regular replacement is necessary to maintain print clarity.

- Toner Cartridges: Essential for delivering ink, cartridges should be replaced when low to avoid print quality issues.

- Fuser Assembly: This part bonds the toner to the paper using heat. Over time, it can wear out, requiring replacement for optimal results.

- Transfer Belt: Ensures proper transfer of the image to paper. Regular checks and timely replacement can prevent streaks and smudges.

Maintenance Tips

- Regularly inspect components for signs of wear or damage.

- Keep spare units on hand to reduce downtime during replacements.

- Follow manufacturer guidelines for installation and maintenance procedures.

By focusing on these essential components and adhering to maintenance tips, you can significantly extend the life of your equipment and maintain high-quality output.

Where to Find Parts Diagrams Online

Locating detailed schematics for various machinery and equipment has become increasingly straightforward with the advent of digital resources. These illustrations are essential for understanding the components of a device, enabling effective repairs and maintenance. Various online platforms cater to this need, providing a wealth of information for users seeking guidance.

Manufacturer Websites

Many manufacturers host official websites that feature comprehensive documentation for their products. These resources often include downloadable illustrations, which can be invaluable for troubleshooting and repairs. It’s advisable to navigate to the support or downloads section of the website to find the necessary visuals tailored to specific models.

Online Forums and Communities

Engaging with online forums and communities can yield a treasure trove of information. Enthusiasts and professionals frequently share resources, including schematics and maintenance tips. Platforms like Reddit, specialized repair forums, or social media groups can be great places to ask for assistance or search for shared content.

Comparing Microline Models and Parts

When evaluating various models within a specific line of printers, it’s essential to consider their design features and component differences. Each version presents unique functionalities that cater to different printing needs, making it crucial for users to understand how these distinctions impact performance and maintenance.

| Model | Print Speed | Connectivity Options | Paper Handling |

|---|---|---|---|

| Model A | 300 cps | USB, Parallel | Manual Feed, 50 sheets |

| Model B | 400 cps | USB, Serial | Auto Feed, 100 sheets |

| Model C | 500 cps | USB, Network | Manual Feed, 200 sheets |

Each variant not only showcases differences in printing speed but also in connectivity and paper handling capabilities. Understanding these variations helps users select the most suitable model for their operational requirements, ensuring efficient and effective printing solutions.

Step-by-Step Repair Process Overview

This section provides a comprehensive guide to the systematic approach for troubleshooting and fixing printing devices. By following a structured methodology, one can efficiently identify issues, implement solutions, and restore functionality.

Preparation and Safety Measures

- Gather necessary tools: screwdriver set, cleaning materials, and replacement components.

- Ensure the device is powered off and unplugged to avoid electrical hazards.

- Work in a clean, well-lit area to facilitate visibility and organization.

Diagnosis and Troubleshooting

- Start by identifying visible problems such as error messages or unusual noises.

- Check the user manual for common issues and recommended troubleshooting steps.

- Inspect internal components for wear, damage, or loose connections.

- Run diagnostic tests if available to pinpoint specific faults.

Following these steps will provide a clear pathway for resolving issues, enhancing the longevity and performance of the equipment.

Tips for Troubleshooting Hardware Problems

When facing issues with your equipment, a systematic approach can significantly enhance your ability to diagnose and resolve problems effectively. By following a series of logical steps, you can identify the source of the malfunction and implement appropriate solutions.

| Step | Description |

|---|---|

| 1. Check Connections | Ensure that all cables and connections are secure. Loose or damaged cables can lead to various issues. |

| 2. Restart the Device | A simple reboot can often clear temporary glitches and restore functionality. |

| 3. Inspect for Physical Damage | Look for any visible signs of wear or damage on components. This could indicate a need for replacement. |

| 4. Consult the Manual | Refer to the user manual for troubleshooting guidance specific to your device. |

| 5. Update Drivers | Outdated software can lead to compatibility issues. Check for and install the latest updates. |

| 6. Test with Different Equipment | Try using alternative cables or devices to determine if the issue lies with the original components. |

| 7. Seek Professional Help | If problems persist after basic troubleshooting, consider contacting a technician for advanced diagnostics. |

By adhering to these practical steps, you can efficiently address hardware challenges and minimize downtime. Staying organized and methodical in your approach will often yield the best results.

Benefits of Regular Maintenance Checks

Conducting routine maintenance inspections is essential for ensuring the longevity and optimal performance of equipment. These systematic evaluations not only help identify potential issues before they escalate but also contribute to enhanced reliability and efficiency. Regular check-ups can save time and resources in the long run, making them a vital practice for any operation.

Prolonging Equipment Lifespan

Consistent maintenance plays a crucial role in extending the lifespan of machinery. By addressing minor problems early, users can prevent more significant, costly repairs. This proactive approach minimizes wear and tear, allowing equipment to function effectively over an extended period.

Improving Efficiency and Performance

Regular inspections help maintain optimal performance levels. Well-maintained equipment operates more efficiently, reducing energy consumption and operational costs. Ensuring that all components are in good working order also enhances the overall productivity of the system, leading to smoother operations and higher output.