Understanding the Husqvarna DRT900 Parts Diagram

When maintaining outdoor machinery, a clear understanding of its various elements is essential for optimal performance. Recognizing how each part interacts with others not only enhances functionality but also extends the lifespan of the equipment. This section will provide insights into the intricate relationships between these components.

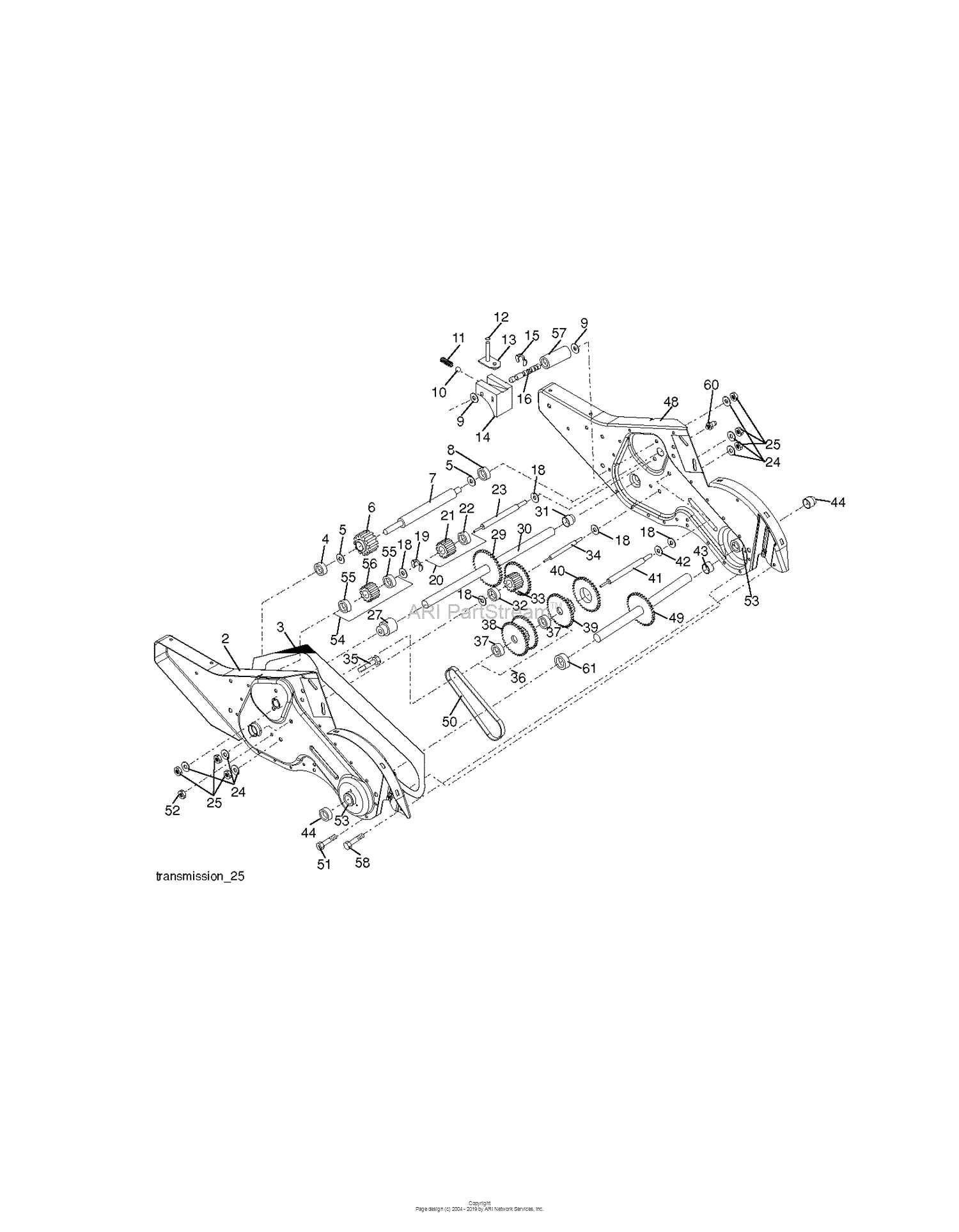

Visualization of the assembly is crucial for efficient troubleshooting and repairs. By breaking down the intricate layout, operators can identify specific sections and streamline their maintenance efforts. The ultimate goal is to empower users to take control of their machinery.

In addition, comprehending the intricacies involved allows for informed decisions when it comes to replacements or upgrades. This knowledge base serves as a valuable resource for both novices and seasoned users alike, facilitating a more confident approach to equipment care.

Understanding Husqvarna DRT900 Components

Grasping the essential elements of any garden tool is crucial for effective maintenance and operation. This knowledge not only enhances performance but also aids in troubleshooting and repair processes. By familiarizing oneself with the various components, users can ensure longevity and efficiency in their gardening tasks.

Main Elements

The core components of this equipment play significant roles in its functionality. Here are some of the primary parts:

- Engine: Provides the necessary power for operation.

- Handle: Offers control and maneuverability during use.

- Tines: Essential for tilling the soil effectively.

- Transmission: Transfers power from the engine to the wheels and tines.

Additional Features

In addition to the main elements, several features enhance usability:

- Adjustable depth control: Allows for customized tilling depth.

- Wheels: Facilitate movement across different terrains.

- Safety guard: Protects users from potential hazards during operation.

- Fuel system: Ensures efficient engine performance.

Understanding these components not only boosts confidence in operating the machine but also aids in performing timely maintenance, ultimately leading to a more enjoyable gardening experience.

Key Features of DRT900 Parts

Understanding the essential components of a specific machine can significantly enhance its performance and longevity. Each element plays a crucial role in the overall functionality, contributing to a seamless operation. Identifying the unique characteristics of these components can aid users in maintenance and repairs, ensuring optimal use.

Durability and Strength

Robust materials are employed in the construction of these elements, providing exceptional resistance to wear and tear. This durability ensures that the machine can withstand demanding conditions, making it reliable for various tasks.

Ease of Replacement

The design of these components promotes simplicity in replacement processes. Users can quickly swap out parts, minimizing downtime and facilitating efficient repairs, which is essential for maintaining productivity.

Importance of Accurate Diagrams

Having precise visual representations is crucial for effective maintenance and assembly of machinery. These illustrations serve as essential tools for users, providing clarity on the components involved and guiding the process of repairs or enhancements. Their accuracy can significantly influence both the efficiency and safety of operations.

Enhancing Understanding

Clear visuals break down complex systems into understandable parts, making it easier for individuals to identify and troubleshoot issues. Users can quickly locate specific elements, which reduces the time spent searching and enhances the overall workflow.

Facilitating Maintenance

Accurate representations are vital for regular upkeep. When users have reliable guides, they can perform necessary maintenance tasks effectively, ensuring machinery operates at optimal performance levels. This not only prolongs the lifespan of equipment but also minimizes the risk of costly repairs.

| Benefit | Description |

|---|---|

| Time Efficiency | Reduces time spent on identifying parts and troubleshooting. |

| Improved Safety | Helps prevent errors during assembly and maintenance, reducing accident risks. |

| Cost Savings | Minimizes the likelihood of damage and the need for expensive repairs. |

Common Issues with DRT900 Parts

Understanding frequent complications related to components can enhance performance and longevity. Many users encounter typical challenges that may affect efficiency and usability. Identifying these issues early can lead to timely interventions and better maintenance practices.

| Issue | Description | Solution |

|---|---|---|

| Wear and Tear | Components may degrade over time, leading to reduced effectiveness. | Regular inspections and timely replacements are crucial. |

| Alignment Problems | Improper alignment can cause operational inefficiencies and increased strain. | Ensure proper setup and adjustments as per guidelines. |

| Clogging | Debris accumulation can impede function, leading to overheating. | Regular cleaning and maintenance will mitigate this issue. |

| Loose Connections | Connections may loosen over time, affecting overall stability. | Periodic tightening and checks can resolve this problem. |

Step-by-Step Assembly Guide

This section provides a comprehensive guide to assembling your equipment, ensuring a smooth and efficient process. Following these instructions will help you understand each component and its role in the overall functionality.

Preparation

Before starting, gather all necessary tools and components. Familiarize yourself with the items by checking their labels and characteristics, which will streamline the assembly process.

Assembly Process

Begin by connecting the primary parts as outlined in your manual. Ensure each piece fits snugly and securely. Once the main structure is in place, proceed with attaching secondary components, double-checking each connection for stability.

Where to Find Replacement Parts

Locating the right components for your outdoor equipment can greatly enhance its performance and longevity. Here are some reliable sources to consider when searching for replacements:

- Authorized Dealers: Visit official retailers who specialize in your equipment brand.

- Online Marketplaces: Websites like Amazon, eBay, and specialty stores often have a wide selection.

- Manufacturer’s Website: Check the official site for direct purchases or listings of local suppliers.

- Local Repair Shops: These establishments can provide both parts and expert advice.

- Community Forums: Engage with fellow enthusiasts for recommendations and shared experiences.

Always ensure the components you choose are compatible with your model for optimal results.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of the machine, saving you time and money in the long run.

1. Regular Cleaning: After each use, clean the exterior and remove any debris. This prevents corrosion and keeps components functioning smoothly.

2. Lubrication: Apply appropriate lubricants to moving parts. This reduces friction and wear, helping maintain optimal performance.

3. Inspection: Periodically check for signs of wear or damage. Early detection of issues can prevent more significant problems down the line.

4. Follow Manufacturer Guidelines: Adhere to recommended maintenance schedules and use specified replacement components to ensure compatibility and reliability.

5. Store Properly: When not in use, store the equipment in a dry and sheltered area. Protecting it from the elements helps prevent rust and degradation.

By implementing these practices, you can delve into the ultimate care for your machinery, ensuring it serves you well for years to come.

Compatibility with Other Models

This section explores the interchangeability of components among various gardening equipment models, highlighting how certain elements can enhance the functionality of your machinery. Understanding this compatibility can significantly improve maintenance and repairs, leading to a more efficient workflow.

Key Interchangeable Components

Several parts are designed to fit multiple models, making them a versatile choice for users looking to optimize their equipment. Below is a table showcasing some of the most commonly shared components:

| Component | Compatible Models |

|---|---|

| Handle Assembly | Model A, Model B, Model C |

| Engine | Model D, Model E |

| Tiller Blades | Model F, Model G, Model H |

Benefits of Compatibility

Utilizing interchangeable parts can lead to cost savings and reduced downtime. Users can easily find replacements without the need for model-specific components, ensuring their tools remain operational and efficient.

Tools Needed for Repairs

Having the right tools is essential for effective maintenance and troubleshooting. A well-equipped toolkit not only streamlines the repair process but also ensures safety and precision while working on machinery.

Essential Tools

Start with a set of wrenches and screwdrivers in various sizes to handle different fasteners. Additionally, a multimeter can be invaluable for diagnosing electrical issues.

Specialized Equipment

Consider investing in a repair stand to stabilize your equipment during service. A parts cleaner can also be helpful to keep components free of dirt and debris, enhancing performance and longevity.

How to Read Parts Diagrams

Understanding assembly visuals is crucial for effective maintenance and repair. These illustrations provide a comprehensive overview of components, helping you identify each piece and its function within the larger system.

Start by Familiarizing Yourself: Before diving into the details, take a moment to familiarize yourself with the layout. Often, the larger sections will group related elements, making it easier to comprehend their interactions.

Identify Key Elements: Look for labels and legends that explain the symbols used. Each part is typically represented by a unique identifier, which corresponds to its description in accompanying documentation.

Follow the Flow: Trace the connections between pieces. Understanding how components interact can provide insight into potential issues and guide you in troubleshooting effectively.

Use References Wisely: Keep related manuals or guides handy for deeper insights. They can offer additional context, ensuring you fully grasp the intricacies of the assembly.

Customer Reviews on DRT900 Parts

This section highlights the feedback from users regarding various components of the model, providing insights into performance, durability, and overall satisfaction. Evaluations from customers can offer valuable information for potential buyers and help in making informed decisions.

Overall Satisfaction

Many users express high satisfaction levels with the quality and reliability of the components. Consistent praise is given for their longevity and performance, ensuring that the machinery operates smoothly.

Common Issues

While most reviews are positive, some users have reported occasional challenges with specific elements, suggesting areas for improvement. These insights can be essential for manufacturers aiming to enhance their offerings.

| Component | Rating | Comments |

|---|---|---|

| Engine | 4.5/5 | Powerful and reliable. |

| Transmission | 4/5 | Smooth shifting, but can be stiff at times. |

| Blades | 5/5 | Excellent cutting performance. |

| Wheels | 3.5/5 | Durable but could use better traction. |