Comprehensive Guide to Husqvarna 570BTS Parts Diagram

When it comes to maintaining outdoor machinery, a thorough comprehension of its various elements is crucial. Each component plays a significant role in the overall functionality, contributing to efficiency and performance. Gaining insights into how these pieces fit together can simplify repairs and enhance the longevity of your device.

Utilizing visual representations of the different segments allows users to identify parts easily and understand their specific functions. This knowledge not only aids in troubleshooting but also empowers operators to conduct maintenance tasks with confidence. Whether you’re a seasoned technician or a weekend warrior, familiarizing yourself with the intricacies of your equipment can make all the difference.

In this section, we will delve into a comprehensive overview of the key components of your machinery. By examining a detailed layout, you’ll be able to pinpoint essential elements, recognize wear and tear, and make informed decisions about replacements and upgrades. Equip yourself with the information necessary to keep your tools in peak condition.

Understanding the Husqvarna 570BTS Model

This section delves into the intricacies of a specific model renowned for its powerful performance and reliability in outdoor maintenance tasks. Designed for both professionals and enthusiasts, this equipment offers robust features that enhance productivity and efficiency. Understanding its components and functionality can significantly improve user experience and maintenance practices.

Key Features and Benefits

The model stands out due to its impressive engine capacity, ensuring that it delivers optimal power while maintaining fuel efficiency. Users can appreciate its ergonomic design, which facilitates prolonged use without discomfort. Additionally, advanced technology incorporated into the device minimizes noise and vibrations, making it ideal for extended working hours in various environments.

Maintenance and Care

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for efficient maintenance and repair. Visual representations of the various elements involved not only streamline the identification process but also enhance the overall comprehension of how different pieces interact with one another. These illustrations serve as crucial tools for both novice and experienced technicians, ensuring that every aspect of the equipment is addressed accurately.

Such visual aids provide clarity in understanding assembly and disassembly procedures, thereby minimizing the risk of errors during maintenance tasks. Moreover, they can facilitate quicker troubleshooting by allowing users to pinpoint specific areas that may require attention or replacement.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Clarifies the relationship between various components. |

| Efficiency | Reduces time spent identifying and addressing issues. |

| Accuracy | Minimizes errors in repair and maintenance processes. |

| Accessibility | Provides a visual reference for users at all skill levels. |

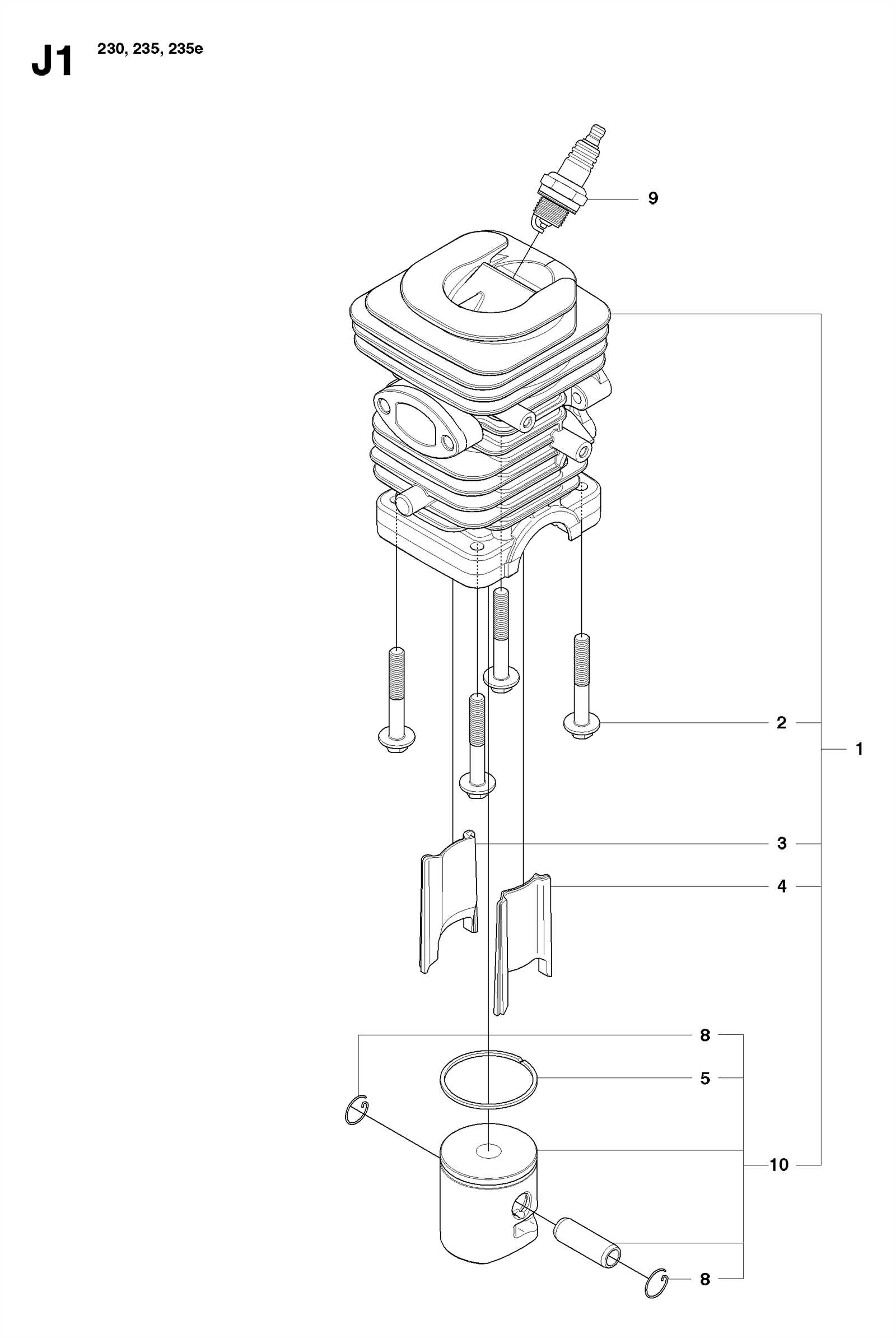

Key Components of the 570BTS

Understanding the essential elements of this powerful tool is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring efficiency and reliability, contributing to the overall functionality and durability of the machine.

Major Functional Elements

The main components can be categorized into various systems, each designed to perform specific tasks that enhance the effectiveness of the equipment. Here are some of the critical parts that work in harmony to provide outstanding results:

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the tool, offering high performance and efficiency. |

| Fan Assembly | Responsible for airflow and cooling, ensuring the engine operates within optimal temperature ranges. |

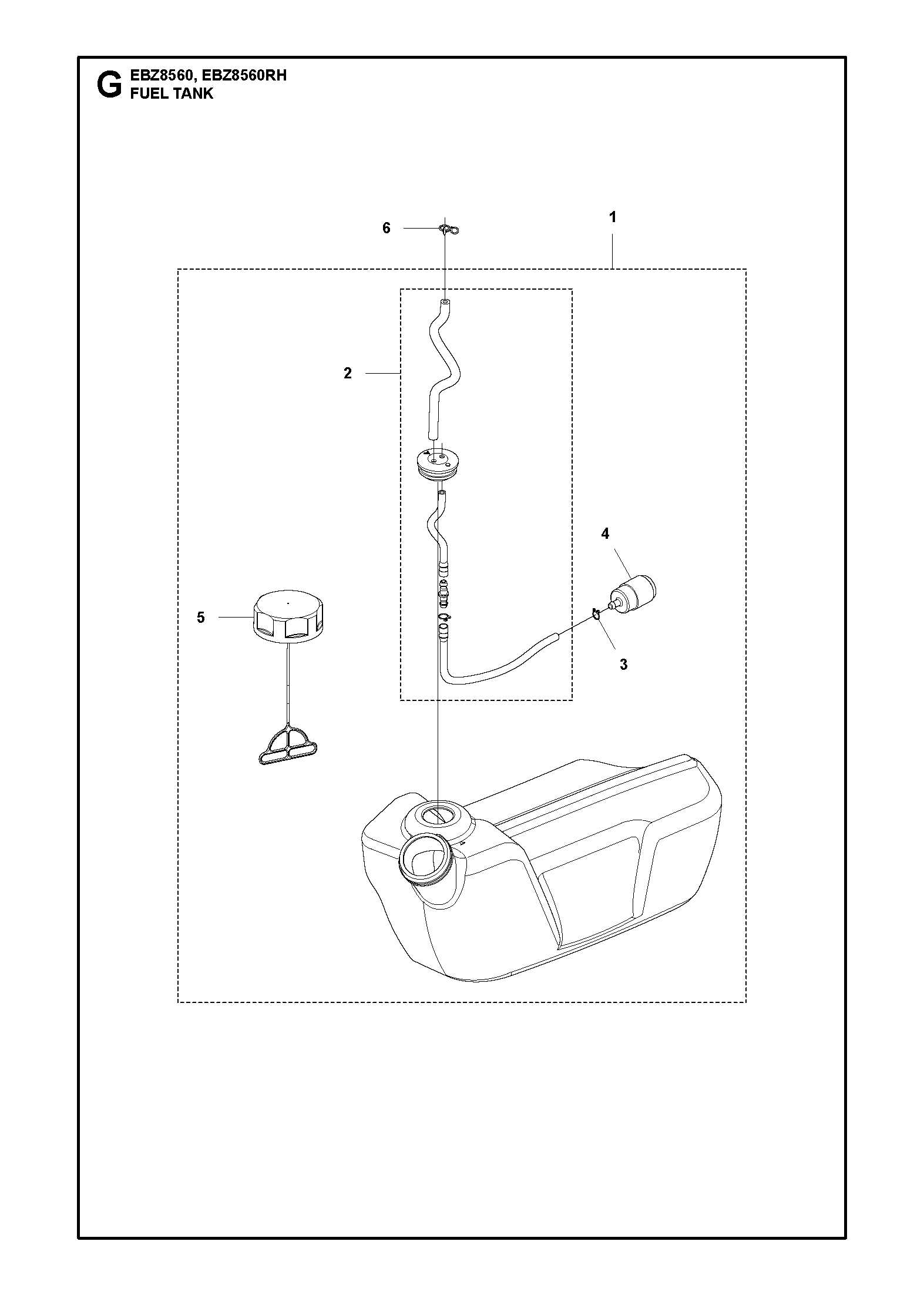

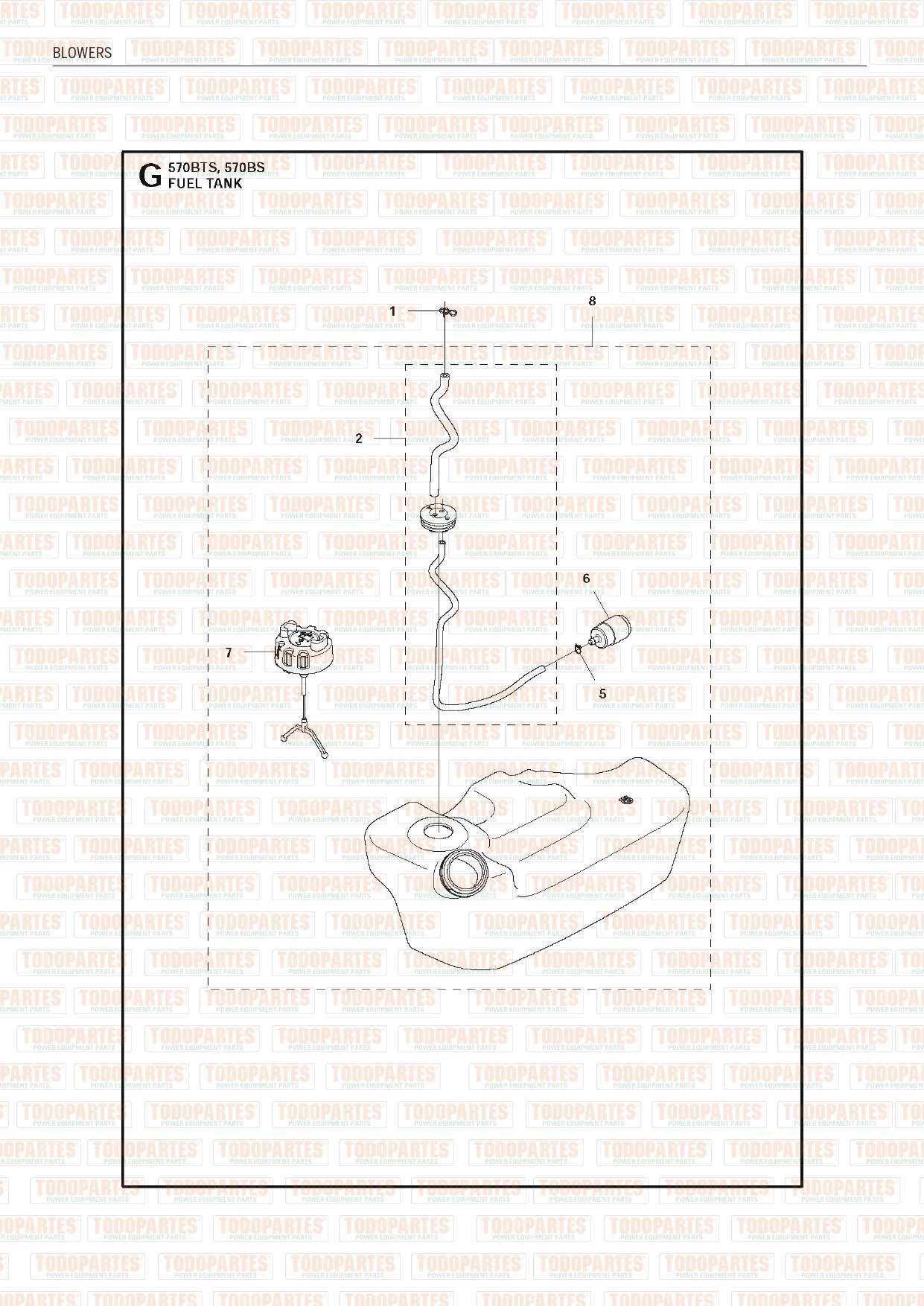

| Fuel System | Includes the tank and delivery system, designed for easy refueling and efficient fuel consumption. |

| Handle and Controls | Ergonomically designed for comfort and control, allowing for precise maneuverability during operation. |

Supporting Components

In addition to the major parts, there are supporting elements that enhance the user experience and overall functionality. These components include:

| Supporting Element | Function |

|---|---|

| Vibration Dampeners | Minimize operator fatigue by reducing the impact of vibrations during use. |

| Exhaust System | Efficiently directs fumes away from the operator, promoting a safer working environment. |

| Starter Mechanism | Ensures reliable ignition, making it easy to start the tool under various conditions. |

| Air Filter | Protects the engine by filtering out debris and contaminants from the air intake. |

How to Interpret the Diagram

Understanding a schematic representation of components is crucial for effective maintenance and repair tasks. These visual aids provide a clear overview of various elements, their arrangement, and their interconnections, allowing users to navigate through the complexities of machinery more easily.

When examining such a visual guide, start by identifying the key sections. Look for labels that denote specific parts, as they often include references that can be cross-checked with manuals or catalogs. Pay attention to the numbering system; it usually indicates the order of assembly or disassembly, which can be invaluable during repairs.

Next, familiarize yourself with the symbols used within the illustration. Each symbol represents a unique component, and understanding these representations will enhance your ability to troubleshoot issues effectively. Often, these visuals include color coding that signifies different categories of parts, such as electrical or mechanical elements.

Lastly, take note of any annotations or additional notes present in the guide. These often provide essential tips or warnings that can save time and prevent damage. By mastering the interpretation of these visuals, you equip yourself with the knowledge necessary for successful maintenance and repairs.

Common Issues with 570BTS Parts

When dealing with the equipment in question, users may encounter a range of frequent complications. Understanding these common problems can aid in timely maintenance and prolong the lifespan of the machine.

- Fuel System Failures:

Issues with the fuel lines and filters can lead to inadequate power and performance. Regular checks are necessary to ensure the fuel delivery system functions properly.

- Air Filter Blockage:

A clogged air filter can restrict airflow, causing the engine to run poorly. It is advisable to clean or replace the filter periodically.

- Ignition Problems:

Malfunctions in the ignition system may prevent the machine from starting. Checking the spark plug and ignition coil is crucial for troubleshooting.

- Vibration Issues:

Excessive vibration can indicate loose components or wear. Regular inspections can help identify and address these concerns before they escalate.

By being aware of these prevalent challenges, operators can take proactive measures to ensure smooth operation and enhance the reliability of their equipment.

Where to Find Replacement Parts

When it comes to maintaining outdoor equipment, sourcing high-quality components is crucial for optimal performance and longevity. Fortunately, there are various avenues available to locate the necessary items for repairs and upkeep.

Consider exploring the following options:

- Authorized Dealers: These establishments typically stock genuine components and provide expert advice tailored to specific models.

- Online Retailers: Websites dedicated to outdoor equipment often feature a wide selection of items, complete with customer reviews and competitive pricing.

- Local Repair Shops: Many local technicians may have spare components available or can order them directly for you.

- Manufacturer’s Website: The official site frequently offers a comprehensive catalog and direct purchasing options for consumers.

In addition to these sources, don’t forget to check online marketplaces, where both new and used components can be found at various price points. Always ensure that you are purchasing from reputable sellers to avoid compatibility issues or subpar quality.

Maintenance Tips for Husqvarna Equipment

Proper upkeep of outdoor machinery is essential for optimal performance and longevity. Regular maintenance not only ensures efficient operation but also helps prevent costly repairs. Adopting a systematic approach to care can make a significant difference in the reliability of your equipment.

1. Clean After Use: Always remove dirt, debris, and grass clippings from your machine after each use. This helps prevent corrosion and ensures that all components function properly.

2. Check Fluids Regularly: Regularly inspect and replace fluids as needed. This includes oil changes, fuel checks, and ensuring that all lubrication points are adequately serviced.

3. Inspect Blades and Filters: Keep an eye on cutting blades and air filters. Dull blades can hinder performance, while clean filters ensure optimal airflow and engine efficiency.

4. Tighten Loose Parts: Over time, vibrations can loosen screws and bolts. Periodically check and tighten all fasteners to maintain structural integrity.

5. Store Properly: When not in use, store your equipment in a dry, sheltered place. This prevents damage from weather elements and extends the lifespan of your machinery.

6. Follow Manufacturer Guidelines: Always refer to the manufacturer’s manual for specific maintenance recommendations and schedules. This ensures that you adhere to the best practices tailored for your model.

By implementing these simple yet effective maintenance strategies, you can enhance the durability and performance of your outdoor equipment, ensuring it serves you well for years to come.

Compatibility with Other Models

Understanding the interchangeability of components across various models can significantly enhance the efficiency of maintenance and repairs. This section delves into how specific units can work seamlessly with others, allowing for greater flexibility and convenience for users.

Key Compatible Units

- Model A: Features similar engine specifications and design, allowing for easy swaps.

- Model B: Utilizes shared components, making it a reliable alternative for replacement needs.

- Model C: Offers design similarities that ensure components fit without modification.

Considerations for Compatibility

- Check the specifications: Always confirm that the measurements match before attempting to interchange parts.

- Consult the manufacturer: Refer to official resources or guides to ensure reliability and safety.

- Test before full installation: If possible, test the compatibility before committing to a complete swap.

DIY Repairs: A Step-by-Step Guide

Performing repairs on outdoor equipment can be a rewarding experience, allowing you to save money and gain valuable skills. With the right approach and tools, you can tackle common issues efficiently. This guide provides a structured process to help you navigate through repairs with confidence.

Before starting any repair, it’s essential to have a clear understanding of the components involved. Familiarizing yourself with the assembly will simplify troubleshooting and reassembly. Below is a table outlining key components and their functions, which will serve as a reference during your repair journey.

| Component | Function |

|---|---|

| Engine | Drives the equipment and provides power. |

| Fuel System | Delivers fuel to the engine for combustion. |

| Air Filter | Prevents dirt and debris from entering the engine. |

| Ignition System | Ignites the fuel-air mixture for engine operation. |

| Exhaust | Expels combustion gases from the engine. |

To ensure a successful repair, gather the necessary tools, including screwdrivers, wrenches, and safety gear. Begin by diagnosing the issue: observe any unusual sounds, leaks, or performance problems. Once you identify the problem, consult your reference material to understand how to access and repair the affected area.

Follow these steps for a systematic approach:

- Turn off the equipment and disconnect any power sources.

- Carefully disassemble the relevant components, noting their arrangement.

- Inspect parts for wear and damage, replacing any faulty items as needed.

- Reassemble the equipment, ensuring all connections are secure.

- Test the equipment to confirm successful repair.

With patience and attention to detail, you can effectively manage repairs, extending the life of your equipment and enhancing your maintenance skills.

Customer Reviews on 570BTS Performance

Customer feedback plays a crucial role in understanding the effectiveness and reliability of outdoor power equipment. Users often share their experiences regarding performance, usability, and overall satisfaction. Here, we explore various insights from consumers who have put this blower to the test.

Many users highlight the following aspects:

- Power and Efficiency: Customers frequently commend the robust power output, allowing for efficient clearing of leaves and debris.

- Weight and Comfort: The design is often noted for its balance, making it easier to handle during prolonged use.

- Noise Level: Some reviews mention that while it is a powerful machine, it maintains a reasonable noise level, which is appreciated in residential areas.

However, some users have pointed out areas for improvement:

- Fuel Consumption: A few reviewers indicate that it consumes more fuel than expected, leading to higher operational costs.

- Starting Issues: Certain feedback highlights occasional difficulties in starting the engine, particularly after long periods of inactivity.

- Maintenance Needs: Some customers express concerns about the frequency and complexity of maintenance requirements.

Overall, the general consensus among users is that this blower offers excellent performance for both residential and commercial applications, despite a few minor drawbacks. These insights can help potential buyers make informed decisions regarding their outdoor equipment needs.

Resources for Husqvarna Owners

Maintaining and enhancing the performance of your outdoor equipment can significantly improve its lifespan and efficiency. Accessing the right tools and information is crucial for any owner looking to optimize their machinery. Below are some valuable resources that can aid in the care and management of your equipment.

Online Forums and Communities

Joining online forums dedicated to outdoor power tools can provide a wealth of knowledge from experienced users. Engaging with these communities allows for sharing tips, troubleshooting advice, and recommendations on accessories. Sites like Reddit and specific brand forums offer a platform for discussions and personal experiences.

Official Manuals and Guides

Utilizing official manuals is essential for understanding your equipment’s features and maintenance needs. These documents often contain troubleshooting tips, maintenance schedules, and safety instructions. Many manufacturers provide downloadable versions on their websites, making it easy to access the information you need. Additionally, instructional videos on platforms like YouTube can serve as practical visual aids for repairs and upgrades.