Kubota RC54-G20 Parts Diagram Overview

In the world of machinery, comprehending the intricate layout and functionality of each element is essential for maintaining optimal performance. Whether you’re a professional operator or a dedicated enthusiast, familiarity with the assembly of your vehicle can greatly enhance its longevity and efficiency. This section delves into the significance of knowing how various elements interconnect and operate.

Visual representations of these assemblies serve as invaluable tools for troubleshooting and repairs. They provide a clear view of the arrangement and relationship between components, allowing users to identify potential issues swiftly. By engaging with these illustrations, one can develop a deeper understanding of their equipment’s mechanics.

Moreover, acquiring knowledge about individual pieces fosters informed decisions when it comes to repairs or upgrades. Being aware of the specifications and roles of each section not only aids in effective maintenance but also empowers operators to enhance their machinery’s capabilities. Embracing this knowledge is a vital step toward ensuring the reliability and efficiency of your machinery.

Kubota RC54-G20 Overview

This section provides an insightful look into a specific model designed for efficient lawn care and landscaping tasks. Renowned for its reliability and robust performance, this machine caters to both residential and commercial needs. Its design reflects a blend of functionality and ease of use, making it a preferred choice among enthusiasts and professionals alike.

The equipment features a powerful engine that ensures optimal cutting performance, while its ergonomic controls allow for comfortable operation. Additionally, the chassis is engineered for durability, allowing the machine to withstand various environmental conditions.

| Feature | Description |

|---|---|

| Engine Type | Air-cooled, four-stroke |

| Cutting Width | 54 inches |

| Drive System | Hydrostatic transmission |

| Weight | Approximately 550 lbs |

| Fuel Capacity | 3.5 gallons |

In conclusion, this model stands out in the market for its engineering excellence and practical features, ensuring a smooth mowing experience. Its combination of power and user-friendly design makes it an excellent investment for those seeking a reliable solution for their landscaping tasks.

Essential Components of the RC54-G20

Understanding the crucial elements of this equipment is vital for effective maintenance and operation. Each part plays a significant role in ensuring optimal performance and longevity.

- Engine Assembly

The heart of the machine, responsible for providing the necessary power for operation.

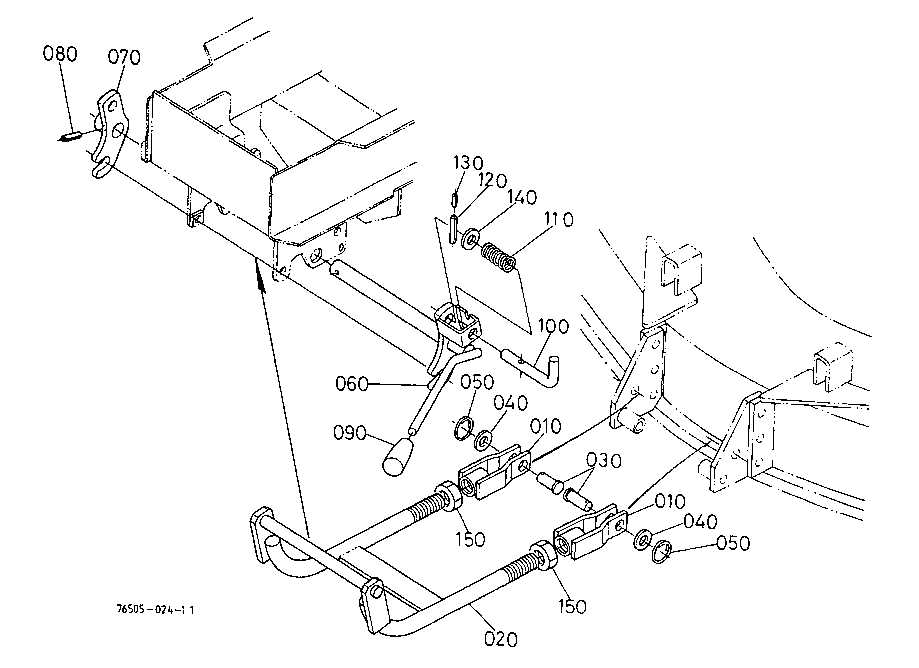

- Transmission System

Facilitates smooth movement and control, allowing for versatile maneuverability in various conditions.

- Cutting Mechanism

Designed to deliver precision and efficiency in trimming grass or other vegetation.

- Chassis

Provides structural integrity, supporting all components and ensuring stability during use.

- Fuel System

Ensures a steady supply of energy to the engine, crucial for uninterrupted operation.

- Control System

Enables the operator to manage various functionalities with ease, enhancing user experience.

Each of these elements must be properly maintained and understood to maximize efficiency and effectiveness. Regular inspections and timely replacements will contribute to the overall performance of the machinery.

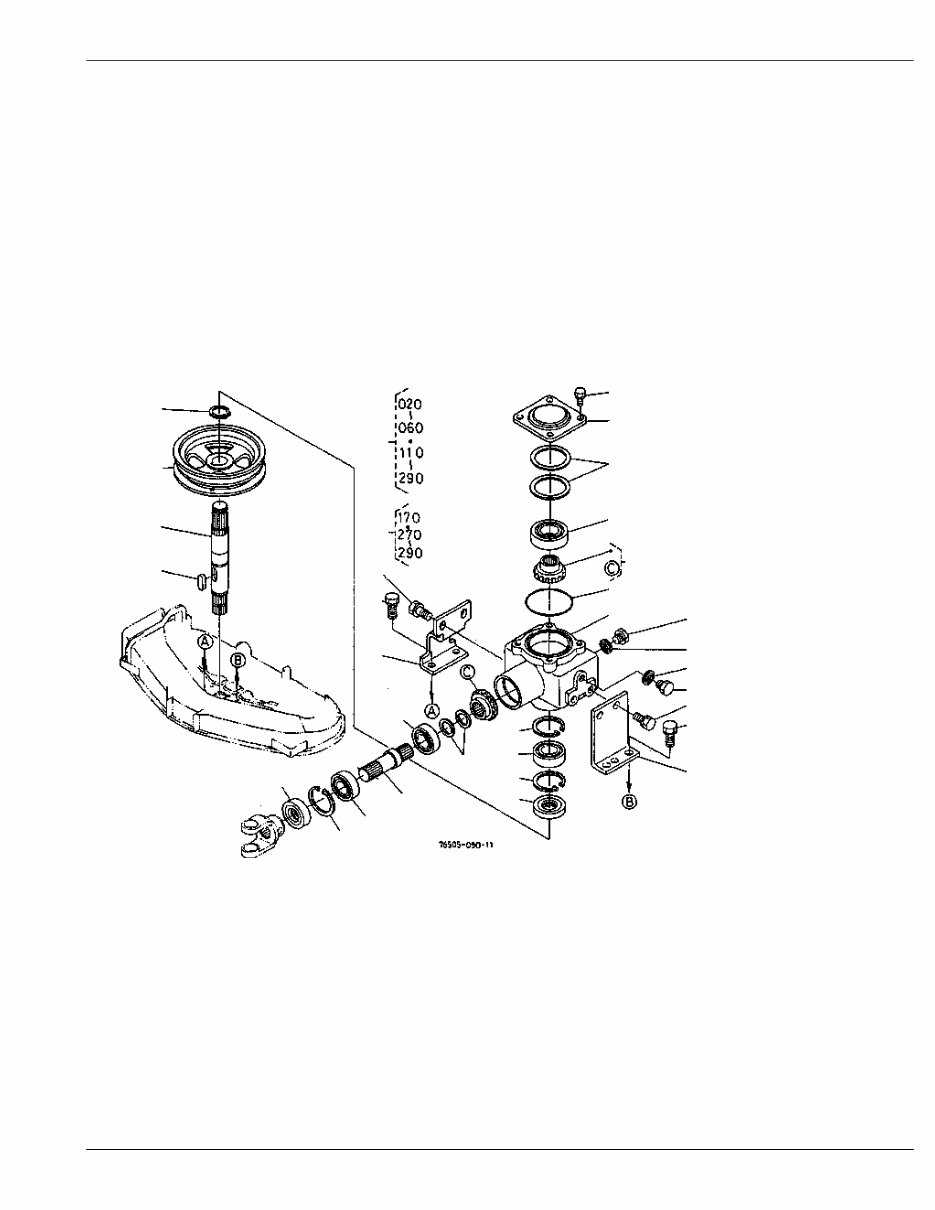

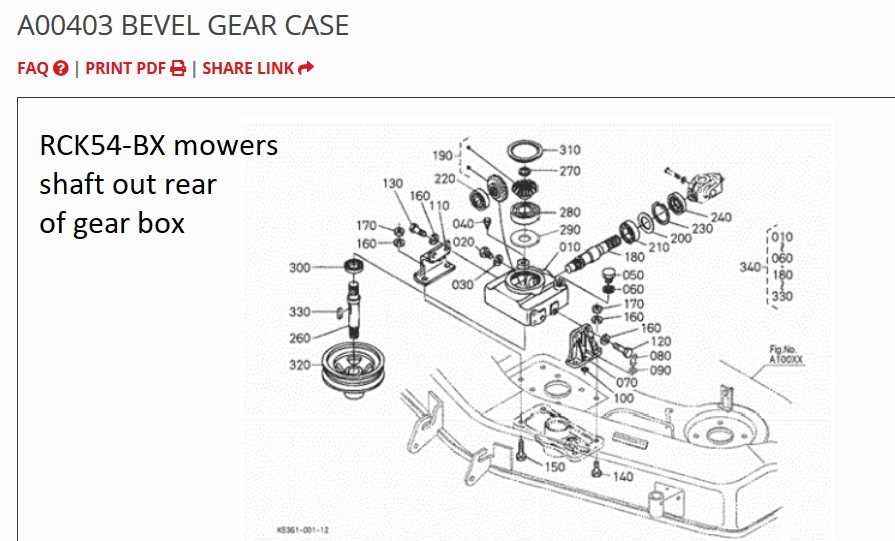

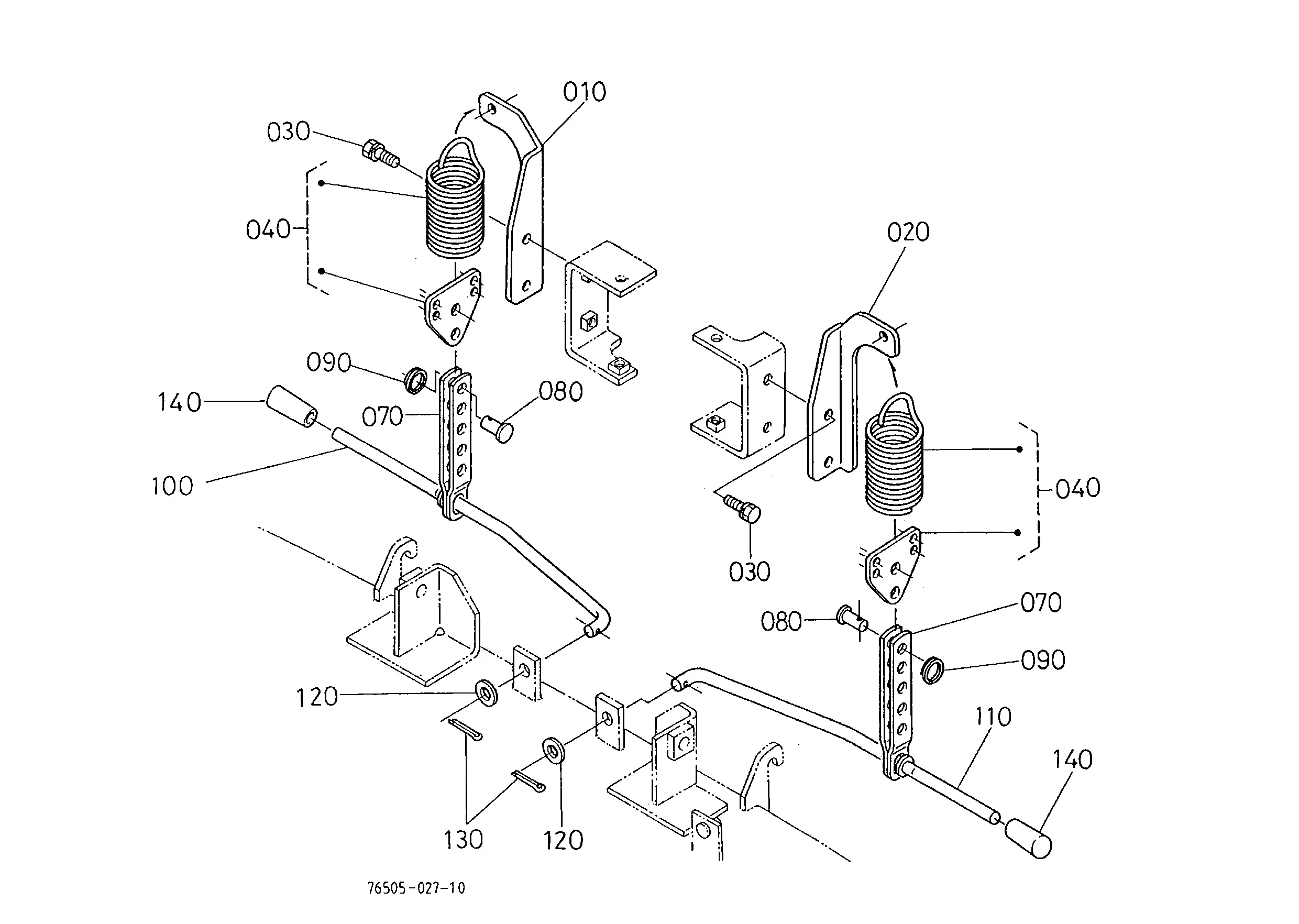

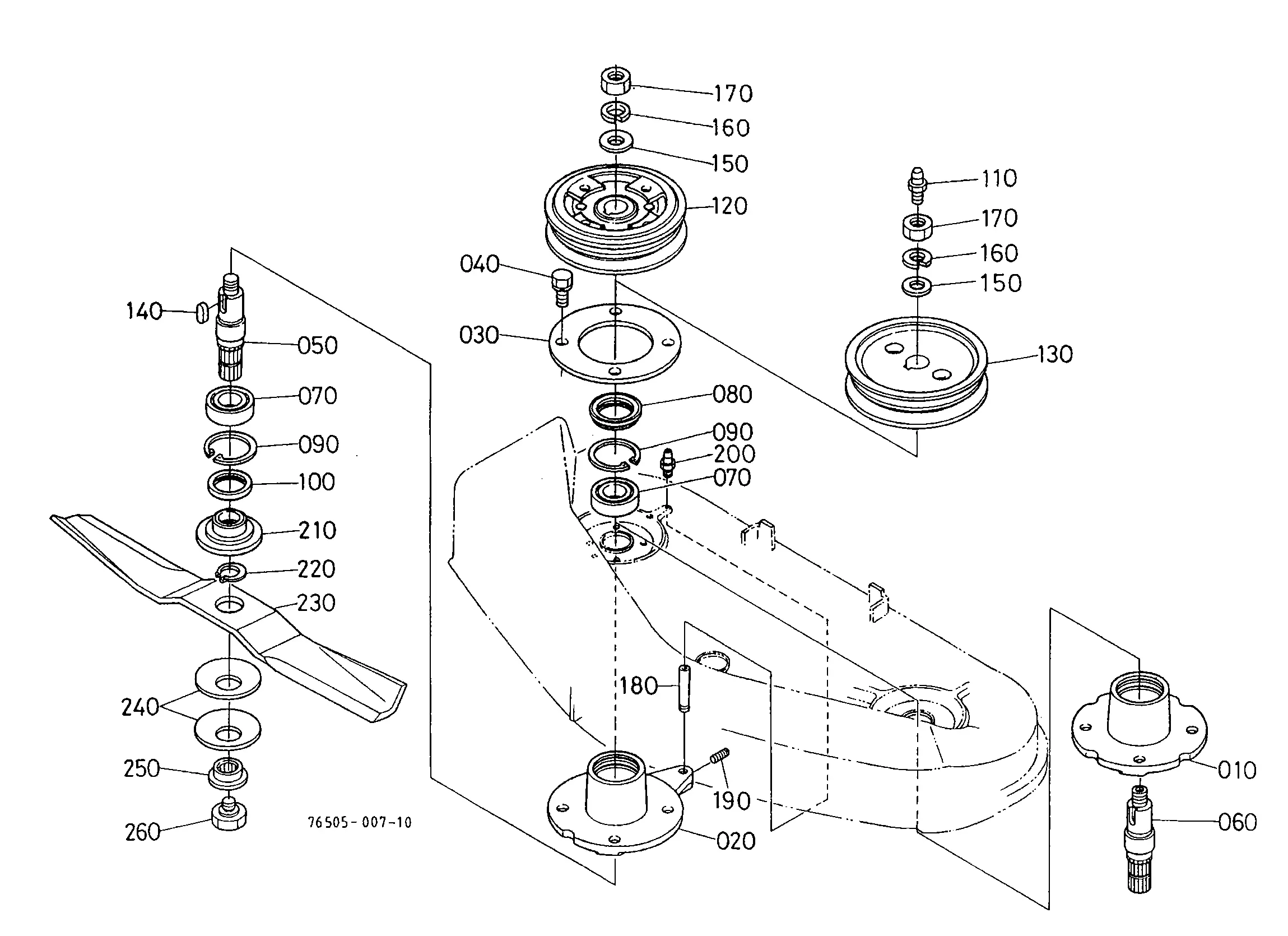

Understanding the Parts Diagram

When working with complex machinery, comprehending the visual representation of its components is essential. This illustration serves as a valuable reference, allowing users to identify individual pieces and their respective functions within the overall system. Familiarity with this layout can significantly aid in troubleshooting, maintenance, and repairs.

Each element in the illustration is typically labeled with a unique identifier, making it easier to locate specific items when ordering replacements or performing upgrades. The organization of these visuals often follows a logical structure, reflecting the assembly of the machinery. This structured approach helps streamline the understanding of how different parts interact with one another.

Additionally, the visual guide can reveal the complexity of the equipment, highlighting areas that may require special attention during disassembly or servicing. By studying this representation, users can gain insights into potential wear points or common failure areas, enhancing their ability to maintain optimal performance.

Maintenance Tips for Kubota Equipment

Proper upkeep is essential for ensuring the longevity and optimal performance of machinery. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency and safety. Adhering to a structured maintenance schedule can make a significant difference in the lifespan of your equipment.

Here are some essential maintenance practices to consider:

| Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 100 hours of operation | Use high-quality oil; check levels regularly. |

| Air Filter Inspection | Monthly | Clean or replace if dirty to ensure proper airflow. |

| Hydraulic Fluid Check | Every 50 hours | Maintain fluid at optimal levels for best performance. |

| Battery Maintenance | Every 3 months | Check connections and clean terminals to prevent corrosion. |

| Tire Pressure Check | Weekly | Ensure tires are inflated to recommended levels for stability. |

Incorporating these practices into your routine will help maintain the functionality and reliability of your machinery. Always consult your equipment manual for specific guidelines tailored to your model.

Common Issues with the RC54-G20

When dealing with outdoor machinery, users often encounter a variety of challenges that can affect performance and efficiency. Identifying these common problems is crucial for ensuring optimal operation and longevity of the equipment. Understanding the frequent issues allows for proactive maintenance and timely repairs.

One of the prevalent concerns is engine starting difficulties. Users may experience trouble igniting the engine, often stemming from issues such as battery failure or fuel delivery problems. Regular checks on the battery condition and fuel system can help mitigate this issue.

Another frequent problem involves blade performance. Dull or damaged blades can lead to ineffective cutting, resulting in uneven surfaces. Regular inspection and sharpening of the blades are essential practices to maintain cutting efficiency.

Additionally, users often report issues with the drive system, including slipping or unresponsive controls. This can be attributed to worn belts or improper adjustments. Keeping an eye on the drive components and making necessary adjustments can enhance overall functionality.

Lastly, overheating is a common concern that can arise from various factors, including low coolant levels or obstructed airflow. Monitoring fluid levels and ensuring adequate ventilation can prevent overheating and subsequent engine damage.

Where to Find Replacement Parts

Locating suitable components for machinery can be a crucial task for maintenance and repair. Ensuring the right fit and quality is essential for optimal performance. Here are some effective avenues to explore when seeking these essential items.

Online Resources

- Manufacturer’s Website: Start by checking the official site for authorized dealers and online shops.

- Specialty Retailers: Many online platforms specialize in specific machinery and often provide detailed catalogs.

- Marketplace Platforms: Websites like eBay and Amazon can be useful for finding new or gently used items.

Local Options

- Authorized Dealers: Visit or contact local dealers for direct assistance and expertise.

- Repair Shops: Many service centers may stock or order components for you.

- Salvage Yards: These can be treasure troves for finding functional items at a lower cost.

Benefits of Regular Maintenance

Routine upkeep of machinery plays a crucial role in ensuring optimal performance and longevity. Regular attention to equipment not only enhances its efficiency but also significantly reduces the risk of unexpected breakdowns. By committing to consistent maintenance, operators can enjoy a range of advantages that contribute to smoother operations.

Enhanced Performance

Regular checks and servicing help in identifying potential issues before they escalate. This proactive approach allows for adjustments and repairs that can improve the overall functionality of the equipment. Timely maintenance ensures that all components work harmoniously, leading to increased productivity and reduced operational costs.

Increased Lifespan

Investing time in the upkeep of machinery leads to a longer operational life. When equipment is well-maintained, wear and tear are minimized, allowing it to function effectively over a more extended period. Preserving your assets not only saves money in the long run but also enhances the return on investment, making regular maintenance a wise choice for any operator.

Upgrades for Enhanced Performance

Improving the capabilities of your machinery can lead to significant benefits in efficiency and output. By focusing on targeted enhancements, users can achieve better functionality and longevity, ultimately maximizing their investment.

- Engine modifications: Upgrading components such as air filters and exhaust systems can lead to increased power and efficiency.

- Transmission enhancements: Opting for high-performance gears or lubricants can improve responsiveness and reduce wear.

- Suspension improvements: Upgrading shock absorbers and springs can enhance stability and handling on various terrains.

Implementing these modifications not only boosts performance but also ensures a smoother and more reliable operation over time.

How to Read the Diagram

Understanding a schematic representation can significantly enhance your ability to maintain and repair equipment. These illustrations provide a visual guide that breaks down complex machinery into manageable sections, allowing you to identify components and their relationships. Familiarity with the layout is key to effective troubleshooting and part replacement.

To begin, focus on the legend or key usually located at the bottom or side of the illustration. This section explains the symbols used, making it easier to understand what each part represents. Symbols can include shapes and lines that indicate various elements such as gears, bolts, and electrical connections.

Next, pay attention to the numbering system employed throughout the illustration. Parts are often labeled with unique identifiers that correspond to the parts list, facilitating quick reference and ordering of replacements. Take note of the arrangement; it typically follows the assembly sequence or functional layout of the equipment.

Lastly, when examining connections, observe how different components interact. Lines may represent physical connections or pathways for fluids and electricity. Understanding these relationships helps you visualize how to disassemble and reassemble parts effectively, ensuring that your equipment runs smoothly.

Customer Reviews and Feedback

This section provides insights into user experiences and opinions regarding a specific model of machinery. Feedback from customers often highlights key aspects of performance, usability, and overall satisfaction, helping potential buyers make informed decisions.

User Experiences

Many users have expressed their appreciation for the reliability and efficiency of the equipment. Positive comments often focus on its robust construction and ease of operation. For instance, one user noted, “The machine has exceeded my expectations in both durability and performance.” Such testimonials reinforce the value of this product in various applications.

While the majority of reviews are favorable, some customers have pointed out areas needing attention. Common concerns include accessibility of replacement components and maintenance challenges. A reviewer mentioned, “Finding certain spare parts can be a hassle, which detracts from the overall experience.” Addressing these issues could enhance user satisfaction further.